Technical characteristics of top combustion boilers using solid fuel

Top combustion boilers are produced with different powers from 8 to 95 kW.

Some models can reach 1200 kW. The higher the indicator, the more efficient the unit’s operation and the larger the area that can be heated. Boilers with minimum power are designed for installation in small houses. Ukrainian "Burans" with 40 kW are intended for heating large houses or warehouses. Solid fuel boiler BURAN-EXTRA 1200

Boiler manufacturing materials are cast iron or steel. A cast iron heat exchanger is more durable, but due to its heavy weight it can cause installation difficulties. Steel heat exchangers are made from steel of various qualities, from low-grade to high-quality, resistant to high temperatures. In addition, steel boilers are often protected by fireclay bricks.

Most often, top-burning boilers operate on wood, but there are models in which coal, peat briquettes, shavings and other fuel can be placed.

The boiler efficiency is 85-93%. According to the manufacturers, the operating time of the device after one load of firewood ranges from 8 to 31 hours, and on coals up to 5 days. The average inexpensive boiler produces heat within 5-8 hours.

Water heating temperature is 70 C for wood and 85 C for coal. The recommended inlet temperature is from 60 C. The heating system can be either natural or forced circulation.

How to increase burn time

Many people want to increase the operating time of the heat generator from one load of fuel in order to replenish the supply less often. Two common methods are used: wet firewood and minimal air supply.

Attention: it will not be possible to significantly increase the burning time . Such methods have more disadvantages than advantages.

For the most efficient operation of the unit, boiler manufacturers recommend using firewood with a moisture content of no higher than 20%. Raw fuel reduces boiler efficiency because part of the energy is spent on moisture evaporation. In addition, a lot of soot and resin are formed, all of which settles on the walls, reducing the efficiency of heating water in the heat exchanger. The gas channels narrow and the boiler smokes.

Equipment manufacturers allow the use of fuel with a moisture content of up to 45% or higher, taking into account the possible negative consequences of such use.

A similar result is caused by cutting off the oxygen supply below the normal level. Combustion slows down, the wood smolders, and excess soot is formed, which settles on the walls, reducing the efficiency of heat transfer. Closing the damper on the chimney leads to similar consequences.

Efficient operation of the boiler is possible at 60-90% power. It is possible to increase the burning time, but within small limits. If this is abused, the house will not warm up as well, and fuel costs will be higher.

Manufacturing of a mine pyrolysis boiler

Today, modified PCs are in great demand, with high efficiency, allowing to save a significant amount of fuel and functioning from one filling for more than a day. The simplicity of the design allows the boiler to be manufactured with even little experience in welding.

Drawing of an ordinary pyrolysis boiler

The basis for creating an effective Kholmov boiler with your own hands will be reliable design documentation: drawings, specifications and calculations, which today can be found on the Internet.

Algorithm for creating a boiler with your own hands.

- They make the main part of the device and divide it into two chambers, installing partitions and valves for air supply.

- The diagram of the parts is transferred to a metal sheet and cut out autogenously.

- The side elements are welded using a reinforced seam.

- Between the boiler and the firebox, 2 holes are cut in the partition - at the top and bottom near the grate.

- Install the furnace parts and scald them.

- Place the valve at the top hole and secure it.

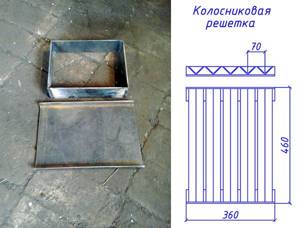

- Grate bars are made with narrow longitudinal slits cut.

- The grate bars are placed on metal corners (cast iron) or welded (steel).

- The doors of the firebox and ash pan are made.

- A boiler made of 25 mm pipes with a water jacket is installed and scalded.

- They set up an afterburning chamber for the smoke-gas mixture by welding a partition next to the grate.

- A hole is made at the bottom to install a 50 mm air pipe with a blind damper at the outlet end and many holes to create a uniform air flow.

- The combustion chamber is insulated with chamotte, and then it is additionally insulated with basalt wool, which increases the thermal efficiency of the boiler unit.

- Next, they install the manufactured equipment, connect the water and smoke gas ducts, install the heating, and then pressurize the system.

DIY mine boiler

There are many drawings of a mine boiler to make it yourself. It is impossible to make a system of the same quality as the manufacturer’s, but a good analogue for home is possible.

