When installing a chimney in a house, you need to take the choice of material from which it will be made very seriously.

Asbestos cement pipe

Not only the longevity of the normal functioning of the heating device, but also the safety of the residents of the house will depend on this factor. Smoke exhaust ducts are built from brick, metal and sometimes asbestos concrete. But recently, installing a chimney from an asbestos-cement pipe has ceased to be popular, as more modern and reliable materials have appeared, which are much lighter and easier to install and operate! To understand what the disadvantages of such a solution are, and why it is better to refuse asbestos-cement pipes in the installation of chimneys, we will tell you below, read carefully so as not to bite your elbows later!

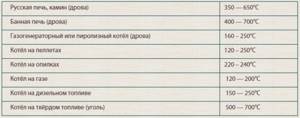

SNiP rules in the fire safety section state that chimney pipes made of asbestos cement can only be installed when using heating devices whose combustion temperature does not exceed 280-300 degrees , or in those parts of the chimney that also do not heat above these temperatures. These can be gas heating appliances with low power, or the upper sections of the chimney channels, into which exhaust gases enter in a cooled state.

What are asbestos cement pipes used for?

Asbestos cement is a durable fireproof material that combines the properties of asbestos and cement. Asbestos, or, as it is also called, mountain flax, is a group of silicate class materials that look like thin, durable threads. These threads are used as a frame into which other building materials are poured or laid. In the case of asbestos cement, such a building material is cement.

Asbestos gives strength to materials and protects them from fire. There are two types of asbestos: chrysotile and amphibole. The first is widespread in Russia, where there are asbestos deposits. This material has been used in construction for about five decades. Amphibole asbestos used to be common in European countries, but has now been banned due to its negative impact on human health.

This is interesting! Asbestos is a proven carcinogen, causing asbestosis and lung cancer in builders who worked with it. In a number of countries its use in construction is prohibited. In Russia, there are special safety standards when working with asbestos. When using products made from it, no health risks have been identified.

Asbestos-cement pipes are intended for those structures where there is water, steam or gas. They can withstand temperature fluctuations and, when installed correctly, last for many years.

Fire safety measures and risks

Asb chimneys can last for decades if you follow the rules of their operation and maintenance.

Fire safety measures are as follows:

- use of fuel with low heat transfer;

- installation of sections in places where the exhaust temperature drops to the optimal value;

- regular cleaning of combustion product exhaust channels;

- use of high-quality thermal insulation.

However, the risk of cracks due to chemical corrosion is always present. It is necessary to regularly check the chimney for leaks.

Scope of application

Asbestos-cement pipes are used in various fields of construction. For example, they are used in the construction of sewage drains, both pressure and non-pressure. They often serve to supply water, both drinking and technical. Such pipes can also be used in the construction of a hot water supply system.

We recommend that you read: Features of cross-linked polyethylene for pipe production and their scope of application

In addition, asbestos-cement pipes are used in agriculture. There they are necessary when installing a reclamation system and drainage structures. In private houses, they are used to build wells, using them as casing pipes. In apartment buildings, there is another area of application for asbestos-cement pipes, in addition to water supply and sewage collection. These are garbage chute pipes. They are designed for both solid and liquid waste.

Due to the fire resistance of both asbestos itself and the structures that include it, such pipes are used for the construction of chimneys. However, there are several limitations in this application.

In general, asbestos cement is used wherever there is a need for waterproofing, heat resistance, wear resistance and durability.

When are chimneys made from asbestos pipes used?

Most often, asbestos pipes are used as a temporary solution for a chimney. However, they cannot be used directly near the firebox. The part of the solid fuel chimney made of brick or metal adjacent to the stove serves not only to remove combustion products, but also for heat exchange inside the room, increasing the efficiency of the heating unit. The temperature of the exhaust gases there can significantly exceed the permissible limit of 300 oC. And only after passing through the channels of the convective zone and rising to the level of the ceiling with the attic, the escaping gases are cooled to a safe 200–250 degrees. There you can build up a chimney with an asbestos pipe, which is several times cheaper than a brick or any other pipe.

Asbestos pipes can be used in the upper part of the chimney, where combustion products enter already cooled

However, most modern thermal units, especially those running on natural gas, are characterized by high efficiency, which indicates the rational use of thermal energy. This applies to geysers, boilers and pyrolysis furnaces, the outlet temperature of which does not exceed 250 oC. Naturally, with such thermal devices it is quite logical to use inexpensive asbestos pipes. The only obstacle can be the increased ability of smoke channels to form condensation. Devices for its collection only partially solve the problem, so accelerated soot formation is inevitable here. The situation can only be corrected by regularly cleaning the smoke channel, which is extremely inconvenient during the heating season.

Another problem is the impossibility of installing inspection windows in asbestos pipes. For this reason, installation of such chimneys is possible only on straight sections.

Summarizing everything said above, we point out the circumstances that prevent the use of asbestos pipes for chimneys:

- High probability of destruction at temperatures above 300 oC.

- Fire hazard due to cracking of the chimney walls with combustion products escaping outside.

- Reduced draft force in the chimney due to the lack of heat capacity supporting it.

