Here you will learn:

- Ideal coolant - myths and disappointments

- Heat capacity is an important property

- Main types of coolants

- Final conclusions

Water heating is usually called heating in which water flows through the heating circuit, while in steam heating superheated steam circulates here. And few people know that in addition to water, many other liquids can be poured into the circuit. When choosing a coolant for the heating system of a country house, you need to pay attention to many factors. For example, on the frequency of residence and the frequency of operation of heating equipment. Let's see what to choose as a coolant for heating your home.

What is a coolant and what should it be like?

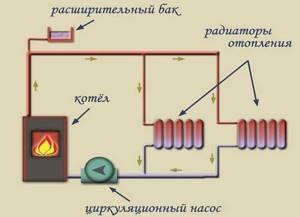

The coolant in a liquid heating system is the substance through which heat is transferred from the boiler to the radiators. Our systems use water or special antifreeze liquids as a coolant. When choosing, you must be guided by several criteria:

- Safety. From time to time, heating systems leak or require maintenance and repair. To ensure that repair work is not dangerous, the coolant must be harmless.

- Harmless to heating system components.

- Must have high thermal capacity to transfer heat effectively.

- Have a long service life.

The coolant for heating systems is selected according to operating conditions

Taking into account these requirements, the most suitable liquid for the heating system is water. It is safe, harmless, has a high heat capacity, and its service life is unlimited. But in those heating systems where there is a high probability of downtime in winter, water can do a poor job. If it freezes, it will burst pipes and/or radiators. That’s why antifreeze is used in such systems. At subzero temperatures they lose fluidity, but the equipment does not tear. So choosing a coolant for a heating system from this point of view is easy: if the system is always under supervision and in working order, you can use water. If the house is temporary (dacha) or can be left unattended for a long time (business trips, winter vacation), if frequent and/or long-term power outages are possible in the region, it is better to pour antifreeze into the system.

How to properly dilute the coolant and is it worth doing?

First, let's answer the main question: if you are interested in the possibility of a process from the point of view of thermophysics, yes, it is possible. Before you begin preparing the solution for pouring into the system, you need to carry out a number of preparatory measures. First of all, calculate the required proportions taking into account the concentration of the original solution and the freezing point of the finished product after dilution. You can mix water and antifreeze in two ways: by pouring separately until the operating pressure in the circuit is reached, or by connecting the components of the solution in advance. The first method is rarely used, because Separate addition of water and glycol is fraught with serious problems:

- Uneven heating in certain sections of the pipeline due to poor mixing of liquids.

- Interruptions in the operation of the pump or its stop caused by heterogeneity of the medium.

- Foaming of the solution, the consequences can only be eliminated by completely draining the antifreeze from the system.

Now about the advisability of dilution. The simplest calculations show that it is more convenient and profitable to immediately order a glycol solution of the required concentration from the manufacturer than to purchase a product with a higher concentration and independently bring it to operating parameters.

Types of non-freezing coolants

Antifreezes based on two organic compounds are available for sale: ethylene glycol and propylene glycol.

Ethylene glycol

Oxygen-containing organic compound, dihydric alcohol. In purified form, it is a transparent, colorless, odorless, oily liquid. Very toxic. The entry of ethylene glycol or its solutions into the human body can lead to irreversible changes and death, that is, you can be poisoned even if it just gets on your hands.

Despite the serious danger, ethylene glycol is very often used as a coolant due to its low price. Plus, antifreeze in its pure form is also chemically active, foams profusely, and emits toxic fumes. If there is the slightest possibility somewhere, ethylene glycol will definitely leak or, at a minimum, begin to release vapors.

Propylene glycol

Dihydric alcohol, colorless viscous liquid with a weak characteristic odor, sweetish taste, and hygroscopic properties. Chemically inert, safe for humans. The downside is loss of fluidity at high temperatures. It costs more than ethylene glycol, but it is the best option for home heating systems.

Special oil is an excellent coolant, but it is not yet very popular in our country. The advantages of thermal oils compared to antifreeze are quite extensive:

- operate in a wide temperature range from 50°C to 410°C;

- have a wide power range: up to 45 MW for one heater;

- optimally distribute heat;

- characterized by high heat capacity and high heat transfer coefficient;

- prevent corrosion in heating systems, as well as other equipment, etc.

Thermal oils are not used in all systems - only in specially designed ones, which is indicated in the technical data sheet of the heating equipment.

What is antifreeze and its types

Antifreeze is a class of liquids that cannot crystallize at low temperatures; their main purpose is to cool automobile engines and operate in low-temperature installations.

There are two main types of antifreeze: propylene glycol and ethylene glycol (glycerin-based formulations are also commercially available); they have different chemical and physical properties and areas of application.

The use of non-freezing liquid in heating systems is justified in cases where the owners of individual houses are absent from them for some time in the winter - in the event of an emergency (breakdown, power outage), the heating system may defrost. As soon as the temperature of the water in the pipes drops to zero degrees, it will freeze and expand by 10%, due to the lower density of ice compared to water by a similar amount. In this case, you will have to change the entire pipeline, completely filled with water, heating radiators and a heating boiler - the losses will be enormous.

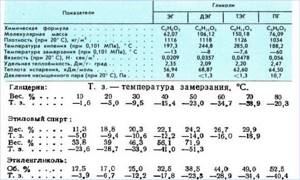

Rice. 6 Physical properties of glycols and freezing points of antifreezes

Pros of using antifreeze

In addition to preventing the pipeline system from defrosting, the use of antifreeze has the following advantages:

- The temperature range of operation of antifreeze compositions for heating systems, which lies in the range from -70º to +110º C, ensures the preservation of the pipeline at any low temperatures existing in nature and effective operation as a coolant.

- When the cooling temperature of glycols is below crystallization, they become jelly-like, expanding slightly in volume - this does not lead to defrosting of the system and its failure. After the pipes have thawed, the liquid can be thawed and reused without loss of quality.