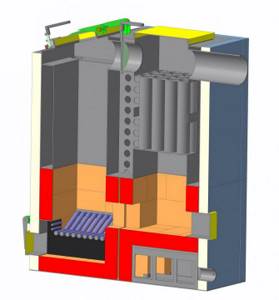

Boiler components for self-assembly:

- Firebox. It takes up half of the entire system. The height of the firebox should be 2 times the width.

- The shaft for loading fuel is located on the side or on top.

- The ash chamber is located under the shaft.

- The grate divides the ash and shaft parts.

- Chambers for heat exchange.

- Chimney.

- Dampers.

- Doors.

To purchase all materials and elements for the heating system, you need to calculate their required quantity.

How to fire a mine boiler with wood

To achieve maximum thermal efficiency, you will need to learn how to properly heat a long-burning wood-burning mine boiler. Only in this case will it be possible to achieve the parameters specified in the technical documentation:

- Autonomous operation for 6-8 hours.

No smoke in the room.

Sufficient heat dissipation.

As practice shows, most consumers find it difficult to switch the usual combustion of wood in a mine boiler to gas generation mode. To do this, perform the following steps:

- Fire wood as usual.

Wait for 15-20 minutes until the boiler reaches operating capacity.

Switch the device to gas generation mode.

If the firewood is selected and stacked correctly, firing the boiler will not cause any inconvenience.

What kind of firewood is best for a shaft-type boiler?

Despite the “omnivorous” nature of the equipment, the efficiency of a mine boiler directly depends on the degree of moisture content of the wood. The operating instructions indicate that the following raw materials, in addition to firewood, can be used for the firebox:

- Briquettes.

Wood waste.

Pellets.

Sawdust and wood chips.

But the main type of fuel for a wood-burning boiler with a shaft firebox remains wood. Even if you plan to use alternative types of fuel, care must be taken to ensure that at least about 40% of the load is well-dried logs. This way, you can ensure maximum heat transfer from the equipment.

Manufacturers recommend heating boilers with any hard wood. It is not recommended to use resinous rocks, as this leads to a reduction in the service life of the boiler.

How to properly stack firewood in a mine boiler

One of the main problems indicating improper stacking is wood hanging in the shaft. The fact is that combustion occurs only at the bottom of the combustion chamber. The firewood falls naturally under its own weight.

Any non-compliance with the recommendations leads to logs getting stuck and, as a result, stopping the combustion process. To prevent this from happening, follow these recommendations:

- The filling is carried out with logs several centimeters smaller than the size of the combustion chamber.

Firewood is stacked across the firebox, not along it.

Dry logs are placed on the bottom; wetter logs can be placed on top.

Detailed instructions regarding fueling and ignition are found in the operating instructions supplied by the manufacturer.

Advantages and disadvantages of shaft-type wood-burning boilers

Hot water boilers with a shaft bunker for firewood have several positive aspects:

- Versatility - boilers can operate on almost any type of solid fuel. It is allowed to use firewood with a relative humidity of 45%.

Performance - models offered by various manufacturers are designed for heating private houses, cottages, industrial and warehouse premises.

Autonomy - non-volatile mine TT boilers with long bottom burning on wood, do not depend on the availability of electricity. In economy mode, one stack of firewood will last from 12 to 24 hours. At maximum load, you will have to add fuel after 6-8 hours.

Simple maintenance - loading fuel and cleaning the chamber, is carried out through different hatches. There is no need to stop the boiler to clean the shaft. The ash is poured into a special box and then removed.

Safety - operation of the boiler does not require the use of complex automation; it occurs in a simple but effective way. The danger of smoke entering the room and carbon monoxide poisoning is almost completely eliminated.

The good technical characteristics of the mine boiler and at the same time the simplicity of the design and internal structure have led to the appearance of many diagrams and drawings indicating how to make a heat generator of this type with your own hands.

It is impossible to completely replicate the quality of factory assembly at home. The result of independent production was an increase in accidents. Safety can only be ensured by heating units manufactured at the factory and having the appropriate certification.

Description of equipment

Long-burning mine boilers are an effective technology that is characterized by the longest possible fuel burning time and unique design features. The presence of a fuel chamber with increased dimensions eliminates the need for frequent loading, and thanks to the special design of the blower, slow combustion is ensured with the release of a large amount of heat.

