Pipeline clamps are a modern solution that allows not only to eliminate a defect, such as a crack, but also to further strengthen the damaged area. In addition to eliminating various damages, the clamp can be put on the site of a remote tap, as well as tighten a completely burst section of the pipeline. In this article we will talk in detail about all types of clamps, as well as how to install them.

Where are clamps used?

Pipe clamps are used strictly on horizontal or vertical sections of the pipeline, because it is impossible to install a clamp on bends, as well as on various connections, for example, on tees. For example, many people do not know what to do if a heating pipe is leaking and how to stop the leak. It is for such cases that clamps are intended.

Speaking about the material of the pipes, we cannot highlight any restrictions, because the clamp can be put on both cast iron and copper pipes. You can also easily purchase clamps for various polymer pipes, be it polypropylene or polyethylene. Speaking about rarer pipes, it is worth highlighting asbestos-cement water pipes, which also use clamps.

Clamps are one of the best solutions to many pipe defects:

- Repairing cracks in the pipeline. You will be able to cover both short and fairly long defects;

- Pipe fractures are a fairly rare but emerging problem in pipelines. Using a clamp with fastening, you can not only bridge the problem that has arisen, but also secure the fracture to the wall to minimize the chance of a leak;

- Repair clamps for water pipes will also help remove fistulas on pipes (pro

Installation and fastening methods

The described cuffs can be used for repairing vertically and horizontally located pipes. On curved sections, the use of such repair equipment is undesirable. The installation process is extremely simple. Installing a clamp on a water pipe is carried out in two stages:

- The base of the bandage is put on the pipe in such a way that the lock that will secure it is on the opposite side from the damaged area.

- The nuts are tightened until the cuff being used is completely adjacent to the base body.

The quality of repair work depends on several criteria: what material the clamp is made of, what strength it has. The contact area of the repair cuff is also of great importance. The larger the pipe defect, the higher the indicated indicator should be.

Reliable manufacturers of pipe repair clamps

In a plumbing store you will probably find a wide selection of clamps, which will differ not only in purpose, but also in the manufacturer.

As a rule, experts identify the following manufacturers:

- Polish company Domex;

- Dutch company Romacon;

- Chinese company IDRA;

- German products often stand out for their quality, so it is also worth paying attention to Melcher and Frenzen Armaturen, two German companies.

Many Russian consumers are interested in goods from a domestic manufacturer, so we’ll talk about them separately. There are enough domestic manufacturing companies, but not every one of them can boast of the quality of their products.

Among the worthy domestic manufacturers, it is worth highlighting Ekkovod, a company that produces excellent products at a low price.

Types of clamps

We said above that clamps can be used for various purposes, so now it is necessary to clarify the specific types of clamps and their purpose:

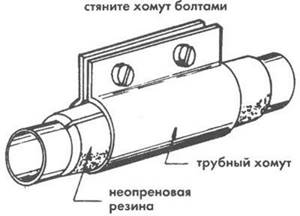

- The double-sided repair clamp is one of the most common models, the focus of which is quite wide. This clamp consists of two halves, which are secured around the pipe with bolts. When choosing such a clamp, do not forget to check the diameter of your pipe;

- The one-sided clamp is U-shaped . Such clamps are only suitable for pipes with a small diameter (up to 5 cm). Fastening is also done with bolts, usually from the top of the pipe;

- A fastening clamp for a pipe against leakage allows you not only to get rid of a defect in the pipe, but also to secure it to the wall. Outwardly, it is similar to the two previous options, but has a distinctive method of fastening: first, the lower part is attached to the wall, then a pipe is inserted into it, after which the upper and lower parts of the clamp are securely tightened with bolts;

- Clamps for large diameter pipes have more than two components. Each part is superimposed on the pipe and attached to the adjacent component with a threaded pair.

How to install a clamp on a pipe

There are two options for attaching pipes to the load-bearing surface:

- Hard. Provides a tight fit and maximum tightening of the clamp on the pipe, preventing its movement.

- Floating. The outlet is clamped by partially tightening the bolts or simply snapping the plastic fastener. In this case, some space is left for the outlet to shift during thermal deformation.

Fixed supports are installed in heated rooms, where there is no significant temperature difference and linear deformation of the channels is not observed.

In unheated buildings, temperature differences can reach up to 50 °C. Changes in tap sizes will be inevitable. Here we need a floating method combined with the installation of fixed fasteners.

General rules for the location of fasteners

To ensure reliable fastening of the entire system, it is important to establish the correct distance between the fastening points. Its size is recommended by the manufacturer in the technical documentation

When positioned horizontally, polymer pipes with a diameter of up to 20 mm are fastened every 500 mm, bends with a diameter over 20 mm - 75 cm. In a vertical position - 1.0 and 1.2 m, respectively. Such a small pitch for narrow pipes is explained by their possible sagging.

Required Tools

The minimum set of tools will be useful:

- Screwdriver.

- Drill driver and drill bits.

- Ruler, construction pencil.

Technology for fixing pipes using clamps

Sequence of actions for installing holders:

- Marking future attachment points.

- Holes for dowels (studs) are drilled at the designated locations.

- Plastic clamps or clamps are installed.

- The pipes are inserted into the fasteners. Tighten the clamps and snap the clips.

Fastening water pipes

Internal water supply lines are installed using plastic holders. They act as movable supports and ensure the mobility of hot pipes during their linear expansion. They provide PVC clamps with a slightly larger diameter than the diameter of the pipes.

When calculating the distance between attachment points, you must adhere to the prescribed standards.

Bends with a diameter of 16 mm for horizontal laying for cold water are fastened in increments of 0.8 m, vertical - 1.2 m. For hot water supply, the fastening increment will be 0.5 m and 0.9 m, respectively.

