Pellet fireplace design features

A pellet fireplace looks like an ordinary cast iron or metal stove, only instead of a blank metal door covering the firebox, a miniature door with fireproof glass is installed. Such a heating fireplace makes it possible to visually enjoy the play of flames inside the firebox.

Pellet fireplace

The next distinctive design element is the fuel supply to the fireplace. As we already know, in conventional stoves the logs are placed into the firebox by hand, but in this type everything is done automatically using an auger and an electric drive.

This type of combustion unit uses fuel in the form of pellets. Pellets are small granules of dry compressed wood that are moved along a conveyor into the firebox.

Pellet fireplace operating principle

To operate a pellet fireplace, it is necessary to fill the supply hopper with dry pressed wood pellets and set the required input parameters on the system control panel. After these manipulations, the control system enters the ignition mode, and the supply system begins to supply fuel to the furnace where it is burned. At the beginning of the process, all air systems are freed to supply air and supply smoke to the smoke exhaust system, which provides the necessary draft for the ignition itself.

After these manipulations, this unit begins to operate in normal mode. At this time, the air supply and exhaust systems are covered so that heat does not fly into the pipe. The heating of the premises itself mainly occurs through convection. The air in the floor area is colder and, due to the pressure difference, is drawn into the lower openings, into the cavity under the casing, heating up, rising up and out into the outlet openings. Thanks to this, warm air begins to circulate. After the air has completely passed through, the room heats up.

Pellet fireplace

The operating principle implemented in the designs of pellet stoves-fireplaces

Products of the mentioned design belong to long-burning furnaces. They operate on pellet pellets, implementing the principle used in convection ovens, but without most of its inherent disadvantages.

- The main difference between convection heaters is heating without the use of liquid coolant. They heat indoor air, which reduces fuel consumption and warm-up time.

- A pellet stove additionally implements this principle due to the gas generator in its design (afterburning chambers in which the gas released during combustion of pellets is burned). This ensures the production of additional heat.

- A number of models of a similar design provide for the arrangement of special convection channels (empty cavities or pipes) located around the entire perimeter of the firebox. This technical solution allows you to use the law of convection. Taking cold air from the floor through the existing openings, pellet stoves-fireplaces heat it, after which the hot air tends upward, giving off heat to the room.

- Pellets are fed into the firebox from a special tank (screw feed), where they end up on a burner or retort. The design features automatic ignition, after which the fuel burns slowly.

In order to increase efficiency, the pellet stove is equipped with additional technical devices (smoke removal systems, forced air supply, dosed supply of pellets, etc.).

Hardwood firewood for heating the stove

Deciduous trees are considered one of the best for use as firewood, but each tree of this type has its own thermal characteristics.

- Oak firewood. They have a solid structure, a long burning period, and excellent heat transfer. We can say that oak, due to its properties, is one of the most suitable for preparing firewood. Despite the fact that oak is quite expensive to purchase, it is economical and consumes more slowly than other firewood. The price is quite consistent with the thermal characteristics.

- Middle-aged oak trees are excellent for stoves; it is this wood that has optimal properties. Young oak trees have a small amount of heat, and they also fill the air with the smell of coal. If you burn with old oak, the amount of ash will increase significantly and the air will be heavy from it.

- During combustion, oak wood emits hot fire and tart forest smoke. When the fireplace is heated with oak logs, a healing atmosphere is created in the room. The healing qualities of oak logs have already been proven. Original Italian pizza is prepared only on oak wood. Moreover, in Italy it is difficult to find oak logs; they are “worth their weight in gold” there.