- The presence of special additives (corrosion inhibitors and others) in the glycol composition prevents the appearance of scale, rust, foam, and airing, thereby increasing the service life of the system.

- The use of dyes makes it easy to detect leaks, and a change in the color of the fluid indicates the need to replace it.

Disadvantages of using antifreeze

The use of antifreeze has the following disadvantages:

- When using antifreeze compounds, it must be remembered that ethylene glycol antifreeze is poisonous; the lethal dose for humans when ingested is 2 mg. per 1 kilogram of body weight. In this regard, environmentally friendly and absolutely safe propylene glycol was developed.

- The big disadvantage of non-freezing liquids is their too high price; a standard 20-liter container of ethylene glycol with a maximum temperature of 65º C costs on average about 30 USD. A 20-liter canister of propylene glycol with a maximum temperature of -30º C has the same cost - in fact, this means that the propylene glycol composition costs 2 times more.

- The use of relatively inexpensive poisonous ethylene glycol is impossible in a house with an open expansion tank.

- Non-freezing liquids have a limited service life, on average it is 5 years or 10 heating seasons, after which the liquid must be drained, the pipeline flushed and a new composition filled in, and when using poisonous ethylene glycol, the issue of its disposal will have to be additionally addressed. This procedure leads to significant financial costs and loss of time.

Rice. 7 The influence of the percentage of ethylene glycol in a solution on its crystallization temperature

- The use of low-quality antifreeze or its use after the expiration of its service life can cause damage to water supply fittings, clogging of pipes and fittings - there are a considerable number of similar examples on the Internet.

- One of the critical disadvantages of using antifreeze compounds is that many boiler manufacturers refuse the consumer further warranty service after adding antifreeze to the system.

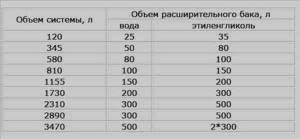

- When using glycols, you will have to install a more powerful circulation pump; propylene glycol will require an increase in its pressure by 10% and productivity by 60%; similarly, a larger expansion tank will be needed.

- It is not recommended to use propylene glycol compounds in electrolysis boilers (Galan) and heating systems with galvanized pipes.

Water

Water is the simplest and at the same time the most inexpensive way to transfer heat from the source to the radiators. If we compare water with other substances in percentage terms, then it accounts for about 70 percent. Actually, this is not surprising, since water is not toxic, although it still has disadvantages. First of all, this is high corrosion activity during contact with metals, as well as the fact that scale forms on the surface of the heat exchanger over time.

But the advantages that such a coolant has for heating systems are also significant: low cost and relative ease of use. Moreover, today a lot of inhibitors are sold, which several times reduce the harmful effects of water on the elements of the heating system. With the use of inhibitors, it becomes inert, which has a positive effect on the service life of the equipment.

Now about the cost. Using water costs practically nothing, unless you buy an additional inhibitor, but this, we repeat, is additional. But if heating will not be used regularly in winter, then it is advisable to abandon water altogether and resort to antifreeze.

Antifreeze selection factors

- Low cost - filling the heating system will require several hundred liters, and during operation it may be necessary to top up or completely replace it.

- No toxic effect on the environment - pipes can leak, even slightly, and the coolant will poison the residents.

- No aggressive effect on heating system materials.

- The maximum possible heat capacity, which will allow you to reduce the amount of fuel to maintain a stable temperature.

The best choice would be to buy a propylene glycol-based antifreeze. Ethylene glycol is a toxic substance. The remaining bases are characterized by aggression on the components of heating systems. Your needs come first. The heating must work properly and without breakdowns. Maintenance should not be expensive or inconvenient.

Heat capacity is an important property

But we forgot about the most important property of the coolant - its heat capacity. The more thermal energy a liter of liquid can transfer, the better. And here the undisputed leader is water, which has the maximum heat capacity. Let's create a table of the specific heat capacity of coolants:

- Water – 4.218 kJ/kg*K;

- Ethylene glycol – 2.2 kJ/kg*K;

- Propylene glycol – 2.483 kJ/kg*K;

- Glycerol – 2.43 kJ/kg*K.

Based on this table, we see that the maximum specific heat capacity is observed precisely at water. If we pour the same propylene glycol into the water system, then when we start the heating we will find that the radiators have become noticeably colder. There are three ways out of this situation:

- Increase the coolant temperature;

- Increase the coolant flow rate using a circulation pump;

- Increase the number of sections in heating radiators.

In some cases, special additives help increase the resistance of the coolant to thermal destruction, but in this case we get a whole chemical cocktail in the system.

It would seem that we have a lot of options. But it's not that simple. If you increase the temperature of the coolant, you will have to look for a liquid that will not collapse when overheated. In the second option, we will be faced with serious costs for the purchase of a particularly powerful pump and the low efficiency of this method. The third option is bad because it is labor intensive - in fact, you will have to rework almost the entire heating system of a country house.

Tips for using coolant

- Use materials recommended by the equipment manufacturer. As a rule, boilers and radiators are tested in the manufacturing plant. During tests, specialists determine the optimal performance characteristics and chemical composition of liquids. Using recommended coolants in the home heating system will significantly reduce the risk of leaks, early corrosion, and slow down the formation of scale and other unpleasant phenomena.

- Do not mix liquids with different compositions and from different manufacturers. Top up the system with the coolant that was used from the very beginning, or with the special THERMAGENT MULTI product. If you do not follow this rule, you can damage the system. At best, the liquid will lose its properties, and at worst, chemical reactions will occur, leading to the formation of insoluble deposits or destruction of network components. To exclude incompatibility of coolants, you can take a sample from the system, mix it with a new product and heat it in a water bath for 30-60 minutes. In the absence of gas evolution or other reactions, you can add the selected composition to the network. It is highly undesirable to dilute organic liquids with water.

- Do not bring the coolant to a boil. When choosing a fluid, consider the design operating temperature. If the coolant in the heating system of a country house boils regularly, it will quickly lose its properties.

