Today, many homeowners prefer heating systems for residential premises, in which the leading place is given to warm water floors. Using the thermal energy of liquid coolant, you can achieve high quality performance in home heating. The design of the heating system itself, at first glance, gives every reason to consider this heating method effective. The operating principle of water floors is fundamentally different from traditional heating methods. In this situation, the functionality of each element, device and device included in a single complex of equipment is important.

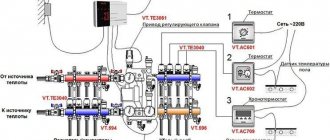

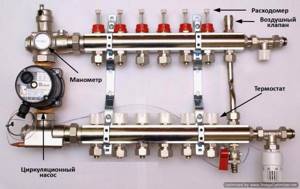

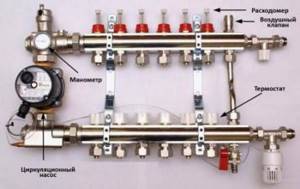

Mixing unit for underfloor heating system with flow meters and thermostats

The high-quality operation of the heating system largely depends on how efficiently the coolant is used in the pipelines of water floors. This task is accomplished by underfloor heating collectors, which together with flow meters ensure rational distribution of boiler water into the heating circuits. What is the technological connection “collector – flow meter”, how important are its functions, and how does it work? Let's try to get acquainted with these and many other issues in more detail.

The feasibility of installing a collector system

But it is impossible to install a collector heating system in an apartment of old multi-storey buildings, because a tee heating system is already working there.

For the collector system to operate, it is necessary to close the hydraulic circuit, which is necessary to create coolant circulation in the system. If a closed hydraulic circuit is created in one apartment, then other apartments will be cut off from the heating system. The collector heating system also cannot be used in areas with unstable power supply, since when the circulation pump stops, the water will freeze and the pipes will fail. But the situation can be somewhat improved by using

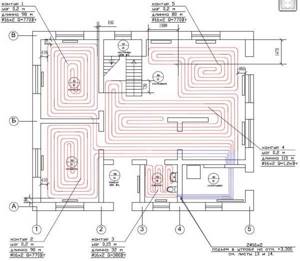

Solving the problem with underfloor heating contours

By connecting underfloor heating circuits to one manifold group, you can balance them in two ways:

- The first method involves creating even rings, but you can put several of them in one room, for example, you can put one heating ring in the bathroom, three in the guest room, and two in the kitchen. Likewise, the heating of all rings will be the same.

- If you do not want to create several rings in one residential area, then there is also a solution for you. Heating circuits can be of different lengths, but they should be connected through a specialized device - a flow meter

for heated floors.

A flow meter

or rotameter is a combination of balancing valves that limit the amount of coolant released into the system. You can see an example of a rotameter in the photo.

Collector heating system. Principles of its work.

How to install a mixing unit for a heated floor with your own hands

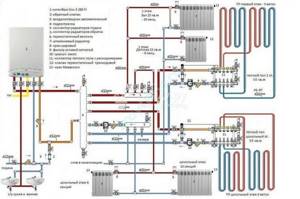

As I said earlier, this type of heating system is most often used in two or more storey buildings. But no one will forbid you to use it in a one-story house. It all depends on expediency. In addition to heating devices, an indirect heating boiler or a heating system for a swimming pool or greenhouse can be connected to the collector. So in a one-story house you can use this kind of trick. The main thing is not to forget that in a collector heating system there can only be forced circulation of the coolant. This means that it must have at least one, and most often several, circulation pumps. Look at the picture below:

The figure shows a diagram without an indirect heating boiler. This is done here because a double-circuit gas boiler is used. Well, if the boiler is single-circuit, then everything will look a little different:

It has everything modern homeowners love:

- Radiators.

- Water heated floors.

- Backup electric boiler.

- Indirect heating boiler.

If you don’t count them together with the boiler pump, then there will be 5 of them. To ensure that the circulation pumps do not create a pressure difference between the “supply” manifold and the “return” manifold, a hydraulic arrow is used here. Thanks to it, the boiler circulation pump can always provide the required coolant flow through the boiler heat exchanger, which has a positive effect on its service life. The underfloor heating circuits are connected through their collectors with autonomous circulation groups. Here you need to take into account the possibility of an emergency power outage. To ensure the operation of the “brain” of the boiler and circulation pumps during a shutdown, you will need. Without it, the circulation of coolant in the system will stop, and this is fraught with all sorts of unpleasant consequences.