- Birch logs. They have special valuable qualities that people have known about since ancient times. Birch firewood is especially suitable for heating sauna stoves. With the help of birch heat, you can disinfect rooms; a wonderful aroma emanates from birch. Such firewood burns for a long time and produces a high, even flame; the fire does not spark. If you take a steam bath heated with birch firewood, colds and many chronic respiratory diseases will go away. However, here we must take into account such a property of birch as the loss of its valuable medicinal qualities just a couple of years after the birch is cut down for firewood. The fact is that birch logs become outdated quite quickly. When the log becomes rotten, such a hot fire will no longer be possible. Birch bark and the wood itself contain a lot of tar. It is a carbon compound due to which birch quickly ignites and burns intensely. This property is used to make splinters for lighting “heavy” wood. Birch has a heat transfer coefficient that is about a quarter higher than that of aspen or pine. However, the fact that birch leaves a lot of soot hinders the constant use of birch logs. Chimneys will have to be cleaned much more often.

- Alder logs. The structure of alder wood is very beautiful in color. It can be ocher, orange, bluish or even bright red. There are more than 25 species of alder, and each has its own shade of color. Alder logs can be stored for a long time, that is, they can be stored for future use for several years to come. For harvesting, as a rule, they choose places in forest areas where humidity is low, away from rivers or lakes, which is where the wood is more suitable for kindling. Alder also has a fragrant smoke that can be heard for about three years after the tree is harvested. Alder retains all other properties much longer. When burning, the heat transfer is very high, the logs almost do not smoke. In the old days, alder was used to heat a black bathhouse. On a note. When burning alder logs, the chimney ducts of the stove are cleared of soot. It is good to use alder firewood for a smokehouse; you get very tasty smoked meats. Therefore, when preparing firewood, there is no need to throw away sawdust; they will come in handy. Alder should be harvested in winter, since it is impossible to get close to it in summer - it loves swampy places.

- Linden logs. They are valued for their intense combustion and quick heating of the stove. However, it is difficult to light a linden tree; many people know this feature. Linden has the same healing properties as birch; they are successfully used to kindle baths. Once upon a time, several grams of honey were added to linden firewood and this was how they treated lung diseases and old wounds that did not heal for a long time. Linden has strong healing properties, but they last no more than two years after cutting. And this is considered the only drawback of linden logs.

Bird cherry or rowan logs like poplar and willow are classified as small-leaved species. This is low quality firewood that produces little heat. Is it possible to heat a stove with bird cherry? Yes, only if you got it for free. Paying for low-grade wood—even very low prices—is overpaying. Such firewood will burn quickly, and you will have to add such logs to the firebox much more often. But there is no harm from such wood either. That is, the only drawback is that a large amount of firewood is required.

What is long burning in heating stoves?

As is known, the intensity of the fuel combustion process depends on the amount of oxygen supplied. If there is enough fuel, the fuel burns intensely, releasing a large amount of heat, but the fuel burns quickly. With limited air supply, combustion can enter the smoldering stage, in which even flames are not always observed.

A solid fuel stove with a sealed door can be switched to smoldering mode

In principle, any furnace can be switched to a long-burning mode by manipulating the valves. Another thing is that not all of them are designed for this mode. Conventional stoves with closed valves can even be dangerous - in smoldering mode they can become a source of smoke or carbon monoxide. So it’s better to look for a fireplace stove for a summer house whose characteristics include the line “long burning” and the maximum burning time for one bookmark. This could be 6-18 hours.

How to determine whether a stove supports long burning or not

One of the characteristics by which you can distinguish a long-burning fireplace stove for a summer residence from a conventional heating stove is its sealed design. After all, you need to make sure that air flows in the right quantity. No more and no less. The second sign is the presence of several adjustable dampers.

Dampers and dampers must be airtight (the photo shows the ash pan door of the Nordika stove)

The tightness can only be checked during combustion, but the presence of dampers can be monitored visually and how tightly they block the access of air, you can also see how well they move. In some models, the air supply is adjusted through the ash drawer. In this case, you need to look at how well it “moves” and how tightly it blocks the air supply. Although the ash box cannot be airtight, it should not leave large holes either. You can also track the presence of a seal on the door, a gate on the pipe. All these are criteria by which you can determine whether a given fireplace stove supports long-term combustion.

