An autonomous water supply system, which independently supplies water to distribution points as in a city apartment, has long ceased to be a curiosity. This is the norm of country life, which just needs to be properly designed, assembled and equipped with equipment capable of starting and stopping the system as the taps are used.

Stable operation of an independent network will be ensured by an expansion tank for water supply. It will protect against water hammer, significantly extend the service life of pumping equipment, guarantee regular filling of the system with water, and eliminate the need to carry it in buckets.

We are pleased to introduce you to the features of the device and the operating principle of the hydraulic accumulator. We carefully describe the rules for choosing a membrane tank, the specifics of installation and connection. We have supplemented the information offered for consideration with useful illustrations, diagrams and video tutorials.

Connection diagrams for hydraulic tanks

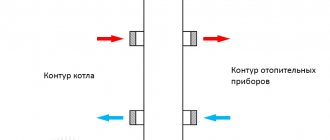

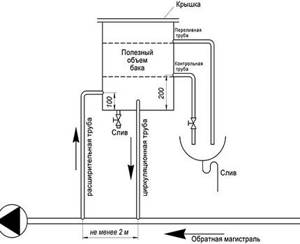

For a hot water supply system, the expansion tank is installed in the section of the circulation line, the suction line of the pump, closer to the water heater.

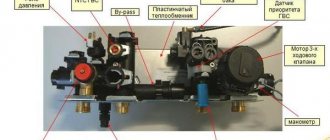

The tank is equipped with:

- pressure gauge, safety valve, air vent - safety group;

- shut-off valve with a device that prevents accidental shut-off.

In a water supply system where water heating equipment is present, the device takes on the functions of an expansion tank.

Installation diagram in the hot water system: 1 – hydraulic tank; 2 – safety valve; 3 – pumping equipment; 4 – filtration element; 5 – check valve; 6 – shut-off valve

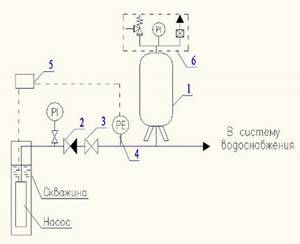

In the cold water system, the main rule when installing a hydraulic accumulator is installation at the beginning of the piping, closer to the pump.

The connection diagram must include:

- check valve and shut-off valve;

- security group.

Connection schemes can be very different. The connected hydraulic tank normalizes the operation of the equipment, reducing the number of pump starts per unit of time and thereby extending its service life.

Installation diagram in a cold water system with a well: 1 – tank; 2 – check valve; 3 – shut-off valve; 4 – relay for pressure regulation; 5 – pumping equipment control device; 6 – security group

In a scheme with a booster pumping station, one of the pumps runs constantly. This system is installed for houses or buildings with high water consumption. The hydraulic tank here serves to neutralize pressure surges, and to accumulate water, a container of as large a volume as possible is installed.

Why do you need an expansion tank?

Installation of such a device allows you to simultaneously solve two load-bearing technical problems, such as:

- contributes to fewer cycles used (switching off and on) of the pump, which allows you to increase its service life;

- allows you to protect the device from possible water hammer, which may indicate that the device is congested or the presence of differences in the electrical network. These points can make the device unstable;

- helps create a reserve volume of liquid, which will be under a certain pressure inside the system, providing an optimal level of water supply anywhere in the house. On average, the tank volume is about 30 liters, which makes it possible to provide one point with liquid for several minutes.

Features of adjusting the hydraulic accumulator

Expansion tanks for water supply are sold with standard manufacturer settings - often the pressure in the air compartment is already set at 1.5 bar. The permissible pressure is always indicated on the label and the manufacturer does not recommend deviating from the specified parameters, especially in the direction of increasing it.

Before proceeding with the adjustment, the system is disconnected from the power supply and the shut-off valves are closed. The membrane tank is completely emptied by draining the water - an accurate pressure indicator can only be measured when the water compartment is empty.

Next, pressure readings are taken using an accurate pressure gauge. To do this, remove the decorative cap from the spool and bring the device. If the pressure differs from the required one, it is brought into compliance by pumping or bleeding excess air.

Considering that the manufacturer is against deviations from the recommended pressure values, it is necessary to select suitable equipment at the design stage, the parameters of which will not conflict with each other

When adjusting the pressure in the gas compartment of the tank, the manufacturer fills it with an inert gas, for example, dry nitrogen. This prevents corrosion of the inner surface. Therefore, users are also recommended to use technical nitrogen to increase pressure.

Setting the tank pressure in the water supply system

The pressure in a closed tank is always set slightly lower (by 10%) than the pressure level when starting the pump. By adjusting the pressure in the device, you can adjust the water pressure. The lower the gas pressure in the hydraulic tank (but not less than 1 bar), the more water it will hold.

