The lack of the usual H2O in the water tap is a common everyday nuisance that is simply impossible to get used to. A person is able to adapt to the systematic shutdown of gas or electricity, but it is the lack of drinking liquid that he endures the hardest. Of course, you can collect life-giving moisture in bottles and cans in advance, but this is not a way out. It is much more reasonable to purchase a storage tank for the water supply system and install the container under the water.

Purpose of the water storage tank

The needs of a modern person are not limited to simply the supply of drink to the home. Every consumer of this resource wants H2O to flow from the tap under good pressure and ensure the uninterrupted functioning of household appliances. However, in a number of situations this is only possible if there is a water storage tank.

Installation is usually done:

- If there are no alternative water sources on the homestead territory or nearby. In this situation, a tank that is systematically filled from a tanker truck will be a real salvation.

- When liquid is supplied to residential premises through a centralized water supply system irregularly or in accordance with an established schedule.

- If you have your own well or well with low productivity. In this case, limited resources simply cannot meet all the needs of residents.

- During frequent power outages, without which pumping units are unable to function.

Design

Storage tanks for water supply are made of food-grade stainless steel (steel grade - 12Х18Н10Т) or food-grade plastic.

The material must be of high quality, otherwise unwanted chemical compounds will get into the water, which is harmful to the health of people consuming this water.

Design Features:

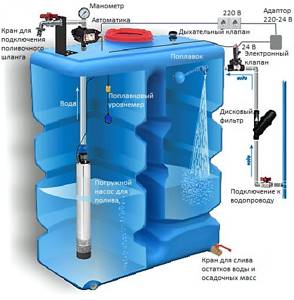

- A float valve of the kind used in toilet tanks is installed on the inlet pipe. If water is pumped into the tank from your own well or well, a float switch for the pump is installed instead of a tap.

- In case of failure of the float mechanism, an overflow pipe connected to the sewer is cut below the inlet.

- It is also necessary to install a filter at the entrance. There are several varieties: mesh (mud collectors), cyclones and centrifugal filter pumps. The first group is used for relatively clean water, the other two – for highly polluted water. A strainer should also be installed on the outlet pipe. It is better if it is located at the entrance of the main pipe into the house immediately before the wiring.

- A level is inserted into a tank with opaque walls. It will help determine whether there is enough water, for example, for a washing machine.

- It is necessary to ensure that sediment can be removed. Underground containers, as already mentioned, are cleaned through a hatch located on top. Tanks intended for installation at the top are equipped with a drainage pipe that cuts into the very bottom.

- Filling the tank should be done through a diffuser - a shower head or garden watering can. This will prevent water from mixing with the bottom layer containing sediment.

- A ventilation pipe (blowhole) cuts into the container from above. It should be curved so that the inlet is directed downward. A mesh should be installed at the entrance to the ventilation pipe to prevent debris and insects from entering the tank.

The ventilation pipe must have a sufficiently large diameter. It is also necessary to ensure that its filter is not clogged with all kinds of debris, for example, poplar fluff. If you drain a tank without air, atmospheric pressure can flatten it like a tin can.

Using the Water Tank

To use the reserve supply of H2O at any time, the storage tank must be connected to the water supply. The connection must be carried out taking into account the supply of an aqueous solution in automatic mode (if there is not enough external pressure) or the activation moment must be set using a conventional valve. There are many ways to install water storage devices. To decide on a specific option, you need to take into account the following factors:

- source type;

- probable location;

- living space layout, etc.

In addition, it is advisable to familiarize yourself in advance with the design of different storage tanks for water supply and consider their connection diagrams. Once all the important nuances have been taken into account and the available information has been studied, you can choose the most suitable configuration.

Installation of storage tanks

The container is lowered using lifting equipment

Installing a container made of different materials comes down to one thing: you have to dig a hole. But the installation is slightly different due to the use of different materials:

- To install a container made of metal barrels, dig a hole with a diameter slightly larger than the barrel. To increase the volume of the container, the barrels can be welded vertically with each other. Moreover, you leave the bottom only in the lower barrel. Measure the depth of the pit according to the height of all welded barrels. Place a 10-15 cm sand cushion at the bottom of the hole. As you know, metal tends to rust and rot. Therefore, to protect the structure from exposure to water, cover the barrels with bitumen or paint before installation. Place the finished container in the hole. In the side of the barrel where the sewer pipe will enter, cut a hole to fit the diameter of the pipe. Insert the pipe into the barrel and seal the joint with sealant. Now you can fill the gap between the walls of the barrel with the pit. As the soil is poured, compact each layer after about 25 cm. Cover the top of the container with a lid with a hatch.

