A gas boiler is a reliable heating device, and it can be installed not only in private homes.

There are models that are quite suitable for city apartments. What criteria should you pay attention to when choosing a boiler? First of all, on the number of circuits.

Single-circuit devices are used only for heating rooms.

Double-circuit ones also provide residents with hot water, although they are more expensive. The area of the heated room, the thermal power of the device and the method of installation of the heating device are also taken into account.

Those who are planning to purchase a single-circuit boiler will find our rating useful.

It includes devices that users and experts called the best in 2021 in terms of price/quality ratio. Also, when selecting models, official test data from Rostest were taken into account.

Rating of the TOP 20 best single-circuit gas boilers of 2021

| Place | Name | Price |

| TOP 3 best single-circuit gas boilers in price/quality ratio for 2021 | ||

| 1 | Protherm Panther 25 KTO (2015) 25 kW | Find out the price |

| 2 | BAXI ECO Four 1.24 F 24 kW | Find out the price |

| 3 | Lemax Premium-30N 30 kW | Find out the price |

| TOP 3 best wall-mounted single-circuit gas boilers | ||

| 1 | Vaillant turboTEC plus VU 242/5-5 24 kW | Find out the price |

| 2 | BAXI LUNA-3 COMFORT 1.240 Fi 25 kW | Find out the price |

| 3 | Bosch Gaz 6000 W WBN 6000-18 H 18 kW | Find out the price |

| TOP 3 best floor-standing single-circuit gas boilers | ||

| 1 | Lemax Premium-25 25 kW | Find out the price |

| 2 | Lemax Leader-35 35 kW | Find out the price |

| 3 | Lemax Leader-16 16 kW | Find out the price |

| TOP 3 best single-circuit gas boilers with indirect heating boiler | ||

| 1 | BAXI ECO Four 1.24 24 kW | Find out the price |

| 2 | Buderus Logamax U072-24 24 kW | Find out the price |

| 3 | BAXI SLIM 1.400 iN (without smoke hood) 40 kW | Find out the price |

| TOP 2 best condensing single-circuit gas boilers | ||

| 1 | Protherm Lynx condensing 30 MKO 30 kW | Find out the price |

| 2 | Buderus Logamax plus GB172-35 i 34.9 kW | Find out the price |

| TOP 2 best single-circuit gas boilers for 24 kW | ||

| 1 | Vaillant atmoTEC plus VU 240/5-5 24 kW | Find out the price |

| 2 | BAXI ECO Four 1.24 24 kW | Find out the price |

| TOP 2 best single-circuit parapet gas boilers | ||

| 1 | Lemax Patriot-20 20 kW | Find out the price |

| 2 | Lemax Patriot-16 16 kW | Find out the price |

| TOP 2 best closed-type single-circuit gas boilers | ||

| 1 | Vaillant turboTEC plus VU 282/5-5 28.9 kW | Find out the price |

| 2 | BAXI ECO Four 1.14 F 14 kW | Find out the price |

Two circuits or a separate boiler?

The most intriguing question is: in what cases is it worth using a double-circuit boiler for hot water, and in what cases is it better to install a separate tank.

If, for example, you have an apartment with its own heating, but only one bathroom, then you can quite easily use a boiler with two circuits. The same applies to private houses. In this case, there will be plenty of hot water.

If you have a substantial house for a large family, 2-3 bathrooms, then in this case it is better to use an indirect heating boiler in conjunction with a single-circuit boiler. The same applies to public facilities.

So, we looked at the features and main characteristics of double-circuit boilers. We hope that the information presented will help you decide on the choice of device for your home. Remember that a properly selected unit will be able to keep you warm and provide hot water. May your home always have good weather, warmth, food and hot water!

How to choose a single-circuit gas boiler?

Choosing a single-circuit boiler is quite easy if you know the basic selection parameters.

If the user has clearly decided to buy a single-circuit device, all that remains is to decide on the dimensions of the boiler and the type of installation.

If you need to heat a large room, you usually buy a floor-standing model. For small homes, a compact wall-mounted unit will suffice.

You should also pay attention to the type of combustion chamber.

Boilers with an open combustion chamber are cheaper, but they are more difficult to install, since you will have to make a hole in the wall next to the device to install a chimney.

Boilers with closed combustion chambers are more convenient, and they can be installed even in apartments of multi-storey buildings.

Minimum characteristics of double-circuit boilers

When choosing a boiler for your home, you need to consider the following parameters:

- Power. Shows how much heat is being produced.

- Efficiency Efficiency of using heat from the flame. Characterizes how economical the boiler is.

- Temperature of the gases released.