Your home is your castle. And everything in it should be as safe and effective as possible. Carefully choose a coolant for heating your home, use the advice of experts, and this will save you from serious mistakes. Detailed information can be obtained by calling the website.

Features of using water as a coolant

From the point of view of heat transfer efficiency, water is an ideal coolant. It has a very high heat capacity and fluidity, which allows it to deliver heat to the radiators in the required volume. What kind of water should I fill? If the system is closed, you can fill it with water directly from the tap.

Yes, tap water is not ideal in composition; it contains salts and a certain amount of mechanical impurities. And yes, they will settle on the elements of the heating system. But this will happen once: in a closed system, the coolant circulates for years, and replenishment with a small amount is very rarely required. Therefore, some amount of sediment will not cause any tangible harm.

Water as a coolant for heating systems is almost ideal

If the heating is of an open type, the requirements for the quality of water as a coolant are much higher. Here, gradual evaporation of water occurs, which is periodically replenished by adding water. Thus, it turns out that the concentration of salts in the liquid increases all the time. This means that sediment also accumulates on the elements. That is why purified or distilled water is poured into open-type heating systems (with an open expansion tank in the attic).

In this case, it is better to use distillate, but getting it in the required volume can be problematic and expensive. Then you can fill in purified water that has been passed through filters. The most critical is the presence of large amounts of iron and hardness salts. Mechanical impurities are also useless, but they are the easiest thing to deal with - several mesh filters with cells of different sizes will help catch most of them.

In order not to buy purified water or distillate, you can prepare it yourself. First, pour and let sit until most of the iron settles. Carefully pour the settled water into a large container and boil (do not cover with a lid). This removes hardness salts (potassium and magnesium). In principle, such water is already well prepared and can be poured into the system. And then top up with either distilled water or purified drinking water. This is no longer as expensive as the initial fill.

Main characteristics of heating fluid

It is possible to determine in advance the coolant flow in the heating system only after analyzing its technical and operational parameters. They will affect the characteristics of the entire heat supply, and will also affect the operation of other elements.

Distilled water for heating

Since the properties of antifreeze depend on their composition and the content of additional impurities, technical parameters for distilled water will be considered. For heat supply, distillate should be used - completely purified water. When comparing coolants for heating systems, it can be determined that the flowing liquid contains a large number of third-party components. They negatively affect the operation of the system. After use for a season, a layer of scale forms on the inner surfaces of pipes and radiators.

To determine the maximum temperature of the coolant in the heating system, you should pay attention not only to its properties, but also to the limitations in the operation of pipes and radiators. They should not be damaged by increased thermal exposure.

Let's consider the most significant characteristics of water as a coolant for aluminum heating radiators:

- Heat capacity – 4.2 kJ/kg*C,

- Mass density . At an average temperature of +4°C it is 1000 kg/m³. However, during heating, the specific gravity begins to decrease. When it reaches +90°C it will be equal to 965 kg/m³,

- Boiling temperature . In an open heating system, water boils at a temperature of +100°C. However, if you increase the pressure in the heating supply to 2.75 atm. the maximum temperature of the coolant in the heating system can be +130°C.

An important parameter in the operation of heat supply is the optimal speed of the coolant in the heating system. It directly depends on the diameter of the pipelines. The minimum value should be 0.2-0.3 m/s. The maximum speed is not limited by anything. It is important that the system maintains the optimal temperature of the heating fluid throughout the entire circuit and that there is no extraneous noise.

However, professionals prefer to be guided by the norms of the old SNiP of 1962. It indicates the maximum values of the optimal coolant speed in the heating system.

| Pipe diameter, mm | Maximum water speed, m/s |

| 25 | 0,8 |

| 32 | 1 |

| 40 or more | 1,5 |

Exceeding these values will affect the coolant flow in the heating system. This can lead to an increase in hydraulic resistance and “false” activation of the release safety valve. It should be remembered that all coolant parameters of the heating system must be pre-calculated. The same applies to the optimal temperature of the coolant in the heating system. If you are designing a low-temperature network, you can ignore this parameter. For classical schemes, the maximum heating value of the circulating fluid directly depends on the pressure and restrictions on pipes and radiators.

To select the correct coolant for heating systems, a temperature schedule of the system’s operation is first drawn up. The maximum and minimum values of water heating should not be below 0°C and above +100°C

Purchasing coolants: modern manufacturers

The market offers goods from domestic producers and imported products. The latter option will cost 2-3 times more. EU manufacturers provide guaranteed safe products for human health. Also, when purchasing imported products, there is a risk of running into counterfeit products. Domestic products will cost less.

Among oil antifreezes, it is worth highlighting the products of Total and RODA. Certified quality from European manufacturers. Dyes are added to the oil to help identify leaks.

Domestic manufacturers of coolants that deserve trust:

- Khimprom is one of the first enterprises in Western Siberia. Market leader. It produces products based on propylene glycol specifically for our climate, with a low freezing point.

- Spetsavia is a modern manufacturer of propylene glycol coolants that are distinguished by high performance. Modern equipment allows us to produce products that are not inferior to European analogues. Has its own accredited laboratory

- Himavto is the manufacturer of the first household antifreeze on the domestic market, which was released in 2001. Since then, the company has been among the leading manufacturers. Has representatives in the CIS countries. Domestic companies can compete with European products. But you need to purchase their goods only in specialized stores, and not in the market.

The best coolant oil

Highly efficient mineral or synthetic coolant for use in liquid phase and forced circulation heat exchange systems. Most often, non-toxic thermal oils are used in a closed system, where contact of hot oil with air is excluded. But it can also be used in an open circuit.

AMT-300

Petroleum liquid non-toxic aromatic mineral oil is produced on the basis of extracts of sulfur petroleum distillates by phenolic purification, followed by purification and waxing. Contains a specially selected composition of additives to improve heat transfer and reduce coke formation.

