Recently, fireplaces have become increasingly popular. And what fireplace can do without such irreplaceable attributes as a chimney and a pipe on the roof of the house? Along with fireplaces, the once popular trend of chimney caps (also called chimney caps and chimney caps) is also making a comeback.

Such a cap is an ancient element of architecture that bears the imprint of antiquity. The presence of a chimney on the roof speaks volumes, in particular about the refined taste of the owner. Of course, today caps are sold in a fairly wide range and, if you wish, you can choose a wonderful decoration for your home, but you can try to do it all yourself. There is nothing complicated in the design of the chimney, but before you begin production, understand the structure of this element and the materials that can be used in the work.

- 1 Covering device

- 2 Why do you need a chimney cap?

- 3 Classification of chimneys 3.1 Video - Cap with weather vane

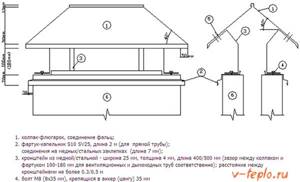

- 5.1 Drawing of the cap for the chimney pipe

- 6.1 Option No. 2 A simple way to assemble a cap for a chimney pipe

Functional purpose of the chimney cap

Sometimes the design of chimney caps is so intricate that they become a real masterpiece of architectural art. However, miscalculations made when installing the hood can lead to a decrease in draft, even leading to smoke in the home.

In the most general sense, the cap on a chimney pipe is designed to serve as a barrier to prevent rainwater, snow or debris from entering the pipe channel, as well as bird nesting. Even the simplest chimney umbrella will protect against these negative aspects, plus it will make the roof look neater.

Regardless of the design of the structure and its cost, the canopy for the chimney pipe performs the following functions:

- ensures the cleanliness of the chimney, preventing it from clogging and moisture ingress;

- protects the brickwork of the protruding part of the pipe from premature destruction, leveling temperature differences and the adverse effects of atmospheric phenomena;

- prevents the influence of gusty, hurricane winds on the movement of air in the system, preventing it from blowing into the pipe.

However, not everyone considers a chimney umbrella to be a necessary element of the heating system, considering its shortcomings too significant. For example, if, due to the installation of a cap, the chimney channel becomes narrower, this affects the performance of the entire heating system, and in the most extreme cases, it can lead to the filling of the home with combustion products, the most dangerous of which is carbon dioxide.

Why do you need a chimney box?

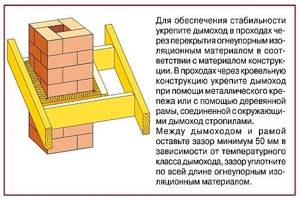

According to safety regulations, there must be a certain distance between the walls of the ceiling and the chimney pipe, otherwise, when smoke passes through, all elements will heat up, and this can lead to fire or damage to integrity.

Products of this type pass through the ceiling and come out, providing the maximum degree of protection, because inside they are filled with materials that can withstand high temperatures quite well.

Many devices for removing combustion products are made of brick; it can be destroyed over time due to weather conditions; a chimney box on the roof will be indispensable in such a situation.

It is equally important that the solution will certainly absorb moisture upon contact with the external environment, and this will lead to cracking and damage. To avoid such excesses, a casing is mounted on the outside of the ceiling.

It is often very difficult to achieve a unified composition on the roof without additional work, because the materials will be different, and modern types are produced in several color options. Such moments can be leveled out quite easily; practical cladding will help with this.

Arguments against installing a chimney cap

As a rule, a cap on a brick pipe rises on the roofs of houses in a holiday village, almost never being found in villages. This is due to the fact that such an architectural element has disadvantages, knowing about which, pragmatic village people refuse additional costs. So, the cap, in any case, is a kind of barrier that makes the draft less than in its absence. This leads to the fact that the wood burns worse, and the smoke moves through the channels of the heating system more slowly. At the same time, the visor is an obstacle to the release of combustion products, which can create a dangerous situation at the slightest disturbance in traction.

