An alternative to traditional energy resources are various types of biofuel, the production of which uses plant or animal raw materials, industrial waste and the results of the vital activity of organisms.

We offer to understand the advantages and disadvantages of using such fuel, find out the production features, functional characteristics, and also evaluate the effectiveness of using different types of biological fuel. The information provided will help you navigate the choice of alternative sources of energy resources.

Raw materials

The prefix “bio” indicates plant (biological) origin, lack of negative impact on the climate and environmental benefits. The raw materials for biofuel production are:

- animal waste,

- oil plants,

- grain crops,

- sugar beet or cane,

- wood and its waste,

- energy plants.

There are 3 generations of the most environmentally friendly fuel, although there is no clear boundary between them. To produce first-generation energy carriers, plants with a high content of fats, sugars, and starch are taken. Second-generation fuel is obtained by processing wood, grass, and crop residues that are not suitable for consumption. Energy sources from algae belong to the third generation. The biological productivity of aquatic organisms is much higher than that of terrestrial plants.

Important criteria for assessing the potential and environmental friendliness of biofuels are yield and price.

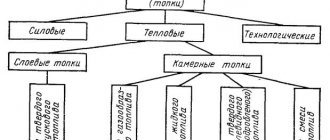

Types of fuel by physical state

According to their state of aggregation, energy carriers can be solid, liquid, or gaseous. The main types of raw materials for the production of solid biofuels include firewood, sawdust, wood chips, and manure. Less commonly processed are walnut shells, olive pits, sunflower husks, and corn pulp. Before use in furnaces and boilers, raw materials are dried, crushed, sifted, pressed into granules (pellets) or briquettes, and homogenized. The final consumers of the product are thermal power plants and private homes.

Liquid

Promising types of liquid biofuels include vegetable oils, biodiesel, bioethanol, biobutanol and biomethanol. In the future, they may completely replace diesel fuel and gasoline.

Vegetable oil fuel

Consists of raw or refined vegetable oil (most often rapeseed) in its pure form. It is used instead of diesel fuel, but differs from it in chemical characteristics, and therefore requires engine modification. Produced in large factories (extraction) and in small oil extraction plants (cold pressing). The main disadvantage of rapeseed biofuel is oxidation under the influence of oxygen and loss of fluidity in winter.

Biobutanol

Also known as butyl alcohol derived from biomass:

- Sahara,

- starch,

- straw,

- wood.

If materials with a high cellulose content (straw, wood) are used, the resulting product is also called cellulosic butanol. n-Butanol and isobutanol (i-butanol) are particularly important as energy sources. They are added to fuel for carburetor engines, and n-butanol is even mixed into diesel or used in its pure form.

Biodiesel

It is a methyl ester of fatty acids (FAME) obtained from vegetable oils. It serves as an environmentally friendly alternative to diesel fuel and has similar physical and chemical characteristics.

Biodiesel is produced mainly from rapeseed in large cyclic plants.

The productivity of modern equipment is about 200,000 tons per year.

Bioethanol

Replaces gasoline, produced by fermentation of biogenic raw materials and subsequent distillation. The raw materials for the production of bioethanol are mainly:

- grain crops (wheat, rye);

- sugar beet;

- corn.

Since the chemical properties of the product differ from those of gasoline, changes in the design of vehicle engines are required.

Biomethanol

It is used instead of ordinary methyl alcohol - one of the main types of raw materials in the chemical industry. A colorless, highly flammable liquid with the odor of alcohol is part of the fuel. Global demand for methanol in 2015 was about 65 million tons. To produce this substance, consisting of carbon monoxide, water and oxygen, non-renewable resources are used: natural gas and coal.

Therefore, scientists are trying to find effective methods for producing bioethanol from microscopic algae - phytoplankton.

Type 1

Typical representatives of this raw material group are peat, wood, waste products of animals and people.