- Where heat is conducted. Water or antifreeze.

- Maximum pressure for work.

- Outlet temperature maximum

- Hot water capacity. How much water heats up in one minute. Depends on the desired water temperature.

- Maximum amount of gas required.

- Gas supply. Characterizes stability of operation during sudden jumps.

- Features of electricity consumption: voltage and frequency.

- The power that is expended.

- Dimensions, including weight, fastening features and gas exhaust dimensions. These features do not indicate whether the boiler is good or bad. They must correspond to the purposes of operation. For example, boilers with different capacities are suitable for heating rooms of different sizes.

But in reality, you will get tired of paying attention to all these characteristics. Just remember that wall-mounted boilers are basically all the same in these characteristics. They differ simply in small details. With floor-mounted ones, of course, more attention is required.

TOP 3 best single-circuit gas boilers with indirect heating boiler

Single-circuit gas boilers with indirect heating boilers are universal devices that can not only heat a room, but also provide residents with hot water.

BAXI ECO Four 1.24 24 kW

The wall-mounted gas boiler is designed for installation in domestic and industrial premises with an area of up to 240 square meters .

An indirect heating boiler can be connected to the device, so this model is suitable not only for heating, but also for organizing hot water supply.

The design of the device involves connection to a main pipeline with natural gas, but, if necessary, it can be converted to liquefied gas, but for this the user will have to separately purchase a set of nozzles.

The device has two heat exchangers: a primary one made of copper and a secondary one made of stainless steel. Both materials are resistant to corrosion and ensure stable temperature maintenance at the user-specified level.

The device is also equipped with all the necessary functions for safe operation: protection against overheating and freezing, gas control and automatic fault diagnosis.

Specifications:

- weight 30 kg;

- height 730 mm;

- expansion tank volume 6 l.

pros

intuitive electronic control panel;

can operate on different types of fuel (natural and liquefied gas);

affordable cost;

works relatively quietly;

Compact dimensions make installation easy.

Minuses

The kit does not include jets for liquefied gas;

Many users complain of a loud knocking noise when igniting.

Buderus Logamax U072-24 24 kW

A reliable and functional gas boiler is designed for wall mounting .

The design of the device is specially adapted for operation in the Russian climate. The boiler itself perfectly withstands unstable pressure in the gas main and voltage fluctuations in the electrical network, while simultaneously providing stable heating of the room.

Additionally, the device has a simple and intuitive control system using an electronic panel with a display . With its help, the user can configure basic performance indicators by pressing a few buttons.

Another advantage of the device is that when an independent boiler is connected, the boiler can also be used for hot water supply, and its power is sufficient for high-quality heating of rooms up to 250 square meters.

The heat exchanger is made of copper, is resistant to corrosion and heats up well.

The combustion chamber is a closed type, so this model is suitable not only for private houses, but also for apartments in high-rise buildings.

Specifications:

- weight 30 kg;

- height 700 mm;

- expansion tank volume 6 l.

pros

completely safe to use due to gas control and a reliable safety valve;

there is protection against overheating and freezing;

adequate cost;

stylish attractive design;

excellent build quality.

Minuses

if the boiler fails, repairs will be expensive;

imperfect firmware causes failures in electronic control.

BAXI SLIM 1.400 iN (without smoke hood) 40 kW

A distinctive feature of this boiler is that, despite the floor installation, it has very compact dimensions .

Thanks to this, the device is perfect for heating large residential and industrial premises, but does not take up much space.

The device has a reliable and wear-resistant cast iron heat exchanger.

The combustion chamber is open type, so the device can only be used in private homes. Since this type of combustion chamber involves connection to a chimney, installation of the device should only be carried out by a specialist.

In terms of control, users have no complaints about the boiler.

At the top of the case (front) there is a convenient electronic panel.

It is covered with a translucent lid, and several buttons and two rotary controls allow you to quickly set the necessary heating parameters. Installing the boiler involves installing a smoke hood, but it is not included in the kit, so the user will have to buy it separately.

Specifications:

- weight 150 kg;

- height 850 mm;

- maximum thermal power 40 kW.

pros

durable and high-quality cast iron heat exchanger;

convenient electronic control panel with display;

high thermal power allows the device to be used for heating large rooms;

can operate on different types of gas (natural and liquefied);

There is automatic fault diagnosis.

Minuses

no built-in expansion tank;

impressive weight.

Boiler power calculation

Like any boiler, a double-circuit boiler must be selected taking into account the required power. You need to select it wisely based on the heat loss of your home, which you can’t always calculate on your own. The roughest approach is to provide 1 kW of power per 10 square meters of your home.