AMT-300

It is used in the liquid phase in closed systems that exclude contact of hot oil with air, in systems with forced circulation, in closed heating systems with a system for removing low-boiling decomposition products. Recommended for industry and production - compliance with fire safety measures is required.

Total SERIOLA ETA

Inhibited mineral oil for closed systems without contact with air is used for industrial and domestic heating. Has high resistance to thermal cracking.

Total SERIOLA ETA

When starting, the flow rate increases instantly. Static and dynamic aging tests of the SERIOLA ETA coolant at temperatures exceeding 340°C have shown that, compared to other used coolants, the amount of deposits in SERIOLA ETA is 10-12 times lower, and the rate of formation of light fractions has been halved. This allows you to increase the service life to an average of 7-10 years, depending on the seasonality of service.

RODA

It is used in closed and open heating, ventilation, air conditioning systems and is compatible with plastic and metal-plastic pipes. Made from glycerin, non-flammable and safe for humans and the environment. It does not freeze and does not increase in volume; at negative temperatures it turns into a jelly-like mass. Does not require flushing the system before use. Service life – up to 10 years.

RODA

It has a fluorescent dye, which allows you to quickly detect the location of a leak in the event of a system breakdown. Inert to sealing and gasket materials. Ensures safe operation of circulation pumps. The composition is completely ready for use.

Rules for diluting propylene glycol

To prepare a coolant based on concentrated propylene glycol, demineralized water is used. Dilution in different proportions, by volume or weight, is acceptable. For convenience, you can use the following information:

| Volume concentration in % | Density at 20°C, g/cm3 | Freezing temperature, °C |

| 25 | 1,023 | -10 |

| 30 | 1,029 | -13 |

| 35 | 1,033 | -17 |

| 40 | 1,037 | -21 |

| 45 | 1,042 | -26 |

| 50 | 1,045 | -32 |

Propylene glycol coolants are not used in systems with galvanized pipes; prolonged exposure leads to peeling of the material.

Keep in mind that when preparing working trains, precautions and fire safety measures must be observed. Work may only be carried out in a well-ventilated area, wearing personal protective equipment. But it is better to buy a ready-made solution and entrust pouring the liquid into the system to professionals.

Important! Do not mix coolants from different manufacturers. Each brand uses its own package of corrosion inhibitors, which can conflict in composition and lead to loss of properties.

Rules for choosing antifreeze

An objective concept of which coolant is best to use in the heating system of a private house under specific conditions arises when taking into account the following series of criteria:

- Type of base and its applicability to equipment and operating conditions.

- Freezing and boiling points, optimal operating heating range - taking into account the dilution of the concentrate.

- Possibility of reducing concentration by adding water.

- Life time.

Note! Antifreeze is not recommended for use in open systems and with natural circulation. In addition, the antifreeze liquid should not come into contact with an unprotected galvanized surface and rubber, silicone seals, as well as oiled tow. In addition, only reliable automation can provide accurate control over compliance with its heating parameters.

Pouring antifreeze into the heating system Source hstream.ru

Types of antifreeze by composition

To understand which coolant is best to use, it is worth understanding the composition and properties of liquids. Modern materials are made on the basis of organic compounds with a low pour point.

Ethylene glycol . The liquid is a dihydric alcohol, has an oily consistency and a faint characteristic odor. Ethylene glycol is volatile and toxic, therefore it is used only in closed systems. Can be used with gas, solid fuel, electric, diesel boilers. It is not recommended to use ethylene glycol in systems with electrolysis equipment and galvanized pipes. Coolant advantages:

- Affordable price.

- High frost resistance, up to -65 °C depending on the brand.

- Compatible with most metals and polymer materials.

- Chemical inertness.

When choosing a coolant for a country house, it is better to give preference to well-known manufacturers. Large factories have their own laboratories that carefully check the composition. A high-quality formulation almost completely eliminates the disadvantages of ethylene glycol.

Propylene glycol . The substance also belongs to dihydric alcohols, but it is a safer and chemically inert coolant for heating systems. Propylene glycol has a low odor and has the ability to absorb and retain water. To improve performance, a package of additives is added to the product. Advantages of the liquid:

- Chemical inertness (due to the work of additives).

- Low volatility.

- Safety for human health and pets.

Heat transfer fluids based on propylene glycol are recommended for use in facilities with increased requirements for environmental friendliness of materials. The liquid is used not only in heating residential buildings, but also in the food industry, in radio electronics, in refrigeration units, etc. The material is fire and explosion-proof, but can accelerate the corrosion of galvanized pipes. It is important to take this property into account when purchasing coolant.

Oils . Thermal oils are characterized by high heat capacity, high heat transfer coefficient, and are used in a wide temperature range, but are not suitable for every system. It is allowed to pour such liquid only into those boilers for which the corresponding manufacturer’s recommendations are given. To understand what coolant can be used in the system, you need to study the equipment passport. Due to the low prevalence of thermal oils, we will further consider only glycol compositions.

Antifreeze for heating

In addition to water, special non-freezing liquids - antifreeze - are poured into heating systems. Usually these are aqueous solutions of polyhydric alcohols. Not so long ago, glycerin-based antifreeze appeared on our market. So now there are three types of non-freezing liquids for heating systems.

Types of non-freezing liquids and their properties

Antifreezes are based on two substances: ethylene glycol and propylene glycol. The first is cheaper, freezes at lower temperatures, but is very toxic. You can get poisoned not only by drinking, but even by simply getting your hands wet or inhaling fumes. The second non-freezing coolant for the heating system is based on propylene glycol. It is more expensive, but safe. Sometimes it is even used as a dietary supplement. Its disadvantage (besides the price) is that it loses fluidity at higher temperatures than propylene glycol.