The main advantage of this heating scheme is the ability to turn off individual branches without stopping the entire system. This feature is very helpful in case of emergency repairs. Well, the downside will probably be the price of all this pleasure. Although, if you are doing it for yourself and for a long time, then it makes sense to do everything wisely. Otherwise, your stinginess will make you pay twice! On this optimistic note, I will end this post, I look forward to your questions and likes on social networks!

Collector installation

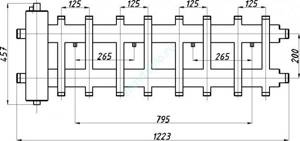

The collector unit is usually mounted in a cabinet, which is mounted on the wall or built into it. It is necessary to provide quick and free access to the collector unit. If heated floors are installed throughout the house, then it is better to install the collector in its central part. The optimal height for mounting the collector unit is at a distance of a meter from the finished floor surface.

Installation begins with the installation of shut-off valves (taps, valves), adapters, an air vent, a thermostatic head, a flow meter (unit configuration according to the project) and brackets for installation on the wall using dowel screws or in a cabinet (the manifold cabinet has guides and bolt fastenings) on the manifolds for collectors). It is necessary to install a ball valve on the return manifold to drain the system. Adapters should be selected from the same material as the manifold. The connection between the collector and the pipe coming from the boiler must be detachable. It is also possible to purchase an assembled collector unit.

To connect the manifold to the metal-plastic pipes of the circuits, the end of each pipe is flared and its internal diameter is cleared of burrs, after which a nut and a crimp washer are put on the pipe. The pipe is carefully installed on the outlet (inlet) of the manifold so as not to damage the O-rings; the nut is first tightened by hand, then tightened with a wrench. During installation, the pipe outlets point downwards, the air vent is directed upwards. Thermostatic heads that regulate the movement of the coolant are mounted on the return manifold.

Connecting the circuits to the manifold and commissioning of the water heated floor system is carried out before the screed is poured. This is the only way to ensure that the installation is done efficiently and all joints are completely sealed. provides a long-term warranty on “Water Heated Floor” systems installed by its specialists.

View other services: installation of home heating systems, installation of a water floor from metal-plastic pipes

Electromagnetic flow meters

Connecting a heated floor to a thermostat

Their operating principle is based on the law of electromagnetic induction, according to which an emf is induced in an electrically conductive liquid passing through an electromagnetic field, proportional to the speed of the flow (conductor).

Such flow meters have found application in volumetric metering systems for coolant and water at industrial and energy enterprises. Disadvantage: high cost and weight for diameters greater than 300-400 mm, difficulty in removing for verification.

Rod electromagnetic water meters operate on the principle of immersing a sensor in a liquid, where the flow rate is measured. Such meters determine the flow of cold water in completely filled pipelines.

Balancing the heating circuit

In order to correctly balance the amount of coolant supplied to the circuits, follow the instructions:

- Calculate the total amount of coolant in liters that flows through the manifold with flow meters for heated floors within one minute. Take the result you get as 100%.

- Next, find the percentage consumption of each heating ring and convert them to liters/min.

- Next, use the tap on the rotameter to adjust the amount of coolant supplied.

- With these actions you will make a tentative balancing of the heating circuit, so in order to set the actual values, you need to monitor the rotameter indicators, thanks to which you can calculate the costs of the circuits connected to the collector.

Selection, installation and adjustment of flow meters

Which electric boiler for heated floors is better to choose?

A water heated floor, as a rule, consists of several circuits of plastic pipes. Hot water, moving through them, gives off its heat and returns through the return supply part of the system. The collector (comb system) of a warm water floor is designed to collect cooled water, mix and supply heated water. In other words, this is a unit that controls the operation of the floor heating system.

To regulate the temperature, flow meters are provided in the manifold. These devices control the flow of coolant, in this case water.

Why do you need a flow meter?

Theoretically, it is quite possible to do without installing a flow meter in the manifold. However, if you do not install this device, then:

- Different rooms will have different temperatures;

- There may be excessive consumption of electricity to heat water in the system;

- Different circuits will heat up unevenly.

A simple example can be given: a bathroom and a bedroom. A gas or electric boiler heats water equally for both the bath and the bedroom. But the bathroom is at least 3 times smaller in area than the bedroom.

Accordingly, the bathroom will be hot and the bedroom will be cool with the same water supply to the floor heating system. This situation is due to the fact that in the bedroom the total length of plastic pipes in the area is much greater.

It is precisely in order to regulate a comfortable temperature in the entire apartment that it is desirable to install such a device.

Advice! When installing a water heated floor, you should strive to make the contours of the pipes approximately the same length. This will save energy costs and allow you to more accurately regulate the temperature.