- Installation of a container made of concrete rings is carried out on a pre-concreted bottom of the pit. Lower the concrete rings into the hole using a truck crane and seal all joints with silicone or cement-based sealant. Waterproof the outer walls of the rings, install sewerage, and fill the gap between the walls of the container and the pit with earth. Place a reinforced concrete cover with a hatch on top. It should protrude above the ground.

- Installing a plastic container follows the same principle. Dig a hole larger in diameter than the container, about 10-15 cm on each side. Measure the depth to the neck. It should be above the ground. The bottom of the pit can be made of a sand cushion, as mentioned above, but there is one problem - plastic is a rather light material, so in the spring, with the rise of groundwater, the container can be pushed out of the ground. The best bottom option for a plastic container may be concrete. The bottom of the pit is concreted along with anchors. When the concrete has hardened, install the container, tying it with straps to the anchors. Connect the sewer and seal the pipe entrance. Backfilling is done in layers of 20-30 cm. As you backfill, fill the container with water so that the pressure of the earth does not crush the soft walls of the plastic. You can fill it with a mixture of sand (6 parts) and cement (1 part), compacting each layer. Place the lid on the neck of the container and the job is done.

- To build a container made of brick or cinder block, dig a hole in the shape of the future container. Concrete the bottom and lay out the walls in a checkerboard pattern. Waterproof the walls with hot bitumen both inside and outside. Make a sewer line and fill the gaps with earth. The top of the container can be covered with sheet metal or knocked down wooden panels.

- A small storage tank can be built from old car tires. When laying them on top of each other, pour bitumen between them to seal.

From tires

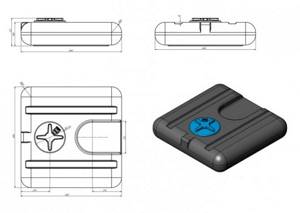

Horizontal storage tank Flotenk

As you can see, installing a storage tank is a fairly simple process and can be done by every owner of his own yard. The best option for installation from the containers described above is plastic. It is lightweight, compact, easy to transport, and most importantly, has the longest service life. Watch the installation video provided and follow the instructions to get to work.

Features of the storage container

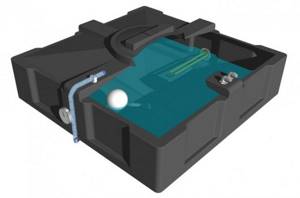

The water tank is designed to maintain the required pressure level (the same as an expansion tank). The optimal solution for these purposes is a storage tank with a closed type membrane. Such models are produced with a membrane base located inside. A mesh membrane divides the internal area into two halves. One section is occupied by air, the second by liquid.

Water storage tanks are used in individual systems. Their use is relevant in case of systematic interruptions in the supply of water to the home. The storage tank replenishes it from accumulated reserves. Water storage tanks are produced by manufacturers in a wide range of sizes and volumetric characteristics. Drainage and water supply adapters, filter elements, and ventilation outlets are located on the surface of the housing. There are also models equipped with pumping stations. They already belong to the category of expensive products.

The storage tank simultaneously performs a number of functions:

- stabilizes the pressure level when the supercharger is inactive;

- protects against water hammer occurring due to the penetration of air masses into the water supply system or power surges;

- maintains the set volume of liquid;

- ensures wear resistance of pumps.

Why does strong condensation form?

Condensation on the toilet flush tank appears as a result of condensation of water vapor that is present in the air. It condenses on surfaces that have a temperature lower than the dew point temperature. This happens because the air, when cooled, can no longer hold the same amount of water vapor in a gaseous state and condensation occurs. In addition to temperature, the relative humidity of the air has a direct influence on the condensation process. As humidity increases, the risk of condensation increases. Unfortunately, determining the humidity value is difficult to predict at the design stage of a bathroom ventilation system.

During construction and renovation, we widely use insulation to reduce energy losses caused by changes in the temperature of the transported medium, when the ambient temperature differs from the temperature inside the system. In the case of devices with average temperatures below ambient, such as a toilet flush cistern, insulation has another very important function - it prevents condensation from forming on the surface of the device.

Types of reserve tanks (water storage tanks) for cold water

In accordance with the technical characteristics and configuration features, water storage tanks are divided into several classes according to:

- Form. They are produced in round, rectangular, cylindrical, and in the form of non-standard models.

- Design differences: closed or open.

- The material from which the tanks are made. The most common are metal, polypropylene, stainless steel, and plastic.

- Volume. Water storage tanks have a capacity from 7 to 500 liters.