With afterburning of gases

How else do long-burning stoves differ from conventional ones? The fact that they can be used to burn gases that are formed during the combustion of wood. In conventional furnaces, these gases escape into the chimney, since their ignition requires a special regime - high temperature and limited access of air. In long-burning furnaces, the fuel chamber can be divided into several parts. In one firewood burns, in the rest there are gases that were formed during the decomposition of fuel. Such furnaces are also called gas generators, since it is in the smoldering mode that the largest amount of gases is formed. What is characteristic is that most of them have a calorific value higher than that of the fuel during the decomposition of which they were formed. So when using conventional ovens, a significant portion of the heat is lost. That is why it is believed that a long-burning fireplace stove is more profitable for a summer house or home, since it requires less fuel.

The technical specifications should contain a line stating that this model supports a long-burning mode. There should also be a maximum time on one tab in long-burning mode

The downside is that a long-burning fireplace for a summer house or home costs a lot of money. The price tag for models that support long-term combustion starts from $400-450, if it is a Russian manufacturer and the body is made of structural steel. Domestic stainless steel costs twice as much, and cast iron costs twice as much. Imported fireplace stoves with a long-burning function, with the same characteristics, are approximately 70-100% more expensive.

The difference between a classic open fireplace and a fireplace stove

A classic open-type fireplace is only an additional source of heat that cannot heat a room in cold weather. It gives heat in small quantities, it spreads only during the combustion of the fuel, and immediately before the firebox. This type of heating device is good for a damp summer or autumn/spring day. In winter, it is not able to provide enough heat for the entire room, since its operation requires good draft, which “pulls out” most of the heat.

One of the simplest models: a long-burning fireplace stove for a summer house and home “Bavaria”. Manufacturer – EKOKAMIN (Russia)

The fireplace stove has different characteristics, a closed firebox. Such a unit can heat the room independently (with correctly selected power). And a long-burning fireplace stove for the country house and home also does this economically, as it uses fuel energy to the maximum.

Is it possible to burn a regular stove with pellets?

It was previously mentioned that pellets are extremely active in everyday life, but a special stove and burner system is required to ensure a normal flame and a uniform heat transfer process.

Despite a number of limitations, pellets can be burned without much difficulty in a conventional stove, however, the advantages of fuel in this format of use are often lost.

The main positive features of the material are:

- Long burning life;

- Low emission of smoke and toxic substances;

- High amount of thermal energy;

- Burnout uniformity.

If you plan to burn pellets in a standard stove without significantly upgrading it, then they will simply burn like regular firewood. Due to their high cost, this format of use becomes unprofitable.

Most often, minor modifications are required according to proven schemes. All of them differ from each other in their complexity, cost of implementation and the need for additional equipment. Despite all the difficulties, already in the first hours after the upgrade you will be able to forget about the difficulties that haunted you earlier.

Using a pellet burner for a stove

Pellet burners are a universal device that fully automates the fuel supply process and maintains a given temperature.

Today on the market you can find a large number of models that have proven themselves successfully. They can operate both using electrical energy and compressed gas. The first option is safer, since the energy supply can be instantly limited in case of an emergency.

Example of a pellet burner

An important feature of such burners is the automated fuel supply mechanism, which does not require outside intervention. All you need to do is enter the settings, check their correctness, change them to the required values if necessary, and then just monitor the availability of fuel

Modern pellet burners have several main parts, including:

- Transport fuel supply mechanism;

- Ignition and fire control systems;

- Microprocessor for automated control of the combustion process;

- The actual body.

The cost of such products is quite high, but the comfort they provide is worth the money spent!

Design and principle of operation

In a brick oven

Installing a burner in a brick oven is quite simple:

- The burner body itself is inserted into the oven, and then carefully secured with screws and other materials.

- Usually there is no gap between the furnace mouth and the burner wall, however, if there is a large diameter hole, it is recommended to seal it with specialized sealants.

- If the burner is electrically powered, the power cable must be protected from high temperatures. It is usually vented away from the furnace and direct flame exposure, so no additional design modification is required.