Principle of operation

The device is installed on the return collector outlets. When the set temperature in the system is reached, the manifold valves narrow the lumen of the energy supply or close it completely. This principle of operation is possible with full automation of the system. For this purpose, the collector is equipped with a temperature sensor.

The flow meter itself consists of several parts:

- Frame;

- Transparent flask with scale;

- Float.

The flask is usually made of durable glass; the body can be plastic or brass. The float is located inside the flask; it serves as an indicator of the coolant speed. The flow meter is also called a float rotameter.

In an automatic water heated floor collector, balancing of coolant flow is carried out using a temperature sensor. If the latter is not provided, then the rotameter can be adjusted manually.

Step-by-step instructions for installation and adjustment

H2_2

The rotameter is installed strictly vertically. To ensure that the liquid level in the flask is accurate, the collector itself is also mounted according to the level. If the comb pipe is installed crookedly, the temperature adjustment will be incorrect.

Since finishing work often occurs after installation of the collector, it is necessary to protect the assembly and its components from possible damage. The best option is to make a niche or a special cabinet for it in the wall.

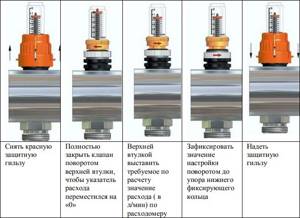

Installation and adjustment:

- Using a wrench, screw the flow meter into the process inlet of the return line of the manifold;

- Turn the membrane (flask) counterclockwise to open the pressure meter;

- Remove the factory protective ring;

- Turn the brass housing ring clockwise to the desired pressure level. This is balancing the energy flow rate. The float on the scale will indicate the set value;

- Cover the brass ring with a cover plate. This must be done to avoid damage to the device, especially if the water heated floor unit is not closed in a niche or cabinet;

- Check the system operation.

During operation of the unit, the flask remains open so that the level of the water float is visible. If balancing is needed during operation, the membrane is simply turned in the desired direction.

Choosing a flow meter for water heated floors

High-quality rotameters should be accompanied by a guarantee of 5-7 years of stable operation. It is recommended to choose flow meters with a brass body

You should also pay attention to the flask; it should be made of transparent glass with good visibility of the water level scale. However, there is an opinion that it is better to choose products with a membrane made of impact-resistant plastic

When choosing a device, you need to take into account the area of the pipeline system

It is also important whether the node is automated or not. In the first case, balancing will be necessary extremely rarely; mechanized collectors require closer attention

Source:

In what case should collector-beam connection of radiators be preferred?

Radiant heating distribution is preferable for large areas of heated private houses (as well as in modern apartments when pipes are laid along the floor). When the goal is not to save money and it is necessary to maintain the aesthetic component of the interior. In other respects, this is one of the best (if not the best) heating layout schemes.

All pipes in the system run through the floor screed and do not interfere with further finishing of the room. Nothing sticks out anywhere. Radiators are connected from the floor, or better yet, from the wall. After installation, we will only be able to observe the heating radiators themselves and no additional pipes on the walls.

This wiring got its name by analogy with its appearance. Pipes radiate from the collector group to the radiators. Hence the name collector-radiant heating system.

Manual adjustment of coolant temperature

How you adjust the temperature will depend entirely on the equipment you are using. For example, if a system with a temperature controller and a servo drive is installed, then the setup is carried out according to the instructions from the manufacturer of this device. In this case, the adjustment is performed automatically. Now let's look at the manual method of setting the temperature using thermal heads.

Thermal heads can be installed both on the supply and return side of the coolant.

First of all, the system up to the heated floor must be completely filled with coolant and freed from air.

But it is important not to rush here, otherwise air jams may form. If the connection was made from the boiler, then before starting water into the heating circuits, turn off all taps

Afterwards, open the supply/return loop on one loop, filling it with coolant. The air should come out of it through the air vent. Now turn on the circulation pump so that the coolant begins to move in this loop. At the same time, turn the temperature on the boiler to 35°. To the touch you should feel that hot water is flowing in the return and supply in the heating circuit. If everything works properly, close this loop and open a new one. Using this method, you pump and check each loop of the heating circuit. When you have configured each circuit, you open all the taps and adjust the required temperature by touch. In some loops the faucet will need to be opened completely, while in others it is enough to open it slightly.

The coolant temperature in each circuit may be different. There are several reasons for this, such as the length of the loop. The shorter the circuit, the faster it warms up and vice versa.

Thus, manual temperature adjustment is carried out. It is enough to do it once a year. But here it is important to take into account the nuance. The underfloor heating system is inertial. What does this mean in practice? If you make changes to one of the hinges, you will have to wait several hours to notice a noticeable change in the temperature inside the room.