- Purpose: for hot water supply, hot water supply, heating systems and irrigation.

- Installation method. Possible vertical or horizontal placement, underground or wall mounting.

Tips for choosing

When choosing tanks for a shower, for a dacha, or just for a garden plot, you should take into account their size. They are available in volumes of 50, 55, 100, 128, 150, 160, 200 and 250 liters. The most popular options are 100 and 150 liters.

When choosing a tank, it is worth taking into account the heating rate of a certain volume of water. Here we should also assume that an adult will need approximately 50 liters. It is clear that smaller tanks heat up faster than larger tanks.

It is also important to take into account that the less the tank weighs, the easier it is to install

The weight of the tanks directly depends on the thickness of the walls of the product. If you choose a tank of significant weight, then you will have to install it using special fasteners. Before purchasing, we recommend that you familiarize yourself with the types of containers. The tanks are produced in vertical and horizontal versions, which is important for taking into account the fasteners for an already purchased booth.

There are also ways to heat tanks:

- using central water supply;

- solar energy, for a dark metal base;

- local heating systems;

- electric heating device.

Plastic options are cheaper; these tanks will last at least 10 years with careful care. It is better to remove them before the frosty winter. Of course, metal tanks will last longer, but they absorb more heat during heating.

The criteria for choosing tanks are:

- significant variability in their configurations, materials and dimensions;

- long service life;

- ease of removal from sediments;

- power of heating elements;

- ease of installation;

- strength;

- affordable prices (purchasing from catalogs without extra markups will be more economical).

Expensive imported versions have a special coating that prevents the formation of scale. This coating is applied to the tank heater - the shower is comfortable, but the water becomes harder.

The weight of the tank is important to consider, especially if the tank is supposed to be installed on glass - a combined heating option. You shouldn’t overpay – make a rational choice. If you have a good understanding of the topic and purchase parameters, you can easily avoid mistakes. The force of water spray from the divider directly depends on the configuration of the tanks and their volume

For supporters of slowly flowing water, a plastic tank (up to 40 l) will be a convenient option. This option will be comfortable for swimming in summer in slightly warm water. Vertical tanks of significant volume provide a strong stream due to the significant pressure of the water column. And if the family is large, then you should select a tank with a volume of 150-200 liters. It is worth considering that not all cabins or glass roofs can withstand such weight. The planned consumption volume of water is calculated at the rate of 50 liters per adult, plus another 30-50 liters of reserve (for those who like to splash around). When purchasing a tank, do not forget about the “breathable” lid for it, it will prevent the appearance of “blooming” water. Compact heated tanks are easier to install and easier to clean. Metal containers are popular and can have different configurations - from flat products to round, barrel-shaped, cylindrical and cubic. Metal tanks are stronger than plastic ones; they have a higher level of resistance to mechanical stress. For example, extreme hail can damage a plastic product, but not a metal product. Metal is less aesthetically pleasing, but fully satisfies the needs of consumers.

Steel containers made from metals with different characteristics are more durable:

- carbon steels;

- galvanized alloys;

- stainless steels.

Often products combine combined heating options. The advantage of such devices is that the liquid does not stagnate in them. Their price tag is higher than their plastic counterparts, but they are completely worth the cost.

The dilemma is galvanized steel or ferrous metal. Any bulk container of dark colors lying in the sun heats up the liquid relatively quickly - the physical parameters of dark surfaces are triggered. During warm times, heat is retained in tanks heated by the sun's rays, so they are often produced without heaters.

A dark steel tank located on the roof will be the most economical option since it works autonomously.

Galvanized products usually last up to 6-7 years, during which time there is no need to worry about corrosion. But they also lose their qualities, usually in the seam area. However, during this time they quite manage to justify themselves. These tanks are affordable in price, however, flat plastic tanks provide them with worthy competition. Often, thrifty summer residents give preference to expensive, durable products that can last for several generations.

Device and diagram for connecting a water storage tank to a water supply system

The liquid level in the storage tank is regulated by built-in level gauges, which are divided into float and electronic versions. The supercharger pumps H2O from the source to the backup storage. The aquatic environment fills the water storage tank to the set value, after which the float valve is activated and the water intake process stops.

When activated, the electric motor of the pump begins to fill the collection compartment of the reservoir. The air space compartment at this moment decreases. A decrease in air volume leads to an increase in pressure. As soon as a certain norm is reached, the injection unit is switched off automatically. It will work again when the atmosphere indicator drops to the minimum level.

