Installation and Installation

A long-burning metal stove for a cottage or home is a fire hazard. So the requirements for its installation are quite strict. No, installation permits are not required, but it is better to comply with fire safety requirements for your own safety.

How and where to install

Each manufacturer completes its product with installation and operating instructions. It specifies the exact requirements specifically for this model. After all, the distances to combustible structures (wooden walls, for example) depend on how hot the body is during combustion, and this depends on the design. And it is the manufacturer who knows the nuances of their product better, since they conduct testing in various modes. Therefore, when choosing an installation location and the distance from the walls to the housing, it is better to adhere to the manufacturer’s recommendations. On average, these distances are 15-25 cm. This may be useful when selecting sizes, but see the instructions for specific numbers.

When choosing a place, you also need to take into account that from the fireplace door

How and where to install

Each manufacturer completes its product with installation and operating instructions. It specifies the exact requirements specifically for this model. After all, the distances to combustible structures (wooden walls, for example) depend on how hot the body is during combustion, and this depends on the design. And it is the manufacturer who knows the nuances of their product better, since they conduct testing in various modes. Therefore, when choosing an installation location and the distance from the walls to the housing, it is better to adhere to the manufacturer’s recommendations. On average, these distances are 15-25 cm. This may be useful when selecting sizes, but see the instructions for specific numbers.

When choosing a location, you also need to take into account that there should be at least 1.5 meters from the fireplace door to the opposite wall. Gas pipes should not pass nearby; electrical wiring should be at least 50 cm away.

A fireproof substrate should be laid on the floor under a long-burning fireplace stove for a cottage or home. It can be a metal sheet, ceramic tiles, brick, stone. The dimensions of the fireproof area should be 20 cm larger than the dimensions of the stove on the sides and back and 40 cm larger in front.

If the floor is wooden, the easiest way is to lay a sheet of metal of the required size and a thickness of 1 mm. Underneath it, a sheet of basalt cardboard (0.8-1 cm thick) is placed on the wooden floor, which serves to insulate and protect the wood from overheating. There is another option: lay a brick with clay mortar (half a brick thick) or ceramic tiles with heat-resistant glue on a metal sheet. In the case of using metal-look tiles, it is also advisable to put basalt cardboard, but of a smaller thickness.

Chimney

For metal fireplace stoves, a metal sandwich chimney is usually used. The minimum internal diameter is 200 mm, the thickness of the thermal insulation (basalt wool) is not less than 60 mm with an insulation density of 15-30 kg/m³, the thickness of the inner wall made of stainless steel is not less than 1 mm. These parameters are the minimum requirements for normal operation of the fireplace stove. A good chimney is one of the most important factors that affects the operation of a heating device.

For a fast-burning stove to work well, a fireplace for a cottage or home must have a chimney at least 5 meters high, if you count from the grate. In addition, you must adhere to the following rules:

- The ledges are made at an angle of no more than 30°.

- The maximum length of all horizontal sections is 1 meter.

- The chimney head is protected from precipitation and debris using a chimney umbrella/weathervane or any other type of head.

- The pipe must be routed through combustible structures (house wall, ceiling, roof) in a special fire-resistant cut.

There is one more nuance. When the stove burns, the fireplace burns out the oxygen that is in the room. To restore it, a ventilation system is needed. The second option is models with external air supply to the firebox. For this there is a special channel that is led out through the wall.

Wood-burning bell-type stoves

This design of wood-burning brick heating stoves allows them to heat up evenly on all sides and remain warm for quite a long time. This is the most modern type of wood burning stove made of brick. The main difference between such a furnace is the absence of long narrow passages in its design, in which soot and ash can accumulate, narrowing the clearance in the chimney over time.

In bell-type heating stone stoves, smoke rises from the fuel chamber and accumulates under the dome, where it remains until it cools, after which it gradually falls down along the walls, transferring heat to them. Sometimes there are several such hoods in a furnace, which accounts for its high efficiency.

The advantages of the design are:

- low construction cost due to compact size and small amount of consumables;

- complete cooling is allowed between heating, which does not affect the high heating rate of the stove and all adjacent rooms;

- the design prevents the formation of reverse draft, so it will not cool down even with the view open;

- It is very easy to light such a stove.

The stove has practically no drawbacks, so it is very popular among owners of small cottages. It can successfully heat a house with several rooms and even floors - it all depends on the number of hoods.