Ethylene glycol coolant is very toxic

Despite their high toxicity, ethylene glycol coolants are more often purchased. This is most likely due to the price - propylene glycol is twice as expensive. But ethylene glycol antifreeze in its pure form is also chemically active, can foam, and has increased fluidity. Foam and activity are combated with additives, and increased fluidity is not corrected in any way. Paired with toxicity, it is a dangerous combination. If there is the slightest possibility somewhere, this antifreeze will leak. And since its vapors are poisonous, this will not lead to anything good. Therefore, if possible, use propylene glycol.

| Name | Substance | Weight | Operating temperature range | Beginning of crystallization | Thermal decomposition temperature | Life time | Possibility of dilution with water | Price |

| Dixis (Dixis) 65 | monoethylene glycol | 10 kg | -65°С ~ +95°С | -66°С | + 111°C | 10 years | Yes | 850 rub. |

| Warm House – Eco | propylene glycol | 10 kg | -30°С to +106°С | -30°C | +170°С | 5 years | Yes | 1050 rub. |

| Dixis TOP (Dixis TOP) -30 | propylene glycol | 10 kg | -30°С to +100°С | – 31°C | +106°С | 3 years | Yes | 960 rub. |

| ANTIFROST based on glycerin | glycerol | 10 kg | -30°С to +105°С | 4 years | No | 700 rub | ||

| PRIMOCLIMA ANTIFROST based on propylene glycol | propylene glycol | 10 kg | -30°С to +106°С | -30°C | +120°С | 5 years | Yes | 762 RUR |

| TERMAGENT 30 | ethylene glycol | 10 kg | -20°С to +90°С | -30°C | +170°С | 10 years | No | 650 rub. |

| Teplokom (glycerin) | glycerol | 10 kg | – 30°С to +105°С | 8 years | No | 780 RUR |

Another important drawback is that ethylene glycol reacts very poorly to overheating, and overheating occurs at a fairly low temperature. Already at +70°C, a large amount of sediment is formed, which settles on the elements of the heating system. Deposits reduce heat transfer, which again leads to overheating. In this regard, such antifreezes are not used in systems with solid fuel boilers.

Propylene glycol, on the contrary, is chemically almost neutral. It reacts less than other coolants with other substances; overheating occurs at higher temperatures and does not lead to the same consequences.

Propylene glycol coolant is safe, but costs more and freezes at higher temperatures

At the end of the last century, antifreeze for heating systems based on glycerin was developed. It is a cross between ethylene and propylene coolants. It is safe for humans, but does not have a very good effect on gaskets, and also reacts poorly to overheating. In terms of price and temperature characteristics, it is approximately in the same range as propylene coolants (see table).

Features of systems with antifreeze as a coolant

When designing a heating system, the coolant must initially be taken into account. This is due to the lower heat capacity of non-freezing liquids, as well as their other properties. If all the equipment was designed for water, and antifreeze is poured into it, the following problems may arise:

- There won't be enough power and the house will be cold. This is due to the lower thermal conductivity of antifreeze. This problem can be solved with little effort - increase the speed of the coolant by installing a more powerful circulation pump. But in an amicable way, an increase in the number of radiator sections is required.

- In closed systems, the volume of the expansion tank may be insufficient. This is due to the fact that when heated, antifreezes expand more than water. The solution is to install another tank. The total volume should be slightly larger than required (the volume can be taken from the table).

Expansion tank volume for different types of coolant - If regular rubber gaskets are used, if ethylene glycol or glycerin is used, they will break down and leak after a short time. Therefore, before adding antifreeze, the gaskets in all detachable connections are replaced with paronite or Teflon ones.

As you understand, the best coolant for a heating system is water. It has better characteristics and is several times cheaper. If the heating is in danger of defrosting, you have to fill in antifreeze, but not for automobiles, but special ones for heating. In this case, if you have enough funds, it is better to use propylene glycol. Ethylene antifreezes are a last resort. They are suitable in closed systems, in which special gaskets and automated boilers are installed that will prevent overheating.

To make it easier for customers to navigate, dyes are added to coolants. Ethylene ones are red or pink, propylene ones are green, glycerin ones are blue. After some time, the color may become less intense or disappear completely. This occurs due to thermal destruction of dyes, but does not affect the properties of the antifreeze itself.

Question answer

After how many years should antifreeze be changed in a private home?

It is better to replace antifreeze every 5-6 years

Heating cost calculation

The cost of repairing heating systems

Cost of installation of water supply

Similar services:

Replacing the coolant in the heating system Installation of heating a house at one of the last stages involves filling the heating system with coolant, which is mainly used as ordinary tap water. It is the composition and condition of the coolant during operation of heating equipment that largely determines the efficiency of the entire complex heating system. Among the row...

Replacing the coolant in dacha heating Creating a warm, safe atmosphere in a summer country house has its own characteristics. Often, owners come here for a short time, and when leaving, they turn off the devices. For this reason, there is a possibility of freezing and further damage to communications. Particular attention must be paid to preparing the heating system for...

Replacement of coolant from 18,000 ₽ Draining the heating system Blowing with a compressor from residual liquid Filling with new coolant Removing air Start-up and adjustment work of the heating system Disposal of old coolant For details, call 8 495 744 67 74 Please note, you may need to ► flush the heating system with chemicals Specialists…

Service life of the heating pump The service life of the circulation pump of the heating system is from 3 to 6 years. Installation, repair, replacement of heating pump in our company...

Cost of installation work HEATING WATER SUPPLY Heating repair Installation of heating in a dacha Installation of winter water supply in a private house Installation of winter water supply in a dacha, installation of heating in a private house Repair of water supply pipes in a private house, replacement of water pipes of a heating system in a dacha, installation of sewer pipes in a country house...

Heating a house 100m As you know, the most important thing in your own private home is warmth, comfort, convenience and coziness. It is necessary for all family members to be comfortable at any time of the year, and not have to dress warmly in woolen clothes and wrap themselves in a blanket in the evenings...

Frequency of maintenance of heating systems It is no secret that of all the engineering systems that provide comfortable living in a country house, heating is the most expensive and technically complex. The comfort and the very possibility of living in a house in the winter, as well as the work of related...