But it's another matter if you are going to use the second circuit on an ongoing basis. Based on the boiler power, the amount of hot water released per minute depends. Everything is simpler here. You need a minimum of 24 kW of power to be sure that you will have enough hot water production. Typically, a boiler of this power is capable of releasing 12-14 liters of water per minute. This volume is just enough to take a shower or completely wash the dishes.

Which company should you choose?

Since a gas boiler is an expensive device that is purchased for a long time, it is better to give preference to appliances from well-known brands.

Companies that specialize in the production of heating equipment provide a guarantee for their devices, and use high-quality materials and modern technologies for their manufacture. In 2021, as an analysis of user reviews showed, boilers from Protherm, Vaillant, Lemax, Baxi and Bosch were recognized as the best. It is these devices that are included in this rating.

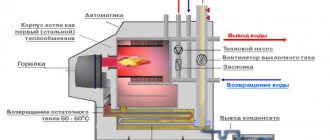

How a wall-mounted heating boiler works and works

In addition to heating elements, a wall-mounted heating device consists of additional equipment that ensures efficient operation. Main nodes:

- Gas-burner. Generates thermal energy. The nozzles assembled into a rectangular contour distribute the gas evenly and efficiently in the chamber to warm up the unit. Modern models from good manufacturers are equipped with the function of regulating the flame and maintaining a set temperature.

- Heat exchanger. Provides water heating due to the heat generated by combustion products. In the tank, liquid circulation begins through the heat supply pipes.

- The combustion chamber. It contains a heat exchanger and a gas burner. The main purpose is gas combustion.

- Circulation pump. Promotes the movement of heated liquid through pipes from the heat generator to the heating radiators.

- Expansion tank. Designed to receive excess water (appears during thermal expansion of the liquid during the heating process).

- Device for removing combustion products. Designed to remove exhaust gases.

- Electronic control unit. Monitors the uninterrupted operation of the unit according to a given program.

- A fan used to force combustion products out.

Modern wall-hung double-circuit boilers have an excellent design, a minimum of communications around them and operate almost silently.

The operating mechanism of a wall-mounted gas boiler depends on their performance and energy efficiency. For different modifications, the basic functioning is similar. The automatic control system records the desired temperature using sensors and calculates the heat requirement. Based on these indicators, gas is supplied to the burner and ignition occurs (electric or piezoelectric). Thanks to the circulation pump, heated water is supplied from the heat exchanger to the heating system.

After reaching the set temperature mark, the burner operation automatically stops.

Materials for heat exchanger: which is better

The heat exchanger plays one of the main roles in the design of a gas heating device - the coolant circulates through it. The most common materials used in the production of heat exchangers for gas boilers are copper, cast iron, and steel.

Steel version of the heat exchanger

The cheapest, and as a result, the most popular material for a heat exchanger is steel. Therefore, it is actively used by domestic manufacturers in order to reduce the cost of the final product. Unlike cast iron, it is not brittle.

Compared to cast iron, steel is much lighter, but when compared to copper, it significantly exceeds its weight and makes the boiler structure heavier.

The steel heat exchanger heats up and cools down quickly. In addition to convenience, this leads to negative consequences - “fatigue” of the metal causes damage. The disadvantage of steel is also its susceptibility to corrosion.

During operation, both the internal and external sides of the steel heat exchanger are subject to corrosion. Over time this leads to its destruction

Copper type heat exchanger

The material has many positive properties - corrosion resistance, small volume, low inertia. Due to its compactness and low weight, copper is actively used for the production of lightweight wall-mounted boilers.

Non-corrosion is one of the main qualities for heating equipment intended for heating process water.

The opinion about the fragility of copper heat exchangers has long been refuted by manufacturers of modern heating equipment - in them, the burner power is reduced by 30%, which reduces the thermal effect on the metal and has a good effect on the duration of operation.

Boilers with cast iron heat exchanger

The main quality of cast iron that should be noted is its inertia. The material takes a long time to heat up and cools down for a long time, which increases the efficiency of heat transfer.

Such inertia can be considered both a positive quality and a negative one - in the event of sudden warming outside, the boiler will maintain a high temperature in the heating system for a long time.

A cast iron boiler weighs twice as much as a steel one, so the boiler design is made sectional to make it convenient to deliver, install and repair

Cast iron is subject to dry and wet corrosion. The latter contributes to the appearance of rust, but due to the thick walls, the corrosion process extends over a long time.

The disadvantages of cast iron boilers include the fragility of the material, which manifests itself as a result of improper operation - temperature changes, mechanical damage during transportation and installation.