Thermal and noise insulation of walls in an apartment is a popular job now, performed in almost every house and apartment. Everyone began to conserve heat, since this is a serious saving on the family budget, and excessive noise adds stress to our already intense lives. Home should be a place where you have the opportunity to relax, which is why such technologies have become so popular.

First, let's look at the materials, firstly, generally thermal insulation materials can rarely boast of soundproofing properties, of the most affordable and popular there are only three of them - wool (eco, glass and mineral), cork sheets and isolon. Polystyrene foam and polypropylene foam do not insulate sound well, and wallpaper linings or special mixtures that can remove extraneous noise do not provide heat. You can either use one of the options listed, or build a structure from a combination of heat and sound insulators.

In order to finally convince you of the reasonableness of choosing one of the three proposed options, we will consider the advantages and disadvantages, and the installation features of each of the listed materials.

Types of noise

- Airborne (pets, construction going on next door, passing machinery, etc.);

- Shock. These are sounds from impacts on walls and partitions (operation of a hammer drill, hammer blows, drilling, etc.)

- Structural. This is any noise that penetrates the structural elements of a building.

To protect against various kinds of extraneous noise, a set of measures is taken to soundproof walls, ceilings, and floors. For this purpose, special materials are used that have sound-proofing and sound-absorbing properties.

Sound-absorbing materials are used to ensure that sound coming from the room does not return back into the room. The structure is usually fibrous, granular or cellular.

Soundproofing materials prevent outside noise from penetrating. And the thicker and denser they are, the more protected the room is from extraneous sounds.

The best option is a combination of both types of materials. As a result, you can achieve a fairly high level of protection of the room from extraneous noise, both from you and from your neighbors.

Preparing the wall for installation yourself

After the material for soundproofing the walls in the apartment has been selected, the preparatory stage needs to be carried out. Preliminary preparation determines the effectiveness of the resulting insulation. During this stage, surfaces are cleaned of dirt, unevenness is leveled and cracks are filled.

Preparation for installation

Work progress:

- Before starting, you need to thoroughly clean the surface of old coating, paint or wallpaper. Also, get rid of dust.

- Then, you need to seal all the cracks and defects on the walls with putty.

- Areas containing heating pipes, electrical supply lines and other communication devices must be treated with a sound-proof sealant.

- Then finish the wall with a primer with deep penetration properties. This will improve adhesion to the sound-absorbing wall material. This will prevent the appearance and development of microorganisms, especially mold fungi.

Fastening mineral wool

Types of soundproofing materials

In general, such materials are necessary so that sound waves are damped (dissolved) in them. This is achieved by using a special structure.

The materials themselves are divided into:

- Soft. These are mainly fiberglass-based boards, mineral wool, etc.;

- Tough. Materials that have a porous structure, for example, gypsum, perlite, pumice, vermiculite;

- Semi-rigid. Foam type, can absorb up to 75% of noise.

Until recently, such a combination was almost impossible - the soundproofing layer turned out to be very bulky, and its installation was quite labor-intensive.

Nowadays, such problems have been solved thanks to the development and production of modern soundproofing materials that have exceptional noise and sound-absorbing properties.

What material is best for soundproofing an apartment?

Minvata

The most common and one of the most effective materials is mineral wool, produced in mats and rolls. It is believed that mineral wool does not allow about 99% of noise to pass through. This is a universal material and is suitable for soundproofing any surfaces in the apartment.

The only thing that holds many people back from using mineral wool is the need to install a frame into which it is installed.

The advantages of mineral wool as sound insulation

- Light weight;

- Affordable price;

- Non-flammability;

- Simple installation (laying);

- Efficiency;

- Additional thermal insulation;

The main disadvantages are the need for a frame and loss of properties after exposure to moisture. Therefore, mineral wool is usually not used in rooms with high humidity (bathrooms, showers, etc.) Although in this case there is a way out - installing a vapor barrier material. How effective it will be depends on the humidity level.

Cork

Another great sound-reflecting material is cork. Usually available in slabs and can be laid on almost any surface. Cork is considered the most effective for protecting against impact noise. It’s not suitable for soundproofing the ceiling, but it’s just right for the floor.

Soundproofing systems ZIPS

This is a modern material for sound insulation. Available in the form of slabs, fastened using a hammer drill and dowel-nails with umbrellas. Installation is very simple and you can easily handle it yourself.

Many manufacturers and experts claim that ZIPS is the best material for sound insulation. The only drawback for many apartment owners is the high cost.