If the draft disappears, then all the smoke from the stove goes into the house Source ptzgovorit.ru

In addition, the visor requires maintenance and periodic replacement, which is not always convenient and safe. In particular, ice forms on it in winter, blocking the exit of carbon dioxide. To remove it, you need to go up to the roof and mechanically clear off the ice. However, the main arguments against installing a fungus do not even concern its disadvantages, but its inexpediency in general. In particular:

- modern chimneys are narrow and round in shape, which makes bird nesting impossible;

- a well-designed flue has a special compartment for collecting condensate and moisture;

- caps made of galvanized steel are short-lived, burn out within 5 years and require replacement.

The most important counterargument against installing an umbrella on a chimney among most skeptics remains the need to incur additional costs that can be avoided without compromising safety and comfort.

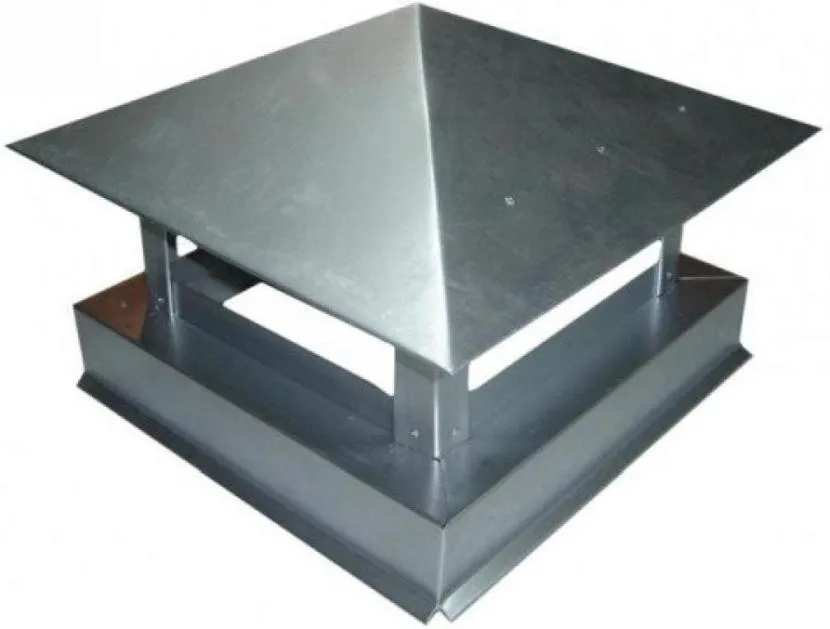

Covering device

The design is extremely simple: it consists of an umbrella that protects the chimney pipe from precipitation, and a drip - a device that drains water. Thanks to the use of a cap, the formation of ice in winter is minimized. If we talk about the principle of operation, then it can be described approximately as follows:

- Air flows that rise through the pipe encounter an obstacle - a deflector on the chimney.

- The air stream sliding along the cylinder turns upward, as a result of which the smoke coming out of the pipe is, as it were, sucked in.

- This leads to an increase in the speed of movement of heated air through the chimney duct.

- At this time, the cap protects the chimney channel even during air movement due to the fact that it has small gaps.

- If the wind moves downwards, then air vortices are formed under the chimney (they slow down the exit of smoke). To eliminate this, the cap design has a reverse cone.

Types of chimney caps

Today, developers have access to a huge variety of options for chimney caps, from budget models made of tin to ornate multi-level products with forged copper elements.

Copper pipe head - relatively durable, but expensive Source avito.st

See also: Catalog of companies that specialize in the installation of fireplaces and stoves, as well as related work

The choice of one option or another depends on three factors:

- Financial opportunities . You can make a simple galvanized steel cap with your own hands for no more than 1,000 rubles, while an exquisite copper cap with decorations and a weather vane can cost several tens of thousands of rubles;

- Heating system design . When planning the head for a pipe, take into account its diameter and features. A cap that is raised too high will not prevent birds from entering the chimney with all the ensuing consequences, but a cap that is set too low will inevitably have a negative effect on the traction force.