If you installed flow meters on the collector, the difference between the readings can reach up to 0.5 liters.

Radiators and heated floors - working together, how it is ensured and regulated

It is recommended to create a combined heating system in houses - radiators with heated floors. In this case, the energy comes from one boiler, the hydraulic circuits are interconnected. It is also necessary to coordinate their operating modes. Many people are interested in the question - how to properly configure warm floors and radiators to work together? And preferably in automatic mode - in order to devote less time to the issue and not delve into unnecessary details...

Are radiators needed for heated floors?

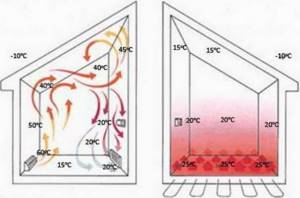

Many people want to save money and limit themselves to one thing. Warm floors look preferable due to their special comfort. Then why not heat with one heated floor? In fact, in the conditions of the middle latitudes of the European part (rare frosts down to -30 degrees), this can be done. But only if you put up with special shortcomings:

- lack of thermal curtains under the windows - it blows cold in frosty weather, and fogging is possible due to the too low temperature of the internal glass at normal humidity;

- The heat transfer of the heated floor will require at least 80 W/m2. in an insulated house. The floor will feel exactly warm – more than +28 degrees. For most people, a long stay will not be comfortable. There are also warnings from doctors not to do this.

There can be no talk of colder regions at all...

The basic principle by which work is combined

In our climate, heated floors must be supplemented with radiators. The radiator network allows you to do the following:

- React quickly to changes in temperature in rooms, due to weather changes, or cooling, for example. A heat-intensive massive floor screed (when created normally) cannot keep up with temperature changes.

- Create thermal curtains in the coldest places - under windows, near long external walls, near doors. Eliminate “cold corners” in the house.

- Add heating power in cold weather, without increasing the temperature of the heated floor to an uncomfortable level. This is especially true for the bedroom and children’s room, since warming up the bed may be completely unacceptable...

- If the boiler is not a condensing boiler, then low temperature conditions (below 55 degrees at the return) will lead to condensation on the heat exchanger and its rapid failure.

- Windows without a thermal curtain, with cold inner glass, will sweat as dampness accumulates in the house.

- The window area will be cold and uncomfortable throughout the entire house.

- In the event of a sharp cooling or warming, the heated solid floor will not respond promptly to the change, and you will feel discomfort in temperature.

- During the coldest weeks, the heating output at normal temperatures will not be sufficient. To raise the temperature in the house, you need to increase the temperature of the floor covering above 28 degrees C., which is not suitable for most people, especially interferes with night rest (hot bed), can lead to foot diseases, destruction of the floor covering, or even destruction of the enclosing screed. Otherwise, you will have to put up with the relative coolness in the house and insufficient heating power.

Heated floors have a constant temperature regardless of the weather

Thus, only a heated floor together with radiators will be a high-quality heating system.

In this case, the floor is primarily assigned a comfort-forming role. He must create conditions so that there is no cold underfoot so that children can play on it.

What floor temperatures do users typically prefer? For a long stay, “invisibility and neutrality” are comfortable - approximately +23 - +26 degrees C. Where they play sports - +18 degrees. In the bathroom - +33 degrees turns out to be the norm, but there are occasionally...

Thus, no matter how cold it is outside, a constant temperature of the surface of the floor covering is maintained. Then radiators must compensate for the lack of power when the outside temperature drops significantly...

In the off-season we use heated floors

Normal heating mode - the first priority is to turn on the heated floors. In the off-season, the house gradually cools down, the humidity increases, then the residents manually, if there is no computer automation of the heating system, turn on the heating embedded in the screed under the floor covering.

When frost hits and noticeable cold blows from the windows, the coolant will be redistributed into the radiator networks - the control valve on the line is manually opened.

Here is the simplest way to adjust and combine the operation of radiators and heated floors - by opening the taps (adjusting the thermal head) manually, which requires attention from users and can be tiring. It also lacks the significant cost savings that come with automated control.

Economy heating option with underfloor heating alone

In the central region, in a relatively insulated house, it is possible to install heating using only underfloor heating using the most economical option, and at the same time the housing will remain habitable. It is enough to connect the heated floor collector directly to the gas automated boiler, which should only have control valves for adjusting each circuit. There are no radiators, no pipework for them, no additional pump with a mixing unit, the system is really cheap and efficient. But there will be disadvantages.