With each subsequent increase in diameter within the range of standard sizes established by GOST, the fastening pitch increases by 100 mm for horizontally located pipes, by 50 mm for vertical ones.

In addition, it is recommended to install fasteners 5 cm from the installation sites of fittings, fittings and the intersection of bends.

Fastening sewer pipes

The installation of sewer lines is carried out with a mandatory slope of 0.2 m per one meter towards the drain.

Installation is carried out from the lower support of the riser, at which the fixed element is attached. Subsequently, the fastenings are made in such a way that all segments of the system are in the same plane and alignment.

Clamps are attached near branches and at connecting points. The fastening spacing is at least 10 pipe sections.

To create an indentation from the wall, brackets are used.

DIY clamp

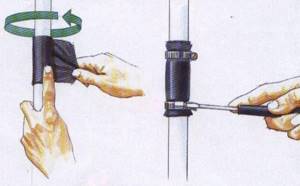

If you don’t have the opportunity to go to the store, and the plumbing requires urgent repairs, then you can fix the problem yourself:

- Find around the house some adhesive tape or electrical tape, wire and a rubber band that can be cut from a bicycle inner tube;

- Apply a tourniquet to the damaged section of the pipe;

- Tighten the harness by wrapping it with wire. When making the winding, pay special attention to the edges of the clamp;

- Wrap the resulting structure with tape or tape. Next, the result can be painted over.

Main stages of installation

After selecting and purchasing the desired clamp, its installation is carried out in the following sequence:

- Before starting installation, you should unscrew the fastening element of the clamp. The ends of the product are spread to the desired width so that it can be easily placed on the pipe.

- Next, you need to be careful and make sure that the rubber layer is located directly above the damaged area and completely covers it. It is desirable that the edges of the gasket extend 3 cm beyond the damaged area.

- Then the product is secured. Fasteners are inserted into the holes located along the edges. The resulting structure is tightly tightened with nuts. If the pipe continues to leak, then it is worth tightening the clamp even more until the damaged area is reliably plugged.

When choosing a clamp for pipe repair, you first need to pay attention to the nature of the damage. These products have a wide enough range to choose the necessary device for repairing pipes for any purpose. When installing a clamp with your own hands, you need to strictly follow the necessary rules and then this product will help to effectively solve the problem that has arisen.

Advantages and disadvantages of using clamps

First, it is necessary to highlight the main disadvantages, or rather, limitations of such clamps:

- The clamp can only be used on straight sections of the pipeline, so such repairs will not help on a pipe bend;

- You will not be able to repair a pipeline with a diameter of 35 cm or more with a clamp;

- Only a hole of up to 10 mm between the ends can be sealed, and the deviation of their axes should not exceed 3°;

- The clamp on a metal pipe should be 15-20 cm wider than the hole being sealed. If the clamp is put on a plastic pipe, then the margin should be from 20 to 30 cm;

- The damage should not exceed 60% of the pipe body covered by the clamp.

Limitations on the use of clamps

The water supply repair coupling is installed on the sewer connections:

- only on straight sections of the highway;

- outer diameter should not exceed 35 cm;

- the line gap should not exceed 10 mm;

- axial deviations no more than 3 degrees;

- if more than 60% of the total area covered by the clamp is damaged, the area is cut out and a new one is inserted.

If you follow the rules for installation and subsequent operation of the water supply system, high-quality clamps will last at least 5 years and do not require repairs.

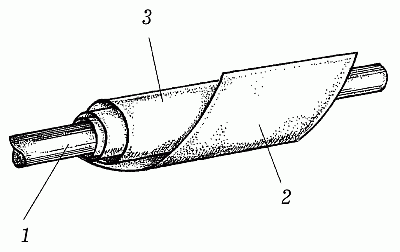

What is a bandage

A bandage or repair clamp is a device designed for repairing pipelines, has a rubber seal and is fixed to the surface using tightening screws. It consists of two connecting parts (strong, thick metal) or a solid metal plate (thin sheet steel) that is pushed onto the repaired area by expansion.

The products are produced in different diameters to fit standard pipe dimensions in inches; to join the parts, screws for a flat-head screwdriver, a Phillips screwdriver, or a hex wrench are used.

The main material for the manufacture of sliding devices is galvanized steel, grade 304 stainless steel, two-component types are made of duralumin, cast iron or similar alloys.

Depending on the design and purpose, bandages come in the following types:

- Double sided. They consist of parts connected with bolts and are available in different diameters depending on the product being repaired. One of the varieties is a two-part design with a threaded outlet for a tee connection.

- U-shaped. They are a metal bracket with holes along the edges into which a tightening fixing bolt with a nut is inserted.

- Clamp. The device consists of a round steel plate with slots along its entire length and an adjusting screw. This design allows you to change the diameter of the clamp within a wide range.

- Mounting clamp. Has a welded screw, designed for mounting pipes on various surfaces.

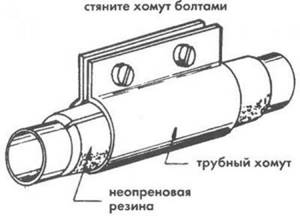

Rice. 2 Bandage for pipelines

How to get rid of a leak in a pipe

If a fistula is detected in the pipeline, it is necessary to immediately begin to prevent the leak. To do this, we suggest using one of the options:

- Installation of the clamp.

- Application of a bandage connection.

- Use of cold welding agent.

Installation of clamp connection

The most common method of repairing cracks in a pipe is a clamp connection. The specialized device consists of the following connecting elements:

- Iron plate.

- The sealant (rubber) is placed inside the plate.