- General concept of the architectural project and personal preferences . The main principle of architecture is harmony, therefore, on a modest one-story building, an elaborate cap on a brick chimney pipe will look bulky and inappropriate, just as an artisanal cap on the chimney of an elite mansion will spoil the appearance of the facade.

The classic chimney cap resembles a house with a sloping roof and looks very elegant. Very popular today are finials with a rounded roof, which can be found in old Europe.

The simplest cap for a round chimney Source tildacdn.com

Domestic developers of the budget segment prefer cone-shaped canopies with an adjustable base diameter, which makes it possible to make their size universal.

As for the newfangled forged umbrellas for the chimney pipe, for all their attractiveness, it is important to understand that they will burn out at exactly the same speed as less expensive ones, although they will please the eye many times more.

Boxes and casings for pipes

① Choose any basic model on our website or draw your own sketch.

② Decide on color according to RAL or RR >>

③ Write a request by e-mail: or call

④ Agree with the manager on the form of payment and production time

⑤ The order can be picked up at one of our offices or ordered delivered to your site

R.S. You can call our specialist for measurements and subsequent installation

The following colors are available:

| RAL 1014 | RAL 5005 | RAL 7024 |

| RAL 1015 | RAL 6002 | RAL 8017 |

| RAL 3005 | RAL 6005 | RAL 9003 |

| RAL 3009 | RAL 7004 | RAL 9004 |

| RAL 3011 | RAL 7005 | RAL 9006 |

| RR 32 | RR 11 | RR 29 |

Other colors and coatings are available upon request

If you choose a color from stock items, then the planks (additional elements and flashings) can be picked up the next day. We make fence caps and chimneys within 5 working days. If the color is custom-made, then the production time is individual, but in any case it increases by 1-3 weeks due to the delivery of materials.

Powder painting is possible in any RAL color, including with additional effects.

What is a false pipe

The casing (or false pipe) is a special metal lining of the main brick pipe. It can be installed on top of the brickwork of the pipe to protect the pipe from the negative effects of the external environment. The casing is installed for several reasons, for example: In order to make a collapsing pipe look more presentable.

The casing encircles the pipe on all sides and thereby extends its service life. Chimney pipe covers are an ideal solution in this case. If it is not possible to brick the pipe, you can install a false pipe. Then such a pipe will look aesthetically pleasing and give the entire roof a finished look.

For example, if the roof is copper, then the casings for the chimney pipes can be made of copper.

Protective covers for pipes can be made of different materials, any color and texture.

What types of protective covers are there for chimney pipes?

Galvanized Pipe Casing

Will last a very long time. This casing is fire-resistant and fireproof. Such a pipe heats up quickly, which provides good traction. Moreover, it is easy to install.

Corrugated box for chimney pipes

Very convenient for installation. It can be bent and given the desired shape. Usually made of stainless steel. Resistant to temperature changes, it is not afraid of corrosion.

Pipe insulation casing

Can be galvanized, aluminum, stainless. This metal casing has a number of advantages. For example, it is completely ready for installation, easy to install, durable and aesthetically pleasing.

It is best to order a protective casing for a pipe from professionals who can be contacted through the website on the Internet. There you can also see photos of finished products and read reviews from other customers.

The casings designed by us will hermetically protect the pipe and give a beautiful appearance to the entire roof. Pipe covers are perfect for any roof structure; be it metal, profile, soft roofs, copper or galvanized roof coverings, natural tiles.

Order aprons and pipe casings

At your request, we carry out measurements, design, engineering, order the necessary materials, both in Russia and abroad (if necessary), and provide turnkey delivery and installation.

To manufacture the hood for the hood and the apron for the chimney, we use only modern, high-quality materials and technologies

Pipe covers enable efficient and quick finishing around chimneys.

Chimney pipe covers are an elegant solution for masking edges along pipes

You can leave a request on our website right now>>

Source: https://eurogib.ru/products/list/kozhuhi_dlya_trub/

The main mistakes when installing a cap on a chimney

The most common mistake when installing an umbrella on a chimney lies in the use of bird netting around the perimeter. The problem is that even without it, condensation appears along the contour of the visor during the cold period, which freezes in winter, turning into thick ice. As soon as the ice blocks the access of air to the pipe, the release of combustion products will stop, smoke will begin to enter the room, and the draft will disappear. If the roof is additionally framed with bird netting, the formation of ice will occur faster than it can melt and the owner will have to regularly climb onto the roof to clear the ice deposits.