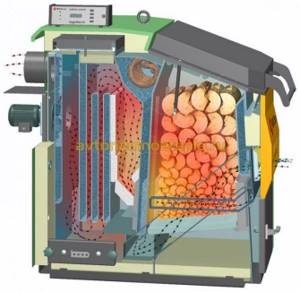

The most widespread today are two designs of mine boilers:

- Pyrolysis.

- With normal combustion.

Both of these designs have two chambers, one of which contains a heat exchanger, and the second is used for burning fuel. The shaft-type boiler with bottom combustion is characterized by a simple design and has a firebox as high as the entire unit, which makes loading significantly easier. The combustion chamber resembles a shaft in appearance, which served as the name for heating equipment of this type.

In this video we will look at a mine boiler:

The heat exchanger chamber is made using classic fire tube technology.

Inside this compartment there are numerous pipes through which a heat exchanger circulates, heated by hot air coming from the firebox. The chimney can be made either in the form of a vertical pipe or a coaxial type, which is discharged through the nearest wall to the street. Read more: DIY chimney.

Mine boilers for long-term bottom burning with wood received a modified design, which made it possible to ensure the longest possible combustion. This boiler is supplemented with the following elements:

- In additional chambers located under the heat exchanger, carbon monoxide is burned, which improves the efficiency of the boiler.

- Pipes with numerous small holes are installed in the pyrolysis chamber, which allows the supply of air necessary for the combustion of carbon monoxide.

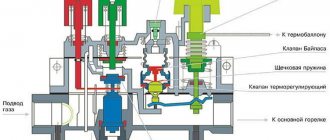

- Directly above the pyrolysis chamber there is a valve, which allows you to reduce and increase the intensity of fuel combustion.

This is interesting: which firewood produces the most heat.

The operating principle of such a pyrolysis mine boiler is based on limiting the flow of air into the combustion chamber. Accordingly, wood burns extremely slowly, which leads to the formation of large amounts of carbon monoxide. This design allows for equipment efficiency of 90%.

How to use the device

Optimal performance of any equipment depends on operating conditions and fuel characteristics. To prevent soot and condensation from forming in the air ducts, the furnace must operate in optimal mode. “Stifled” operation with a lack of air leads to a sharp decrease in efficiency: the boiler consumes a lot of firewood. It burns for a long time, but heats weakly.

Boiler room

The boiler room has the following important parameters:

- Isolation. Smoke from kindling should not enter living spaces. It is optimal if the boiler room is located outside the residential premises, in a separate building or room with access from the street.

- Volume and ease of maintenance. The equipment is installed on the foundation, and there is free space around it for easy access to the piping units, valves, and cleanings.

- Availability of chimney and ventilation. Long-burning solid fuel boilers are prone to increased condensation formation. A brick chimney is not suitable - condensation will penetrate through the masonry. It is worth using stainless steel sleeves and ceramics.

Fuel

Solid fuel boilers will operate in long-burning mode only if appropriate fuel is available. There are no miracles - to obtain a kilowatt of energy you need to burn a certain amount of energy. The amount of fuel is calculated simply: you need to know the calorific value and multiply it by the efficiency of the boiler.

Firewood. Only dry wood should be used, preferably hardwood. The preparation costs will be repaid by trouble-free heating operation.

Pellets. The manufacturer supplies ready-made high-calorie and technologically advanced fuel. Pellets are free-flowing, but do not leave debris. They were invented to facilitate the transportation of industrial waste. Pellet fireboxes are easy to automate; with large bunkers, the boiler can burn for months without human intervention!

Sawdust, wood chips. The use of wood waste has 2 problems: moisture and debris. Sawdust has a fairly low density, therefore, low calorific value.

This pays off with the low cost of fuel; many enterprises give it away for free or for next to nothing.

Loose plant residues: straw, cake, husks. A new word in alternative energy is the use of renewable fuel. Residues from production, straw, sunflower stalks and other local fuels were previously disposed of as garbage. The use of such fuel pays off due to its low cost, but it is worth using if there is a constant opportunity to purchase a new batch.

Difficulties in storing and transporting bulk fuel are solved using containers, big bags, and packaging in paper bags.