- Bolts to connect the structure together.

To install the clamp yourself, follow these steps:

- Thoroughly clean the required pipe section from rusty coating and dust deposits.

- Wrap the surface of the pipeline with a clamp.

- Fix the device securely with bolts.

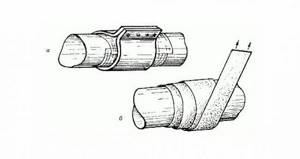

Application of a bandage element

If you don’t have a clamp at hand, in this case, leaks on the pipe surface can be eliminated by using a bandage. It comes in several types: rubber, glue or cement.

Rubber bandage

- Rubber material. A small section from a bicycle inner tube will do. A medical tourniquet is also suitable to stop bleeding. This piece is used to wrap the crack in the pipe.

- Small clamps for screeds. Additional accessories: wire, straps for fixation so that rubber can be attached to the surface.

Adhesive bandage

- Use a solvent to thoroughly clean the area of the pipe leak where the bandage will be applied. There should be no dirt or dust.

- Prepare pieces of gauze, bandage or material with glass inserts. Then soak them generously in a special adhesive solution.

- Wrap the surface of the pipe with material at the crack site. Make several layers. Secure with wire.

- Allow time for the adhesive to dry completely.

Cement bandage

The steps are similar to those with glue. Prepare a semi-liquid composition from cement in an equivalence of 1:10. Soak fiberglass or a piece of gauze in it and wrap it around the pipe.

On a note! If you don’t have special glue at home, you can replace it with epoxy resin. If there is a crack in an iron pipe, then you can use the most common table salt.

Cold welding

This technique can be classified as a new technology. After all, to eliminate a leak, all you need to do is apply a special compound to the crack site - cold welding. It is suitable for repairing pipes made of metal, plastic, metal-plastic. The compositions of cold welding are also different.

Below we will consider a general analogue of using the mixture. The same instructions are printed on the bottle itself.

- Before applying the composition to the required section of the pipe, it should be thoroughly cleaned of dirt deposits. If the pipeline is made of metal, then an additional agent is applied to remove rust and paint layers.

- The mixture is applied to the prepared section of the pipe. If the adhesive weld has a liquid form, you can use a brush to make it easier to apply. If cold welding is in the form of plasticine, then before use it is kneaded so that the structure becomes soft and homogeneous.

- Welding is distributed evenly along the entire length of the crack. In this case, it is necessary to go beyond its edges by 3-4 cm.

- For cold welding to fully set, it will take an average of 2.5-3 hours.

Application of bandages

Repair clamps are used in the following conditions:

- The devices are used in the repair of copper, steel, cast iron, asbestos-cement, ceramic, and various types of plastic pipelines in heating, water supply and sewerage systems.

- Repair bandage devices are installed only on vertical and horizontal sections of pipelines.

- The outer diameter of the pipes on which the bandage is used must correspond to its internal dimensions and in no case be less than its internal diameter.

- A clamp whose width corresponds to the outer pipe diameter should be used for pipe sizes of approximately 350 mm. The length of the clamp is selected to be 150 mm longer than the defect, and for large pipeline sizes – by 200 mm. wider than the damaged area.

- If it is necessary to repair a broken water pipe or join two of its parts, the distance between the sections should not exceed 10 mm, and the deviation angle should not exceed 2 - 3 degrees.

- The use of a bandage is ineffective if the damage size is more than 60% of its working area.

- When repairing a water or sewer PVC pipe, the width of the working part of the work should be one and a half times the size of the defect.

If the damage in the pipeline is long (longitudinal crack), to eliminate it, cut out the damaged section, insert a new section of pipe into the opening and install bandages on both sides.

Rice. 3 Installation of repair clamps

Operating conditions

Clamps have certain characteristics and the conditions of their use must comply with them.

- It is strictly forbidden to use a device whose length is less than the diameter of the pipe being repaired.

- If the pipe diameter is 350 mm, then in this case it is recommended to use models whose length is 150 mm longer than the size of the damaged area.

- For pipelines with a pipe diameter of more than 350 mm, devices are used whose length has a margin of 200 mm.

- When repairing a plastic pipe, you should choose a product with a length 1.5 times longer than the damaged area.

- When connecting two pipes, it is worth remembering that the distance between them should not be higher than 10 mm. The deflection angle of the pipes is allowed within 2–3 degrees.

- If the area of pipe damage exceeds 60%, a complete replacement of the problem area is recommended.

Fixing leaks in pipelines with your own hands using a bandage

The bandage is a specially designed device for eliminating leaks, ensuring high tightness and reliability of connections of all types of pipelines; its installation (two-component model) is carried out according to the following scheme:

1. Disassemble the repair clamp, unscrewing the connecting bolts, protect the surface of the pipeline from rust, paint and other types of contaminants.

2. Install the rubber gasket in the center of the damage so that its edges overlap the hole by 30 mm. on both sides;

Rice. 4 Repairing the water supply using a bandage

3. Place two metal halves on the gasket and connect them with four bolts, gradually tightening the bandage on both sides. At the same time, you should not overtighten the connection if plastic pipes are being repaired - this can lead to their longitudinal cracks. When screwing, it is better to leave a small leak and wait some time so that the plastic rubber ring better grips the pipe and seals the hole tightly.

4. A two-component repair bandage can serve for at least 5 years; if necessary, you can always replace the rubber seal in case of a leak and use the product for an unlimited period.

Mechanical methods of pipeline repair

These methods are quite numerous, since craftsmen successfully use various available materials.