Fireplaces for cottages and country houses

Recently, fireplaces for summer cottages have become increasingly popular. Photos of such fireplaces are presented below. Fireplaces are no less popular among residents of country houses and cottages. Fireplaces are multifunctional heating devices - they heat the room and at the same time play the role of interior decoration.

Classification and types of fireplaces for summer cottages

Fireplaces can be classified according to the following characteristics:

- according to the material of manufacture - brick or metal (cast iron or steel);

- according to the installation method - island (placed in the center of the room), corner (in the corner for heating adjacent rooms), built into the wall, wall-mounted, with the ability to rotate around an axis by 360°;

- by design - classic, hi-tech, modern, country;

- by fuel used - solid fuel (wood, peat, coal, coal briquettes, pellets), gas and electric;

- According to the design of the firebox - open and closed with a door on the firebox.

Separately, it is worth mentioning such a model as fireplace stoves, which combine the functions of both a fireplace and a stove. These heating devices will be discussed further.

https://youtube.com/watch?v=-nnCaipq3o4

Advantages of fireplace stoves

These heating devices have the following advantages:

- Multifunctionality - they perform the functions of a fireplace and stove, and on some models that have an additional hob and oven, you can also cook food.

- The presence of two separate fireboxes for the fireplace and stove makes it possible to use them together or separately. To quickly warm up a room, it is advisable to use a fireplace, and to retain heat for a long time, a stove. Once the temperature has reached the optimal level, you can leave only the oven running.

- Some models have a built-in water circuit, which allows you to connect to heating radiators and heat several rooms.

- Using a “clean combustion” system for optimal use of energy from fuel combustion, which increases efficiency to 75–80%.

- The use of pellets (compressed wood pellets) as fuel in modern models. Granules are automatically fed into the firebox from a special container - this technology allows the furnace to operate autonomously and increases its efficiency by an additional 5–7%.

- The use of a convection system allows you to efficiently and quickly warm up the room and increases the service life of the fireplace stove.

Construction of fireplace stoves

These heating devices are made of metal (usually cast iron) or brick. A brick fireplace stove is a massive and expensive structure that is suitable for a large house. A metal fireplace stove is much smaller in size, and therefore it is advisable to use it for heating summer houses, small country houses and cottages.

The firebox of the fireplace stove is high, the firebox window is large, and the fireproof glass door occupies almost the entire area of the fireplace façade.

To enhance heat reflection, the side walls of the firebox are slightly turned towards the firebox window. The inside of the firebox can be lined with heat-resistant plates. The firebox is made of cast iron or steel. If steel is chosen as the material, then it is lined with bricks made of kaolin or fireclay clay - this prevents the steel from burning out.

As a rule, the metal of the firebox is coated with dark heat-resistant paint. The fireplace stoves themselves are painted with shiny enamel, which can be of any color.

The body can be decorated with ceramic tiles or tiles - these finishing elements also serve as additional heat storage devices.

Oven Fire-Battery 11 (Termofor)

According to the manufacturer, the distinctive features of this stove are:

- The stylish design allows you to install the stove in the most modern interior.

- A cast iron burner with two rings of different diameters allows you to cook food over an open fire in dishes of different sizes, load fuel from above and clean the upper part of the stove from soot.

- A stainless steel heat exchanger (in versions with the letter “B”) allows you to heat water for domestic needs.

- Highly efficient slot convectors protect against harsh infrared radiation and convert 77% of useful heat into soft convection currents.

- The large vertically oriented firebox door allows you to conveniently fill the stove with wood to the very top.

- Fine adjustment of the combustion intensity allows you to steplessly select any operating mode of the stove.

- The universal chimney outlet makes it equally convenient to lead the chimney upwards and backwards.

This stove has no other special advantages.

Based on reviews on the Internet, based on the criterion of convenience, a stove of a later design, Fire-Battery 11, costing 20,000 rubles, was chosen. Taking into account all the necessary additions (chimney, fire protection on the walls...), the cost of this stove was about 40,000 rubles. Of course, you will have to do the installation of the stove yourself.

If you decide to install such stoves in a two-story house, then keep in mind that you will have to put a door on the stairs on the first floor; the second floor should be fairly hermetically separated. Otherwise, all the warm air will go upstairs (on the second floor it will be +40C, and on the first floor +5C). In addition, in some cases (with separate rooms) it would not hurt to organize forced air convection.

