Basic coolant parameters

One of the most significant parameters is the temperature of the coolant in the heating system of the house. It is under the influence of temperature that the liquid used to transfer heat can change its properties. And the heating efficiency depends on this. Other characteristics include viscosity and volume of thermal expansion. Also an important parameter is the optimal coolant speed. It depends on the diameter of the pipes. The minimum value is from 0.2 m/s, there is no upper limit.

Below are some requirements that the coolant must meet:

- Contribute to the transfer of the maximum amount of heat in a minimum period of time along the entire perimeter of the room with minimal losses.

- Non-corrosive.

- Have a low degree of viscosity. This indicator affects the speed of the coolant in the heating system, and therefore the efficiency.

- Be affordable. And if the price is high, then the coolant must have properties that allow it to be used for a longer time.

- Provide safety. The liquid should not contain toxic or harmful substances and should not ignite at high temperatures.

Main characteristics of the coolant

The main condition that high-quality antifreeze must meet is already clear - this is an extremely low freezing point. There are enough options on the market that have a crystallization temperature of several tens of degrees below zero. Now let’s take a closer look at what characteristics of fluids for engineering systems you should pay attention to when purchasing:

- High turnover. This parameter is one of the key ones, because if the liquid is excessively viscous, it will increase the load on the circulating pump and can cause premature failure of expensive components and components.

- High thermal conductivity coefficient. It is this characteristic that determines the performance of a heating or cooling system. The higher the specified parameter, the less amount of coolant must be used. The right choice allows you to save money on the purchase and maintenance of antifreeze.

- Minimal toxicity. There are unforeseen systems in the operation of engineering systems, so the selected composition in the event of a leak should not cause an environmental disaster or become a threat to the lives of personnel.

- Long service life. Good coolants can last 5-10 years without losing basic technical characteristics.

These are not all the properties that the selected composition must meet. Experts pay attention to the class of fire or explosion hazard, and to the dependence of the freezing point on the concentration. Each of the coolants on the market has its own characteristics, so study their properties very carefully.

| Coolant | Advantages | Flaws |

| Water | Availability, low price, environmental and toxicological safety | Freezing point 0°C |

| Ethylene glycol aqueous solution | Good thermophysical characteristics, freezing temperature up to – 60°C | Toxic |

| Aqueous solution of propylene glycol | Satisfactory thermophysical characteristics, toxicologically and environmentally safe, freezing point up to – 58°C | In terms of thermophysical characteristics, it is 10-20% inferior to ethylene glycol and costs more |

Types of coolants and their comparative characteristics

Before you buy a coolant for a heating system, you need to decide on the type. As a rule, water or antifreeze liquid is used. Only fully purified water – distillate – is suitable for heating systems. Running water contains many third-party components that have a negative impact on the functioning of the heating system, reducing its service life. Therefore, preparing water for the heating system is a very important process.

To determine the maximum temperature of the circulating fluid in the heating system, you need to know the properties of the coolant and what restrictions exist in the use of pipes and batteries. The elements of the heating system should not be damaged by high thermal effects.

Distilled water has the following characteristics:

- mass density: 1000 kg/cub.m at a temperature of +4 degrees. When heated, the specific gravity decreases;

- heat capacity is 4.2 kJ/kg*C;

- boiling point - +100 degrees. But as the pressure increases, it increases. For example, at a pressure of 2.75 atmospheres, the boiling point will be +130 degrees. It should be noted that the optimal coolant temperature in the heating system is +75 degrees. But when weather conditions change, this indicator can be adjusted. For example, in steam systems the normal temperature is + 120 degrees.

Antifreeze is often used as a coolant.

This liquid has a low freezing point - about -30-65 degrees. Contains ethylene glycol, which is hazardous to health. But many modern brands of antifreeze are produced using harmless propylene glycol. The main advantage of antifreeze liquid over water is its high resistance to frost. You can read about the choice between water and antifreeze for coolant here.

To determine which coolant is better for the heating system, you need to compare the characteristics of the two liquids:

- Water is not harmful to human health. But antifreeze is toxic.