Medical bandage and cement

This is the simplest option if the “appearance” of the pipe is not nearly as important as its tightness. In this case, the operation consists of simple steps:

- first the bandage is cut into pieces, then a not too thick cement mortar is made;

- strips of material are thoroughly impregnated with the mixture, after which they are quickly wound around the damaged area.

The resulting cocoon is again coated with the solution, then left to dry. Such an almost “concrete structure” dries out in about a day. The finished patch is painted.

Help with self-tapping screws and bolts for metal products

This is another popular option when considering repairing water pipes without welding. It is suitable if the thickness of the metal walls is more than 3 mm, and the diameter of the hole that appears is no more than the same 3 mm (maximum 4 mm). The role of the “plug” is played by ordinary galvanized self-tapping screws, supplemented with a rubber washer. The operation is quite simple:

- The sections of the pipe near the hole are cleaned of rust with a file or sandpaper.

- Then a self-tapping screw is screwed into it. To facilitate the operation, use a screwdriver.

It is better to use a cordless tool. The fasteners must be selected so that the part of the self-tapping screw inside the water supply is minimal. It is clear that such repairs are still a temporary measure. To get more reliable protection, it is recommended to use a bolt. In this case, the procedure is different. First, a thread is made into the hole with several self-tapping screws, then a bolt, also equipped with a rubber washer, is screwed into it.

Some craftsmen believe that it is not always advisable to screw in bolts, especially if the case is an emergency. When the age of the pipe allows, the element can simply be driven in, but the hammer must be used carefully.

Using a rubberized metal clamp

This method is also used if the hole in the pipe is relatively small. A metal clamp is chosen with the same diameter as that of the damaged water supply section. If several leaks occur in one area, it is recommended to purchase a device of greater width.

The rubber gasket on it is a mandatory element, so it is better to immediately purchase just such a product. However, the seal can be made independently from a rubberized material whose thickness is at least 3 mm. The recommended width of a homemade gasket is 2-4 mm larger than that of a clamp. Length - 10 mm less than the circumference of the pipeline.

Using a temporary bandage

Such repair of water pipes without welding may be necessary if an emergency occurs at an inconvenient time, when it is not possible to do a quality job. This will help temporarily eliminate holes that are oblong in shape. In this case, first look for a suitable material for the bandage. It could be:

- bicycle tire;

- boot top;

- medical tourniquet;

- thick glove.

The main condition is that the size of the material is sufficiently large: it must completely block the flow. Such “temporary structures” are fixed with bolts and clamps.

Magnet for small leaks on metal

This method is quite original, but it is said that it still works if the hole diameter does not exceed 1 mm.

- The leaky area is processed with a file until smooth.

- Then a magnet is attached to it.

The method uses the properties of a magnet to collect metal particles present in tap water. As a result of its “attractiveness,” a metal plug is collected near the hole, which can reliably close the hole.

Using a plug

This “old-fashioned” method is similar to sealing pipes with self-tapping screws or bolts, but here a wooden cap acts as a “super plug”. Its advantage is the ability to use a plug for a pipeline that deserves to be called “dilapidated”. Metal products are contraindicated in such areas.

Pipe plugs are recommended to be made from moisture-resistant coniferous wood. To further protect the elements from the influence of liquid, they are treated with resin. After some time, the cap will begin to swell, so it will completely block the leak. This option is only suitable for metal pipes; wooden plugs are not used for plastic products.

Methods and materials for repairing steel pipes in heating systems

In addition to repair clamps, there is a fairly wide variety of methods for repairing damaged metal pipes, including various methods of applying patches and mechanical fasteners, which can be used in curved areas that are unsuitable for the use of bandages.

Rice. 5 Method for eliminating leaks in the hose using a medical tourniquet

Metal threaded bolt or self-tapping screw

If the diameter of the fistula is small on curved sections of the main line or in heating radiators, threaded metal fasteners are used for repair, screwed forcefully into the hole. To obtain the most reliable connection, proceed as follows:

- A hole is drilled in the pipe for a thread slightly larger than the size of the fistula, usually it is 0.5 - 1 mm smaller. standard diameter (4, 5, 6 mm and so on).

- Use a tap to cut a threaded profile for a bolt of the selected size.

- The bolt is cut so that its head rests on the edge of the hole during installation, after which a rubber gasket is placed on it and screwed into the hole.

A significant disadvantage of this method is that the bolt significantly blocks the water supply channel in small-diameter mains; for horizontal sewer lines, the method is not very suitable - fibrous waste will be retained on the protruding surface of the bolt.

Cold welding

Cold welding is a popular component for plugging various types of holes; its composition, penetrating into the product, is used to seal water pipes made of different materials for supplying cold and hot water.

Installation of clamps

Material selection

Clamps come in various sizes and designs, but all types have a spherical shape that follows the bend of the pipe. The design of the product necessarily contains clamping bolts, which make it possible to tighten the clamp as tightly as possible around the pipe being repaired/installed. According to the scope of application, these products are divided into fastening and repair items.

Mounting clamp: photo

The clamp fastener consists of a metal shell and a corrugated rubber gasket, which prevents noise from vibration and excessive compression when tightening. A prerequisite for this type of product is the presence of a side fastening, which is most often made in the form of a welded nut - with its help, the pipe is mounted/suspended on a wall or ceiling.

Leak repair clamps have a wider metal shell and a solid rubber gasket that seals the leak on the pipe. There are also specialized products for inserting an additional branch into a water supply system - with its help you can create a branch without the use of a welding machine. The only condition for its use is the absence of strong pressure in the system.