- The last step is to secure the pellet storage chamber on top of the burner. The case has a special mechanism, so you only need to install it in the appropriate grooves.

Examples of installation in the photo:

Photo 1

Photo 2

In a metal oven

Installing a pellet burner on a metal stove is practically no different from the brick version

The only thing you should pay attention to is to prevent contact of the burner body with the walls of the furnace, since high temperatures can lead to failure of the mechanism

Installation example

Pellet burner installed in a potbelly stove with a hopper

Pellet loading technique

Heating a simple brick stove with pellets is quite simple. If the burner has an electric ignition mechanism, then you just need to press a special button. Cheaper models do not have this functionality, so a gas burner is used.

The combustion rules are quite simple - fuel should be supplied evenly and fairly slowly. If a large amount of ash is formed, then the feed rate should be reduced, since the pellets simply do not have time to burn, but melt under the influence of high temperature.

Installation

The installation method for a homemade pellet boiler is practically no different from the installation of other types of solid fuel equipment. The main task in this case is to correctly place the boiler itself and the fuel supply auger. A distance of 70 cm must be maintained between the individual modules, and 2 meters of free space must be left in front of the boiler itself. The supply of coolant to the heating boiler at the time of its ignition can lead to condensation with ash and soot. It is very difficult to remove. Therefore, during the installation of the boiler, it is connected to the water circuit, in which the mixing unit is built-in.

As a rule, a three-way valve is used, which supplies coolant inside the water jacket only after warming up to the appropriate temperature. In this case, the circulation pump forces the water to circulate in a small circle. As soon as it heats up, the three-way valve gradually mixes it into the coolant of the heating circuit until it completely closes the small circle.

Please note that system security must be ensured. It assumes the presence of a pressure sensor and a safety valve installed on the outlet pipe. These measures are mandatory so that the oven can be used without any danger.

In conclusion, we note that the efficiency of industrially produced pellet stoves is much higher. However, homemade devices are much cheaper and more reliable in operation.

Mistakes when using pellet stoves

A pellet boiler can be expensive and of high quality, but if the choice of the device was wrong, disappointment is inevitable. The main mistake lies in the general incompatibility of the boiler with the goals of consumers. It is necessary to clearly understand your needs and how much the oven can satisfy them. First of all, equipment must be assessed in terms of its type and selection criteria.

A common mistake is incorrect calculation of boiler power and room heat loss. The result is too low or too high a temperature. It is better to spend more time, but make the right calculations. It’s even better to entrust this to a specialist.

Poor furnace performance is another annoying problem. It is usually connected (if we are not talking about low-quality equipment) with the typical realities for Russia - mentioned by the poor quality of electrical networks and fuel.

Let's briefly list three more possible troubles:

- chimney sparking; the reason is the wrong choice of the latter;

- wood dust flying around the room; the reason is an incorrect choice of location for the stove;

- increased frequency of filling the ash pan; The reason is incorrect setting of the pellet burner.

Operating principle of a pellet stove

Pellet stoves are equipped with a special tank for a certain number of pellets. Pellets can be stacked on the side or on top. There are some differences: if pellet stoves are loaded from above, then their productivity is greater, but the quality of the pellets must be high. Side-loading pellet stoves require such a fastidious attitude to the quality of fuel.

The volume of the pellet loading tank may vary. The duration of operation of the furnace, as well as the frequency of loading fuel into the tank, depends on this. For most home and garden stoves, the standard period of operation without adding fuel is several days. The pellet stove has a control unit that regulates the intensity of the flame. You can use a thermostat that will be connected externally. During regular use, it will be necessary to clean the ash pan of the pellet stove at intervals of 1 week.