Modernization of the furnace, increasing efficiency

There are three main ways to increase the efficiency of a stove: one of them is related to the chimney, the second is related to the fuel, and the third is related to operating conditions.

Chimney design optimization

For the chimney, as already noted, a pipe with a diameter of 15 cm and a length of 5 m is used. If you install a smaller pipe, especially in diameter, then it will not cope with the resulting loads. And the furnace itself will operate with reduced efficiency. To adjust the draft, a valve is installed in the pipe. A door is created at the bottom of the chimney for easy cleaning.

Condensation forms and accumulates in any pipes. And in pipes during pyrolysis it turns out even more, since the gases, having parted with all their heat, have negative temperatures at the outlet. This trend becomes the reason for high-quality insulation of pipes. The sandwich technology copes with this task perfectly. Its essence: a second one is introduced into one pipe, and a thermal protection layer is made between them.

You can also make a sandwich pipe with your own hands by wrapping the chimney with insulating material and protecting the structure with an outer pipe

In areas where pipes pass through the roof, it is necessary to perform thermal insulation using a metal box filled with insulation. A deflector is placed on the head of the pipe. It prevents precipitation from entering the system and also protects against the effects of wind.

If the installation site for the stove is a stoker, there is no need for a reflector. When the stove is located in a room, the surrounding masonry performs two functions:

- Protective screen for walls and things.

- Heat accumulator.

Since the body of the structure is metal, the oven quickly heats up and cools down. Cooling occurs immediately after the fuel burns out. Therefore, a brick screen created on three sides of the stove accumulates heat and releases it over time. You can use corrugated sheets or a smooth metal sheet as a reflector.

What fuel is better to use in long-burning stoves

The efficiency of the furnace also depends on the fuel used. It is best to use dry logs. But since the stove is homemade, you can save on fuel. The device can even work on waste made from natural materials.

Experts recommend using pellets (granulated fuel) created by dry pressing in such stoves. The basis for pellets can be:

- cones;

- wood chips;

- sawdust;

- nutshell;

- straw.

Coal gives a good combustion temperature. But its use is justified when the oven is made only of materials with a decent thickness. Otherwise, such a unit will quickly burn out. A table showing the specific heat transfer of various materials can serve as a guide.

Table: specific loading coefficient and specific heat transfer of various types of fuel

| Type of solid fuel | Specific loading coefficient, kg/dm3 | Specific heat transfer, kW/h |

| Standard size aspen | 0,143 | 2,82 |

| Coniferous shavings or sawdust | 0,137 | 3,2 |

| Alder pellets | 0,285 | 3,5 |

| Hard coal grade DPK | 0,4 | 4,85 |

| SSOM grade coal | 0,403 | 5,59 |

| Coarse anthracite | 0,5 | 5,72 |

| Peat briquettes | 0,34 | 2,36 |

Tunnel stove options

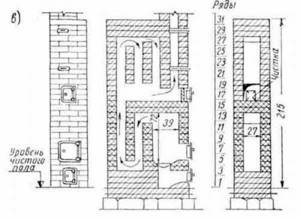

Tunnel brick ovens can be made with vertical or horizontal smoke channels.

Horizontal smoke channels

Hot gases in this type of stove give off their heat along the way to the chimney. It is necessary to provide a cleaning door on each channel, since soot and ash settle on the horizontal surface in large quantities.

To increase the heat transfer of gases, you can also make special heat pockets. By increasing the internal area of the channel, the speed of movement of hot air through them is reduced. Consequently, the stove becomes more heat-intensive.

This chimney system is not particularly popular.

Vertical smoke channels

A design with this arrangement of channels prevents the free movement of gases inside the chimney. This often leads to overheating of the first channel. In addition, in this case it is necessary to build a higher chimney than with a horizontal scheme.

But this option has serious advantages: due to the large height of the structure, it is less susceptible to air blowing. This way the stove becomes more heat-intensive.

The main difference between counterflow designs and models with vertical channels is that the hole where the gases fall has a wider cross-section. They move at a lower speed, managing to transfer more heat to the brick walls.

Combined smoke exhaust systems

Combinations of different systems are often used. This makes it possible to use all the advantages of each design and get rid of its disadvantages for individual design. There are a lot of options for this combination.

Not all designs are suitable for heating stoves. Some of them are used to construct simple fireplaces.