MBFT-75 Membrane for 75GPD

SF-mix Clack up to 0.8 m3/h

SF-mix Runxin up to 0.8 m3/h

Installation of water supply

The installation of the water supply network is carried out in stages.

If water is extracted from a well, a pump is installed on it.

Its type depends on the depth of the source:

- up to 8 m – surface pump;

- from 8 to 20 m – surface pump with a remote ejector;

- over 20 m – submersible pump.

The suction line of the surface pump must be equipped with a check valve. If a submersible pump is used, a check valve is installed on the pipeline leading to the house.

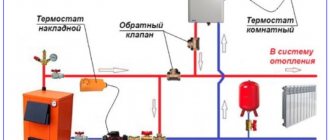

In automatic mode, the pump is turned on and off by coordinated signals of three elements:

- level sensor installed in the well;

- dry running protection relay;

- float switch installed in the storage tank.

Using a flexible reinforced hose with a diameter of 1" the pump is connected to a polyethylene pipeline (outer diameter - 32 mm) laid to the storage tank.

If the tank has a large volume and is installed on an interfloor ceiling, a flooring of thick boards should be laid under it, which will distribute the weight load over a large surface.

Installation of the float valve is carried out in the following order:

- A washer is put on the valve shank, after which it is inserted into the inlet hole.

- Then, from the inside, they put on the shank: a stiffening plate, a second washer and a fixing nut.

- Now, from the outside, you need to screw the adapter to the shank, to which the supply pipeline will be connected.

- The float switch for the pump is installed in the same way.

When installed at the top, the tank remains connected to the sewerage system and water supply network. If the tank is located underground, it is necessary to install and connect a pumping station with a membrane accumulator. Like a well pump, the station must have dry-running protection, which will turn it off as soon as the tank is empty.

Nuances of choosing a storage tank

When choosing a suitable water storage tank, focus on the needs of future consumers of the water resource. Determine how many people will use it. Also count the number of water intake facilities in the house or apartment. These include: kitchen taps, showers, various household appliances that consume H2O during operation. Plus, consider the possibility of use by several people at once. So that it doesn’t happen when one family member is washing, and the second cannot wash the dishes at that time.

Purpose

Tanks are used for collecting and storing drinking liquids and other non-aggressive substances that meet the food category. A variety of sizes of water supply storage tanks with and without a pump for water in an apartment allow you to save a sufficient amount of resource. A certain amount of reserves is especially relevant during systematic supply cuts. And also in cases where there is no source on the plot.

Shape and volume

Many who in practice have encountered the purchase of reserve capacity believe that the optimal displacement should be 250 liters. This is exactly the amount of liquid that will be sufficient for mass flow. For example, it will be spent cleaning the house, washing the car, filling the bath. The aqueous solution will constantly move without stagnating. 150 or 200 liters is not enough for this.

However, it is impossible to confidently recommend any specific parameters. The most common but valuable substance - H2O - is consumed differently by everyone. Therefore, when purchasing a storage tank, focus on the needs of your household.

Materials

Manufacturers produce devices of two types: metal and plastic.

The first option is products made of stainless steel, which is impervious to mechanical damage and rust. In this regard, metal models are quite expensive and are often made to order. To avoid the negative effects of corrosion when collecting and storing hot liquid, the tanks are coated on the inside with heat-resistant enamel.

Storage tanks made of plastic are the most practical and common. They are easy to manufacture, light weight and low cost.

Types of tanks

All tanks are divided into types according to two criteria: installation method and material of manufacture. According to the installation method, tanks are:

- built-in;

- remote;

- samovar type (mounted on a chimney).

According to the material of manufacture:

- cast iron;

- stainless steel;

- made of enameled steel.

Each type has models that differ in shape, volume, and wall thickness. Most containers are equipped with standard taps and have shower outlets, but there are also those from which water is drawn through the top using a ladle. In order not to make a mistake when choosing, you should familiarize yourself in detail with the advantages and disadvantages of all these types.

Built-in tanks

Built-in tanks

The most economical and convenient option. The tank is installed during the laying of the furnace. Its lower part is located inside the firebox, due to which the water is heated directly by the flame. Hot water is drawn through the top using a ladle or using a built-in tap.

Brick oven with water tank

Due to direct contact with fire, the walls and bottom of the container must be as thick as possible, therefore the most preferred material for such a tank is cast iron with a thickness of 5 mm. Stainless steel tanks with wall thicknesses of 1 and 1.5 mm are considered no less popular. Enameled steel containers are not suitable for this installation method. Cast iron tanks are bowl shaped, stainless steel tanks are usually cube or cylinder shaped.