Attention! You cannot store such fuel in a large pile! Moisture condenses, the fuel begins to rot, overheats, and there is a risk of spontaneous combustion. It is more convenient to store in bags placed on shelves for air access

It is more convenient to store in bags placed on shelves for air access.

Rules for safe use

- Chimney installation. It is where the chimney passes through the ceilings that fires begin. Good thermal insulation of the chimney and compliance with operating rules will protect against fire.

- Periodic cleaning of soot from the heat exchanger and chimney. Uncleaned chimneys can cause soot to catch fire. The combustion temperature of soot is above 1000 °C, and a huge number of sparks fly from the chimney. Dangerous! There is a huge risk of fire!

- Do not leave open flames unattended. Do not entrust heating to children or people with mental disabilities.

- Long-burning boilers are technological devices. Read the instructions carefully and follow the manufacturer's recommendations.

Advantages and disadvantages

Main advantages compared to other types of boilers:

- Ability to burn fuel of any quality. In addition to firewood, wood briquettes, pellets, and wood processing waste are used.

- Efficiency reaching 85%.

- Ability to adjust power.

- Long-term operation without supplying additional fuel.

- Convenient design with separate hatches for loading firewood and removing ash.

- Operational safety. The possibility of carbon monoxide entering the room is zero.

Disadvantages include increased soot formation and tar deposition on the walls. Periodic cleaning is required to maintain optimal heat output. In addition, the large size and weight of the equipment complicate installation.

Advantages and disadvantages of homemade boilers

Do-it-yourself, long-burning wood-burning boilers are becoming increasingly popular, the reason for this being the obvious advantages of such units:

- The duration of operation from one filling of the firebox with wood is 2 times longer than that of traditional boilers, and from 1 loading of coal – 3 times.

- The simplicity of the design allows you to make a boiler installation yourself, which will be much cheaper than a factory-made analogue.

- Possibility of design improvement. For example, the “trendsetter” in this direction, the STROPUVA brand, indicates in its technical specifications an operating pressure of 1.6 Bar. This is a low indicator; by strengthening the design, you can make your own solid fuel boiler with a working pressure of up to 3 Bar.

- Undemanding to the type of fuel. You can put firewood, coal, sawdust and other combustible waste into the combustion chamber. The main thing is to provide air access to it. There are also no special requirements for wood moisture content.

Craftsmen have somewhat simplified the design so that homemade long-burning boilers using coal or wood can be made at home. The change concerns the way air is supplied to the firebox. The folding telescopic structure is quite difficult to manufacture and requires additional costs.

Instead, they install a steel pipe, the length of which is 300-500 mm greater than the height of the firebox, welding a “pancake” and air diffusers at the end. The other end simply sticks out of the boiler lid; an air damper is made on it to regulate the air supply, which is turned manually. A fan is not used for injection; combustion occurs due to natural draft. Changes in the design can be traced by studying the drawings of solid fuel boilers made by yourself.

The disadvantages of homemade long-burning boilers largely replicate the shortcomings in the design of factory units. But there are ways to fix them:

Difficulties in manufacturing a cylindrical body. Without a rolling machine or at least a pipe bender, it is very difficult to make a round body from sheet metal. As an option, craftsmen use propane cylinders or pipes of the appropriate diameter for heating. This will add weight to the structure, since standard large-diameter pipes have a wall thickness of 5 mm or more. To make a water jacket, it is better to use thin-walled pipes.

Factory long-burning boilers are difficult to ignite when the combustion chamber is loaded to a quarter. Long-term operation of the unit is not always required; sometimes you need to heat the house a little. The boiler body is round and high; it is very difficult to fill the firebox a quarter of the way through the loading door and light it up. In homemade units, you can provide an additional door in the middle, not forgetting about its high-quality sealing.

Due to the design features, it is not recommended to load long-burning wood or coal boilers with fuel “on the go”; you must wait until the previous portion is completely burned. If you lift a load during operation and open the door to load firewood, smoke will pour out of it directly into the room. You will have to throw wood quickly and somehow, this is unacceptable. The deficiency can be treated by installing a heat accumulator, which experts recommend including in the piping of any solid fuel boiler.

In the upper position, the air supply pipe of a homemade boiler will stick out to a height equal to the height of the firebox. This should be taken into account when choosing a location for the water heating installation.

We make honest boilers!