Repair clamp with rubber gasket

When purchasing, special attention should be paid to the sizes of plumbing pipe clamps - an incorrectly selected size will make the purchase in vain. The diameter of the pipe is determined by a caliper or, in the absence of one, you can simply measure the external cross-section of the pipe

The presence of a rubber gasket is also important - it is not always included in the basic package. If there is a choice between products with and without a seal, then you should give preference to the first option, even if its price turns out to be an order of magnitude higher - the gasket significantly increases the technical characteristics of the fastening

Sizing

Installation of fasteners

- The path of the future pipeline is marked and the location of the fastenings is noted. The distance between the fasteners is determined depending on the length and weight of the pipe - in standard situations it is about one to two meters;

- At the site of future fastening, a hole is drilled into which a plastic dowel is inserted, and a threaded pin is inserted at the end. The clamp is screwed onto the pin in the open state - you should screw it all the way, but you should not be too zealous so as not to deform the shell of the product;

Installing pipes is not difficult to do yourself

The pipe is inserted and the clamp is clamped

It is important here to create a floating clamp and not to overdo it - it should not be too tight to compensate for the thermal expansion/contraction of the material;

Repairing leaks

- Before placing the clamp on the pipe, it is advisable to turn off the water supply to the system. If this is not possible, installation is also possible, but you will have to get pretty wet;

- The clamp is placed over the broken area so that the crack/cavity is located approximately in the middle of the rubber gasket. The rubber seal should lie flat, without wrinkles. The fasteners are tightened as tightly as possible to avoid leakage;

Repairing leaks

The connection point is wiped dry, the water supply is restored and the pipe clamp is inspected for leaks. If this occurs, then the fastening is additionally tightened;

Pipe tapping

First of all, a hole of the required diameter is drilled, then an adapter is put on it. The main thing is that the sealing gasket fits without bending. After tightening the clamps, the connection is ready for installation of an additional water supply branch.

Inserting a branch into a water supply system

Homemade clamps

If your pipe bursts and you don’t have the necessary clamps on hand, you can temporarily fix the leak using improvised means. The answer to the question of how to make a pipe clamp is quite simple - you will need ordinary clamps of any design and a piece of thick rubber that will act as a gasket.

The leak area is tightly bandaged with rubber, after which clamps are put on at both ends - there should be at least two of them. In the absence of such, you can use ordinary wire, through which the joint is pulled on both sides. It should be noted that although such a “repair” may last for several years, this solution is temporary.

Rubber pipe bandage

Repair of water supply and sewerage systems made of cast iron

In residential buildings, cast iron is widely used in risers; leaks often occur at the socket connections with plastic outlets. There is practically no pressure in the riser, so its repair consists of simply sealing the defective area.

The technologies used in sealing steel lines and some other methods are suitable for carrying out this work.

Cement piping

If you don’t have an elastic bandage at hand, you can use regular gauze in combination with cement mortar, performing the following operations:

- Mix cement with water until a creamy mass is obtained.

- Dip a medical bandage into the solution and soak it with a cement composition.

- Wrap the defective area several times in a spiral in 3–4 layers.

- The pipeline can be used after the composition has dried a day later.

Caulking

The technique is used to close cracks and fistulas in cast iron pipes and involves driving lead rivets into the slot cavities. As a soft substance, lead reliably covers and seals the defective area when the hollow compartment is filled.

Rice. 9 Method for sealing leaks in cast iron pipes

Padding

Leaks often occur in the socket joints of cast iron elements; to seal them, packing made of fibrous materials impregnated with bitumen is used, the work is carried out in the following order:

- Remove the old packing using sharp objects, freeing up space for laying repair components.

- A jute or hemp rope (rope) impregnated with bitumen is tightly pushed into the resulting gap along the entire perimeter, leaving a distance of about 10 mm at the top.

- Cover the packing with cement mortar, covering the free space with it.

Chopiki

Chopik refers to a method of repairing Soviet-era cast iron and steel pipes; wooden plugs made from hardwood are used to seal holes. The main advantage is the closure of the fistula, through which water flows under pressure and there are no standard factory devices at hand, within a few minutes.

When using it, a wooden peg is sharpened at any angle and lightly driven into the hole; after exposure to moisture, the wood expands and tightly closes the fistula. In steel lines of the Soviet era, chopiks stood for 5 years; when leaks appeared as a result of widening holes, they were simply driven deeper.

Rice. 10 Method of repair work using choppers

Making a clamp from scrap materials

If there is a leak in the water supply system, and you do not have a set of bandages at hand, or they do not fit in diameter, you need to urgently take measures to eliminate the leak using available materials.

Water mains can be shut off as follows:

- You need to cut a piece of thin rubber. An old bicycle tire, rubber gloves, and an elastic bandage will do. The width should be such that the rubber covers 3 cm of area on both sides of the leak. Apply rubber to the crack.

- Take a flexible wire and wrap it around the rubber, pressing the rubber firmly so that it does not come off.

- Wrap the connection with tape on top, grabbing the pipe around the edges.

Winding the wire is necessary to ensure that the structure can withstand pressure. Cold welding is used, but for this you will have to shut off the water in the riser, since the substance does not bond well with the metal in a humid environment. Once cured and applied, the top can be wrapped in rubber to reduce the risk of re-cracks.

To repair water mains, clamps are made from gauze bandage and cement mortar. The bandage is immersed in the solution and wound around a section of pipe in 3–4 layers in a spiral. It is allowed to use the pipeline after the cement has dried - within a day.

Epoxy resin and an elastic bandage also stop the leak in the line. Before this, the work area is cleaned and degreased. Epoxy resin is applied layer by layer, wrapping a bandage on top - this way several times. Drying takes about 1.5 days, after which you can turn on the water.

Such measures are being taken urgently. To make a metal bandage with your own hands, you will need special tools and time.

Repair methods for plastic pipelines

Various plastic pipes are repaired using clamps, applying patches, and sealing holes.