Most likely, the head will have to be cleaned regularly Source myguru.ru

What needs to be protected from the top of the chimney?

Let's start with the fact that even the simplest smoke caps can add up to 20% to the traction force. If your home is heated by a stove, this is an important advantage, as it promotes complete combustion of solid fuel and increases the efficiency of the system as a whole.

For a brick chimney, a chimney is also needed as protection from precipitation. With constant exposure to dampness, the cement between the bricks may begin to crumble over time, and the entire masonry may collapse.

Also, to protect the chimney from debris and birds, chimneys with mesh, popular in the West, are increasingly being used.

Another important function of the cap over the pipe is protection against backdraft. If the chimney is completely open, the wind can create back pressure and impair draft. And sometimes the air flow overturns, reverse draft occurs, and smoke begins to flow into the room. This is not only unpleasant, but also dangerous to health and life.

That is why the chimney of a stove or fireplace needs a certain barrier from the effects of wind and precipitation. For this purpose, the following designs are used: deflectors, weather vanes and caps. Let's look at each of these chimney devices separately: what are their pros, cons and application features.

How to make a chimney cap with your own hands

Despite the fact that it is not difficult to make a chimney pipe cap yourself, most developers prefer to buy ready-made ones, saving time and effort. This approach is not without common sense, since professional production of chimney caps allows you to obtain products of a more aesthetic appearance, equipped with additional functions and decorations. Particularly attractive is the opportunity to order a visor according to an individual sketch, taking into account all your wishes.

However, if you try, you can make a chimney cap of quite decent quality and appearance yourself. This requires five steps:

1) Draw a sketch of the cap , carefully measuring the internal diameter of the chimney pipe. The dimensions are calculated as follows:

- diffuser diameter = inner pipe diameter × coefficient 1.3;

- diameter of the base of the cap = diameter of the inner pipe × coefficient 1.7;

- cap width = inner pipe diameter × factor 1.9.

It is important! It is necessary to ensure that the dimensions of the canopy are 10 cm larger than the size of the pipe, protruding at the edges on all sides by 50 mm.

2) Purchase sheet metal and scissors for cutting it, as well as a rubber mallet, metal corners and hardware.

3) Give the sheet of metal a square shape and bend its corners in pairs towards the opposite ones.

4) Attach the resulting pyramid to the base post.

5) Install the cap on the pipe, securing it, having previously adjusted it to size.

Before installation, be sure to check the technical regulations of the region and ensure that the work meets the requirements. This will not only save you from troubles with putting the building into operation, but will also provide the opportunity to obtain insurance in case of damage or loss of the structure.

Installation of the structure

Before lifting the finished chimney box, you need to insulate the joints at the point of contact with the roof; roofing felt or good-density polyethylene are perfect for this. After completing the manipulations, the casing is put on the frame and secured with screws, and the void is filled with fireproof material.

For work, it is better to take a screwdriver; working with a drill at a height will be uncomfortable due to the wires coming to it. Decorative corners will not only ensure tightness, but can also significantly transform the appearance, making it as aesthetically pleasing as possible.

Using a detailed algorithm of actions, you can design and install sufficiently high-quality protection against fires and pipe destruction with your own hands, while saving money.

How to install a cap on a chimney pipe

When installing the headrest, it is important to remember that the safety of the system and its proper functioning are more important than the aesthetics of appearance. That is why it is necessary to strictly follow the rules for installing the visor, namely:

- If the efficiency of the heating boiler exceeds 85%, it is unacceptable to use the classic pyramid. Only a conical visor with an open nozzle is suitable here, which will not become covered with ice in any frost;

- If the chimney is made of brick without inserts and is directly connected to the heat generator, it should be covered with a lid with a through pipe;

- A stainless steel plate should be placed inside the chimneys, which will significantly extend the life of the visor;

- If the umbrella for the pipe has vents, it is optimal to use gable or hip umbrellas.