Our boiler is 6 kW, shaft 110 liters

Boiler 30 kW, shaft 140 liters. You can look at the “bedside tables” in any store.

Boiler 20 kW, shaft 140 liters, weight 350 kg, water circuit 135 l.

Delivery

Delivery is possible by a transport company of your choice. Delivery can be calculated on the ZhelDora website, average weight 350 kg volume 1 m3, from Tver. For example, delivery to Irkutsk costs 9,500 rubles. To Vladivostok 12,000 rubles. You can buy a solid fuel (fuel) heating boiler with delivery throughout Russia. Mine boilers are already operating in: Yaroslavl, Moscow, Kashin, Kaluga, Tver, Arkhangelsk region, Kirov region, Nizhny Novgorod, Naberezhnye Chelny, St. Petersburg, Velikiye Luki, Vladivostok.

What is a mine boiler and who invented it.

A shaft-type boiler is primarily a HT boiler with two shafts, one with fuel, and the other shaft with a heat exchanger. In the first, the firewood sags under its own weight, falling into the lower burning zone; the released heat enters the second chamber, where it is partially transferred to the walls of the boiler (water circuit), and then into the pipe.

Many people want to buy Kholmov’s mine boiler, mistakenly considering him to be the inventor, but work in this direction was carried out by a Russian scientist in the field of heat engineering, Professor Kirsh K.V., back in 1907. He created many scientific works on steam boilers, boiler installations, and the use of various types of solid fuel.

Unfortunately, the Russian plant prefers to produce a solid fuel boiler of the “iron box” type, so it is almost impossible to buy a good boiler in a store. In most cases, we are simply deceived: long-lasting, pyrolysis, 2-fold savings, heat-resistant steel, etc. Read forums and reviews to buy a TT boiler that meets the declared characteristics. Very often the price for the same “box” can differ up to two times.

How to heat so that coal burns as long as possible

The correct firing of a long-lasting coal boiler largely depends on the presence of control automation and, of course, the quality of the coal itself.

What coal is better to use

Manually operated boilers can operate on coal of any fraction. But it must be taken into account that the temperature of the gases in the chimney during long-term combustion is much lower than during direct combustion: the use of raw fuel can lead to the accumulation of excess moisture in the pipe and the formation of condensation - a black viscous liquid with a tar smell. Therefore, the relative humidity of coal (like any other solid fuel) should be no more than 15–20%.

Correct firebox

The combustion of a long-burning boiler is carried out according to the following scheme:

- Fuel loading - the distributor is raised to its original position so that it is just above the loading door, and all the coal is immediately poured.

- Kindling - dry wood chips and paper are placed on top of the coal, after which they are ignited and burn with the top door open and the air duct closed.

- Combustion - when the temperature in the heat exchanger reaches 50-60 °C, the door closes tightly, then the telescopic air duct regulator opens.

- Temperature adjustment - the boiler automatically enters the optimal mode, but if necessary, the temperature is adjusted by the air duct damper.

Upon completion of the full combustion cycle, it is necessary to remove sintered pieces of coal from the loading chamber, clean the ash pan and fill in a new batch of fuel.

How to make a mine boiler at home

There are many drawings of long-burning units for self-production.

It is impossible to completely replicate an industrial design, but many craftsmen manage to create an analogue.

To assemble a Kholmov boiler at home, you will need to make:

- firebox;

- loading shaft;

- ash chamber;

- grate;

- heat exchange compartment;

- doors;

- dampers;

- chimney.

The most important thing is to make the heat exchanger correctly. If you place it too low, the boiler will instantly boil, which will lead to unpredictable consequences.

Manufacturing instructions

When starting the production process, you need to start by preparing all the essentials:

- Pipes with the following diameters - 30 cm, 5-6 cm, 10 cm (the wall thickness of each is at least 3 mm)

- Steel sheet with a thickness of more than 4 mm

- Bulgarian

- Welding machine

- Hand tools

It is recommended to place the boiler on a level, hard surface. If such an installation will be installed at home in a boiler room, you should think about arranging the foundation, a few words about which will be said later.