In this case, the pressure will become uneven - strong when the tank is full and increasingly weak when it is empty. To ensure a strong and even flow of water, set the pressure in the chamber with air or gas to within 1.5 bar.

The water pressure in the water supply is set using a relay. When setting the pressure in the expansion chamber, these values must be taken into account

Adjusting the hydraulic tank in the water heater trim

The expansion tank, which is used for hot water supply, should initially not contain water. The pressure in the device is set at a value that is 0.2 greater than the upper pump shutdown threshold.

For example, if the relay is configured to turn off the equipment at a pressure of 4 bar, then the pressure in the gas compartment of the expansion tank should be set to 4.2 bar.

Installed in the water heater piping, the tank does not serve to maintain pressure. It is designed to compensate for expansion when water is heated. If you set the pressure in it to a lower value, then there will always be water in the tank.

Right choice

When you come to the store, remember that expanders are divided according to their use in heating or water supply.

Often, it is impossible to distinguish models externally; the device is even painted in one color, usually red.

Differences in the properties of the membrane can lead to accidents if you install a model that does not match the characteristics.

Pay attention to the characteristics of the device, which are indicated on the nameplate.

The label contains information about the characteristics of the device.

If it is indicated that the pressure is 10 bar, the temperature is +70 degrees, then the model is intended for pipelines with cold water .

The next thing you need to pay attention to is the volume of the steel container, which is determined as follows:

- the volume of models for heating should be equal to 10 percent of the amount of coolant used in the pipeline. This calculation will allow you to install the expander with a small margin;

- for cold water supply, the device is selected based on the parameters of the pump, which should not produce more than 50 on/off cycles per hour. The consultant in the store will tell you the exact parameters of the expander. Read about straight collet fitting here;

- The boiler tank is selected based on 10 percent of the water heater volume.

Do you know how to build a pond at your dacha with your own hands? Diagrams, photos, videos and step-by-step instructions are published in a useful article.

Read how to make a pipe cutter with your own hands here.

On the page: https://ru-canalizator.com/santehnika/s-oborudovanie/truborezy.html it is written about a manual pipe cutter for large-diameter steel pipes.

IMPORTANT !

An expander used in cold water supply is installed for the boiler.

Hydraulic tank maintenance rules

A routine inspection of the expansion tank consists of checking the pressure in the gas compartment. It is also necessary to inspect the valves, shut-off valves, air vent, check the operation of the pressure gauge and water pressure switch. To ensure the integrity of the tank, an external inspection is carried out.

During preventive maintenance, the pressure in the hydraulic tank should be measured and adjusted if necessary.

Despite the simplicity of the device, expansion tanks for water supply still do not last forever and can break. Typical causes are rupture of the membrane or loss of air through the nipple. Signs of breakdowns can be determined by the frequent operation of the pump and the appearance of noise in the water supply system. Understanding how your accumulator works is the first step to proper maintenance and troubleshooting.

Why does blood pressure drop?

The indicator should be constant, but in some cases there are problems with deviation. The value decreases:

- When a leak occurs. They rarely occur in water-filled systems. Other liquids contribute to the formation and expansion of small cracks that cause the problem.

- In case of malfunctions with the boiler. If there is no leak, but the pressure drops, you should call a specialist. He will help identify the problem and recommend a solution.

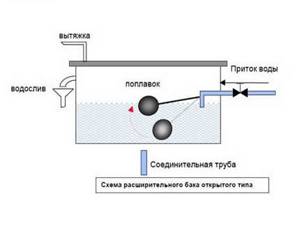

Installation of an open type hydraulic tank

An open-type device is used less and less often, as it requires constant user intervention in its operation. An open expansion tank is an unsealed container that serves to generate pressure in the water supply system, accumulate water, and also serves as an expansion chamber.

The tank is connected to: a drain tap, pipes for the recirculation and supply pipes, a control and overflow pipe

The tank is installed above the highest plumbing point, for example, in the attic, water enters the system by gravity. Every meter the device rises increases the pressure in the water supply by 0.1 atmospheres.

To automate the process of providing water, the tank is equipped with a float switch and an automatic relay is installed that will turn the pump on and off.

The container is mounted in a frost-free room, covered with a lid to prevent dust and debris, and the walls are wrapped in mineral wool or other insulation.

This method of organizing water supply requires regular monitoring by the user, otherwise the water may freeze at subzero temperatures (if the room is not heated). The liquid will evaporate, so you will have to constantly add it.

In addition, such a container is bulky and not aesthetically pleasing; it requires an attic space in the house. But the main drawback of the device is that the tank is not designed to work under conditions of high water pressure in the system.