Maintenance of a private house Country private houses and cottages usually do not have the ability to connect to a central heating and water supply system. Owners are forced to look for service providers to install water heating boilers and boilers for the heating system of a private home. After installation and signing of the completion certificate...

Heating without electricity Many summer residents and owners of country real estate are interested in the possibility of organizing heating for their homes without electricity. Their concern is understandable; it is caused by disruptions in the supply of electricity in areas remote from the metropolis. When choosing a method of heating a home, they firstly do not want to depend on...

Heating systems and boilers for heating industrial buildings Heating systems and boilers for heating industrial buildings Heating of industrial buildings has its own characteristics and requires a special approach to the issue, individual in each specific case. The heat sources for various heating methods are most often industrial boilers operating at different…

Heating in a private house with gas Gas heating for a private house is a very profitable option in terms of the return on investment of the heating system. Natural gas, if supplied to the house, will cost slightly less than electricity, which allows you to save on fuel. In addition, a chimney for gas heating is much simpler…

Installation of heating pipes in a dacha Installation of heating in a dacha Service center LLC DESIGN PRESTIGE LLC DESIGN PRESTIGE is a 24-hour emergency service designed to solve absolutely any problems related to the engineering operation of any buildings, including country houses and cottages. Engineers and employees of the emergency and installation team have…

Order heating installation for a private home Installation of a heating system for private homes With the onset of cold weather, many things change in our lives. It is unlikely that a modern person could survive in conditions that are completely unacceptable for living, and no matter how luxurious the house is, if it is cold, few people...

Autonomous home heating systems Advantages of autonomous heating Autonomous home heating systems have a number of important advantages: · independent regulation of hot water and heating temperature; · savings on monthly utility bills; · ...

Gas heating of a country house In a warm house, you can always shelter from cold and bad weather, even if it is a country house. After all, now you can easily install a heating system in it. Especially among the owners of such houses, gas heating is in demand. With its unrivaled performance and ease of use,…

Electric home heating Electric home heating is much more amenable to automation than any other heating method. In an electric boiler, water is heated using a heating element similar to those used in a conventional electric kettle. The temperature of the heating element is easily regulated within a fairly wide range, which makes it easy to control…

Heating a private house - boiler room Heating a private house for Russia is one of the most important topics when starting construction. But despite its importance, many consider it too simple a task to think about designing. In fact, even a system assembled without a design or calculations...

Choosing a heating system Choosing a heating system Choosing a heating system for a summer house is a complex problem. In old dachas it still reigns......

Installation of heating in a dacha Often in dachas water heating is used, in which pipes with water are heated by an electric source. But purchasing pipes, their installation and maintenance is another burden on the family budget, and besides, various force majeure circumstances are possible with power supply. Heating installation at the dacha...

Ethylene glycol

It is worth knowing that ethylene glycol is very dangerous, so it should be used with extreme caution. So, if the walls of the system are damaged, the consequences can be very dire. So its use in double-circuit boilers is undesirable. In addition, ethylene glycol is strictly prohibited from being used in cases with open expansion tanks, since if it enters the human body (especially a substance with the third hazard class), it will negatively affect health. Although it is impossible to recognize it by smell due to its absence, there is only a slight sweetish aftertaste. So all this is very dangerous and requires caution.

Today, almost all antifreezes in the world are made based on ethylene glycol. Its cost is approximately 80 rubles per kilogram.

Rating of the best coolants on the domestic market

WARM ECO HOUSE

Propylene glycol substance. The manufacturer recommends using it in dual-circuit heating systems. During operation, it significantly loses its anti-corrosion properties. Not suitable for electrolytic boilers.

ADVANTAGES:

- Fire and explosion proof

- Provides reliable protection of heating and air conditioning systems from defrosting, scale and corrosion

- Additives based on mineral salts do not contain harmful nitrites, amines and phosphates

- Do not have an aggressive effect on metals, plastic, metal-plastic, rubber, paranit and flax

FLAWS

- Not detected

WARM ECO HOUSE

DIXIS-65

They are used both in industrial systems and for heating small private houses. Feature - freezing temperature - 65 degrees. When used in a region with mild winters, the substance can be diluted with water, which will reduce its cost. It has gentle properties on heating system materials and extremely low flammability.

ADVANTAGES:

- High frost resistance

- Heat exchange devices are not destroyed when frozen

- Maintains the heating system in ideal condition in the temperature range -65°C ... +95°C

- Can be used by diluting with regular tap water

- Prevents scale formation

FLAWS

- Not detected

DIXIS-65

Warme ECO 30

Harmless glycerin antifreeze, which has a neutral effect on humans and the environment. Diluted with a complex of additives to reduce the aggressive effect on the components of the heating system. Thanks to this, the metal and sealing elements do not damage. Contains a phosphor dye.

ADVANTAGES:

- Environmentally friendly product

- Incombustible

- Non-toxic

- Explosion-proof

- Contains a special complex of anti-corrosion additives

FLAWS

- Not detected

Warme ECO 30

TermoTactic EcoGreen – 30°

It has a glycerin base with added additives. Produced on the basis of European production. It is environmentally friendly and therefore recommended for residential buildings.

ADVANTAGES:

- Highly hygroscopic

- Easily mixes with distilled water in any proportions

- Non-toxic, ensures the safety of the environment and human life during operation and disposal

- The presence of a functional additive “corrosion inhibitor” - prevents the occurrence of physiological and physico-chemical processes when interacting with metals, plastics, rubber and paranitic seals

- Retains unchanged its original state when heated and cooled

FLAWS

- Not detected

TermoTactic EcoGreen – 30°

PRIMOCLIMA ANTIFROST – 30

Does not swell when frozen. There are no toxic components in the composition. Can be used for up to 8 years without replacement. The additives in its composition allow you to extend the life of heating system components.