For common polypropylene pipelines, a special technology has been developed, the essence of which is to seal the fistula with a heated polypropylene rod. In this case, the hole is drilled to the required diameter, its ends are heated with an iron rod inserted into a soldering iron, then a molten polypropylene pin is placed inside the hole, the protruding end of which is then cut off.

The second repair method is to cut out the damaged area, after which the pipe ends are connected with an external coupling using a plumber's soldering iron.

If you don’t have a special tool, you can try to repair the polypropylene pipe yourself by doing the following:

- Drain the water from the system, drill a round hole in the pipe and cut out a slightly larger rod from polypropylene (polypropylene rods are available for sale on the construction market).

- Melt the pipe hole with an inserted heated metal pin, while simultaneously heating the polypropylene insert until softened with a construction or household hairdryer, the air temperature of which reaches 800 C. (melting point of polypropylene is 260 C.)

- Place the heated insert into the hole, and after cooling, its upper end is cut off.

Technique for repairing PVC sewer pipes

Sewer lines are under low pressure and are connected using a socket method, so the easiest way to repair a hole or crack is to replace the damaged segment. If this is not possible, metal clamps or strapping with sealing strips, tape, or insulating tapes are used. You can stick a patch made of dense material onto the damaged area using a special PVC glue, seal it with epoxy resin or cold welding.

Rice. 11 Method for repairing plastic pipes

The use of a bandage in cases of damage to pipelines is the most effective way to repair them at home on straight sections. If damage occurs in hard-to-reach or curved places on bends, options using adhesives, tapes, and inserts made of various materials are used.

Using special repair clamps, you can repair various pipelines. At the same time, thanks to the large assortment of such products, you can choose a clamp for pipes for different purposes from different materials. In our article we will tell you what repair clamps are intended for, what types of such products exist, and how to use them correctly in a given situation.

Repair of cast iron and steel pipes

The choice of one or another method for eliminating a leak depends not only on the location of the defect, but also on the material of the pipeline. Let's look at each of them.

How to fix leaks in cast iron pipes

Cast iron pipelines are most often found in sewer systems. Since the pressure in them is low, eliminating the leak will not be difficult. You can temporarily solve the problem on your own until you completely or partially replace old pipes and fittings using one of the methods below.

Applying a bandage

It’s quite easy to make a bandage with your own hands, using a regular bandage and cement. This procedure is performed in the following sequence:

- Cement is mixed with water until the consistency of thick sour cream is obtained.

- The bandage is soaked in the resulting solution.

- The leak site is carefully wrapped in several layers. It is necessary that each subsequent turn of the bandage overlaps the previous one by about a quarter.

It will be possible to use the sewer system after about a day - during this time the solution should harden.

In some cases, instead of cement and bandage, fiberglass in combination with epoxy glue is used to eliminate water leaks.

Due to the high reliability of the cement bandage, this method of eliminating water leaks is widely used both in the repair of cast iron pipes and steel water pipes. However, it is not recommended to use it in places of threaded connections, since disassembling them in the future will be very difficult.

Applying a patch

Before eliminating the leak, drain the water from the damaged pipeline and thoroughly clean the defective area from corrosion, various contaminants or paint. To do this, you can use a grinding machine or a wire brush.

After drying and degreasing the surface, a layer of epoxy resin is applied to the leak site and a fiberglass patch is applied. It is important that this material is well saturated with glue. For greater reliability, you can wrap mounting tape over the patch. It is advisable to use the pipeline no less than 24 hours after repair.

Caulking

One of the effective ways to get rid of cast iron sewer leaks with your own hands is to drive lead cones into leaks and cracks in pipes. Due to the plasticity and pliability of this metal, it is easily flattened, filling all kinds of voids.

When connecting pipes of sewer systems with sockets, “caulking” is carried out using cement and packing. If a water leak occurs in this place, then to do the repair yourself you need to:

- Clean the gap between the outer surface of the pipe and the inside of the socket.

- Wrap oiled tow around the pipeline and drive oiled tow into the crack using a special spatula, which should tightly fill the space to 2/3 of the height of the socket.

- Lay the top layer of tow without any impregnation in order to improve adhesion to cement.

- Seal the pipe connection using asbestos compound or cement mortar. The use of modern materials such as silicone or mastic is allowed.

- To avoid cracking, the sealing layer should be covered with a damp cloth for a day to allow it to harden slowly.

When caulking the gap, do not allow tow to get inside. Any foreign object in the pipeline can cause a serious blockage in the system.

Fixing leaking steel pipes

On a straight section, you can repair a broken water pipe by analogy with cast iron - by applying a bandage or patch. But since steel pipes are usually used in the construction of pressure mains, attention should be paid to more reliable repair methods.

Emergency glue

The most technologically advanced method for eliminating pipe leaks is the use of special glue. It is enough to buy the so-called emergency metal polymer at a hardware store. It is sold in the form of two components - a hardener and metal dust mixed with resin. The glue is prepared by simply mixing them immediately before starting repair work.

This composition can eliminate water leaks in both dry and wet areas of pipes. However, it is advisable to turn off the taps - high pressure in the system is unacceptable. The pipeline can be used immediately as soon as the glue has completely hardened.

Repairing leaks using self-tapping screws and bolts

If a small hole (no more than 4 mm in diameter) appears in a steel pipe under pressure, the leak can be stopped using a metal screw with a press washer. It must be screwed tightly into the site of the fistula.

Step-by-step instructions for eliminating water leaks when breakthroughs of 5 mm or more appear are as follows:

- First of all, the water supply to the damaged area is cut off.

- The damaged area is drilled to obtain a smooth hole.