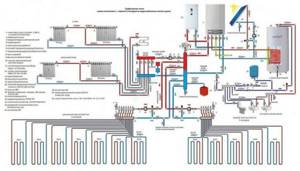

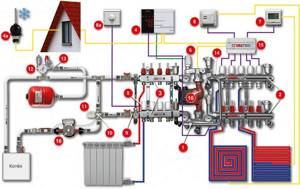

VALTEC combined heating diagram

We present to your attention an example of a modern energy-efficient heating system based on VALTEC equipment. It is designed for a country house or any other facility with an autonomous heat source (boiler, etc.). The scheme provides for the combined use of traditional radiators and underfloor heating. This combination of technologies, as well as the applied automation, makes it possible to provide a high level of comfort at optimal costs for the purchase of equipment and its operation. The diagram uses and displays components from the current VALTEC range.

| № | vendor code | Name | Manufacturer |

| 1 | VT.COMBI.S | Pumping and mixing unit | VALTEC |

| 2 | VTC.596EMNX | Manifold block with flow meters | VALTEC |

| 3 | VTC.586EMNX | Stainless steel manifold block become | VALTEC |

| 4 | VT.K200.M | Weather-compensated controller | VALTEC |

| 4a | VT.K200.M | Outdoor temperature sensor | VALTEC |

| 5 | VT.TE3040 | Electrothermal servo drive | VALTEC |

| 6 | VT.TE3061 | Analog servo | VALTEC |

| 7 | VT.AC709 | Electronic room chronothermostat with floor temperature sensor | VALTEC |

| 8a | VT.AC601 | Room thermostat | VALTEC |

| 8 | VT.AC602 | Room thermostat with heated floor temperature sensor | VALTEC |

| 9 | VT.0667T | Bypass with bypass valve to ensure circulation when loops are closed | VALTEC |

| 10 | VT.MR03 | Three-way mixing valve to maintain return temperature | VALTEC |

| 11 | VT.5012 | Thermal head with remote sensor | VALTEC |

| 12 | VT.460 | Security group | VALTEC |

| 13 | VT.538 | Squeegee | VALTEC |

| 14 | VT.0606 | Dual manifold nipple | VALTEC |

| 15 | VT.ZC6 | Communicator | VALTEC |

| 16 | VT.VRS | Circulation pump | VALTEC |

Explanations for the diagram:

The use of the VALTEC COMBIMIX pump and mixing unit allows you to link high-temperature circuits (heat source and radiator heating) and underfloor heating circuits with a low coolant temperature into a single system.

The distribution of coolant flows is organized using collector blocks VALTEC VTc 594 (radiator heating) and VTc 596 (warm floor).

The wiring of the high-temperature heating system and the heating circuits are made of VALTEC metal-plastic pipes. The pipelines were installed using press fittings of the VTm 200 series; connection to manifolds – with crimp manifold fittings for metal-plastic pipe VT 4420.

Regulation of the underfloor heating is organized using the VALTEC K100 controller with weather compensation function. Thanks to this, the water temperature in the heated floor circuits changes depending on the outside air temperature, which guarantees savings in energy resources used for heating. The control signal from the controller is sent to the analog electrothermal servo drive of the control valve of the COMBIMIX unit.

Thermal comfort in rooms with underfloor heating is maintained by a room thermostat VT AC 602 and a chronothermostat VT AC 709, equipped with air and floor surface temperature sensors. Through electrothermal actuators, these automation modules control the valves on the return manifold of the VTc 596 block.

A thermostat with a remote temperature sensor VT AC 6161 was used as a safety thermostat. It stops the circulation pump of the COMBIMIX unit if the specified maximum temperature of the coolant in the supply to the heated floor circuits is exceeded.

The heat output of the radiators is regulated by the room thermostat VT AC 601, which controls the valves of the VTc 594 manifold block using electrothermal actuators.

The heat source circuit is equipped with a boiler safety group, a membrane expansion tank, and VALTEC check and drain valves.

Ball valves of the VALTEC BASE series were used as shut-off valves.

Ideal design of the collector group

The best system is considered to be this collector group, in which the supply manifold is equipped with a rotameter, and a thermostat is installed on the return manifold. Such a system will make it possible to direct a sufficient amount of coolant to each circuit, and the return collector of such a system will close and open the circuits as the water cools.

It is also necessary to say that the system can be improved with an automated Mayevsky tap, which is placed on the supply manifold; for its part, it must be connected to a circular pump with a bypass valve.

It will work like this:

- Mayevsky taps will remove air from the system, which interferes with its good operation;

- If it gets warmer outside, the external water thermostats will close the circuits, and the bypass valve will reduce the increased pressure from inside the system.