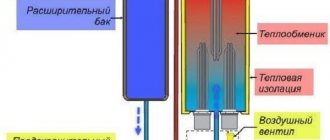

Construction of stoves operating on fuel pellets

Figure 3. Construction of a pellet stove

*

Granulated pellet stoves have the following design:

- metal body – high-quality stainless steel or cast iron;

- bunker area for filling fuel; some models are designed for external bins;

- an electric auger that feeds granules in portions into the combustion chamber;

- fan; its purpose is to supply cold air from the room into the device and remove hot air (along with exhaust) to the outside;

- firebox;

- burner;

- ash pan - an element for collecting wood waste;

- heat exchanger designed to circulate cold/hot air;

- thermostat and control panel.

Gray or white: which pellets are better?

In the process of producing gray fuel, timber waste is used as a raw material, which contains bark, which gives the granules an ashen tint, while increasing the ash content. Darkening of the fuel is possible if the drying process of the raw material proceeded at approximately 200 °C. In this case, a significant contribution to the future color of the fuel is made precisely by the temperature, and not by the bark.

The light yellow color of pellets is given by raw materials from carpentry waste or wood processing. Drying of the material is not required, since it was carried out at the production stage, where the temperature reached no more than 100 °C.

There is a misconception that gray granules are not recommended for heating specialized boilers. You can often find pellets made from debarked slab chips, the ash content of which is approximately 0.6%, but they are dark in color because they were dried at high temperatures.

For this reason, first of all it is necessary to pay attention to the percentage of ash content, and not to the color of the fuel. If the indicator does not exceed 1%, then you will have to clean the ashpit much less often than with a higher percentage, but the price of white granules is significantly higher

What are pellet stoves?

Pellet boilers, or fireplaces, are structures that heat rooms by burning a special type of fuel - pellets. The latter are small pressed pellets made from wood waste. The fuel is completely safe – the absence of any harmful substances makes it environmentally friendly. Including glue.

Pellets come in two main types:

- industrial; they are made from different types of waste, so the consumption of granules is higher, and the efficiency of the furnace is lower;

- household; These are made from high-quality raw materials, and therefore the thermal efficiency is much higher.

To load boilers in private buildings, it is recommended to use only the latter type. Moreover, it is advisable to select pellets based on the characteristics of a particular device - this will increase the heat transfer and service life of the stove.

Advantages and disadvantages

The positive qualities of pellet installations include:

Fully automatic. Fuel is supplied automatically in accordance with the set heating power. There is a function for programming the exact operating time of the equipment for a whole week. In this way, you can program the time to turn the fireplace on and off at any time of the day or night.

High efficiency indicators. In these devices, the efficiency is 2 times higher than that of a fireplace with an open flame. Thanks to the water circuit, you can connect additional radiators to heat other rooms.

Fire safety. Automatic control ensures safety throughout the entire heating process. When the device is turned off, all pellets in the burner are completely burned. A small amount of fuel burns out and the fireplace turns off. This process is carried out within 5-10 minutes after shutdown.

Does not dry out the air in the room. In the room where the pellet fireplace is installed, the air is not burned. This is due to the fact that the supplied combustion stream is separated from the surrounding air. Typically, this is done using an air circuit that takes oxygen from the basement while simultaneously drying out the space at high humidity.

Can be controlled remotely. The remote control function helps you control the operation of the equipment from anywhere in the room. Once you fill the fuel tank, you can go without adding more pellets for several days.

Pellet equipment with a water jacket performs several functions simultaneously and opens up the following possibilities:

- The pellets themselves are made of the same size and therefore it is possible to use automatic fuel supply in fireplaces.

- A constant supply of pellets can keep the heating system in active mode for 6 hours, and sometimes for about a day. The operating time is related to the operating characteristics of each system.

- By adjusting the fuel supply, you can adjust the temperature in the room.

- For normal operation there is no need to install an expensive chimney. For pellet structures, you can install the most common stainless steel chimney. In any case, the draft will be good, since the water circuit warms the internal air and accelerates the release of exhaust gases.

- Ease of installation, especially if you already have a ready-made fireplace, then pellet equipment is installed inside.

- Economy and financial costs are equal to wood-burning stoves with a water circuit or a regular fireplace. This means that pellets are more profitable to use for heating than gas or electricity.