Let's start making the boiler:

- Take a pipe suitable for its characteristics and cut off a piece from 70 to 100 cm. A short length will not allow you to load a sufficient amount of firewood, a large length will make loading extremely inconvenient

- Now you need to build a distributor. In order for it to move freely, its diameter is made 15-25 mm smaller than the main pipe

In the center of the circle you need to drill a hole with a diameter of 15 mm - air will flow through it into the combustion chamber. To ensure that the disk does not fit tightly to the panels and there is space for air circulation, it is necessary to weld an impeller to its inner side - several plates up to 5 cm high

A pipe with a diameter of 5-6 cm is welded in the center of the regulator, while its height is made 10-15 cm larger than the boiler. As mentioned earlier, it is recommended to make a damper at the top, which will allow you to adjust the draft at any time, thereby controlling the smoldering process. A door is cut out at the bottom with a grinder, through which ash will be removed

Also, the bottom is securely welded at the bottom of the boiler. At the top it is necessary to run a horizontal chimney pipe with a diameter of 8-10 cm and a length of no more than 40 cm (this is what is passed inside the heat exchanger)

The finishing touch of the design is the boiler lid, in which a hole is cut for the air intake pipe. It should lock the camera as tightly as possible

A good alternative to firewood is heating briquettes - see our review

Chimney and reflector

The walls of the boiler will constantly heat up and radiate thermal energy. If the installation is installed to heat a small room, reflectors should be placed around it - they will distribute the flow, increasing the heat flow inside.

If the oven will be located in a room where people are constantly present, you should think about their safety. One solution to the problem is to cover the structure with brickwork.

The chimney can be made from a 20 mm pipe. The horizontal straight section should be 5-10 cm larger than the diameter of the combustion chamber. It is necessary to take it outside with a minimum number of bends - 2 x 45 degrees.

A few other features:

- It is recommended to make the chimney collapsible so that it can be easily cleaned of soot 2-3 times a season

- The chimney sections must be connected in the direction opposite to the gas movement

- All structures and objects that are easily flammable must be kept at a safe distance

We are building the foundation

It can be assumed that a long-burning wood-burning stove will constantly heat up to high temperatures. A simple leveled floor is not the best solution for it - a foundation should be built.

The base can be made of burnt brick or rubble. They do not heat up when exposed to elevated temperatures. All those who want to make a more solid foundation can pour a solid monolithic slab.

The boiler can also be installed on legs, which can be easily welded from channel wood. They hide from view behind brickwork.

Using the boiler

Unlike a classic stove, air must enter a long-burning wood-burning boiler in a certain quantity. To achieve this, the filling must be done in full, trying not to leave any free cavities. It is recommended to add sawdust, pellets, peat or combustible waste to the logs.

Fuel must be added according to the following instructions:

- Remove the cap and remove the regulator from the tank

- Pack the fuel tightly

- Spray flammable liquid on top

- Install the regulator, cover with the lid and open the damper

- Throw a splinter into the air pipe and when it starts to smolder, close the damper

Let's sum it up

A simple long-burning wood-burning boiler is ready. You can install such a structure in any unheated room: from a small garage to a workshop. If everything was done correctly, there will be no doubt about the efficiency and high efficiency.

Step-by-step instructions for making a wood-fired mine boiler

They start by studying the drawing, after which they transfer the dimensions of the parts onto sheet metal. The elements are cut out and the body is welded.

Next, proceed to the manufacture and installation of internal parts:

- A partition is cut to size for installation between the boiler chambers. Holes are made in it: on top and slightly above the grate.

- The part is installed inside the body and welded.

- On the firebox side, a valve is installed on the upper hole of the partition. The chimney pipe is installed on the reverse side.

- Steel grates are welded: cast iron ones quickly deform. You can make them yourself from sheet metal or buy them.

- A hole for the ash pan is cut out in the lower part of the firebox. A similar operation is performed in the wall of the heat exchanger chamber.

- Necks are welded to the holes made, protruding outward by 6 cm and inward by 3 cm.

- Prepare the base for the water jacket: corners are welded horizontally from the inside of the second compartment. The distance to the top should be 4 cm, the bottom row should be located level with the bottom of the afterburning chamber.

- A water jacket and a pipe heat exchanger are installed. The finished part is inserted inside and scalded.

- In the afterburning chamber, the bottom is welded at the same level as the grate. At the internal partition, a third of the part is located horizontally, then it rises according to the drawing.

- A hole is cut above the bottom for the air pipe. They make a lot of holes in it and weld it into the body. The pipe extends 60 mm outwards, and there are no holes in this section.