If we talk about how a heated floor

, you need to make a correction: there are three types of rotameters:

- The measuring rotameter is installed simultaneously with the valve, which is changed manually, depending on the measured readings;

- The calibrating rotameter controls the amount of incoming coolant;

- The 3rd type combines the previous two, but it also has a very high cost.

Valtec underfloor heating collector for 2-4 circuits 20-60 sq.m.

Maximum heated floor area: 60 sq.m; Manual regulation. (For automatic control, it is necessary to additionally install a VT.M106.0.230 servo drive and a control thermostat or controller)

Specification

- 1 - Mixing valve MIX 03 3/4" - 1 piece;

- 2 - Nipple adapter 1-3/4" (VTr.580.N.0605) - 2 pcs;

- 3 — nipple 3/4" (VTr.582.N.0005) — 1 piece;

- 4 - tee 3/4" internal-internal-internal. (VTr.130.N.0005) - 1 piece;

- 5 - elbow 3/4" external-external. (VTr.093.N.0005) - 1 piece;

- 6 - American 3/4" (VTr.341.N.0005) - 1 piece;

- 7 - circulation pump with 1" union nuts;

- 8 - ball valve 3/4" internal-internal. (VT.217.N.05) - 2 pcs;

- 9 - collector 3/4-1/2" external. (VTc.500.N.0502) - 2 pcs;

- 10 - collector connector 16-1/2" (VTc.710.N.1604) - 4 pcs;

- 11 — connector with ext. threads 20-3/4" (VTm.302.N.002005) - 1 piece;

- 12 — connector with external threads 20-3/4" (VTm.301.N.002005) - 1 piece;

- 13 — collector tee (VTc.530.N.0500) — 2 pcs;

- 14 — automatic air vent 3/8" (VT.502) — 2 pcs;

- 15 - drainage valve 1/2" (VT.430) - 2 pcs;

Connection

Using connectors (10), a metal-plastic underfloor heating pipe with a diameter of 16x2 is connected. The high-temperature circuit supply (boiler supply) is connected to terminal 16, and the boiler return is connected to terminal 17.

Valtec underfloor heating manifold with manual adjustment for 2 circuits. For normal operation, the loops must be approximately equal in length. It is advisable to install American taps at the inlet and outlet of the heating system 16, 17.

If 3 or 4 circuits are used in the above heated floor mixing unit, then two manifolds (9) are replaced with one adjustable manifold (VTc.560n) and one manifold with ball valves (VTc.580n).

Where to buy manifold and fittings in Ukraine

It is convenient and profitable to order the necessary products on our Obigriv website. We present:

- mixers with thermostat;

- heating collectors;

- components for underfloor heating manifold;

- pump units;

- thermostatic taps and thermal heads;

- manual shut-off valves and taps;

- pressure regulators.

We offer high quality products from leading manufacturers at prices lower than in stores. You can pick up your purchase in Kyiv yourself or arrange delivery with a courier service throughout the city. For buyers from other cities of Ukraine, we will arrange delivery of goods by postal service.

Problems that may arise

Let's give a specific example.

Difficulties in installing the system

The length of the contours in rooms of different sizes is different. This creates problems.

- A heated floor circuit is installed in the bathroom, living room and kitchen.

- It connects to one collector.

- It is clear that the floor surface area in these rooms is different. Consequently, the length of the pipelines laid under the coating also differs.

- This means that the coolant consumption in them will also be different.

Note! In short heating rings, the level of hydraulic resistance of the tubes is lower. Based on this, water circulates in them faster than in long analogues

Consequently, at the same temperature of the liquid on the supply manifold, the floor will be overheated in some rooms, while in others it will remain cold.

The same situation can arise when using radiator heating circuits that have a different number of sections and different lengths of pipes that are connected to the same floor collector. That is, some rooms will be overheated, while others will be cold.

To prevent this from happening, the instructions recommend determining the water flow in the radiator system by installing a thermostat on each battery. In essence, it is a valve that quantitatively regulates flow. Approximately the same can be done with a floor heating system.

Ways to solve the problem

It is possible to balance the heating circuits of an underfloor heating system that are connected to the same collector group in two ways.

- When using the first of them, you need to make all the rings of equal length and correctly distribute them under the coating. For example, three circuits will be in the guest room, two in the kitchen and one in the bathroom.

- The second way is to mount only 3 circuits, according to the number of rooms. However, they will need to be connected not directly to the collectors, but through special devices - flow meters for heated floors, also called rotameters. They are intended to be balancing valves.

In the example given, the term “flow meter” does not mean a measuring device, but a special tap with which you can control and set the flow rate of the coolant.