- Using an appropriate tap, the thread is cut.

- A pre-prepared bolt with a rubber gasket is screwed into the pipe.

This method of repairing pipes with your own hands will allow you to forget about the damage for several years. But this measure, like all others, is only temporary. It is not recommended to overly delay replacing a defective section of the water supply system.

Purpose

The repair clamp can be used in the following situations:

- To seal a pipe that has been damaged by corrosion.

- To seal leaks due to the formation of holes and fistulas. In this case, you need a repair clamp with a special sealing gasket. It presses tightly against the defect and reliably protects against leaks.

- If a pipe bursts in the transverse or longitudinal direction, it can be repaired using this product. If such a breakdown occurs on a moving section of the pipeline, then it is better to use a clamp that will not only close the leak, but also allow you to fix the pipe to the wall or floor.

- In the case when you urgently need to prevent a leak, but there is no way to turn off the water or drain it from the system.

- The repair clamp is suitable for repairing leaks in the event of a leak in the socket connection of sewerage pipelines.

Advantages

The repair bandage is quite a sought-after and popular product due to its large list of advantages:

- The element can be used for pipes made of different materials, which makes it a universal repair product.

- The bandage is quickly and easily installed so that the work can be done with your own hands without the relevant experience.

- This leak repair product is reasonably priced.

- Thanks to the material used, repair clamps have an impressive service life and a neat appearance.

- The product is not exposed to aggressive environments and can withstand temperatures up to 100 degrees.

- The bandage is ideal for quickly eliminating leaks.

- Repair work can be carried out without turning off the system and draining water from it.

- Most clamps are made from passivated 304 stainless steel, so they do not require additional corrosion protection.

Varieties

Repair clamps for eliminating leaks from pipes are selected depending on the degree of damage to the pipelines, the material from which the pipes are made, and the purpose of the utilities.

Depending on the design and purpose, the leak repair bandage can be of several types:

- A double-sided repair clamp consists of two parts connected using a bolted connection. This is a universal product that can be used in different situations and is selected depending on the diameter of the pipe being repaired.

- A single-sided bandage is a U-shaped bracket that has holes along the edges for fixing to the pipe. A rubber gasket is used to seal the inside. These products are suitable for small diameter pipes.

- Standard clamp.

- Standard two-piece repair product.

- A three-piece bandage is suitable for eliminating leaks on large-diameter communications.

In addition to repair clamps, there are also fastening clamps that can serve as repair products if, in addition to eliminating a leak, it is necessary to fix the pipe to the surface of the wall or floor. Essentially, this is the same one-sided or double-sided clamp, only on one side it has a nut welded for screwing to a support element fixed to the wall.

Depending on the material from which the clamps are made, they are:

- steel (without anti-corrosion coating);

- made of cast iron;

- made of stainless steel;

- made of galvanized steel.

In addition to the bandages themselves, some manufacturers produce kits of composite elements that are suitable for repairing large-diameter pipelines. The number of fragments in the set depends on the diameter for which the product is designed.

Main types of repair clamps

Based on material, repair clamps are divided into:

- plastic;

- metal.

Plastic products can be used to secure a pipe that is in a moving state. They can be solid or double. Plastic products are practical and very durable devices that allow you to quickly and reliably cope with pipe repairs. The main positive quality of polymer devices is their resistance to the destructive effects of corrosion. The disadvantage of this type of clamp is their weak resistance to mechanical stress.

Repairing a plastic pipe can also be done using a clamp

Important! Using a clamp is considered a temporary solution to the problem. In any case, it is better to completely replace the damaged section of the pipeline.

Metal products are capable of making reliable and durable connections. Unlike plastic analogues, they are more resistant to mechanical damage. Steel products, which are usually made from galvanized or alloy steel, are extremely popular. These clamps have a rubber layer on the inside. Another difference from plastic fixtures is that metal clamps are able to absorb vibrations in the system.

The main types of clamps according to design features:

Unilateral. A common type of clamp is made in the shape of the letter U with perforation in the upper part. This type is usually used for repairing small diameter pipes (for example, DN 50).

Bilateral. This product consists of two elements that are connected to each other with special screws. The choice of such a device is made taking into account the diameter of the pipe and the nature of the damage.

Multi-component. Devices of this type are used for repairing pipes with large diameters. A multi-piece clamp consists of three or more elements. This device is installed on several threaded pairs.

Fastening. Its characteristics are practically no different from the one-piece and two-piece types.

The difference between this type of product is that it has a special fastening element, which includes a self-tapping screw. Thanks to this, the clamp securely attaches the pipe to the wall.

Specifications

- The material for making the bandage is steel (galvanized or stainless) with a thickness of 1-2 mm. Sometimes carbon steel 20 with a thickness of 1.5-3 mm is used. Stamped clamps are made from steel. Some manufacturers make elements for the same purpose from cast iron.

- A cuff made of cellular corrugated rubber acts as a seal.

- The clamp fasteners are made of galvanized or stainless steel.

- The maximum operating pressure is in the region of 6-10 atm.

- The product can be used in an aquatic environment. Air and inert gases are also considered the working medium.

- The repair clamp can be operated in the following maximum temperature range – 110-120 °C.

- The nominal operating temperature is 20-60 degrees.

- An element for this purpose can have a diameter from 15 mm to 1.2 m.

The most popular are single-sided and double-sided repair parts. Thus, a double-sided stamped clamp is made from carbon steel 20. It is used for repairing water supply pipes and consists of the following components:

- Two steel or galvanized stamped coupling halves, which are reinforced with stiffening ribs.

- Rubber sealing gasket.

- Connecting bolts with washers and nuts made of stainless or galvanized steel.