Cast iron water tanks

Advantages of built-in tanks:

- water heats up quickly;

- the water temperature is maintained for a long time;

- free space is saved since the tank does not protrude beyond the stove;

- easy installation.

Flaws:

- the heat transfer of the furnace decreases, since the main part of the heat is spent on heating water;

- the dimensions of the tank are limited by the size of the furnace;

- the tank must have thick walls, which increases its weight and cost.

Metal tanks for sauna stoves

This method is convenient in cases where no more than 4 people are steaming in the bathhouse at the same time, or people wash separately. For example, if 3-4 people take turns steaming in a bathhouse, this takes quite a lot of time, and accordingly, it will take longer to maintain the water temperature by adding firewood. The built-in tank allows you to save on fuel while remaining hot for a very long time. But for large companies, this option is not the most optimal, since it does not provide the required amount of water.

Remote tanks

Remote tanks

The remote tank is located at a distance from the firebox and is connected by pipes to a heat exchanger built into the furnace. Without this, its operation is impossible. Most often, such a tank is installed in a washing room or mounted on the wall of a steam room next to the stove, if its dimensions are larger than the area of the firebox. When choosing a location for a container, it is necessary to take into account that the length of the pipes should not exceed 2.5-3 m. Remote tanks can be made of stainless steel or enameled, cylindrical, rectangular or even triangular in shape - for installation in the corner of the room.

Triangular shaped water tank

Advantages:

- the tank is installed where it is more convenient;

- Large containers can be used;

- there is no direct contact with fire, so the tank can be enameled and with thinner walls.

If 6-8 people regularly steam in a sauna, a remote tank is an excellent option.

Flaws:

- without maintaining a fire in the firebox, the water quickly cools;

- the oven cannot be used without water in the circuit;

- more complex installation compared to a built-in tank.

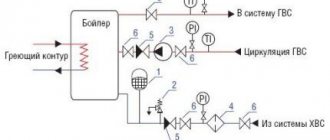

Remote tank connection diagram

Connection options

You can connect the storage tank to the water supply using two different methods: by placing it at a certain height or by placing it at ground level.

Upper placement is used mainly when there are no household appliances in the living space that are particularly demanding of good pressure. For the minimal needs of household members, such as washing dishes, cleaning the house, hygiene procedures, it is optimal.

The lower location is more efficient. Suitable for residential buildings that have all the amenities familiar to city residents. This type of installation requires mandatory equipment with a pump, since in its absence it will not be possible to obtain the required pressure.

SF-mix manual up to 0.8 m3/h

AMETHYST - 02 M up to 2 cubic meters/day.

Aeration unit AS-1054 VO-90

Types of plastic tanks

Storage containers for water made from polymers vary in shape, volume, color, material and purpose. When choosing a suitable tank, it is necessary to analyze which characteristics of the product will be optimal for meeting household needs.

Material for production

Light polymers are used to make containers: polyethylene and polypropylene. Polyethylene products are used in everyday life for storing drinking and industrial water.

Polypropylene tanks are suitable for use in industrial enterprises and factories. Dense, stable containers for technical and chemical liquids are made from polypropylene sheets.

Tanks with smooth, thin walls cannot be called particularly durable, and if you need a structure that is resistant to deformation, choose tanks with thicker walls and stiffeners

Plastic barrels for drinking water are made from pure food-grade polyethylene. This material ensures the preservation of the chemical composition of water and prevents the proliferation of putrefactive microbes and bacteria.

There is a technology where the base material is coated with a special antiseptic coating on the inside of the tank. The inner, white layer protects the liquid from blooms and bacteria, and the outer, blue, creates a barrier to the penetration of sunlight.

To treat double-layer drinking water storage tanks, abrasive cleaning agents should not be used so as not to damage the integrity of the thin coating.

Difference between containers by color

Polyethylene containers are available in four colors: white, blue, green and black.

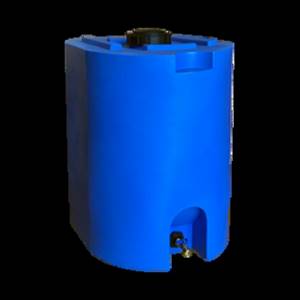

Blue tanks are universal and are used for storing food and process water outdoors and indoors. Since the dense layer of dark blue plastic does not transmit UV rays, water, even after long-term storage, does not lose its chemical properties and does not bloom.

Green polyethylene containers are similar in properties to blue and dark blue products. The choice of a green or blue tank is based on the personal preferences of the buyer.

