Why is an expansion tank needed in a heating system?

When the coolant is heated, the pressure in the boiler and the heating system circuit increases significantly due to the temperature increase in the volume of the coolant fluid. Considering that the liquid is a practically incompressible medium and the heating system is sealed, this physical phenomenon can lead to the destruction of the boiler or pipelines. The problem could be solved by installing a simple valve that could release the excess volume of hot coolant into the external environment, if not for one important factor.

When cooling, the liquid contracts and air enters the heating circuit in place of the discharged coolant. Air jams are a headache for any heating system; they make circulation in the network impossible. Therefore, it is necessary to bleed air from heating radiators. Constantly adding new coolant to the system is very expensive; heating cold water is much more expensive than heating the coolant that came into the boiler through the return pipeline.

This problem is solved by installing a so-called expansion tank, which is a reservoir connected to the system by one pipe. Excess pressure in the heating expansion tank is compensated by its volume and allows for stable operation of the circuit. Externally, expansion tanks for the heating system, based on the calculation results and the type of heating circuit, are different in shape and size. Currently, tanks are produced in various shapes, from classic cylindrical tanks to so-called “tablets”.

What it is

Not every owner of a private house or apartment knows exactly what an expansion tank is. In this case, the name of this device speaks for itself - under conditions of a fixed mass of coolant in the heating circuit and pipeline, which are not elastic, with a change in the temperature of the coolant, the pressure level in the entire system will necessarily change. Here it is worth considering the fact that liquid expands when heated. The moment the force becomes stronger than the strength of the flow pipe/radiator, a serious accident will occur. Its main reason in this case will be the fact that water, when its volume changes under heating conditions, becomes almost incompressible. From this property comes the definition of water hammer.

The solution to such a serious problem is quite simple. It is necessary to place a special reservoir (expansion tank) in the heating system, equipped with a substance that can be easily compressed.

Types of heating systems

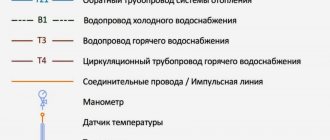

There are two schemes for building heating networks - open and closed. An open (gravity) heating system is used in centralized heating networks and allows water to be directly withdrawn for hot water supply needs, which is impossible in private housing construction. Such a device is located at the top point of the heating system circuit. In addition to leveling pressure drops, the heating expansion tank performs the function of natural separation of air from the system, since it has the ability to communicate with the outside atmosphere.

Thus, structurally, such a device is a compensation tank of the heating system, not under pressure. Sometimes a system with gravitational (natural) circulation of a heat-carrying fluid may be mistakenly called open, which is fundamentally incorrect.

With a more modern closed circuit, an expansion tank of a closed-type heating system with a built-in internal membrane is used.

Sometimes such a device can be called a vacuum expansion tank for heating, which is also true. Such a system provides for forced circulation of the coolant; air is removed from the circuit through special taps (valves) installed on the heating devices and at the top of the system pipelines.

Common problems

Expansion tanks, like any other heating units, are subject to a number of specific problems. Let's get to know them.

The most common breakdown of such units is the rupture of the membrane part. As a rule, this occurs due to too high pressure (above normal) or uneven loads. Please note that replaceable elements break much more often than compressed ones, since stronger materials are used for the latter, because they can be changed at any convenient time.

The problem of a damaged membrane can lead to many unpleasant consequences. For example, this often causes water to leak from the air valve.

If the membrane is not replaced in time, its rupture will lead to the fact that over time the tank will simply fail. This is due to the fact that liquid gets on the inner surface of the tank, after which it can become covered with rust and become unusable.

Also, users quite often encounter damage to the tank body. If such a problem occurs with your equipment, it is better for you to seek help from a specialist. Do not attempt to repair damaged cabinet elements yourself, especially if you have never encountered such work before.

There are also cases when the expander boils. Most often, this problem occurs in homemade open-type structures. The main essence of this problem is the lack of circulation speed (or its complete absence).

Here are the main reasons for such breakdowns.

- Reduced wiring diameter. The main single-pipe heating circuit is usually installed with a pipe that is no less thin than DN 32.

- No slope. After the heating boiler, you need to make a so-called accelerating manifold. To do this, the pipe must be raised to the upper section of the circuit, where the expander is installed. The remaining part of the contour should be laid with a downward slope.

Many users are wondering how to fix such a serious problem without completely dismantling and reinstalling the heating system. The answer is simple - you need to install a circulation pump. This part works great in many systems (especially the open type). The pump must be placed on the return line directly in front of the boiler.

Another problem with expansion tanks is air blockage in the heating system circuit. To avoid colliding with it, you need to monitor the volume of water.

Device and principle of operation

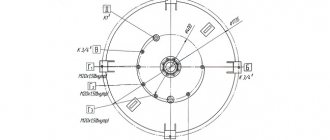

A structurally closed expansion tank in a heating system is a cylindrical tank with a rubber membrane installed inside, which divides the internal volume of the vessel into air and liquid chambers.

Membranes are of the following types:

- balloon type, with the coolant inside the rubber balloon and air or nitrogen under pressure outside;

- in the form of a diaphragm dividing the internal volume of the expansion tank for a closed heating system into two parts - with water and pumped air or gas.

Gas pressure is adjusted individually for each system, which is described in the instructions supplied with devices such as an expansion tank for closed-type heating. Some manufacturers provide the possibility of replacing the membrane in the design of their expansion tanks. This approach slightly increases the initial cost of the device, but subsequently, if the membrane is destroyed or damaged, the cost of replacing it will be lower than the price of a new expansion tank.