Thermosound insulation

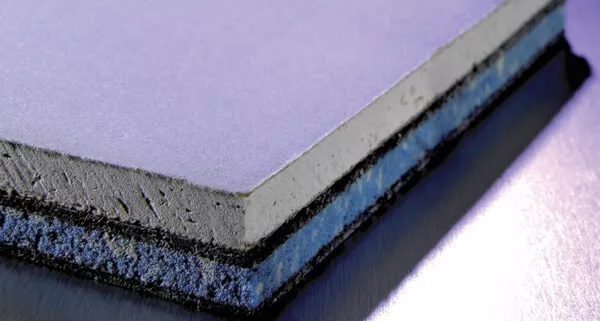

Another modern material that has recently appeared on the market. Has good soundproofing properties. It is made from synthetic components. It is recommended to lay it in several layers, since this material is produced with a thickness of only 5-8 mm, which, as practice shows, is not enough for an apartment.

Special soundproofing panels

Such panels are attached directly to the wall, after which all joints are filled with acoustic sealant. The thickness varies from 4 to 12 cm. The outer surface is suitable for finishing (putty, painting, wallpaper, drywall, etc.)

Soundproofing membranes

Suitable for comprehensive protection of a room from extraneous noise or as an independent material, but with less effect.

Advantages:

- Dense and thin, while providing quite a decent level of noise protection;

- Argonite, which is safe for human health, is mainly used for production.

- Flexible, easy to install at any angle.

Don’t know what material to use to soundproof the walls in your apartment? This is not surprising - in construction stores the choice is simply huge and it can be very difficult to choose a decent option from the whole variety of products. Next, we list the most popular and most effective brands of soundproofing materials.

External thermal and noise insulation of walls

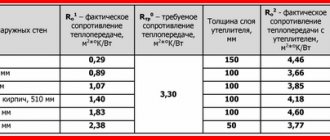

The advice of experts is practically the same - you need to choose this type of insulation (if this is the main task), since it is easier to prevent the cold from penetrating the wall of the room than to deal with the consequences of its freezing. There is a certain algorithm of actions that is applicable to thermal and noise insulation outside the house.

Frame for heat and noise insulation

- The walls must first be prepared. The base must be dry, clean and durable. If we are talking about work that requires a frame or sheathing, before constructing it, you need to take care of the vapor barrier so that the materials are not exposed to moisture. This is especially true for working with cotton thermal and noise insulators, since one of the disadvantages of the latter is precisely the fear of moisture. Under its influence, cotton wool loses its properties, and the work will not bring the desired effect. If you want to work with adhesives, the wall must be thoroughly dried. It is not recommended to carry out such external work in the autumn - spring period, when humidity is high, it is better to choose a summer day during a sunny week, then your walls will dry on their own, naturally, without your help.

- Placement of heat and sound insulator. The material should be secured using the method indicated in the technology above - either by gluing (attaching with a stapler) or by placing it under the frame (formwork). It is customary to cover the insulator with special materials for facade work. This could be slabs, siding, or something else.

If you do not have the opportunity to insulate the walls in your apartment from the outside, you can resort to internal installation. We have already presented insulation and soundproofing technologies in this article.

The best material for soundproofing walls in an apartment: a review of brands

Before you start choosing sound insulation, you need to know about such a parameter as decibels (dB) - this is an indicator of sound level. The permissible level in an apartment building during the day is 40-45 dB, at night (from 7:00 to 23:00) - 25-30 dB.

KRAFT wall panels

They are slabs made of wood fiber. One side is covered with corrugated cardboard, the other with wax paper. Environmentally friendly and efficient material. Mounted by gluing. The front part is subject to finishing (puttying, painting or wallpaper).

Characteristics:

- Noise reduction: up to 23 dB;

- Dimensions: 2700 x 580 mm;

- Weight: 5.5 kg;

- Thickness: 12 mm.

EcoZvukoIzol panels

Made from quartz sand and cardboard (7 layers). Installation is easy to do yourself - the panels are glued to the wall using liquid nails. Environmentally friendly material, safe for health.

- Noise protection: up to 38 dB;

- Weight: 10.5 kg or 18.5 kg;

- Dimensions: 1200 x 450 mm or 1200 x 800 mm;

- Thickness: 13 mm.

ISOTEX – sound and heat insulation panels

Fiber from coniferous trees is used for production. Distinctive features: flexibility, strength, elasticity, simple installation (tongue and groove system), stylish decorative design. Optimally suitable for protection against impact and airborne noise. Easy to cut with a hacksaw or even a construction knife.

- Noise protection level: 23 dB;

- Weight: 1.2 kg;

- Dimensions: 2700 x 580 mm;

- Thickness: 12 mm.

Sound and heat insulating panels ISOPLAAT for walls

Protects the room not only from noise, but also from the penetration of cold. The panels are “set” on liquid nails, the front side is suitable for any type of finishing.

- Noise protection: 23 dB;

- Weight: 4 kg;

- Dimensions: 2700 x 1200 mm;

- Thickness; 10 mm.