- The diameter of this clamp can vary between 15-600 mm.

Another popular repair item is a single-sided stainless steel clamp. It is made in the form of a solid steel strip (coupling). Its edges are connected to each other using screws and nuts or special fasteners made of galvanized steel.

Species diversity of clamps

On sale you can find many types of pipe clamps, which differ in size, design features, and material of manufacture. As for materials, products made from cast iron, ordinary, stainless or galvanized steel are presented (read: “Types of steel clamps for fastening pipes, differences and features of fasteners”).

Structurally, repair clamps are represented by the following types:

- Single-sided

, horseshoe-shaped with a hole at the top. Such models are used for threaded connections of pipes with a small diameter (maximum DN 50 mm). - Double-sided

. They consist of two separate parts, mounted together with screws. You can ensure a more secure fit to the pipe using crimp clamps. The size is selected based on the parameters of the pipeline. - Multicomponent

. Such products have several parts and are intended primarily for pipelines with large cross-sections. Installation is carried out using several pairs of threads. The collar cuff has a cellular surface.

- Fasteners

. Such clamps are intended primarily for fixing pipes to the surface. Mount it to the wall using a screw passed through the perforation in the lower part of the part. The pipe is laid after fixing the part.

Installation sequence

After selecting and purchasing a repair product of the required diameter, work is carried out in the following order:

- The fastening elements must be unscrewed and removed from the holes, and the ends of the clamp must be spread apart so that it can be easily put on the damaged pipe.

- After this, you need to check that the rubber sealing gasket is located exactly above the damage to the pipeline. In this case, its edges must overlap the entire section of the pipe by at least 3 cm on each side.

- After this, we insert the fasteners that come with it into the holes on the edges of the product. We tighten the bolts with nuts so that the clamp fits snugly to the pipe along the entire plane.

- Now all that remains is to check that the leak has completely stopped.

Important: this method of repairing pipes is considered temporary, so it is better to replace the damaged section of the pipeline. However, after installing such a repair product, you can use the pipeline for at least 5 years without replacing the pipes.

Clamp for repairing steel lines

Repair clamps for steel pipes are made of steel, and most often these devices are installed on the water supply network. This part for steel pipes is folded:

- Several galvanized or steel coupling halves.

- Gaskets.

- Bolts, nuts and washers made of steel or galvanized materials.

The nominal volume of such a device for steel pipelines is from 1.5 to 60 cm. These devices are made in the form of a tape, the edge parts of which are fastened with galvanized tubes.

The cuff on these devices is made of cellular material, which creates a hermetically sealed passage of the mechanism to the emergency location on steel pipelines. The thickness of the metal on them is 1 mm.

They are not subject to corrosive formations, and their use is economical and simple.

Their features

A repair clamp for cast iron, metal, polyethylene pipes has a large number of advantages. It can be used for fragile cast iron and any other system, and everywhere such devices turn out to be multifunctional.

Installing these mechanisms is simple, and anyone can carry out such work with their own hands. During operation, these fasteners allow you to connect cast iron and any other pipe.

When installed on a metal system, they make it possible to extend the life of the line.

Such a device for a cast iron system can be installed by anyone without special skills. These mechanisms for cast iron and any other network can withstand high temperatures.

But in order for these technical characteristics to meet all requirements, you need to buy products only from a trusted manufacturer.

Application and installation sequence

It has already been noted that installation in this case becomes quick and uncomplicated. A brief description of such work looks like this:

- The mechanism must be wound around the circumference of the pipe and secured to the part opposite from the accident.

- Then the nuts are attached; they must fit tightly to the pipeline.

The quality of installation in the emergency zone directly depends on the material of the coupling and its strength. An important detail during operation is the peculiarity of the interface between the fastening device and the system.

There is no need to change the mounted device; it can last the same period as the pipe product itself. Therefore, it is economically beneficial to buy several clamps for repairs, rather than spending money on replacing a pipeline or a separate piece of it.

When selecting the right device for repair, it is necessary to take into account the degree of damage. At the same time, metal, plastic and other devices are installed that most effectively help cope with the resulting breakdown.

Each repair mechanism is designed in the form of a semi-closed cuff and a screw tie. All components of this design are tightened using bolts. Its diameter must exactly correspond to the dimensions of the highway; only this condition becomes the key to reliable sealing.

Watch the video

repair clamp

The described fastening method is versatile and simple. Although difficulties often arise during installation that will require certain skills. For example:

- Stable mounting option. The main points of support with a fixation zone are considered to be those places where a pipe product is secured with a clamp without the likelihood of its subsequent movements. This fastener is made near the socket point on the body. This system makes it possible to use devices of various shapes and creates a durable structure.

- Floating fastening method. Metal or steel coupling mechanisms are connecting parts, but such a coupler requires a lot of effort. Another option for this method is plastic types. They need to be selected for a larger diameter; only in this case can an effective level of fastening be ensured.

Metal and plastic clamps

The pipeline installation process involves a variety of shapes and sequence of coupling attachments. And only in this way is the stability of the reproducible structure created. And additional devices are used in the area of branching and turning of the highway.

It is advisable to use rigid and immovable fasteners for a metal or plastic coupling in a heated room. In other options, plumbers use a movable fastening method using elastic inserts.

If the system is under the influence of high temperature, the pipe needs to be fitted with coupling devices of various shapes with a movable design and an elastic gasket.

The use of various options: metal, plastic, steel, aimed at performing plumbing measures associated with eliminating defects in systems. An option for fastening them is to fix them to the wall with sharp metal studs.

For example, fastening a polypropylene pipeline is carried out at a distance of 2 m, and a plastic pipeline is allowed to be fastened at less frequent intervals.