Brick oven

In a small house, you can install one stove, which will require firewood or coal to fire it. Modern stove heating of a private house provides many types of heating structure designs. You should choose one that is intended not only for heating the room, but also for cooking. Before installing the stove, you need to choose a suitable place so that its use is as efficient as possible:

- The firebox should be directed towards the corridor or kitchen, and the heated surfaces should be directed towards the rooms. When designing a stove, you should know that 1 m² of its area heats up to 30 m² of room.

- You cannot place furniture near the stove or install partitions, and do not build the stove in the corner of the room. Its large wall should go into the living spaces, then they will always be warm.

- The design of the stove should be chosen according to its purpose. They are used only for heating the room or also for cooking. In this case, you should take into account the hob and oven

Heating stove:

Construction of a furnace structure

The stove structure is erected during the construction of the house, but the foundation is built separately from the general foundation. You can install a stove in an already built house, but then you will need to raise part of the floor and make holes in the ceiling and roof to install the chimney.

Detailed furnace laying:

The size and depth of the foundation depends on the type of furnace structure. It is erected immediately after the construction of the general foundation of the house. For a brick oven, it should be monolithic reinforced concrete, 10-15 cm larger than its parameters on each side. It is required to observe the depth size - from 0.5 m to 1 m. If the soil is loose, or groundwater is close, you do not need to deepen the foundation, but increase its area.

To build a stove, you should use well-burnt red brick. When tapped, it gives off a metallic sound. If it falls, it breaks into large pieces. It is easy to work with, as it can be broken correctly. The areas of the stove in contact with the fire are lined with refractory bricks (the firebox and part of the chimney).

Detailed furnace laying:

Room heating process

A well-thought-out design of a stove in a private home determines effective heating of the room. Solid fuel (usually wood or coal) is burned in a combustion chamber with air supply. Natural draft promotes the movement of flue gases through the channels to the vertical exhaust passages, from where they exit outside. During this time, the brick walls of the oven warm up, and the heat from the hot stone spreads throughout all the rooms.

A well-thought-out stove design in a private home determines the quality of heating of the room

Design features of industrial furnaces

The main element of the furnace is a functioning pressure chamber, isolated from the environment. Outwardly, it looks like a huge oven. The processed raw materials or products are placed in this chamber, and then the device is turned on using certain technological parameters.

Additional equally important elements of electric furnaces are:

- Construction and engineering structures (casing, frame, foundation).

- A heat sink that safely cools recycled products.

- Automated technical control system. processes.

- Electricity and fuel supply devices.

- Chambers for recycling combustion products and excess thermal energy.

- Transport system.

- Devices that load raw materials and remove combustion products.

Furnace manufacturers continue to improve devices to this day to increase their performance, durability and reduce maintenance costs. maintenance, cost of the structure and its repair.

Cast iron stoves from manufacturers

Today it will not be difficult to choose an excellent option for a particular home from the wide range of cast iron models presented. They are made in the form of a combustion chamber enclosed in a metal casing. There is a gap between the walls of the firebox and the body through which air moves. Since cast iron has excellent thermal conductivity, there is no need to make a smoke channel in the form of a labyrinth for efficient heat transfer. Hot air, heated by the flame of a fire, will quickly transfer its energy through the walls of the firebox to the circulating flows.

At this point, the difficulty of choice has not been overcome, since one has to give preference to one or another manufacturer, and since comparing models according to one parameter with similar indicators of the others can take an infinitely long time, we present some brands that have earned the trust of users.

Termofor. The Russian company specializes in the production of high-tech heating systems. Termofor stoves are represented by models with original names: “Fire-battery”, “Gymnasium student”, “Assistant professor”, “Professor”

It is not difficult to guess that the importance of the status hides the power of the device. In addition, all models are equipped with electronic combustion intensity control, an automatic constant temperature maintenance system, and additional cooking equipment

Eco fireplace. A popular brand from the company is a model called “Bavaria”. This is a whole range of devices that differ in characteristics. They are designed for installation in the corner of the room and against the wall. Most models are equipped with a water circuit along with the fireplace

You should pay attention to its presence when purchasing, as there are also options without it

Meta. It is gratifying that this company also represents our country. The names of the models come from the names of Russian rivers. There are known options such as Angara, Yenisei, Oka. The example shown demonstrates a device for corner placement. Firewood is used as fuel, because there is simply no better option for a summer house.

Swedish wood-burning brick stove for home

If you compare a Swedish stove with a Dutch one, its main difference will be its higher efficiency. The “Swedish” can include a hob, niches for drying clothes or shoes, an oven, a fireplace and even a bed.