Step by step procedure

The instructions for external and internal sound insulation will be similar, but there are some points. Option for internal insulation :

- The walls are cleaned, if there is old covering, it is removed.

- Sockets and switches are dismantled, and sockets from sockets are also covered with a solution.

- Install a sheathing made of wood or metal. The profiles are attached to the wall using self-tapping screws at a distance of 50 cm.

- The frame is filled with soundproofing material.

- The frame is covered with large and even sheets of plasterboard.

At the final stage, finishing is performed. Many people choose drywall because it is smooth and easy to cover with plaster or putty; it is also easy to glue wallpaper to it.

When installing noise insulation on external walls, do not forget about installing waterproofing and windproof film. The entire choice of material must match the material of the walls, otherwise condensation may occur and the walls will begin to become damp.

Watch a video on how to make soundproofing in an apartment with your own hands:

Review of materials for soundproofing floors in an apartment

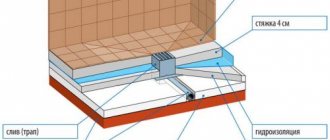

To protect the floor from extraneous noise, roll underlays for parquet, linoleum, laminate, etc. are used. The most effective option is a “floating” floor (a multilayer structure consisting of a main slab, screed and underlay)

Soundproofing

Roll material with excellent noise, heat and waterproofing properties. Provides good protection against impact noise. Used for installing a “floating” floor as a substrate. Recommended for use in schools, kindergartens, hospitals and ordinary apartments.

Schumanet

The optimal option for both noise and vibration insulation of the floor. Distinctive features: simple installation and affordable cost. The base is made of fiberglass and bitumen.

MaxForte-EcoPlate

Available in the form of slabs, designed for soundproofing walls, ceilings and floors. In the latter case, it is laid in a lag structure. It consists of 100% crushed basalt stone without harmful impurities.

Fonostopduo

Membrane material in rolls. Ideal for soundproofing floors from impact noise. Provides a protection level of up to 26 dB. Thickness – 6mm.

What material to choose for soundproofing the ceiling?

For the ceiling, a suspended structure is usually installed, into which soundproofing material is placed. Some panels can be mounted on dowels with large-headed nails (umbrellas) or liquid nails.

Zvukanet Acoustic

Rolled membrane material, suitable for soundproofing walls and ceilings. The front side is prepared for wallpapering.

Characteristics

- Noise protection: up to 21 dB;

- Roll width: 500 mm;

- Roll length: 14 m;

- Thickness: 5 mm.

EcoAcoustic

This is a modern heat and sound insulating material made on the basis of polyester fiber. The composition does not use harmful adhesives. It resembles foam rubber and is suitable for use in a hanging structure.

- Dimensions: 1250 x 600 mm;

- Thickness: 50 mm;

- Colors: green, gray and white.

Tecsound

Roll material for sound insulation. It has excellent characteristics and high density. It has a self-adhesive surface that facilitates the installation process.

- Dimensions: 5000 x 1220 mm;

- Thickness: 3.7 mm;

- Noise protection level: up to 28 dB.

Some useful tips when choosing material for noise and sound insulation.

For a reliable result after soundproofing walls, ceilings or floors, it is necessary to take into account some nuances.

- Whatever manufacturers and sellers promise when offering ultra-thin panels and slabs, effectiveness depends on the thickness of the soundproofing material. A barrier with a thickness of at least 50 mm can absorb sound waves. In such isolation, noise “gets stuck” both on one side and on the other. Of course, you will have to sacrifice room space, but sound insulation will be more effective.

- To soundproof the ceiling, it is better to use basalt mineral wool with a thickness of at least 30 mm and a density of at least 40 kg/m3.

- Before carrying out work, you should make sure that there are no cracks, voids, or joints, and if there are any, seal them with putty. It is also necessary to fill all holes under sockets, switches, distribution boxes with foam or other material.

- If you want to carry out comprehensive sound insulation of your apartment with modern materials, then it is better to contact acoustics specialists who will calculate the required level of noise absorption and the necessary characteristics of the material.

Polystyrene foam or polypropylene foam? Is it worth it?

If sound insulation is not fundamental, and the financial capabilities are not enough for large-scale insulation work, we can offer an option suitable for private houses or apartments where the main concern is external noise (from the street). This is the installation of foam plastic or foam propylene boards. Due to their porosity, they absorb a certain amount of noise, although their performance is significantly lower than that of mineral wool, isolon or cork. Of course, it is possible to carry out interior decoration using these sheets, but some experts are concerned about their toxicity, so we do not recommend taking risks.

Installation of such sheets is very simple - they are glued to special mixtures, secured with so-called fungi, plastered and painted. The density and thickness of the material varies and you can easily choose the right option for yourself.

Whatever your choice of thermal and noise insulation and the location of its placement, I would really like for you to succeed, and for your work to bring you joy and satisfaction.