Green water containers look harmonious in the front garden, garden and vegetable garden, therefore they are often used for watering

White canisters should be stored indoors without natural light, as light-colored plastic does not protect the liquid from possible reactions. White tank walls have an advantage over colored ones only in that you can control the amount of liquid in the tank.

Black containers are intended for watering or for arranging a summer shower. Such products do not transmit UV rays and get very hot in the sun. Therefore, underground tap water quickly heats up and becomes suitable for bathing and watering garden crops.

Storage volume and shape

Storage containers have different capacities. The smallest ones hold 20 liters of water, the largest ones – 10 tons.

To transport drinking water to the dacha, it is advisable to purchase containers with a volume of 20-50 liters. To equip a summer shower, tanks of 100-200 liters are in demand.

If the supply of tap water is unstable, then a container with a capacity of 1000-2000 liters is suitable for irrigation and domestic needs.

The wall thickness of containers with a volume of 20 to 1000 liters ranges from 4 to 6 mm. For tanks from 2000 to 10000 liters, from 6 to 10 mm

Tanks for 3, 5 and 10 cubic meters of water are used for industrial purposes and for transporting liquid and bulk cargo in special vehicles.

Polypropylene water tanks come in various shapes. Therefore, both the cottage owner and the summer resident will select the best option for the bowl, based on the capabilities and purpose.

Cylindrical tanks take up minimal space, so they are used in bathhouses and homes.

Rectangular universal containers for storing liquids can be located underground and on the surface. A vertically standing rectangular tank significantly saves space.

Cubic tanks have a large volume and a wide neck opening for easy filling. When installing the bottom tap and installing the barrel on the podium, complete drainage of water is possible.

To equip a summer shower, you should purchase horizontally oriented tanks made of black plastic to increase the natural heating surface

Flat elliptical or elongated conical tanks are installed on the roof of a summer shower. The shape, when the lower part is wider than the upper, allows you to increase the pressure of the liquid. For ease of filling, such containers are equipped with a wide neck opening.

This variety will allow you to install a water container in any free corner without losing useful space, even if the country house or plot has a small area.

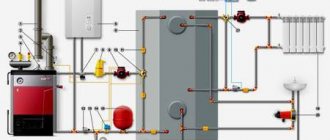

Water supply schemes with storage

They largely depend on the location and type of source, the process of preparing hot water, as well as the selected pumping system that supplies water to the container.

So, if water is drawn from a 7-8-meter well, it is quite enough to purchase a surface pump. A check valve will need to be installed on the inlet pipe to prevent H2O from escaping.

It will be possible to lift the aqueous solution from a depth of 15-18 meters only with the help of a remote ejector, which must be equipped with a supercharger.

Well, for an artesian well you can’t do without a submersible device.

Centralized water supply

When installing a water storage tank, regardless of the type of connection, you will definitely need a shut-off element. It is this that prevents the stored liquid from escaping back into the water supply.

Upper connection

The storage tank is mounted under the ceiling above the pipeline or in the attic. At the initial stage, it should already have a falling and water intake fitting, as well as a pipe for discharging excess into the sewer.

Next, a coarse filter device, a check valve, a water meter, and a valve are installed. Only after this can a tee be installed that leads the tube to the inlet adapter.

A hose to remove excess H2O is lowered into a sewer pipe or simply taken outside the living space, for example, to a garden or personal plot.

To control the filling level, special float elements are used.

Leading from below

In this case, all manipulations are performed similarly to the previous method. But unlike this, a pumping station is installed at the outlet, creating a certain pressure in the pipeline. To use the liquid, you must first activate the pump.

Bottom connection of storage tank with membrane

When studying water supply schemes with a storage tank for storing water in an apartment, one cannot help but pay attention to this option. You can connect a water storage tank of this type using just one tube connected to the water supply through a tee and valve. The water storage tank must be installed after the cleaning device, water meter and check valve.

Main table dispenser AquaPro 919H/RO (hot and cold water)

Main table dispenser AquaPro 929CH/RO (cooling/heating)

Floor dispenser AquaPro 311 (empty, without cooling)

Autonomous system

Supplying H2O from an individual well or borehole source is extremely simple. It is lifted using a supercharger, the configuration of which depends on the height of the shaft and the depth of water resources.

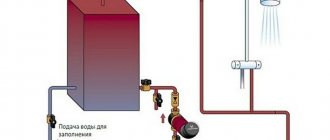

Water tower

The storage tank is mounted 15-20 meters above the ground on an equipped tower or in the attic. The liquid from the pumping station is sent to a reserve tank, and from it is supplied to the toilet or kitchen in the living area. The necessary pressure is created due to the level difference between the water storage tank and the home tap.