Inside, the Swedish heating wood-burning stove for a brick house has a system of channels, but it also acts as a bell-type stove, in which the flue gases burn out under the arch of the firebox. Such a stove is used to heat two adjacent rooms, but it is not designed for a large area.

Among the advantages of the design are:

- more efficient use of fuel;

- high warm-up speed;

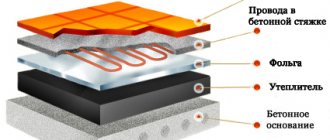

- additional heating of the floor surface due to design features;

- possibility of cooking;

- the presence of niches for drying clothes and storing dried fruits;

- possibility to build in a heat exchanger for heating water.

Here are a few disadvantages of the Swedish stove:

- during construction, some structural elements must be made of refractory bricks, which increases the cost estimate;

- to avoid heat loss through the lower section of the stove, it needs thermal insulation;

- It is advisable not to allow the stove to cool completely in winter, otherwise the masonry will gradually begin to collapse due to condensation and temperature changes during kindling.

The scope of application of the Swedish stove is small houses for permanent residence, or installation as an auxiliary heat source.

How to install a ready-made device

A stove with a fireplace can be successfully placed in different parts of the room. A corner location (or near one of the walls) is especially popular, but if there is no connection to an air duct or water circuit, it will be more effective to place the fireplace stove closer to the center of the room. The location of the chimney is of great importance: it is better to organize it so that the pipe exits at the ridge or at the edge of the roof.

Installation procedure for a finished fireplace:

- Preparing the site. In a selected area of the room, a platform is laid out from non-combustible material (with an area of 20-30 cm larger than the area of the stove). For this task, tiles, porcelain stoneware, glass magnesite, and steel sheets are suitable. It is better to sheathe the walls in the place where the stove will stand with heat-resistant material or lay them out with tiles.

- Chimney gasket. The outer part of the pipe must be insulated; it is best to lay out a brick casing. The fireplace pipe itself must be reliably protected with heat-resistant material from contact with wooden parts of the ceilings and walls.

- Connection. The stove is installed on the prepared site and the chimney is connected. If necessary, the oven can be equipped with a hob and a water circuit can be connected.

For installation in a country house, the model most often chosen is a conventional wood-burning fireplace or a long-burning one.

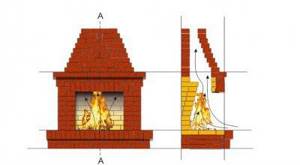

Diagram of a conventional wood stove with a fireplace

Due to their low efficiency, open-hearth fireplaces that burn wood are usually installed for decorative purposes; Most of the heat during combustion escapes through the chimney, and the room is heated by the heat of the open fire and immediately cools down when the flame burns out.

The firebox of such a device must be sufficiently wide and shallow; a protective spark catcher is installed in its upper part.

If a stove with a closed firebox is installed, the heating efficiency increases several times. In this case, the oven door is made of fire-resistant transparent glass, which allows you to admire the flames.

A box is often placed above the firebox of such a device to retain hot air - the flows exit through the side grilles and circulate inside the box, heating its walls and creating an additional heating element. Such a box must be located at a safe distance from the ceiling (at least 30 cm).

Long-burning wood-burning stove: the best in the rating for use in the country

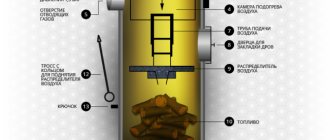

Such devices necessarily have a closed type of firebox and regulation of air flow, and the combustion chamber itself consists of two compartments. In the first, equipped with a window-door, combustion and smoldering of the fuel occurs, in the second, the gases released during combustion, mixed with oxygen, are burned out.

The duration of this combustion process is much longer than usual (up to 8-12 hours), and the temperature in the combustion chamber can reach 1000 degrees. This allows not only to heat the room using air currents, but also to effectively use the water circuit system.

In long-burning stoves, air is taken from the top of the firebox, so the firewood does not ignite in its entire volume, but slowly smolders, starting from the top layer. For heating using such devices, both ordinary firewood and various scraps, sawdust, wood chips, and peat briquettes are suitable. Thanks to its power, efficiency and autonomy, a long-burning fireplace is an ideal choice for heating a country house.

Photo 2. Drawing of a stove with a long-burning fireplace with a closed firebox. Front and side views.