From a practical point of view, the shape of the membrane does not in any way affect the operating efficiency of the devices; it should only be noted that a closed-type balloon expansion tank for heating holds a slightly larger volume of heat-carrying liquid.

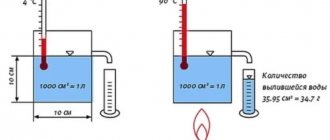

The principle of their operation is also the same - when the water pressure in the network increases due to expansion when heated, the membrane stretches, compressing the gas on the other side and allows excess coolant to enter the tank. When it cools down and, accordingly, the pressure in the network drops, the process occurs in the reverse order. Thus, regulation of constant pressure in the network occurs automatically.

It is necessary to focus on the fact that if you buy an expansion tank for the heating system at random, without the necessary calculations, then it will be very difficult to achieve stable operation of the heating network. If the tank size is significantly larger than necessary, the pressure required for the system will not be created. If the tank is smaller than the required size, it will not be able to accommodate the excess volume of heat-carrying liquid, which may result in an emergency situation.

Calculation of expansion tanks

To calculate an expansion tank for closed-type heating, you first need to calculate the total volume of the system, consisting of the volumes of the circuit pipelines, heating boiler and heating appliances. The volumes of the boiler and heating radiators are indicated in their passports, and the volume of pipelines is determined by multiplying the internal cross-sectional area of the pipes by their length. If the system contains pipelines of different diameters, then their volumes should be determined separately and then added together.

Further calculations for devices such as an expansion tank for closed-type heating are carried out using the formula V = (Vc x k) / D, where:

Vс – volume of heat-carrying fluid in the heating system, k – coefficient. volumetric thermal expansion, taken for water 4%, for 10% ethylene glycol - 4.4%, for 20% ethylene glycol - 4.8%; D is an indicator of the efficiency of the membrane unit. It is usually indicated by the manufacturer or can be determined by the formula: D = (Рм – Рн) / (Рм +1), where: Рм is the maximum possible pressure in the heating network, usually it is equal to the maximum operating pressure of the safety valve (for private houses it rarely exceeds values 2.5 – 3 atm.) Рн – initial pumping pressure of the air chamber of the expansion tank, taken as 0.5 atm. for every 5 meters of height of the heating system circuit.

In any case, it should be assumed that expansion tanks for heating should provide an increase in the volume of coolant in the network within 10%, that is, if the volume of coolant in the system is 500 liters, the volume together with the tank should be 550 liters. Accordingly, an expansion tank of the heating system with a volume of at least 50 liters is required. This method of determining volume is very approximate and can result in unnecessary costs for purchasing a larger expansion tank.

Currently, online calculators for calculating expansion tanks have appeared on the Internet. If such services are used to select equipment, it is necessary to carry out calculations on at least three sites to determine how correct the calculation algorithm of a particular Internet calculator is.

Calculation

To determine the volume of the expander, you can rely on several different methods.

To do this, it is advised to contact specialists in special bureaus. As a rule, to carry out all the necessary calculations, they use special programs that allow them to take into account all the features and nuances that affect the operation of the heating system. However, it must be taken into account that the services of such specialists are in most cases expensive. You can also calculate the volume of the tank yourself. To do this, use the generally accepted formula. In this case, you need to be as careful as possible, since even a small mistake can lead to incorrect values.

When making calculations, it is important to take into account absolutely all the nuances: the volume of the heating system, the specific type of coolant, and even its physical properties

In the given formula:

- C is the total volume of coolant in the system;

- Pa min – indicator of the initial absolute pressure in the tank;

- Pa max is the highest pressure parameter that can occur in the unit.

If you are afraid of making a mistake or you do not have time to carry out all the required calculations, then you should turn to the help of special online calculators. However, in this case, it is recommended to double-check the results obtained on several sites so as not to encounter incorrect operation of one or another portal.

Some people make it simpler - they estimate the necessary parameters by eye. In this case, the specific capacity of the heating system is equal to 15 l/kW. The result will be approximate values. But keep in mind that this method is only allowed during the feasibility study process.

Manufacturers and prices

Currently, the problem of buying an expansion tank for heating lies only in the correct selection of the type and volume of the device, as well as the financial capabilities of the buyer. The market offers a wide selection of instrument models from both domestic and foreign manufacturers. However, it should be noted that if the purchase price for such devices as a closed-type expansion tank for heating is much lower than that of its main competitors, then it is better to refuse such a purchase.

The low cost indicates the unreliability of the manufacturer and the low quality of the materials used in its manufacture. Often these are products from China. As with all other goods, the price for a high-quality expansion tank for heating will not have a significant difference of about two to three times. Conscientious manufacturers use approximately the same materials, and the difference in price of models with similar parameters of about 10-15% is determined only by the location of production and the pricing policy of sellers.

Domestic manufacturers have proven themselves well in this market segment. By installing modern technological lines in their production, they achieved the production of products whose parameters are not inferior to the best global brands at a lower cost.

It should be borne in mind that it is important not only to buy an expansion tank for closed-type heating, it also requires its correct installation.

Having the necessary skills and following the instructions, you can install it yourself. If the technician still has any doubts about his knowledge, then it is best to turn to professionals to guarantee stable operation of the heating network and eliminate possible malfunctions.