Since this issue is of importance that determines the reliability of operation of the entire heating system, it is better not to try to solve it yourself, but to seek advice from specialists.

Types of boxes

The design can reduce heat loss and eliminate unnecessary condensation accumulation, but the issue of choosing the material of the product should be taken seriously; first of all, pay attention to ease of installation and durability. Among the common types, it is worth highlighting the following execution options:

- Tree.

- Fireproof plasterboard.

- Metal.

Galvanized and stainless steel are popular among owners, because the service life of such a product is long. Installation will not require much time and effort, and the created casing or finished copy can be painted to match the color of the roof, achieving maximum harmony.

Wooden panels are installed as a basis for further cladding, and the space between the pipe is filled with fireproof materials; specialized drywall also serves as a decorative cladding, but the durability of these components without proper care and treatment is not very high.

Therefore, most experts advise using them directly between the ceiling and the chimney outlet from the roof.

Why do you have to change the caps on the chimney pipe?

Not a single cap on a chimney, even the most expensive one, will last forever and will sooner or later require replacement. The reason for this is the effect of high temperatures on the vulnerable metal. At the outlet, the temperature of the smoke stream exceeds 150 °C - 180 °C and its constant impact on the walls of the canopy leads to its burnout. A galvanized steel sheet will last no more than 3-5 years, or 7-10 if it is equipped with a reflector. In comparison, a luxury copper chimney cap will last up to 50 years.

Luxurious forged chimney cap Source metkolor.ru

Making a wooden frame

Making a frame is one of the important things when working. After all, the durability and stability of the entire structure will depend on its characteristics. Often, wooden sheathing is used for gas boilers and ducts, which will subsequently be treated with picket fences or OSB sheets. It is not justified to install wooden frames for metal or plastic parts. After all, more space will be required for the slot at the base of the roof, which will have a rather negative effect on the load-bearing capacity.

Chimney box design

Manufacturing stage:

- Measure the required dimensions on the roof.

- According to size, hold, drank in the rafters and ceiling.

- Make four U-shaped timber blanks, which will subsequently be joined in the ceiling itself.

- Consider extreme sheathing and vapor barrier.

- Also, don't forget that you will need to make the bottom.

Considering temperature changes, it is better to make it from metal or, in extreme cases, from plastic. Wood is not the best option for such purposes, since it will play and constantly “take on” different dimensional structures.

It is better to make a chimney box with an assistant. This makes it easier to dock and secure a weighty structure.

Manufacturing of metal casings for generators

Generators are protected from mechanical damage, dust and moisture by special casings. Additionally, they can have noise protection, anti-corrosion properties, be all-weather or cold, and also custom-made due to the non-standard nature of the object being protected.

In addition to manufacturers of generators and power plants, specialized companies can manufacture metal casings. In this case, the protective shell can be given various operational properties and technical characteristics.

Basically, metals (for example, steel or alloys), as well as polymers, are used to make casings. Steel is the most commonly used material that reliably protects generators from mechanical stress. The interior of the protective shell, if necessary, is finished with materials that have heat and sound insulation properties.

Depending on the type and characteristics of the generator, the method of manufacturing and further modification of the casing is selected.

In most cases, the containment looks like a custom-built container made from steel sheets. If a metal casing is required for a diesel generator, then there must be enough space inside the container to allow repair and maintenance of the installation. However, the protection does not significantly affect the dimensions of the power plant.

The container must have holes through which air can penetrate inside, as well as openings that can be closed with lids and allow the technician to service the generator.

If we are talking about a regular cold-type protective casing, then it looks like a metal container. If the functions of the shell are not limited only to protection from mechanical damage, but must also protect from cold and noise, heat and sound insulating materials that are non-flammable and resistant to elevated temperatures are used to treat the inner surface of the container.

The outer side of the casing is painted and galvanized to protect against corrosion.

If it is necessary to protect small generators, then it is possible to use a cast shell made of polymer materials.