Along with the numerous advantages of this type of heating equipment, it has the following disadvantages:

- Expensive equipment. Not all consumers can afford to pay a high price for this design; its cost is significantly higher than that of wood-burning fireplaces.

- Stopping the entire system during a power outage. A very small amount of electricity is required to operate, although in its absence the operation stops completely.

- Only pellets are used as fuel. It is impossible to replace special pellets with other fuel.

- This equipment has low performance and cannot be used as the main heating system. It is usually combined with other heating methods.

By combining a pellet fireplace with a gas boiler or electric heater, you can save a significant amount of money. At the same time, the room is additionally decorated with the appearance of a live fire in a designer fireplace.

Blagodarova gas generator boiler

During the operation of the Blagodarov boiler, all substances produced as a result of combustion are burned.

The design of such equipment consists of 3 parts. These are combustion and gasification chambers and a bunker for burning fuel combustion elements. The fuel material burns in the 1st of 2 chambers, and in the 3rd it becomes a gas.

The undoubted advantage of this heating equipment is long-term fuel combustion (the device is superior to other heating boilers in this indicator) and good heat transfer. Regardless of electricity, it always produces the power that is required.

During the combustion of firewood and wood processing waste, the grate covering the bottom of the fuel chamber contributes to the formation of a high level of heat under natural draft conditions. With a Blagodarov boiler, you can expand the volume of the fuel bunker without affecting the efficiency of the device. The rails installed in the combustion chamber are a good heat accumulator.

Coal, sawdust, and peat can be used as fuel. In winter, the fuel chamber can be regularly replenished so that the optimal temperature regime is maintained in the heated room.

Profitable arithmetic

Before installing a pellet fireplace, it is necessary to consider issues of feasibility and profitability. First of all, do not forget that the fireplace is not a complete source of heat. However, this type of fireplace is not suitable as an additional source due to its high cost.

Good to know: Main types of fireplaces, we classify devices according to different criteria

Fireplace power ratings range from 3 to 15 kW. Theoretically, a power of 1 kW is enough to heat 10-15 m2 of area. But the increased efficiency, which reaches 95%, increases coverage. However, there are some recommendations for choosing a fireplace or boiler. Up to 100 m2 can be safely heated with a fireplace. The fireplace will also cope with an area from 100 to 300 m2, but here boilers begin to enter the “arena”, and indicators over 300 m2 are not available for fireplaces.

Mobile home heating device

Choosing a pellet fireplace for heating a frame house

When choosing a pellet boiler, I was horrified by their appearance - such a monster should be placed in a separate room and people who need to be scared should be allowed there on a tour. I didn’t want to have a separate technical room at all: our house is not big. I wanted to have a fireplace with a live fire. So in the evening, turn off the light in the living room and sit on the sofa, drink hot wine, and look at the reflections of the fire on the walls, out of the corner of your eye seeing snowdrifts and snow-covered conifers outside the window.

A solution was found - a pellet fireplace with a water circuit - an aqua fireplace. I also immediately chose the model - Laminox ESTER IDRO 15 “all in one”:

— safety valve — expansion tank — circulation pump — automatic air vent

According to my calculations, a power of 15 kW was enough for a house. But after calling a company that exclusively supplies Italians and deals with connecting and servicing aqua fireplaces, my choice was finally formed: LAMINOX ELISA PHANTOM IDRO 16 - a flat burgundy-colored aqua fireplace with a vertical outlet.

Well, I can now say that the choice was right. The aqua fireplace works quietly - the monotonous rustling of the fan. You can't hear the pellet feeding screws at all.

The chimney is 8 cm - I ordered a 10 cm sandwich, painted brown - it fits into the future interior. The chimney on the roof does not smoke and does not give itself away in any way. Sometimes with a gust of wind you can catch a sweetish aroma - this is what a good Italian liqueur smells like.