It should be taken into account that devices from some manufacturers can only be connected to a return manifold.

Optimal design of the collector group.

- The best option is when the manifold assembly has this design - the supply manifold is equipped with a rotameter, and a thermostat is installed on the return analogue.

- Thanks to this, the supply part of the group directs a precisely dosed volume of coolant to each of the heating circuits. The return manifold closes and opens the circuits as the liquid cools in the pipes.

- In addition, it is desirable that the supply manifold for heated floors with flow meters have an automatic air vent and be connected to the return analog by a bypass having a bypass valve.

Note! Air that interferes with its operation is removed from the heating system through a vent. When it gets warmer outside, the thermostats close the circuits, at which time the bypass valve turns on and reduces the increased pressure.

At the moment, manufacturers produce many flow meters, which are both measuring devices and regulators of coolant flow. There are also devices that combine these functions. Naturally, their price is higher.

If you purchase only a measuring device, it will need to be installed together with an ordinary valve. By opening or closing the tap, according to the readings of the rotameter scale, you can regulate the flow of coolant.

How to balance heating circuits

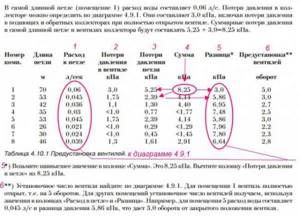

An example of system balancing.

- The total passage of coolant through the collector (l./min.) is taken as 100 percent.

- Next (also in percentage) the consumption for each of the circuits is determined. For example - 15%, 35% and 50%. They are converted (proportionally) to liters per minute.

- Then you need to unscrew or tighten the head of the rotameter (or the tap connected to the measuring flow meter), thereby setting the required readings.

- It should be taken into account that this way only calculated balancing of the circuits can be carried out.

Assembling a manifold with flow meters.

- The actual adjustment is made based on the actual coolant flow. For this purpose, it is necessary to place a measuring rotameter in front of the supply part of the manifold for heated floors. Based on its readings, it will be possible to distribute the total costs among the circuits connected to the collector group.

Results

It is important to ensure that when the water floor heating system is operating, the flow rate on the collector is visible. This is necessary for maintenance. Each water circuit must have its own flow meter.

We recommend: How to install Lavita underfloor heating?

As you can see, in the equipment, each element performs its own functions, so each one needs to be given sufficient attention, and in order for the entire system to work as one whole, it is worth equipping it with a flow meter and a collector, which will evenly distribute all the heat.

- Related Posts

- How to lay a heated floor in a bathroom under tiles?

- How to choose a thermostatic valve for underfloor heating?

- How to install a heated floor sensor?

- How is a heated floor connected?

- How is the mesh for underfloor heating installed?

- How to choose tile adhesive for underfloor heating?

Time-pulse ultrasonic counters

The time-pulse method (or, in other words, phase shift) is based on measuring the travel time of a signal against the flow and in the direction of fluid movement. To convert the ultrasonic signal, two or four piezoelectric elements are installed on the pipeline, offset along the movement of water. As a rule, disk elements are used, less often - ring elements (for small diameters).

Piezo elements can be installed inside the flow (on the inner walls of a pipe or channel) or outside the pipeline (in this case, the signal passes through the outer wall). Depending on the sensors used, meters can be installed in gravity systems (both open and closed), as well as in completely closed pipelines with excess pressure of the environment. There are the following types of speed sensors:

- pipe - cut into the water supply from the outside. Can be used in pressure and non-pressure environments;

- wedge-shaped - installed on the bottom or inner wall of the pipe. As a rule, they are used in non-pressure channels or in pipelines of large diameters, if installing and servicing the sensor outside is inconvenient;

- spherical or hemispherical - mounted on inclined walls of open trapezoidal channels;

- rod - have the form of tubes, installed on the vertical walls of the channels;

- overhead – non-contact sensors, placed on the outer surface of the pipeline.

Depending on the method of installing sensors, contact and non-contact devices are distinguished. The advantage of non-contact portable flow meters is the ability to install them on pipelines without compromising their integrity. They are rarely installed permanently; they are more often used for calibration measurements at different points.

Time-pulse flowmeters are suitable for determining the flow rate of clean or slightly contaminated water (with minor inclusions of suspended particles). They are used in water supply and drainage, in cooling circuits, in irrigation schemes, at pumping pressure stations, in open natural and artificial canals and rivers. They are used for both commercial and technological accounting.

Criterias of choice

The quality of functioning of the underfloor heating system depends on the correct selection of the flow meter. Three types of rotameters are produced:

- Measuring. This type of flow meter is installed with a manual adjustment valve. Control is carried out taking into account measurement readings.