ADVANTAGES:

- Effective package of anti-corrosion additives

- Inertness to sealing and gasket materials

- Long service life - up to 8 heating seasons

- Cost-effective - with a system volume of 100 liters, 115 kg of coolant will be required, and the product is completely ready for use

- Compatible with most antifreezes on a similar basis

FLAWS

- Not detected

PRIMOCLIMA ANTIFROST – 30

Aquatrust – 30

Propylene glycol antifreeze with extended service life. It is characterized by high cost. Used in enterprises, including public catering. Has antibacterial components.

ADVANTAGES:

- Latest anti-corrosion formula

- Extended life of corrosion inhibitors and antibacterial additives

- Improved heat transfer properties

- Service life is 3 times longer than traditional coolants

FLAWS

- Not detected

Aquatrust – 30

Certificates and approvals

It is no secret that the global center of production today is in China. With all due respect to the volume and speed with which industry operates in this country, it is impossible for an ordinary Russian to determine the quality of products made in China. Meanwhile, China today produces everything, including additive packages and bases for many technical and special fluids, including various glycols. They do not differ in quality and are most often poisonous.

Large and trusted manufacturers have long-term contracts with leading European manufacturers and suppliers. This is how, for example, a Russian manufacturer works. producing coolants under the Thermagent brand. This guarantees the consistent quality of each batch of base, which comes to the plant directly from Europe's largest chemical concern .

The quality of the Thermagent line of coolants is confirmed by certificates and approvals from leading manufacturers of boiler equipment - , etc.

Propylene glycol

But propylene glycol is safer in terms of toxicity, that is, it is completely non-toxic, so it is allowed to be used in all countries. Moreover, it can even often be found in food (look for it under code E 1520). So, the advantages of the substance include complete safety in terms of environmental protection, as well as excellent physical characteristics (such as a very low crystallization temperature - minus 40 degrees). But all the advantages pale in comparison to the main disadvantage - the very high cost (from 150 rubles per kilogram) . This is why propylene glycol is so rare.

How to pump coolant

Problems usually arise only with closed systems, since open ones are filled through an expansion tank. The coolant for the heating system is simply poured into it. It spreads throughout the system under the influence of gravity. It is important that all air vents are open when filling the system.

An open heating system is filled through an expansion tank

There are several ways to charge a closed heating system with coolant. There is a method of filling without the use of equipment - by gravity, there is a submersible pump of the “Kid” type or a special one, with the help of which pressure testing of the system is done.

Fill by gravity

Although this method of pumping coolant for a heating system does not require equipment, it takes a lot of time. You have to squeeze out the air for a long time and also gain the required pressure for a long time. By the way, we pump it up with a car pump. So you will still need equipment.

Finding the highest point. Usually this is one of the gas vents (we remove it). When filling, open the valve to drain the coolant (lowest point). When water runs through it, the system is full.

With this method, you can connect a hose from the water supply, you can pour prepared water into a barrel, raise it above the entry point and then pour it into the system. Antifreeze is also added, but when working with ethylene glycol you will need a respirator, protective rubber gloves and clothing. If the substance gets on fabric or other material, it also becomes toxic and must be destroyed.

You need to monitor the pressure using a pressure gauge

When the system is full (water runs out of the drain tap), take a rubber hose about 1.5 meters long and attach it to the entrance to the system. We select the entrance so that the pressure gauge is visible. At this point we install a check valve and a ball valve. To the free end of the hose we attach an easily removable adapter for connecting a car pump. Having removed the adapter, pour coolant into the hose (keep it raised up). After filling the hose, use an adapter to connect the pump, open the ball valve and pump liquid into the system. You need to make sure that air is not pumped in. When almost all the water contained in the hose has been pumped in, the tap is closed and the operation is repeated. On small systems, to get 1.5 Bar, you will have to repeat it 5-7 times, with larger ones you will have to tinker longer.

Fill using a submersible pump

To create working pressure, the coolant for the heating system can be pumped with a low-power submersible pump like Malysh. We connect it to the lowest point (not the system drain point). We connect the pump through a ball valve and a check valve, and install a ball valve at the drain point of the system.

We pour the coolant into the container, lower the pump, and turn it on. During operation, we constantly add coolant - the pump should not drive air.

We monitor the pressure gauge during this process. As soon as its needle moves from the zero mark, the system is full. Until this point, manual air vents on radiators can be opened and air will escape through them. As soon as the system is full, they must be closed.

Next, we begin to increase the pressure - we continue to pump the coolant for the heating system with the pump. When it reaches the required level, we stop the pump and close the ball valve. We open all the air vents (on the radiators too). The air comes out, the pressure drops. We turn on the pump again, pump up a little coolant until the pressure reaches the design value. We release the air again. We repeat this until air stops coming out of their air vents.

Next, you can start the circulation pump and bleed the air again. If the pressure remains within normal limits, the coolant for the heating system is pumped. You can put it to work.

We use a pump for crimping

The system is filled in the same way as in the case described above. In this case, a special pump is used. It is usually manual, with a container into which the coolant for the heating system is poured. From this container, liquid is pumped through a hose into the system. You can rent it from companies that sell water pipes. In principle, it makes sense to buy it - if you use antifreeze, you will have to change it periodically, that is, you will need to fill the system again.

This is a manual pump for pressure testing, with which you can pump coolant for the heating system

When the system is filled, the lever moves more or less easily, but when the pressure rises, it becomes more difficult to work. There is a pressure gauge both on the pump and in the system. You can follow where it is more convenient. Next, the sequence is the same as described above: pump up to the required pressure, deflate the air, repeat again. Do this until there is no air left in the system. After that, we also start the circulation system for about five minutes (or the entire system, if the pump is in the boiler), and bleed the air. We also repeat several times.

Pressing the heating system

Pressing the heating system

Before filling the heating system with coolant, it is necessary to check the tightness of all joints and connections. To do this, pressing is performed - creating excess pressure in the pipes, i.e. a situation of destabilization of the system is artificially created.