At night I see reflections of flames on the windows of the first floor - while the house is drying and finishing, the aqua fireplace is working around the clock. Consumption of pellets (I bought 2 tons for testing) per day, one bag of 15 kg. In the future it will consume less.

The aqua fireplace is controlled automatically. 5 buttons and menu. You can set the combustion power and the room temperature that the aqua fireplace will maintain.

The only inconvenience: the aqua fireplace hopper for pellets is 15 kg. That is, you have to add pellets once a day. Therefore, despite the fact that you can connect an Internet module to the aqua fireplace for remote control of heating (for example, while in Thailand a few days before arrival, set the temperature in the house to 23-24 degrees), this task cannot be realized due to the limited capacity of the bunker.

You can come up with something with installing an external bunker and increasing the volume to 200-300 kg, but it won’t be pretty. Therefore, here: - either beauty and aesthetics - or practicality

We chose beauty and aesthetics.

Practical recommendations

Before you start assembling a pellet fireplace stove, you should decide what parts you need to purchase - we are talking about the burner and industrial automation. You should not experiment and assemble the burner yourself. Even if a lot of effort is put into it, its functionality may be very questionable.

It is best to purchase ready-made elements and use them later when assembling a pellet stove. If you make the boiler multifunctional, that is, provide it with a water circuit and the ability to work both on pellets for the fireplace, and on wood and coal, then in the future it can be modernized.

It is worth noting that heat exchange in these types of heating will differ only in the type of solid fuel and the method of its combustion.

The advantages of a universal boiler will be:

- If there are interruptions in the supply of pellets for the boiler, the boiler can still be used. To do this, remove one burner and put on another to heat the stove with prepared wood and coal.

- Alternatively, you can install a special burner in the boiler for burning natural gas or liquid fuel.

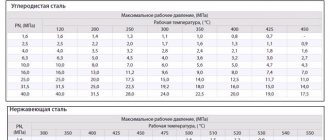

The combustion chamber is usually made of heat-resistant steel 5 mm thick. It is advisable to use ST20 carbon steel for these purposes, but the casing can be made of ST3 sheet steel with a thickness of 3 mm. The fire tubes and chamber doors are made of 6 mm steel, and the grate should be as much as 10 mm thick. In order not to bother with purchasing and assembling parts, sometimes it is much easier to purchase ready-made equipment.

If you make the boiler yourself, you will need a welding machine. The water grate must have very rigid walls. To do this, metal corners or pieces of reinforcement are sometimes welded onto them. At the end of the work, it is necessary to double-check the reliability of all welds. If flaws are found, they must be eliminated.

Key Features

The reliability of a pellet boiler, like any equipment, is expressed in the warranty period, overhaul and service intervals. As a device for producing energy and transferring it to a coolant, the device is characterized by:

- energy efficiency of fuel combustion;

- power;

- battery life on one tab.

Thermal power, what is the smallest

How much heat is generated per unit of time as a result of fuel combustion is shown by the main characteristic of the heat generator - thermal power.

It is selected based on the purpose of the room, area, ceiling height, heat loss when passing through the enclosing structures.

The power values of a pellet boiler are in the range of 12–500 kW.

Less power makes the device unprofitable; with more power it loses its advantages over other heat generators:

- works with efficiency - less efficiently than gas, liquid fuel, coal boilers;

- fails after 3-5 years.

Efficiency

The efficiency of the device shows what share the pellet boiler was able to “take” out of the calculated amount of heat that the fuel “gave up” during combustion. Efficiency is reduced by insufficient or excessive loading of the firebox, low-quality fuel, and improper operation of equipment.

The higher the heat of combustion, the more efficient the fuel. The leaders in efficiency are fuel oil and diesel. The combustion heat of pellets is 2.4–4.3 times lower and depends on the type of feedstock:

- woody - 17.5-19 (MJ/kg);

- straw - 14.5;

- peat - 10.

According to this indicator, granules from wood processing waste are comparable to coal (15-25 MJ/kg) and superior to the source material - sawdust, wood chips, shavings (10 MJ/kg).