- Regulating. It performs only one function - controlling the amount of coolant entering the water circuits.

- Combined. Such a device combines two actions - adjustment and measurement. The cost of the product is significantly higher than that of models performing the same type of functions.

When purchasing a flow meter for heated floors, you should pay attention to the following product parameters:

- Case material. Devices made of brass have high wear resistance. The top of such a body should be covered with nickel. Plastic products are cheaper, but they have a reduced strength rating.

- Device integrity. Before purchasing a rotameter, it is recommended to carefully inspect the housing and transparent bulb to exclude the presence of cracks or other defects.

- Inner part. The spring in the middle of the flowmeter body should be made of stainless steel.

- Flask. The transparent cap with a measuring scale in high-quality models is made of polycarbonate. This material is quite strong and has high heat resistance, which is especially important when used in heating systems.

- Specifications. The instructions supplied with the device indicate the temperature level. This indicator should be no lower than 110 degrees. Also equally important is the pressure - at least 10 bar.

- Maximum throughput value. The rotameter must be able to conduct at least 2-4 meters of coolant through itself in an hour.

Flow meter for heated floors

The manufacturer of the product should also be considered. The main indicator of the reliability of a product is the availability of a quality certificate and the provision of a guarantee, which responsible companies offer for up to five years.

Cross-correlation ultrasonic counters

Such flow meters operate using the ultrasonic signal cross-correlation method. This technique is based on the principle of constructing velocities at different flow levels; the meter makes it possible to construct a real diagram of the distribution of velocities in the flow. The flow level is also measured.

Ultrasonic pipe and wedge-shaped speed sensors installed in the flow are used with water meters; the liquid level is determined using surface and underwater sensors. It is possible to design combined speed and level sensors.

Meters are used in pressure and gravity, open and closed systems. This is an accurate measurement method that gives reliable results for flows of varying degrees of contamination, including it is effective in heterogeneous media. Flow meters are used in process pipelines, wastewater treatment plants, rivers and reservoirs, etc. In large channels, several sensors can be installed across the entire width to obtain more accurate results.

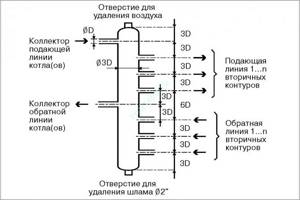

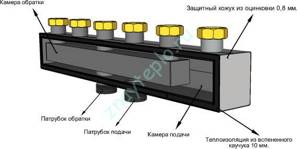

How does a heating manifold work?

The most common horizontal version of the balancing manifold is designed like this:

At the moment, you can find many different designs of collectors on the market. The picture above shows a horizontal manifold with a hydraulic arrow, but there are vertical versions of a similar design and it looks something like this:

The essence here is similar to that implemented in the vertical design. But there is a slight difference in the piping. Here someone needs to look locally for what is more convenient. Such a collector can be made from a large-diameter polypropylene pipe. In this case, it is advisable to maintain the proportions indicated in the figure.

If you are short on space, then there is another very interesting design. It can be called coaxial:

Here two pipes are inserted into one another. In this case, the hydraulic arrow can only be connected separately.

Okay, let's talk about collectors, and now let's look at a heating system based on it. Let's move on!

How is balancing done?

Depending on the flowmeter model, after installation and pressure testing of the heating system, they are set to the initial “open” position. For devices that do not have a built-in valve with speed graduation, an additional valve is set to the “fully open” position, and the system is balanced after startup.

Standard assembly of the manifold group

In combined models, it is possible to preset the number of full valve revolutions. Each revolution reduces the clearance by a fixed amount.

First, the volume of coolant required for each circuit is calculated and its share is determined as a percentage relative to the total volume of coolant for the entire system. In accordance with these indicators, the initial position of the flowmeter valve head on each circuit is set.

The final adjustment is made during operation. At the same time, they are based on real temperature indicators and feelings of comfort.

Doppler method

Counters operating using this method measure the difference in wavelength reflected from a moving stream relative to the wavelength of the emitted signal. Measuring the received and transmitted signals to determine the difference between them is done using wedge-shaped or pipe speed sensors installed at the bottom of the channel or pipe.

Water meters operating on the Doppler effect are used in pressure and gravity systems, fully and partially filled pipes, and open channels. They work in streams of varying degrees of pollution (except clean water). Doppler flow meters are used for commercial metering in pipelines and gravity canals, for measuring flows in rivers and canals of irrigation systems, in storm sewers, at pumping stations, water intake pipelines and discharge of wastewater into reservoirs.