- When overheated, water does not change its properties. Antifreeze foams and releases a sediment that remains on the walls of the heating structure in the form of soot. Which has a bad effect on the operation of the heating system.

- Price difference: an antifreeze system will cost 10-40% more than a water one.

- Water can be combined with pipes made of any material. Antifreeze - no.

- Water is always suitable, and the service life of antifreeze is no more than 5 years.

For electrode heating boilers, a special antifreeze is used, which has a special composition and provides the necessary ionization, electrical conductivity and electrical resistance. You need to choose a coolant for electrode heating boilers by monitoring the market and reading user reviews. After all, you can buy antifreeze that is optimally combined with boiler equipment, or you can buy an unsuitable option or a fake.

Heating system operating on antifreeze

With the arrival of winter cold, non-freezing coolant for heating systems becomes relevant (read: “Non-freezing liquid for heating systems - making the right choice”). Pipelines filled with such coolant will not be damaged at low temperatures. This is relevant for owners of buildings in which they do not live all the time and use heating systems periodically. This coolant includes antifreeze for the heating system, the properties of which allow it to be used at temperatures of minus 30°C and even at extremely low temperatures.

In cases where the temperature is below normal, antifreeze intended for heating systems does not harden like water, but takes on a gel-like state.

When this type of liquid returns to its original state, its parameters are maintained and there is no threat to the integrity of the heating circuit. To remove scale or possible pockets of corrosion, special inhibitors (additives) are added to the liquid at the production stage. As a result of their use, the service life of the heating structure increases, and significantly. But we should not forget that antifreeze for heating is not a universal coolant, so additives can be used provided that the structural elements are made of certain materials. The fact is that some inhibitors destroy polymer pipes, while others promote electrochemical type corrosion.

On average, antifreeze can last for 5 years. After this, the coolant in the heating system is replaced (for more details: “How to replace the coolant in the heating system of different heating systems”). Antifreeze manufacturers themselves recommend doing this every three years.

Antifreeze has a number of disadvantages compared to water:

- quality such as increased viscosity requires the installation of a powerful circulation pump;

- the heat capacity of this liquid is 15% lower, which means less heat supplied to the room;

- detachable connections require better sealing;

- it is necessary to use radiators with a volume 50% larger than when using water;

- it is necessary to install a closed expansion tank, since increased expansion of the liquid is observed when heated;

- toxicity of the composition, for example, ethylene glycol.

Thus, when using antifreeze, the pipes must be large in diameter and the radiators more voluminous. When sealing detachable connections, it is advisable to use Teflon or paronite gaskets. To dilute antifreeze, you can only use distilled water. Before changing it, drain the coolant from the heating system and thoroughly flush it, including the boiler.

Features of choosing a coolant

In order for the heating of the room to be effective and the system to function correctly, you need to know how to calculate the volume of coolant in the home heating system.

The approximate value of this indicator can be determined from the ratio: 1 kW of power equals 15 liters of liquid. But it is advisable to know the exact data. For these purposes, special calculation tables have been developed. Based on them, the volume of coolant in the heating system for the aluminum radiator section is 0.45 liters. And the cast iron battery section holds about 1 liter of liquid.

It is also important to determine the coolant flow rate in the building’s heating system. This indicator is calculated by dividing the estimated heat demand by the heat output of 1 kg of circulating fluid. Flow is usually measured in kg/h.

Thus, different types of circulating fluid are commercially available today. Which heating fluid to buy depends on the parameters of the heating system, operating conditions, and the size of the budget.

Rules for using coolant

- Before installing the heating boiler, check the technical documentation for compatibility with the selected type of coolant.

- When diluting a high concentration glycol solution, use only demineralized water.

- Before completely replacing the coolant, flush the system. Take into account the manufacturer’s recommendations for regular replacement and monitor quality.

In addition to purchasing the selected glycol solution, you can order comprehensive coolant maintenance and entrust monitoring to professionals.