This can be done in two ways - using air injection or coolant. This must be done before the heating system of the double-circuit boiler is filled. This procedure can be carried out using a mechanical (electric) pump or by connecting the water supply. The last option is not recommended, since it will be very difficult to control the process. The order of execution is as follows:

- Preliminary visual inspection of joints and connecting nodes;

- Connecting the mechanism to the inlet pipe of the system;

- Creation of excess pressure, the value of which should exceed the norm by 1.5 times.

The condition of the heating elements must be checked. If a leak occurs, the process stops immediately and can only begin when the defect is repaired.

Reviews from buyers of heating fluids

Review of Dixis Top antifreeze

Dixis Top antifreeze. It is a coolant for heating systems (radiators, heated floors, boilers)

In my opinion and not only that, this product is one of the best of its kind; it is produced on the basis of food-grade propylene glycol, which is very important, because it is environmentally friendly! (unlike many others)

Unlike ethylene glycol, propylene glycol is practically non-toxic, therefore it is used in food, pharmaceutical, and other industries where ethylene glycol cannot be used for fear of the latter entering the human body. This antifreeze has a crystallization temperature of minus 30 degrees C, therefore it is very good for filling radiators and heating systems of a country house (it’s just that the pipes will not freeze, unlike filling with water, which is very important and what is also important if there is any malfunction , or a leak in the heating system, then there will be no harm to health, as stated above).

It can also be safely used in open systems and in double-circuit heating boilers, and will also allow commissioning to be carried out at sub-zero temperatures.

So I highly recommend this particular antifreeze, I didn’t find any cons in it!

Author: Profler https://otzovik.com/review_4504888.html

Popular coolants based on propylene glycol and ethylene glycol

THERMAGENT ECO . A modern coolant for the home, which is also successfully used as a refrigerant. Operating temperature range - from -30 to +106 °C. The composition also includes an additive package. Additives eliminate foaming, protect metal surfaces from corrosion, and prevent the appearance of scale. The service life specified by the manufacturer is 10 heating seasons. The characteristics of the coolant are confirmed by the CU TR declaration of conformity and the safety data sheet for chemical products.

THERMAGENT MULTI . The coolant is designed specifically for adding to already operating systems. The composition of the liquid ensures complete safety for metal, plastic pipes, and rubber components. The product does not affect the color and properties of the original coolant. Although THERMAGENT MULTI is based on propylene glycol, it combines well with ethylene glycol fluids.

THERMAGENT -30 and THERMAGENT -65 . Coolants are produced on the basis of purified ethylene glycol with the addition of additives. The materials are suitable for use in difficult conditions and are used in heating systems at facilities in the northern regions of the country. Additives provide anti-corrosion, antibacterial properties and prevent foaming.

Finally, about coolants for electrode boilers

Electric water heaters of this type operate on the principle of a “soldier’s boiler” consisting of two blades connected to a 220 volt network. Water simultaneously serves as a coolant and electrolyte; heating occurs due to its conductivity, which depends on the content of magnesium and calcium salts.

This is why electrode boilers do not work with distillate and significantly lose power with under-salted water. According to the passport of the Galan heater, the resistance of the working fluid should be no more than 3200 Ohms per 1 cm.

If you pour regular ethylene glycol into an electrolysis heat generator, the substance will enter into a chemical reaction, foam and lose additives against corrosion and scale formation. The problem can be solved in 2 ways:

- A special antifreeze designed for electrode-type units is purchased. Special additives that resist foaming are dissolved in the working environment.

- A saline solution of the required concentration is prepared, as shown in the video below. Such water will begin to crystallize at a lower temperature, although it cannot be compared with antifreeze in terms of frost resistance.

You should pay attention to the preparation of tap water - pass it through a filter and let it sit for 1-3 days. A good solution is to buy a corrosion inhibitor separately and add it to the coolant for the heating system in advance.

Antifreeze characteristics

With the onset of cold weather, you can use the so-called anti-freeze agent that fills the pipes. They will not burst even at low temperatures, which is very important for owners of private property that are not used regularly. Antifreeze is designed to operate over a wide temperature range, ranging from -30°C and above. You can find antifreeze on sale that can be used down to -65°C.

If you need to arrange heating for a country house, the coolant can be represented by antifreeze. When the critical temperature drops, it will not freeze, but will become gel-like. As soon as the temperature rises, the liquid will return to its original state without losing its properties.

It is noteworthy that antifreeze does not pose a threat to the heating circuit. In order to eliminate pockets of corrosion and rid the inner surface of pipes of scale, manufacturers add special inhibitors to it.

Briefly about the main thing

The coolant for heating a private house allows you to efficiently and safely transfer thermal energy from the heating circuit of the boiler to the radiators, which in turn release heat to the surrounding space. The coolant must meet the following series of requirements:

- Complete heat transfer.

- Chemical inertness.

- Optimal operating temperature range.

- Absence of harmful components.

- Stability and constancy of operating parameters.

- Safety for people and the environment.

Water can be used as a coolant. It tolerates heat best, is free and accessible. However, it freezes already at zero degrees, causes corrosion and can form insoluble salts. Non-freezing liquids do not have such disadvantages.

Antifreezes are divided according to their chemical composition into ethylene glycol, propylene glycol, and glycerin. There are also special ones for electrode boilers and mineral ones. Antifreeze cannot be used as a cheap alternative. You can add antifreeze manually or with a pump. At the same time, monitoring performance characteristics and strict adherence to technology are extremely important.

Read later

Additional features of antifreeze

Before choosing this coolant and filling the heating system, you should study its characteristics. For example, the choice should be influenced by the purpose and composition of the additives, as well as possible interactions of the substance with the components of the heating system, which can be made of cast iron, plastic, non-ferrous metals or rubber.

The temperature of the heating fluid must also be taken into account, since each manufacturer indicates this parameter for its product. It is also important to take into account the service life, as well as safety for nature and human health. If you use water as a coolant, then the system is arranged according to a traditional closed or open type scheme.