To make it more convenient to install the heat exchanger, the side of the housing on the side of this chamber is welded after installing the water jacket.

The inside of the boiler chambers is lined with fireclay bricks. For the passage of gases, holes are left opposite those made in the metal.

Features of installing roller blinds

When installing roller blinds, there is no need to drill mounting holes, which undoubtedly simplifies the entire process of hanging the equipment. There are two types of fastenings for roller window systems:

- Fastening with hooks that simply cling to the top of the sash.

- Fastening equipment with double-sided construction tape.

Detailed recommendations for installing curtains with step-by-step instructions are included with each purchased product. By following the instructions for assembling curtains offered by the manufacturer, you can easily and quickly complete the work yourself.

When installing roller blinds, be sure to use a building level; this will protect against distortions and help secure the curtains as accurately as possible.

Principle of operation

Increasing the duration of the combustion process is achieved not only by a large firebox. The organization of furnace combustion in the form of layered combustion with upper combustion and upper supply of blast air has a significant impact on efficiency and heat transfer, so gas-air flows do not circulate at all in the lower fuel layers.

Operating principle of a boiler unit with long-term combustion of solid fuel: The air required for fuel combustion is taken directly from the combustion chamber and passes through a preheating stage in the upper heating chamber of top-combustion boilers.

A pipe air distributor is built into the heating chamber to supply hot air to the combustion device. The feeding system can be gravitational or forced.

The air distributor is equipped with channels directed vertically. Before loading fuel, it is raised using a built-in mechanism, then fuel is poured in and the distributor, which rests on the upper fuel level, is lowered. As it burns out, it falls down the combustion space. This movement of the distributor provides air supply to the top layer of hot fuel.

Here, flammable substances burn out completely, transferring heat through the walls of the firebox to the heating fluid circulating in the built-in heat exchanger. Flue gases are discharged through the gas outlet pipe into the chimney. The ash is collected in the ash box located at the bottom of the boiler unit, under the firebox. The volume of the box allows it to be cleaned at intervals of 2 to 5 loads.

Heating unit

The first step in making a mine boiler is to assemble the firebox body. It is made from metal parts, the thickness of which is 4 mm. They need to be secured by welding. It’s worth starting from the bottom, where the side parts, the vault cover, and the holes for the doors will be attached. It should look approximately the same as in the photo:

Welding of walls

You need to follow the drawing. The sheet on the bottom should be released in each direction. It will also serve as the bottom part of the ash compartment doors. It will be necessary to secure the shelves in the chamber by welding. The materials indicated the corners. There will be a grate there. After welding, it is important to check each compartment for leaks, thoroughly welding all joints.

Welding of walls

Next you need to insert the water coat. Material – 3 mm metal. The thickness of the side walls should be 2 cm, so a steel strip extending 20 mm is welded to the firebox. You need to attach sheets of steel to the walls - sheathing.

Tank walls

It is important to consider that the water coat should originate at the level of the grate. It should not wash the ash compartment.

Next, as you can see in the photo, you need to install the clips in a checkerboard pattern. It should be butt welded to the firebox at one end, and welded around the hole at the other.

From the photo you can determine where to place the bottom of the water coat.

Next, pipes are installed through which the heat will escape. They are placed in the upper part of the mine boiler tank. As shown in the drawing, holes need to be cut in the back and front where these pipes will be placed. Their ends must be thoroughly scalded, as well as the other joints of the water coat.

These pipes should diverge in the shape of a fan

The next stage is the installation of doors and grate. You need to weld a strip in 2 rows to the door on the inside. An asbestos cord is inserted between the parts, which will become the seal of the vestibule. The outer corner of the grate must be welded down. This will disperse the air that is blown into the ash compartment by a fan.

Grate

After completing all the activities, you need to cut the fittings into the walls of the mine boiler. Pipelines will be connected to them: supply and return. The air duct should enter the ash compartment near the middle of the back wall. It is located immediately under the water coat.

Pipeline installation

Afterwards, you need to weld the door hinges and embedded parts that will help install the decorative trim.

Loops

The long-burning boiler tank must be lined with insulation on each side. You can secure it with a cord. There is little left to do: screw neat metal sheets to the parts and install the door.

No need to use glass wool or other materials. Basalt insulation does its job well.