You may be interested in the following products

| Name | Price per kg, rub. VAT included | Purchase |

| Ethylene glycol solution | from 37.65 rub./kg | Order |

| Propylene glycol solution | from 37.65 rub./kg | Order |

| Boiler water | from 33.25 rub./kg | Order |

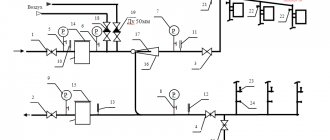

Hydraulic calculation of a heating system - calculation example

As an example, consider a two-pipe gravity heating system.

Initial data for calculation:

- design thermal load of the system – Qzd. = 133 kW;

- system parameters – tg = 750С, tо = 600С;

- coolant flow (calculated) – Vсо = 7.6 m3/h;

- The heating system is connected to the boilers through a horizontal hydraulic separator;

- the automation of each boiler maintains a constant temperature of the coolant at the outlet throughout the year - tg = 800C;

- an automatic differential pressure regulator is installed at the inlet of each distributor;

- The heating system from the distributors is mounted from metal-plastic pipes, and the heat supply to the distributors is carried out through steel pipes (water and gas).

The diameters of the pipeline sections were selected using a nomogram for a given coolant speed of 0.4-0.5 m/s.

A DN 65 valve is installed in section 1. Its resistance, according to the manufacturer’s information, is 800 Pa.

A filter with a diameter of 65 mm and a throughput capacity of 55 m3/h is installed in section 1a. The resistance of this element will be:

0.1 x (G/kv) x 2 = 0.1 x (7581/55) x 2 = 1900 Pa.

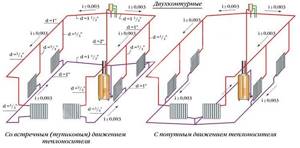

Options for a two-pipe heating system

The resistance of a three-way valve dу = 40 mm and kv = 25 m3/h will be 9200 Pa.

The total pressure loss in the heat supply system of the distributors will be equal to 21514 Pa or approximately 21.5 kPa.

A homemade stove is well suited for heating a country house or utility room. Do-it-yourself stove from a gas cylinder - see the manufacturing instructions.

You will learn how to assemble a press for fuel briquettes with your own hands in this article.

The remaining parts of the distributor heat supply system are calculated in a similar manner. When calculating the heating system, the main circulation ring through the most loaded heating device is selected from the distributor. Hydraulic calculations are made using the 1st direction.

Determination of coolant flow and speed

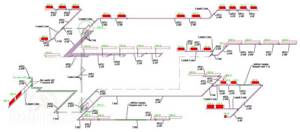

The most well-known method for calculating hydraulic systems is based on thermotechnical calculation data, which determines the rate of replenishment of heat loss in each room and, accordingly, the thermal power of the radiators installed in them. At first glance, everything is simple: we have a general value of thermal power and then dose the flow of coolant to each heating device. For greater convenience, an axonometric sketch of the hydraulic system is first constructed, which is annotated with the required power indicators of radiators or water heated floor loops.

Axonometric diagram of the heating system

The transition from thermal engineering calculations to hydraulic ones is carried out by introducing the concept of mass flow, that is, a certain mass of coolant supplied to each section of the heating circuit. The mass flow is the ratio of the required thermal power to the product of the specific heat capacity of the coolant and the temperature difference in the supply and return pipelines. Thus, key points are marked on the sketch of the heating system, for which the nominal mass flow is indicated. For convenience, the volumetric flow is determined in parallel, taking into account the density of the coolant used.

G = Q / (c (t2 – t1))

- G—coolant flow, kg/s

- Q - required thermal power, W

- c is the specific heat capacity of the coolant, for water assumed to be 4200 J/(kg °C)

- ΔT = (t2 - t1) - temperature difference between supply and return, °C

The logic here is simple: in order to deliver the required amount of heat to the radiator, you must first determine the volume or mass of coolant with a given heat capacity passing through the pipeline per unit time. To do this, it is necessary to determine the speed of movement of the coolant in the circuit, which is equal to the ratio of the volumetric flow to the cross-sectional area of the internal passage of the pipe. If the speed is calculated relative to the mass flow, you need to add the coolant density value to the denominator:

V = G / (ρ f)

- V - coolant movement speed, m/s

- G—coolant flow, kg/s

- ρ is the density of the coolant; for water it can be taken as 1000 kg/m3

- f is the cross-sectional area of the pipe, found by the formula π r2, where r is the internal diameter of the pipe divided by two

Data on flow and speed are necessary to determine the nominal diameter of the decoupling pipes, as well as the flow and pressure of the circulation pumps. Forced circulation devices must create excess pressure to overcome the hydrodynamic resistance of pipes and shut-off and control valves. The greatest difficulty is presented by the hydraulic calculation of systems with natural (gravitational) circulation, for which the required excess pressure is calculated based on the speed and degree of volumetric expansion of the heated coolant.

Types of coolants for the heating system, their optimal parameters and an example of volume calculation

Effective operation of a water heating system is only possible with the correct choice of coolant. Before creating a heat supply project, it is necessary to determine in advance its type and find out the main technical and operational characteristics. There are certain parameters characteristic of the heating fluid: temperature, volume of thermal expansion, viscosity.

Functions of the coolant in the heating system

How to choose the right coolant for heating? To do this, you need to decide on its purpose for heat supply systems. Calculation of its characteristics is included in the design. Therefore, it is necessary to know the functional characteristics of water or antifreeze in heating.

Heating fluids

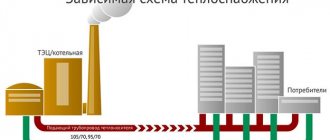

The main task that a safe coolant for heating systems must perform is the transfer of thermal energy from the boiler to batteries and radiators.

In autonomous heating, this process is carried out using a heating element, which increases the temperature of the coolant to the required level. Then, thermal expansion and the operation of the circulation pump create the proper speed of hot water to transport it to the system radiators.

Before calculating the volume of coolant in the heating system, it is recommended to familiarize yourself with its secondary functions:

- Partial protection of steel elements from corrosion. This will only happen if there is a minimum oxygen content in the water and there is no foaming. It has been observed that in unfilled heating, rusting occurs much faster;

- Cooler for circulation pump. The most common pump model has a so-called “wet rotor”. Even if the maximum temperature of the coolant in the heating system is reached, it will still reduce the heating level of the pump power unit.

These functions are influenced by the parameters of the heating system coolant. Therefore, when choosing, you should carefully study the characteristics of water or antifreeze. Otherwise, the actual heat supply parameters will not coincide with the calculated ones, which will lead to the creation of an emergency situation.

Even if the heating system is filled with plain water, it cannot be used to supply hot water to the house. During operation, the content and parameters of the heating system coolant change

Types of coolant for heating

Water and some types of antifreeze can be used as the circulating fluid. This does not affect the amount of coolant in the heating system, but it does affect heat transfer, movement speed and system safety requirements.

Heating system of a private house

To identify the most appropriate option, it is necessary to compare coolants for heating systems. Most often, ordinary water is used. This is due to its affordable cost, good heat capacity and density. When the boiler stops operating, it can accumulate the resulting heat for some time to transfer it to the surface of the batteries. In this case, the volume of coolant in the heating system will remain the same.

However, despite its positive properties, water has a number of disadvantages:

- Freezing. When exposed to negative temperatures, crystallization and increase in volume occur. This is what causes damage to pipes and radiators. Therefore, the optimal temperature of the coolant in the heating system must be maintained;

- Impurity content. This applies to ordinary water. Often this is what causes scale to appear on batteries, radiators and the boiler heat exchanger. Experts recommend using distilled liquids, in which the percentage of alkalis, salts and metals is minimal;

- With a high oxygen content, it provokes the rusting process. This is more typical for open heating systems. But even in closed heat supply schemes, the percentage of oxygen content in the water may increase over time.

At the same time, water can be used as a coolant for aluminum heating radiators. If the composition of the liquid and the minimum amount of oxygen are observed, destructive processes will not occur in it.

If the operating conditions of the heating system imply the possibility of exposure to negative temperatures, a different type of circulating fluid should be used. How to choose a coolant for heating systems in this case, and what criteria should be followed?