Fuel consumption and bunker capacity

The average annual consumption of recycled wood pellets is 1/5 less than brown coal (by weight) and several times less than lump wood (it is more moist and less dense).

The exact figure depends on the properties of the boiler and its operating settings, as well as on the volume of the heated room, the material and design of the external walls.

The volume of the pellet bunker determines how long the heating boiler will not require human intervention and varies from tens of liters to a cubic meter or more.

Reference.

Automation of fuel supply is possible if it is initially provided for by the boiler design. The fire safety distances in the boiler room also depend on the volume of the bunker.

Additional functions

Automation of the operation of a pellet boiler is not limited to the mechanized supply of fuel from the operational reserve to the burner. Boiler models with additional functions reduce manual labor for servicing the unit to a minimum:

- optical elements control the flame;

- the electric spiral ignites the fuel supply;

- water temperature and pressure are measured by a thermomanometer;

- thermostats turn the burner and pump on and off, protect the system from overheating;

- The boiler power is adjusted by the potentiometer;

- The fuel burnout sensor reacts to the temperature of the burner surface.

This is an incomplete list of electronic, mechanical, and chemical devices that a manufacturer can equip its products with.

A high degree of automation allows the pellet boiler to operate without human intervention for more than 7 days. Communication with a personal computer makes control remote. Cleaning or replacing the ash pan manually takes no more than half an hour.

Important! The technical parameters of a pellet boiler declared by the manufacturer are the result of tests carried out with the prescribed fuel. The instructions for the device contain requirements for the quality of pellets: grain size (mm), calorific value (J/kg), humidity (%), ash content (%). The properties of the fuel affect the power and efficiency of the heat generator

The properties of the fuel affect the power and efficiency of the heat generator.

Advantages of the fuel used

To operate such fireplaces, small compressed granules – pellets – are used. They consist of waste obtained from wood processing. To form the pellets, shavings and sawdust are compressed under high pressure without the addition of chemicals.

Pellets are cylindrical in shape and are produced in a length of no more than seventy millimeters. Their maximum diameter is nine millimeters, which, unlike firewood, makes storage much easier. Also, compressed wood raw materials have a number of other advantages:

- Environmentally friendly fuel. Wood pellets do not have toxic impurities and are completely safe for the environment. Their use does not cause allergic reactions.

- Increased level of heat transfer. The heat exchange of pellets is two and a half times higher than that of firewood.

- Safety. The granules do not contain dust and are not at all susceptible to self-ignition.

- Compactness. Due to the small size of pellets, they are not difficult to transport and store.

- Absolute automation of the heating process. The homogeneity and small size of compressed wood fuel allows for automated loading of raw materials into heating appliances.

The moisture content in pellets is half that of firewood, which allows you to get more heat during their combustion.

Light the stove and add wood

First, the seed is made. Tree bark or crumpled newspaper is placed on the grates in the stove opening. Wood chips and finely chopped logs are placed on top. Gaps must be left between them so as not to interfere with the free circulation of air. Do not use gasoline for ignition. This is fraught with the risk of a fire, and the released steam will lose its healing properties due to the presence of chemicals in it.

The order of kindling is as follows:

- We ignite the seed from below. We close the firebox door so that no smoke comes into the dressing room and the flame flares up well.

- If a steady sound comes from there, there is combustion. If it is absent, the procedure is repeated again.

- You need to close the ashpit and open the valve.

- Firewood is added at intervals of 5-15 minutes. It all depends on the degree of dryness and heating of the stove.

- After the first batch has burned out, the firebox door is opened, the coals are leveled with a poker and logs are laid.

- Firewood must be placed so that the distance between it and the top of the firebox is at least 25 cm. Fuel is placed closer to the door, away from the chimney.

- During the combustion process, you need to monitor the water level in the boiler and add it as needed.

To heat the sauna faster, it is not advisable to water the heater during the heating process. It is better to wait until the bath procedures begin.