Advantages of stove heating

The main advantage of stove heating for a home is the ability of brick structures to first accumulate heat and then gradually release it into the room, maintaining a comfortable temperature inside the room. In addition, if you often fire a brick stove for your home in winter, the house will always be dry and warm, and the stove draft allows you to ensure natural ventilation of the house.

At the same time, too hot summer air is vented from the house into the ground through the foundation and chimney, so it becomes cool.

Depending on the purpose of using a stove for a brick house, it can perform the following functions:

- cooking;

- drying clothes and shoes or storing dried fruits;

- warming up the beds for subsequent sleep;

- serves as a source of open fire.

If a stove performs several functions at once, it is called combined. This category includes fireplace stoves, cooking and heating stoves, some traditional varieties, in particular the Russian stove.

Among the disadvantages of brick stoves for heating a house is their lack of efficiency if we are talking about a large house with many rooms. In this case, you either need to install another similar instance, or combine the stove with other types of heating systems.

If the house is small and includes one or more rooms, the optimal location for a large brick stove will be the central part of the building. Thus, the stove will be able to extend its walls into all rooms at once. In this case, a hob with an oven is located in the kitchen, an open firebox in the living room, and a bed in the nursery or bedroom.

Types of brick stoves

There are several types of stove structures, which are built most often and are in demand because of their functionality and convenience. However, in each specific case, the furnace parameters are adjusted to the parameters desired by the customer. Let's look at the main types of stoves.

Criterias of choice

Having put together all the requirements, you will have to make a choice in favor of a specific device that can be used in the country. In order not to introduce a complex and multi-level classification of all devices, we will decide on the parameters that satisfy us.

- It is necessary to choose a device that would heat all rooms.

- This device must be equipped with a fireplace, since the presence of this addition affects the efficiency of relaxation.

- It is necessary to evaluate the performance of ready-made factory models and consider options for self-construction.

After the introduction of such restrictions, the range of available models has narrowed significantly, which will allow you to quickly determine the appropriate option.

Stove-fireplace

Steel “Fire-battery” (from 14 thousand rubles). Photo: Termofor

Fireplace stoves (as well as fireplace stoves) are devices that are equipped with a door with glass and are completely ready for installation, that is, they do not require cladding. Our market offers products from Russian companies, Meta, EcoKamin, etc.; foreign Invicta, Supra, Tim Sistem, Vermont Castings, Jotul, ABX, etc. The fireplace stove weighs 60–100 kg, which means the device can be installed even on the second floor of a house with beamed floors.

Oven AOT-06 (from 17 thousand rubles) (g), can be used for cooking. Photo: Breneran

The cost of stoves starts from 13 thousand. rub. and depends on the name of the manufacturer, dimensions, material and complexity of the design. Cast iron appliances are more expensive than steel ones (from 22 thousand rubles), are considered more resistant to high temperatures and, moreover, due to the significant (up to 10 mm) wall thickness, are able to accumulate heat. However, the vast majority of high-quality steel models (from 16 thousand rubles) are lined (finished from the inside) with fireclay blocks or plates of vermiculite (a refractory mineral), therefore they also have thermal inertia and are durable: their actual service life reaches 25 years.

Most modern fireplace stoves have a secondary combustion function; air is supplied to the flue gas combustion zone through the rear wall of the furnace (Emdip) or through injectors (Edil Kamin, La Nordica, Jotul). But to prevent additional heat from the combustion of flue gas from leaving the house through the chimney, it is necessary to provide special heat removal and heat storage elements (made of cast iron, ceramics, stone) in the lower part of the latter.

Small in size, the Ilot fireplace stove has a thermal power of 8 kW. The main features of the unit are a two-chamber firebox and a detachable decorative radiator casing. Photo: Invicta

On the market you can also find steel fireplace stoves without lining, which cost no more than 12 thousand rubles. and weigh 40–60 kg, which makes them easier to transport and install, however, the walls, made of thin (less than 3 mm) steel, can become deformed during intensive use, which leads to the destruction of welding seams.

Some stoves are lined with thin-walled ceramics or natural stone, such as soapstone. The price of this option is noticeable (from 10 thousand rubles), but the stove looks more elegant and does not emit unbearable heat, like a potbelly stove, since ceramics and potting stone absorb and dissipate part of the thermal radiation from the steel body.

Stove with ceramic finish ENBRA Pegas. Photo: ENBRA