Antifreeze for heating system

One of the determining parameters is the freezing temperature. For antifreeze it can be from -20°C to -60°C. This allows you to operate the heat supply even in subzero temperatures without causing breakdowns.

However, antifreeze has a higher density than water - the optimal coolant speed in the heating system in this case can only be achieved by installing a powerful circulation pump.

Depending on the composition and components, there are the following types of antifreeze:

- Ethylene glycol. It is characterized by low cost, but is extremely toxic. Not recommended for autonomous heating of a private house;

- Propylene glycol. Completely safe for human health. Has a worse thermal conductivity coefficient than ethylene glycol-based liquid. It is characterized by high cost;

- Antifreeze based on glycerin. It is most often chosen as a coolant fluid for heating. The price is much lower than that of propylene glycol compositions, it is non-toxic, and has a good heat capacity.

You need to know that calculating the amount of coolant in the heating system for antifreeze will be more difficult. This is explained by their foaming when reaching the maximum temperature. To minimize this phenomenon, manufacturers add special inhibitors and additives to the liquid composition.

Before purchasing a safe coolant for heating systems, you should read the recommendations from boiler and radiator manufacturers. Not all types of antifreeze liquid can be used for aluminum radiators and gas boilers.

Main characteristics of heating fluid

It is possible to determine in advance the coolant flow in the heating system only after analyzing its technical and operational parameters. They will affect the characteristics of the entire heat supply, and will also affect the operation of other elements.

Distilled water for heating

Since the properties of antifreeze depend on their composition and the content of additional impurities, technical parameters for distilled water will be considered. For heat supply, distillate should be used - completely purified water. When comparing coolants for heating systems, it can be determined that the flowing liquid contains a large number of third-party components. They negatively affect the operation of the system. After use for a season, a layer of scale forms on the inner surfaces of pipes and radiators.

To determine the maximum temperature of the coolant in the heating system, you should pay attention not only to its properties, but also to the limitations in the operation of pipes and radiators. They should not be damaged by increased thermal exposure.

Let's consider the most significant characteristics of water as a coolant for aluminum heating radiators:

- Heat capacity – 4.2 kJ/kg*C;

- Mass density. At an average temperature of +4°C it is 1000 kg/m³. However, during heating, the specific gravity begins to decrease. When it reaches +90°C it will be equal to 965 kg/m³;

- Boiling temperature. In an open heating system, water boils at a temperature of +100°C. However, if you increase the pressure in the heating supply to 2.75 atm. — the maximum temperature of the coolant in the heating system can be +130°C.

An important parameter in the operation of heat supply is the optimal speed of the coolant in the heating system. It directly depends on the diameter of the pipelines. The minimum value should be 0.2-0.3 m/s. The maximum speed is not limited by anything. It is important that the system maintains the optimal temperature of the heating fluid throughout the entire circuit and that there is no extraneous noise.

However, professionals prefer to be guided by the norms of the old SNiP of 1962. It indicates the maximum values of the optimal coolant speed in the heating system.

| Pipe diameter, mm | Maximum water speed, m/s |

| 25 | 0,8 |

| 32 | 1 |

| 40 or more | 1,5 |

Exceeding these values will affect the coolant flow in the heating system. This can lead to an increase in hydraulic resistance and “false” activation of the release safety valve. It should be remembered that all coolant parameters of the heating system must be pre-calculated. The same applies to the optimal temperature of the coolant in the heating system. If you are designing a low-temperature network, you can ignore this parameter. For classical schemes, the maximum heating value of the circulating fluid directly depends on the pressure and restrictions on pipes and radiators.

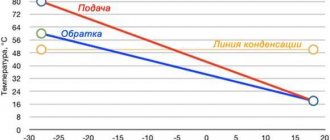

To select the correct coolant for heating systems, a temperature schedule of the system’s operation is first drawn up. The maximum and minimum values of water heating should not be below 0°C and above +100°C

Calculation of coolant volume in heating

Before filling the system with coolant, it is necessary to correctly calculate its volume. It directly depends on the heat supply scheme, the number of components and their overall characteristics. They influence the amount of coolant in the heating system.