You need to attach a fan to the duct flange and install the purchased control unit. The temperature sensor should be located under the basalt insulation near the rear of the unit. You can install additional units in the boiler, otherwise called “bragman”, which will be useful:

- You can install an additional water tank where the water will be heated.

- When the power is turned off, you can install an immersion thermometer sleeve.

- Install a heating element that can heat the water after the wood has completely burned.

The legs for the unit are welded at any stage of work. For this purpose, suitable metal pieces are used. Below are diagrams of a mine boiler.

Top 5 best models

In the trading network today you can find both relatively inexpensive and simple domestic boiler units, as well as fully functional automatic boilers from Western manufacturers of popular companies: Stropuva - a Lithuanian manufacturer, Buderus - a German boiler brand, WATTEK - a Czech boiler ACV - a Belgian manufacturer of boiler equipment and the Austrian brand Wirbel.

The most popular manufacturers of Russian companies producing long-burning boiler units are Magnum, Novosibirsk Metalworking Company, ZOTA, produced by the Krasnoyarskenergokomplekt company and Teplov Universal of the Kostroma plant.

Stropuva S 15 U

A small Lithuanian boiler with a thermal power of 15.0 kW, capable of heating a house up to 150 m2, is the best unit for heating small private houses. The S 15 U brand is versatile and can operate on any solid fuel.

The best characteristics of the boiler are ensured when using coal; when it is loaded into the combustion chamber of 217 liters, the boiler is capable of operating for 7 days with an efficiency of 86 to 90%, producing a coolant with a temperature of 75 C.

When working with firewood, you should use only dry wood to prevent the formation of tar on the walls of the firebox. The boiler has a mass of 205 kg and a service life of more than 10 years.

Price: 91,500 rub.

Liepsnele L20-U

Lithuanian boiler unit, with a more powerful unit of 20.0 kW, an analogue of Stropuva, with more advanced characteristics and therefore expensive equipment for the unit. It has the most voluminous firebox - 320 liters, and an efficiency almost equal to a gas boiler - up to 91%. The cast iron heat exchanger ensures a service life of up to 25 years.

Fuel versatility allows the use of any solid fuel, but the longest period of operation at 1 filling station, up to 7 days, is provided by coal. The maximum temperature of water leaving the boiler is 80 C.

The low working pressure of the hot medium, 1.5 atm, allows its use only in heating systems with natural coolant movement.

Price: 110,000 rub.

Galmet Top

Polish top combustion pyrolysis boiler with a thermal power of 20 kW, for heating a house with an area of 160-200 m2. This is a very modern universal modification with a 100% level of automation, a smart PID controller, an electric blower fan and weather-dependent automation.

The outlet temperature of the coolant is 55-80 C. The distinctive ability to control two heating circuits: warm floor + hot water, and also has a built-in recirculation pump.

Despite very high-quality thermal insulation, the manufacturer was unable to achieve high efficiency of the boiler; it does not exceed 87% for coal fuel. The heat exchanger is made of steel, so the service life is also not long - 15 years.

Price: 89,000 rub.

Week KO-60

A very popular model in Russia and the CIS countries with a name that is responsible for a week’s work from one load, while the chamber volume does not exceed 160 liters. The power is very high for such dimensions: peak 60 kW, and in long-burning mode 25 kW, controlled automatically and can heat an area of up to 350 m2.

The highest efficiency - 92% is achieved when using high-quality coal. This is also facilitated by the working control panel for the thermal processes of the Prond Proton 405.01 boiler and the WPA X2 blower fan to create pressurization of the boiler.

The heat exchanger and body of the unit are made of very thick combustion steel, which increases service life, although it leads to an increased weight of 420 kg.

Price: 130,000 rub.

Station wagon TA-40

Bottom combustion water heating boiler with top loading Teplov Universal 40 kW from the Kostroma plant has the ability to heat any residential and industrial premises up to 400 m2 with simultaneous preparation of hot water supply. The fuel boiler is universal, capable of operating on any solid fuel.

Automated or non-volatile unit layouts are available for sale. The efficiency of the boiler is not higher than 82% in manual mode; when using automation it exceeds 85%.

The boiler software is capable of maintaining the temperature in the house throughout the day, as well as distributing power according to the “heating - hot water” priorities in 4 modes. Price: 103,500 rub.