Bottom connection

In this case, the storage tank is installed at the same height as the injection system or no higher than the first floor. Filling is carried out using a pump. The float switch acts as a control element. Optimal scheme for excessive H2O consumption.

Membrane design

Such a storage tank is installed immediately after the supercharger and the shut-off part (valve) through a lower connection.

Using a hydraulic accumulator

This device is designed to ensure the start of the pumping station. Can also be used as a reserve water tank. The more impressive the dimensions of the device, the higher the efficiency. However, the cost increases accordingly. Thanks to good tightness, it keeps the aqueous solution suitable for drinking.

Application of water heater

Installed for heating liquids in residential premises. At the same time it serves as a water storage tank. It is characterized by ease of installation and the ability to obtain heated H2O, regardless of the season.

Installation process

The most affordable option for organizing an autonomous water supply system in a house or bathhouse is to install a container in the attic.

To do this, you need to make or purchase a bath tank of the required volume and configuration.

The container is installed on the top beam or in any convenient location in the attic.

Installation work is carried out in stages:

- The base under the water tank is being strengthened. The floor beams are covered with wide boards.

- The drive is installed on the prepared base.

- A float type valve is being installed. Step back 7.5 cm from the top edge, make a mark and cut out a hole of the required diameter. The tail part of the valve with a plastic sealing washer is threaded into the hole. A special stiffening plate is installed on the opposite wall of the container, another sealing washer is installed, and a nut is screwed on. All fasteners are securely fixed, a connector is screwed to the tail part, with which the water pipe is connected.

- Holes are made for outlet pipes of the required size. A connector with a washer is screwed into the finished holes on the inside of the container. The thread is strengthened with a special tape. Next, put on the washer and tighten the nut.

- Shut-off valves are inserted into the outlet pipes.

- Overflow is in progress. To do this, set a mark 2.5 cm below the location of the float-type valve and make a hole. The overflow pipe is led into the sewer system and secured to the walls of the tank using connectors using a similar principle. Next, the pipes are connected with compression fixation. The finished sections of the pipeline system are mounted to the walls of the tank and a wooden base.

- The connected tank is filled with water to check the tightness of the system, as well as to regulate the float valve.

- The container is insulated using polystyrene sheets or rolled mineral wool.

In this simple and reliable way, you can set up an autonomous water supply system, the main element of which is a storage tank for a bathhouse or home.

Where are water tanks installed?

The choice of location for storage tanks depends on many factors that must be taken into account when planning installation work.

- You can provide backup water supply to a private home through a storage tank by installing the tank in a utility room under the ceiling.

- Install a water tank in the attic or loft. If necessary, the structure will have to be insulated.

- Place it directly on the floor surface or in the basement. Without a pumping station, of course, such a scheme will not work.

Manufacturing technology of plastic containers

Thanks to the production technology of polymer containers, they can store technical and drinking water for a long time. Therefore, they are in demand both in summer cottages and for farming in a private home.

Water tanks are produced using seamless technology. The material for production is plastic in sheets, which, according to international quality criteria, is environmentally friendly, safe and durable. It is convenient when creating products, as it is easy to cut and weld.

Plastic water containers, unlike metal barrels, are suitable for storing aggressive substances without additional processing. They are lightweight, practical, durable, do not require periodic maintenance and repair of seams

To make tanks, sheets of plastic are heated, shaped into the desired shape and secured together by seamless welding using welded rods.

The heated material is plastic and easy to mold. Therefore, at this stage, additional parts are installed.

Depending on the purpose of the storage tank, it can be equipped with:

- fittings;

- bends;

- flanges;

- shut-off ceilings;

- pumps;

- handles for transportation;

- drain;

- heating element;

- stiffening ribs;

- legs.

After giving the product the required shape, the finished tank must cool. After hardening, it is sanded in places where sheets are joined and additional elements are installed.

Polyethylene water tanks do not have a negative impact on humans and are safe for the external environment, and their affordable cost is an additional argument in their favor

Polypropylene containers must be purchased in accordance with their intended purpose, therefore, before choosing a container for the dacha or for agricultural needs, you need to decide on the package.

At the customer's request, the tank can be equipped with additional accessories:

- float to visualize the liquid level;

- galvanized metal frame for added strength;

- cover and tray, for outdoor use;

- lid with an air valve to preserve the properties and freshness of drinking water.

Conscientious manufacturers use certified equipment and materials. The consumer, in this case, receives the product without additional seams, from a material of a homogeneous fraction. Such a product will be durable, environmentally friendly and reliable in operation.