First, the parameters of the supply line are analyzed. The material used to make it is important. To calculate the volume of coolant in the heating system, you need to know the internal diameter of the pipe. According to modern standards, the internal cross-sectional size is given in the article number of steel pipelines, while the external cross-sectional size is accepted for plastic ones. Therefore, in the latter case, it is necessary to subtract two wall thicknesses.

In order to independently calculate the volume of coolant in the heating system, you do not need to do calculations. It is enough to use the data from the table below. With its help, you can calculate the amount of coolant in the heating system.

| Diameter, mm | Coolant volume (l) per 1 m.p. pipes, depending on the material of manufacture | ||

| Steel | Polypropylene | Metal-plastic | |

| 15 | 0,177 | 0,098 | 0,113 |

| 20 | 0,314 | 0,137 | 0,201 |

| 25 | 0,491 | 0,216 | 0,314 |

| 32 | 0,804 | 0,353 | 0,531 |

| 40 | 1,257 | 0,556 | 0,865 |

Having this information, it is enough to determine the length of pipes of a certain diameter using the heat supply diagram and multiply the resulting value by a volume of 1 m.p. In this way, the volume of coolant in the heating system is calculated, but only in the pipes.

Heating radiator dimensions

But in addition to the supply lines, the heating circuit contains radiators and batteries. They also affect the volume of coolant in the heating system. Each manufacturer indicates the exact capacity of the heating device. Therefore, the best calculation option would be to study the battery passport and determine the amount of coolant fluid required for heat supply.

If this is not possible for a number of reasons, you can use approximate figures. It is worth noting that with a large number of batteries, the calculation error will increase. Therefore, to accurately calculate the amount of coolant in the heating system, it is recommended to find out the battery specifications. This can be done on the manufacturer's website in the technical information section.

The table shows the average volume of coolant for one section in aluminum, bimetallic and cast iron heating radiators.

| Radiator type | Center distance, mm | ||

| 300 | 350 | 500 | |

| Aluminum | — | 0,36 | 0,44 |

| Bimetallic | — | 0,16 | 0,2 |

| Cast iron | 1,1 | — | 1,45 |

These numbers must be multiplied by the total number of sections in the heating system. Then the already calculated volume of water in the pipes should be added to the data obtained and the total amount of coolant in the heating system can be determined.

However, it should be remembered that when comparing coolants for heat supply systems, it was noted that over time the volume may decrease for objective reasons. Therefore, to maintain the operation of the system, coolant should be periodically added to it.

To accurately calculate the volume of water in the heating system, it is necessary to take into account the capacity of the boiler heat exchanger. For solid fuel models, this figure can be several tens of liters. For gas ones it is slightly lower.

Methods for filling a heating system with coolant

Having decided on the type of coolant and calculating its volume in the heating, it remains to solve one problem - how to add water to the system. This is an important point in the design of heat supply, since when a critical water level is reached, the boiler heat exchanger and radiators may fail.

Feeding unit for a closed heating system

For an open heating system, water can be added through an expansion tank located at the highest point of the system.

To do this, it is necessary to install a supply line and connect it to the tank structure. When the coolant volume decreases, it is enough to turn on the supply of a new portion of water to supplement the system.

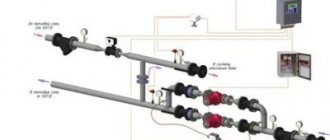

Filling a closed system is carried out according to a different scheme. It must have a recharge unit. This component is located on the return pipe, in front of the expansion tank and circulation pump. The make-up unit includes the following components:

- Shut-off valves installed on the connected pipe;

- Check valve that prevents a change in the direction of coolant flow;

- Mesh filter.

To automate the operation of the unit, you can install a servomechanism on the crane. It connects to a pressure sensor. When the pressure decreases, the servomechanism opens the tap and thereby adds coolant to the system.

The video describes the parameters for choosing a coolant for a heating system:

www.strojdvor.ru