Wood

Since ancient times, people have used firewood to heat their homes and cook food. This practice is still found today in different countries where heat and electricity are obtained using wood. For example, the famous Austrian thermal power plant with a capacity of 66 MW runs on wood fuel.

The disadvantages of this raw material include its low energy value. Also, burning wood is accompanied by the deposition of soot, which must be periodically cleaned. It is important to understand that new trees do not grow very quickly: as a rule, it takes at least 15-20 years.

A good alternative to firewood are pellets made from substandard wood waste - bark, chips, knots, sawdust, etc. To obtain convenient granules, the raw materials are crushed to dust. Next, the finished mass is dried and compressed at high temperature. Wood contains lignin, which has adhesive characteristics. This facilitates the formation of small cylindrical granules 5-70 mm long and 6-10 mm thick. You can make pellets yourself using a special press.

Wood chips are often used as biofuel: this material is the main fuel in European thermal power plants. Chips are produced at logging sites or special enterprises where shredder machines are installed.

Peat

This popular type of biofuel comes in swamp and forest varieties. It is widely used in various industries and in everyday life. Peat refers to partially decomposed moss or grass. As a rule, peat deposits are most often located in swamps and forests. Many countries can boast of such reserves, including Russia, Belarus, Canada, Sweden, Ukraine, etc.

It is economically profitable to organize the processing of raw materials directly at their extraction sites. First, the peat is cleaned and sifted, removing extraneous inclusions from its composition. Next, the material is dried and formed into briquettes or granules.

Agricultural waste

During the production of agricultural products, quite a lot of waste of plant origin remains - nut shells, plant shells, straw, etc. From these raw materials, by pressing and granulating, you can obtain high-quality pellets, which in their performance are no different from wood material.

Animal biofuels

In addition to firewood, ancient people widely used animal waste as fuel, in particular dung (as dry manure is called). By drying and processing, high-quality solid biofuel without a specific odor can be obtained from dung.

Considering the fact that in the modern world livestock waste accumulates in large volumes, using it to produce fuel makes it possible to simultaneously solve the problem of its disposal.

Gaseous

Gaseous fuels obtained from biological mass include biogas, biomethane and biohydrogen. This is a future alternative to natural gas, gasoline, and kerosene.

Biogas and biomethane

Biogas is a gas that is produced from energy crops, poultry manure, sewage, slurry and/or organic by-products. When subsequently processed into biomethane, carbon dioxide and hydrogen sulfide are removed and the remaining product is compressed (densified). It is well suited for vehicles converted to run on natural gas. Biomethane is also used to replace gasoline.

Biohydrogen

Biohydrogen production is based on biological or chemical processes. On a laboratory scale, it is produced by anaerobic digestion. From energy-rich organic compounds (proteins, carbohydrates, fats), bacteria synthesize H2 along with CO2.

On an industrial scale, biohydrogen is produced by thermochemical treatment (gasification or pyrolysis) and steam reforming from:

- biomass (wood, straw, hay, etc.),

- other bioenergy carriers (biogas, bioethanol, etc.)

The second way to produce biofuels is by using living biomass (eg, cyanobacteria, algae). During certain metabolic processes (photosynthesis, nitrogen fixation), hydrogen is produced by certain enzymes, such as nitrogenase or hydrogenase.

Advantages of the energy resource

Biological and scientific interest in natural energy resources arises due to the following positive qualities of the product:

- Economic availability of the material . Many countries spend a lot of money to buy oil or natural gas. The state economy is suffering losses. Biological fuel can be obtained in almost any country. Local production of fuel will reduce the cost of importing foreign energy resources.

- Mobility . Wind or solar installations are intended exclusively for stationary use. Not transportable. Biological materials can be transported from one region to another if necessary.

- Biofuels are a renewable resource . Plant and animal waste will never go away.

- The natural resource reduces the amount of greenhouse gas emissions into the atmosphere. Prevents the likelihood of global warming.

- The use of biofuel for car engines reduces the cost of its maintenance.

In the near future, running combustible fuel will be cheaper than using gasoline.

