Warm floors from the Kaleo brand are an innovative infrared heating system that is suitable for creating high-quality coatings in apartments and private houses. The company's technology has proven itself well in Russia, and the company's warm floors are popular among consumers. Caleo floors provide maximum comfort in summer and winter thanks to their special composition and specificity. Before installation, you should learn more about their features, advantages and installation requirements.

Customer reviews about Caleo warm floor

Having moved to a new apartment, we decided to install a heated floor on the balcony. We installed Caleo underfloor heating with a specific power consumption of 200 W.T. While we were waiting for the main heating, we went to the balcony to warm up. very pleased with the choice of flooring , so far there are no complaints.

Igor

We live on the first floor, and the floor was always very cold. With the arrival of a child, they decided to install heated floors in the house. We chose Caleo Grid because it has an anti-allergenic effect, ionizes the air and does not dry it out. In addition to the warm floor, we are charged with useful ions and are calm about the child that he is playing on the floor. Nikita

Equipment

Having purchased a Caleo floor heating system, the consumer will find in the package:

- thermal film rolled into a roll;

- contact clamps;

- electrical wiring;

- bitumen insulation.

The kit also includes a brochure that provides detailed instructions for installing heated floors.

The kit does not include a thermostat or temperature sensor. They need to be purchased separately. Also, to install the system you will have to purchase a special film that reflects heat. With it, users of the heating system do not have to worry that not only their floor will be heated, but also the ceiling of their neighbors below. If laminate will be laid on thermal film, it is advisable to buy a substrate that promotes noise reduction.

Other benefits

Caleo has a number of advantages over its competitors:

- Price. Although it is not the lowest, it is quite competitive. Considering that the country of origin is South Korea, which means the quality will be much higher. For comparison: National Comfort heated floors cost the same as Caleo Grid, but the quality of the parts is much lower, as is the service life. This is because “National Comfort” supposedly produced in Russia, but in fact – in China;

- Quality of parts. The weakest point of all infrared floors is the connection. Caleo made them really well, and the contact groups supplied in the kit will really last the entire service life of the floor;

- Fire safety. Caleo does not burn and does not support combustion;

In general, if we take away the “fairytale” promises of sellers, Caleo underfloor heating is a completely acceptable option for additional heating, but not for the main one.

Caleo product line

Kaleo-Global LLC produces sets of infrared floor heating systems, manufactured in the form of thin mats, where thin and flexible carbon rods act as heating elements.

Types of Caleo underfloor heating

The thermomat works like any other infrared film heated floor: a current passes through the conductors, heating the rods to +60°C. But unlike cable analogues, carbon rods emit heat in the infrared range, which not only contributes to effective heating of the floor surface and surrounding objects, but also has a beneficial effect on people’s health.

- CALEO LINE. Infrared film electric heating presented in this series is characterized by its low cost, combined with high reliability. A special feature of this product line is the possibility of installation under linoleum. Line systems are not self-regulating, so they should be installed only on the usable area of the room. The main advantage of these devices is low power consumption. However, Line thermomats can only be used as auxiliary heating of rooms.

Caleo Line set

CALEO GRID floor heating kits

Heated floor set CALEO GOLD

Warm floor CALEO PLATINUM

Warm floor Caleo UNIMAT

It is worth noting that the Gold series includes not only infrared electric heating, but also kits based on resistive two-core cables mounted on a polymer mesh. Unlike infrared devices, heat transfer from cable devices is carried out by converting current into thermal radiation.

Warm floors CALEO and UNIMAT

Kaleo underfloor heating systems: installation features

Depending on the model, installation of Kaleo underfloor heating can be done in two ways:

- into a concrete screed;

- without the use of concrete screed.

Installation of a heated Kaleo floor in a screed or primary floor

In the first case, a substrate with a heat-reflecting surface is laid on the cleaned and leveled subfloor surface. It is very important to carefully secure the substrate to the base so that it does not float up during the process of pouring the screed. Next, thermomats are laid in strips on the substrate. They must also be carefully secured. For convenience, most Kaleo models have a self-adhesive bottom layer.

Installation of heated floor Caleo

After this, the heating elements are filled with a thin layer of concrete screed equal to 2 cm. Then they are connected to the Caleo UTH thermostat. The finishing coating is laid after the cement-sand mixture has hardened.

Kaleo heated floor installation

If the system is installed directly under the tiles, then tile adhesive is applied to the fixed thermomats with a layer of 1 cm, and then the tiles are laid.

It should be noted that the thickness of the tile adhesive together with the tiles must be at least 2 cm. Only by observing this condition can uniform heating of the floor surface be achieved.

Kaleo thermostat instructions

The main advantage of infrared thermomats is the ability to cut and connect them using a wire connecting the rods. As a result, a large area of the room can be covered with several sets of Kaleo, and one large roll of the system can be divided into several small rooms.

Efficient and economical operation of the systems is possible only if you use a thermostat, which is supplied with some heated floor models.