Types of membrane tanks

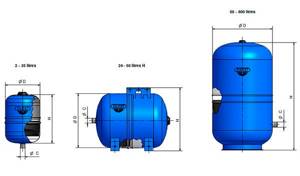

There are two types of expansion membrane tanks:

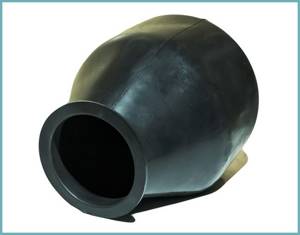

- With a replaceable membrane - models that imply the ability to change the rubber membrane. At the first need, it can be removed through the flange by unscrewing its bolts. In large tanks, the membrane is additionally fixed to the nipple, which allows you to stabilize the device, but even in this case it can be easily removed from the mounts on the back.

Membrane for hydraulic accumulator - With a stationary membrane - tanks in which the separation membrane is fixed as rigidly as possible and cannot be replaced. If it fails, the entire device will have to be replaced. The price of such expansion tanks is lower than the cost of models of the previous type, but there is no need to talk about complete ease of use.

Advice. When choosing between a replaceable and stationary membrane, consider one important factor: in the first case, the water is completely contained in the membrane and does not come into contact with the inner surface of the tank, which eliminates corrosion processes, and in the second case, the contact is maintained, so it is impossible to achieve maximum protection against corrosion.

Natural noise

The rumble of water in pipes and hum are associated with uneven flow of liquid. There are three reasons why the coolant makes noise in the pipes:

- Air that has entered the system through leaks in threaded connections or for other reasons;

- Joining of lines of different diameters, causing acceleration or deceleration of flow;

- Internal obstacles include poor-quality welds, corrosion, scale and dirt accumulated in radiators.

If the water makes a slight noise in the pipes, a hum is heard, then this is not as critical a situation as when knocking occurs. But something needs to be done immediately about the sudden noise. For example, remove air from the heating system, the accumulation of which will ultimately lead to a stop of thermal convection.

When eliminating air pockets, the temperature of the coolant should not exceed 40°, otherwise there is a risk of burns. To do this, you need to use special Mayevsky taps, which should be equipped with all radiators or one, but the top one in the group. In a single-pipe system, air begins to be expelled from the device, which is located at the lower end of the collection line (the last one from the boiler in the direction of the coolant).

How does the above ideal diagram differ from a real expansion tank?

To many. We don't have a piston. Instead of a piston, we have a rubber bag that collapses under pressure. There are no means for neatly folding the bag. The bag wrinkles as it wants. Obviously, it forms all sorts of folds. When water rushes into the bag, it straightens these folds. Again, this bag has a seam.

Rubber itself also stretches, which introduces some nonlinearities into the described process.

And in general, all laws about the relationship between pressure and volume (Boyle-Mariotte) were written for an ideal gas and ideal conditions. In practice, only molecules were considered and that was all. With real gas, especially with air, which is a mixture of gases, everything is more complicated, of course.

In a real system there are contributing factors. Such as the quality of the rubber, the quality of the tank, the setup of the equipment on which the tank was produced, the team of workers who made these tanks. I am sure that tanks made by workers from Albania will be different from tanks made by workers from Serbia. I’m not saying who will do it better - I don’t know. But it is absolutely certain that they will differ.

Antifreeze is leaving - main and side signs

Now everything is clear with the reasons, but how can you understand that coolant is being thrown out of the system? Antifreeze evaporates very quickly, so it is not always possible to catch traces of it, especially if it leaves in small quantities . Of course, when a lot of liquid is squeezed out through the expansion barrel at once, characteristic puddles will remain on the asphalt. Well, in general, you just need to observe the behavior of your “iron horse”; it will indicate in the best way possible a particular malfunction.

So, in cases where doses of antifreeze are squeezed out of the expansion tank all the way into the cabin, a characteristic sweetish smell will appear there. But when clouds of white smoke come out of the exhaust pipe, then, most likely, the coolant goes into the car engine. The most unpleasant situation that can happen is that liquid gets into the engine crankcase, as a result of which the latter can fail. A sign of such a malfunction is the formation of a white emulsion on the surface of the oil filler cap. In addition, sometimes check the condition of the space under the belt cover; increased humidity indicates an antifreeze leak under the timing belt due to pump failure.

You can understand that antifreeze is already boiling in the expansion tank by the following signs. Firstly, the temperature needle will rise abruptly to 130. Secondly, white foam will form on the filler neck. Thirdly, the engine will stop functioning. Fourth, the coolant level will rise sharply. In this case, white smoke will come out of the exhaust pipe. All this should not only alert you, but also prompt you to take action immediately. Why? Let's take a look below!