The performance properties and service life of plastic water containers depend on compliance with production technology and the quality of materials.

Violation of technology during the production process reduces the service life of plastic tanks. Some products are initially unsuitable for use. To avoid such troubles, the company must issue a quality certificate for the product.

Recommendations

When planning to purchase a storage tank and organize its operation in the house, it is worth enlisting the advice of experienced specialists:

- Combine the purchase of a water storage device with the purchase of a filtration device. This way you can get crystal clear drinking liquid. When considering offers on the market, you should pay attention to products. We manufacture and sell water treatment equipment and are ready to help you choose the option that suits you.

- When choosing a water storage tank, do not skimp on quality. If you buy a cheap product, you will probably spend more money on troubleshooting various problems.

- When doing the installation yourself, consider the possibility of dismantling the system for repairs or replacement.

- Be sure to consider grounding to prevent corrosion.

Drinking water tanks made of polypropylene or fiberglass

Drinking containers - reservoirs for storing a supply of drinking water

The development of almost any modern village or small city involves the operation of a water treatment system, which is impossible without the use of special tanks for storing drinking water. At the moment, instead of replacing the short-lived steel tanks used 50 years ago, in most cases plastic/composite drinking water tanks are used, as they are the most durable and easy to install.

The use of plastic tanks in the country

Living in a private country house or in a summer cottage, plot owners have to adapt to field conditions. A serious problem for summer residents is the organization of water supply to the site.

The low price determines the demand for plastic tanks. Such containers are used for collecting rainwater, irrigating the lawn and watering agricultural plants, arranging seasonal showers and drinking water.

Special containers for irrigation are equipped with a pump to create pressure for the outgoing water. If necessary, any universal storage tank can be equipped with a pump

In addition, certain tank models are used for autonomous sewage systems. For people who permanently live outside the city, in the absence of a sewage disposal channel, the installation of this engineering system is necessary.

With bottom or top position

There are three options for connecting a storage tank and using the water supply:

- Top location of the container. In this case, water is drawn under the influence of gravity. The higher the accumulator is located in relation to the consumer, the stronger the water pressure. Every 10 meters of height adds 0.1 atmosphere, or approximately 1 bar.

- Bottom location of a simple storage tank. Gravity will no longer help, and a pump is used to supply it to the water supply system, raising the pressure to the optimal level.

- Membrane-type storage tanks themselves create the required pressure for water supply. A lower location at the consumer level is optimal for them, since there will be no advantage from installing in an attic or tower.

How to determine the best option?

If a house has several floors and it is possible to place a storage tank in the attic, then this will eliminate the need for additional installation of a pump, and there is no need to spend money on an expensive membrane tank. In fact, this is an analogue of a water tower. However, raise the container so high as to ensure a comfortable pressure of 2-2.5 atm. it's still difficult. Moreover, the question arises of insulating the tank so that the water in it does not freeze in winter.

In the event of an emergency shutdown of water, the existing pressure is 0.2-0.3 atm. It will be quite enough to use the faucet in the sink, toilet or even shower, but it will not be possible to use some household appliances, such as a washing machine or dishwasher, which require more pressure to operate the solenoid valves.

Installing the tank at the same level as the consumer is suitable in cases where it is not possible to raise the tank to the attic or at least to a higher floor. The same applies to installing a storage tank in an apartment. You will need a small pump to supply water under pressure to the water supply. To ensure adequate operation, the pump will require a diaphragm expansion tank.

A storage tank with a membrane is perfect for storing water reserves both when using a centralized water supply system and in an autonomous system. However, it does not require additional equipment or overhead location. However, its cost is significantly higher than any conventional storage tank, even in combination with a simple pump.

How to choose

The main working body of the hydraulic tank is the membrane. Its service life depends on the quality of the material. The best membranes today are made from isobutated rubber (also called food grade). The body material only matters in membrane-type tanks. In those in which a “pear” is installed, water comes into contact only with rubber and the material of the body does not matter.

The flange should be made of thick galvanized steel, but better - stainless steel

What's really important about bulb tanks is the flange. It is usually made of galvanized metal

In this case, the thickness of the metal is important. If it is only 1 mm, after about a year and a half of operation, a hole will appear in the metal of the flange, the tank will lose its tightness and the system will stop working. Moreover, the warranty is only one year, although the stated service life is 10-15 years. The flange usually deteriorates after the warranty period expires. There is no way to weld it - the metal is very thin. You have to look for a new flange at service centers or buy a new tank.

So, if you want the accumulator to last a long time, look for a flange made of thick galvanized or thin, but made of stainless steel.