If the thermostat is not included in the package, it must be purchased separately. In this case, the manufacturer recommends using thermostats designed for infrared floor heating systems, for example, the CALEO UTH-155 surface-mounted thermostat.

Connection features depending on the circuit

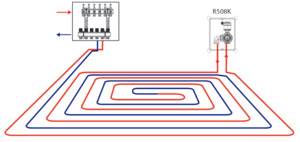

It would be completely wrong to talk about adjusting a water floor without specifying the scheme by which it functions, because in each specific case it has its own structure. Accordingly, completely different elements or components may be responsible for setting temperatures.

The role of the boiler in thermal regulation of the heating circuit

With a simple connection option, when the boiler works exclusively to heat water for the floor circuit, no control devices are required at all.

In the simplest scheme there is only a boiler and a floor contour

If the boiler is a gas boiler of a modern model, it itself is an excellent regulator. The desired coolant temperature is set by pressing buttons on its control panel. A new value, when you need to make the water hotter, cool it, or turn it off completely, is set without problems, in a matter of seconds.

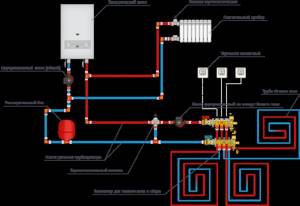

And even when the system is double-circuit - that is, the boiler not only ensures the operation of underfloor heating, but also heats water for radiators and tapping points - the heating temperature of each circuit can be adjusted due to the automation of the boiler itself. No separate devices are required for this.

The same is true when installing an electric boiler, the operation of which can also be easily adjusted from the control panel. True, electricity is not the cheapest heating method, and it is used only when there is no gas in the house. But that is another story.

Control panel of a modern gas boiler

Membrane (expansion) tank connected to a solid fuel boiler

Dependence of pressure in the tank on water temperature

This unit with a pressure gauge and thermostat ensures safe operation of the system

But in order to be able to regulate the temperature when the water is heated not by a gas or electric boiler, but by a solid fuel one, the system must have an expansion (compensation) tank.

The higher the temperature of the water entering it, the higher the pressure. Both are controlled by installing a safety unit on the tank, which includes a pressure gauge, an air release valve and a thermostat, through which the settings are carried out.

Attention! So, in terms of temperature regulation, the type of boiler used is of no small importance - this also affects the structure of the system as a whole. For example, wall-mounted boilers have a built-in pump that circulates water. If the boiler is floor-standing, then both the pump and the thermostat must be mounted separately.

Scheme with a separately mounted circulation pump

In the case of connecting a heated floor through heating, temperature adjustment is carried out according to the same principles. It’s just that in this case, the temperature in the floor circuit will depend on the temperature in the batteries.

It is most difficult to regulate heating with combined connection schemes, when there are many circuits, and in each of them the water must be heated differently.

Factory-assembled control module for water floor systems

Warm floors are a serious cost item during renovation, so it is important to accurately calculate how much and what materials will be needed. To ease your labor costs, we have prepared special instructions telling you how to calculate a heated floor - water or electric. Online calculators included. And in the article “What is needed for a heated floor?” you will find a complete list of everything that may be needed during installation.

This problem can be solved by introducing a mixing unit into the system, which contains a 3-way valve and a servo drive. What is it, how does it function and connect, read on.

Installation features

The installation method for Caleo underfloor heating directly depends on the selected finishing floor material. If parquet or laminate is chosen as cladding, a polyethylene coating should be used. Its main function is to prevent moisture from entering the heating elements. To properly install the heating structure, you need to put a thermo-reflective film on the subfloor, then Caleo heating strips, and lay a polyethylene coating on top. After this, you can install the cladding.

When using carpet or linoleum, the installation technology will differ slightly from that described above. In this case, instead of a polyethylene coating, it is necessary to put any wood sheet material (fibreboard, plywood). This way you can reduce the risk of mechanical damage to the thermal film. Having decided on the type of flooring, you can begin installing the heated floor.

installation of heated floor Caleo (Kaleo)

1. The service is provided upon purchase of a heated floor set of at least 6 m2, including purchases made outside the CALEO branded retail network.

2. List of works and cost:

- visit of an installer in Moscow within the Moscow Ring Road - 300 rubles;

- travel of the installer to Moscow areas outside the Moscow Ring Road and to the near Moscow region (no further than 15 km from the Moscow Ring Road) - 500 rubles;

- installation, installation and connection of heated floors - 500 rub/m2;

- installation and connection of a thermostat - 600 rubles/piece.

How to make initial floor adjustments

The initial launch of a newly installed floor heating begins with adjustment, and it is necessary to carry it out correctly. This is important not only for the system itself, but also for the operation of the floor covering, which should not be subject to overheating.

Water pipes can also be mounted on a dry screed, but most often they are laid in a monolith due to the greater heat transfer of such a pie. Regardless of its design, the initial start-up of the system is carried out before the finishing cladding is carried out.