Ecofuel production in Russia

In the Russian Federation, the new industry is developing slowly. Mainly the production of firewood, fuel pellets and braces has been established. Most of the pellets (80%) are exported. Regional programs to intensify the use of biodiesel are being developed.

The potential for the development of biogas production is high, especially in the Southern, Volga and Central districts of the country.

Solid biofuels have been used in Russia for a long time. Russians know how to make some types of it themselves. For example, dung (dried manure) is prepared in large quantities by residents of Western Siberia.

Disadvantages of biofuels

1. Many biofuel production methods are still in the development or prototype stage. There is no practical experience of large-scale application yet.

2. High production costs. According to the German Institute. Robert Koch, biohydrogen costs 4-5.5 times more than gasoline.

3. Growing energy crops can compete with growing food. The increase in demand for alternative energy sources is considered one of the factors that triggered the food price crisis in 2007-2008.

4. In terms of its physical and chemical properties, biofuel often differs from conventional fuel, so it is necessary to adapt the engines.

5. Since producers tend to use more pesticides and fertilizers when growing energy crops, the environment and residents of villages located near the fields suffer.

Benefits of biofuels

1. With the mass introduction of regenerative fuels, a significant reduction in carbon dioxide emissions (by 50-70%) from vehicles is expected. When burning biofuel, unlike conventional fuel, the same amount of CO2 is released as plants absorb from the air during the growth period.

2. The targeted use of domestic biofuels in industry, agriculture, utilities, transport and forestry leads to a reduction in crude oil consumption. This will make it possible to provide raw materials for a long time to enterprises in those industries where there is still no alternative to mineral raw materials. Among them are plastics factories and pharmaceutical factories.

3. Preparation, transportation, storage and use of biological fuels are not associated with the risk of an environmental disaster, since they easily decompose and do not harm water and soil. The assumption that the cultivation of energy plants will lead to the spread of monocultures is considered unfounded. Rapeseed, for example, grows in one area for no more than 4 years in a row. Rooting deeply, it and other oilseeds loosen the soil, making it suitable for plants with a shallow root system (cereals, corn).

4. Biofuel production helps in recycling agricultural and industrial waste.

5. Biofuel has a low potential for danger to humans and the environment.

Historical reference

The first steps towards the creation of biofuels were taken with the advent of butanol (butyl alcohol). Then, a fermentation process was used with the participation of the bacterium Clostridium acetobutylicum, also called the ABE process after the name of the three end products of fermentation - acetone, butanol and ethanol. The automotive industry played a huge role in the development of biofuels. Already in 1826, the American inventor S. Mori created an engine for which alcohol and turpentine served as fuel. It has been proven that vegetable oil can be used as fuel for steam engines and ships. In 1876, the German inventor N. Otto created the world's first four-stroke internal combustion engine running on ethanol. We still use various modifications of this engine today. Even more unusual projects were created. For example, in 1895 R. Diesel proposed a type of diesel engine based on the use of peanut oil. G. Ford was so confident in the future of alcohol cars that he even built a distillery in the Midwest of the United States, where he invested considerable funds. During World War 1, cars in most countries around the world used ethanol as fuel along with gasoline.

In the 17th century J. B. van Helmont discovered that decaying biomass releases flammable gases. A. Volta in 1776 came to the conclusion that there is a relationship between the amount of decomposing biomass and the amount of gas released. In 1808 Sir G. Davy discovered methane in biogas. The first biogas plant was built in Bombay in 1859. In 1895, biogas was used in Great Britain for street lighting. In 1930, with the development of microbiology, bacteria involved in the process of biogas production were discovered. In the USSR, research was carried out in the 1940s; in 1948–54 the first laboratory installation was developed and built. There is a steady tendency to use biogas to solve a wide variety of energy issues: heating homes, generating electricity, producing reliable automobile fuel. At the same time, the mechanisms for its production are constantly being improved, new, more practical and economical ways to obtain high-quality fuel are being developed.