The initial launch is carried out before installation of the decorative coating

At the same time, residual moisture evaporates from the screed, which is very important when construction is not carried out during the hot season and the cold forces you to hurry. In this case, you can only set the temperature to room temperature (about +20), increasing it by only 1 degree per day.

On a note! Forcing events is inappropriate - gradual heating will eliminate the occurrence of cracks in the screed due to sudden linear expansion.

The system must operate in this mode for at least 2 weeks. During this time, the concrete will dry perfectly, which has a beneficial effect on most finishing materials that do not like moisture.

Table 2. Adjusting the heated floor

| On the back of the device there are two mounting holes, with which it is mounted on self-tapping screws screwed into the wall. | |

| Choosing a location for installation | The location is chosen arbitrarily, as long as it is not exposed to direct sunlight or drafts. It should be at least 1.5 meters from the floor, since the device is very sensitive to temperature changes. |

| The thermostat is not connected to the network, as it runs on two lithium batteries, which are included in the kit. This power supply is enough for the device for 1.5-2 years of regular use. | |

| How data transfer occurs | In this diagram, the thermostat is designated by number 1. Number 2 is the radio module, which receives a signal from the regulator at the set and measured temperature, compares them, and, if necessary, opens the servos. |

GEBO connection for DHW riser

From the description: Gebo products are clamping couplings and repair clips for installation and repair of pipes of various diameters or different types... To connect two pipes, universal clamp connectors for steel and polyethylene pipes are used... A huge advantage of Gebo is that we can reliably connect not only metal pipes, but also plastic ones, as well as a metal pipe with a plastic one. And all this without welding or threading...Gebo connections can be applied to systems with operating pressure: - water - 10 bar - gas - 4 bar - compressed air - 10 bar... Recently we replaced the hot water and hot water risers with reinforced PP and now we have It’s these connections that stand out to me.. Still, are they reliable or not, is there a practice of using such connections “permanently”. Or is this a time bomb and you shouldn’t relax???

- 60 replies

What problem does the make-up valve solve?

Actually, the auto-feed valve, the design of which provides two or three inputs, is designed to maintain thermal balance in the house when there are several circuits.

The valve can be a two-way valve designed for mixing boiling water with cold water. By increasing or decreasing the flow of hot water, we obtain a coolant with a particular temperature.

This process is regulated using a thermal head mounted on the valve. It does an excellent job of protecting the system from excessive heat, but the valve itself does not have a very large capacity.

Two way valve

Therefore, two-way devices are installed mainly in small heating areas. They themselves are very reliable, and can be connected in parallel if there are several heating circuits.

Its disadvantage is that hot water in this case is distributed unevenly, therefore, when installing multi-circuit heating, valves with three inputs are mainly installed. Let's talk about them in more detail.

Three-way valve capabilities

The operating principle of this valve is completely different. It has a thermo-mixing unit, in which the temperature of the water passing through it is determined. If it is too hot, the damper on the pipe with cold water opens, by mixing which cooling is organized (if you remember, in a two-way valve everything happens the other way around).

3-way auto-feed valve

As soon as the flow temperature drops to the set value, the passage on the cold pipe is closed. True, during the initial start-up of hot water, sharp temperature jumps may appear in such a system, which is not good for any pipeline.

Note! To avoid this, servos are additionally installed, which we will talk about a little later.

But the 3-way valve still has more advantages:

- It allows you not only to mix flows with different temperatures, but also to redirect them. But the main thing is that in this case it is possible to obtain a coolant with a stable set temperature.

- Depending on the configuration, the valve can be controlled either manually or automatically. The manual device looks similar to a regular ball valve - except that it has three pipes.

But models that provide automation can be configured so that the temperature is set taking into account the distance of the circuit from the boiler - that is, adjusted for cooling of the coolant.

Accordingly, the system itself works more efficiently - especially when, instead of a thermal head, a servo drive is installed on the valve, which also takes into account the air temperature in the room.

Three-way valve in the diagram

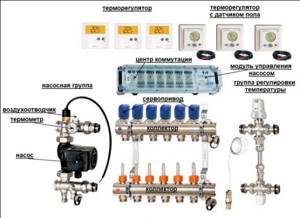

Servo driven system operation

A servo drive is a device equipped with a retractable mechanism (rod) located in the upper part of its body. It is installed either on a separate valve or on the inlets to the underfloor heating distribution manifold, which is clearly visible in the picture.

System elements with names

The device is controlled by a thermostat, on which the required temperature is set. The regulator is very sensitive to its changes; with its help, the adjustment is made more accurately than is possible with a thermal head.

When making adjustments on the thermal head, you can only navigate by lines with numbers, which you can’t figure out without a product passport. The thermostat is convenient because it has a normal display that shows the temperature in numbers, in degrees Celsius. The device can be either electric or operate on the radio principle.

Table 1. Schematic operation of an electronic thermostat

| Thermostat type | Explanation |

Thermostat mounting holes