- Accumulation of condensation on the walls with increased soot formation.

- Inability to install inspection hatches in asbestos pipes.

- The requirement to install such products only in a vertical position.

- The need for regular inspection and cleaning of the chimney from soot.

When heated above 300 degrees, asbestos pipes burst and sometimes even explode

Why and where is insulation necessary?

No one doubts the fact that any structure will begin to collapse over time. This applies to all structures: chimneys made of brick, metal or asbestos pipes. During the removal of gases, combustion products accumulate on the walls of the pipes. Condensation that forms at the dew point settles in them: where cold masses meet warm currents. High-quality insulation solves several problems at once. It allows:

- strengthen the structure, since the thermal insulation frame is additional protection from temperature changes and gusts of wind;

- reduce the risk of destruction of the walls of the structure due to constant contact with condensing aggressive moisture;

- make the operation of the heat generator more efficient, since thermal insulation means less fuel consumption;

- prevent problems with deterioration of traction: high-quality insulation reduces the thermal conductivity of pipes and prevents intensive accumulation of deposits.

An insulated chimney will look better and last longer, as the wear resistance of the protected materials increases. In addition, the roof located near the structure will also receive additional protection.

Insulation is necessary in the place of the pipe where the warm surface of the chimney “meets” the cold air. As a rule, this area is located either in a cold attic, or where the structure is exposed to the roof.

Asbestos chimney size

When selecting asbestos chimney pipes, you need to be guided by the following considerations:

- The use of this material is only possible for gas boilers and pyrolysis heating units, which are characterized by a low flue gas temperature. It should be taken into account that the smoke of pyrolysis furnaces is oversaturated with products that contribute to the formation of condensation, and therefore soot.

- The diameter of the asbestos chimney pipe should not be less than the outlet pipe of the heating unit.

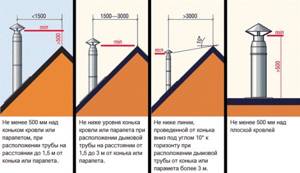

- The total length of the chimney must be at least 5 meters, while the excess above the roof ridge must be at least 0.5 meters.

- Significantly exceeding this indicator will also lead to undesirable consequences due to a decrease in the speed of gas movement in the pipe. This will increase the amount of condensate formed.

The effectiveness of a chimney made of any material depends on its correct installation on the roof of the house

Manufacturing technology

When constructing a chimney from an asbestos-cement pipe, according to the standards, it is required to equip a foundation for the smoke exhaust duct, although in some cases the design of the asbestos purlin rests on the body of the heating device.

The technology for manufacturing a chimney from asbestos-cement products includes the following nuances:

- the length of the run from the grate to the outer end of the channel should be within 5-6 m;

- between the smoke exhaust structure and combustible elements of the roofing system, an interval of at least 1 m should be maintained;

- to connect the asbestos pipe and the heating device pipe, a connecting element 1 m long is used;

- You need high-quality insulation of the chimney line when crossing the floors. The thickness of the fluff layer varies according to the diameter of the pipe;

- the outer section of the run must be equipped with a heat-insulating layer;

- the height of the pipe on a flat roof should be at least 0.5 m above the level of the roof surface, and 1-1.5 m above the ridge if located on a pitched roof. If the height of the chimney structure exceeds 1.5 m, it is necessary to use braces or brackets to strengthen it.

It is recommended to use high-quality couplings for reliable connection of purlin units; it is worth remembering that materials with operating temperatures up to 1000°C are suitable for sealing.

Asbestos chimney installation

The chimney is installed in the following order:

- An asbestos pipe should never be removed directly from the kiln; it should rest on a concrete or brick base. The supply to the heating unit is made through a metal adapter. This part of the chimney is equipped with a flat damper or disc damper to regulate the draft by reducing the passage in the smoke exhaust channel.

- When installing a chimney, a container is provided in its lower part to collect condensate, which must be periodically emptied of black liquid with an unpleasant odor.

For asbestos pipes, plastic or metal condensate collectors of suitable diameter can be used - The upper end of the chimney must be equipped with a cap, and in the best case, with a deflector.

- At the junction with the chimney, a hatch is cut out in the ceiling, which is at least 15 centimeters larger than the dimensions of the pipe. A sheet metal damper is fixed to the ceiling below. Basalt wool is placed tightly into the resulting opening from above and covered with the same metal sheet on top.

When a pipe passes through the ceiling, a protective box of steel sheets is installed - Crossing the roofing pie is done in the same way. Only on the outside of the roofing you need to install an otter - a device to prevent water from entering through the pipe into the under-roof space. On the construction market it is easy to purchase a ready-made structure that matches the size of the pipe and the slope of the roof.

It should be remembered that chimneys made from asbestos pipes should absolutely not be used when installing heating in a bathhouse due to stoves with extremely high heating temperatures.

Fire safety

The requirements for a safe chimney installation do not differ from those for other systems:

- The passage of the smoke duct closer than 70 centimeters from the load-bearing structures of the building is not allowed.

- Chimneys cannot be painted with oil or enamel paint. If necessary, you can use lime or a special bitumen varnish.

- When a chimney passes through a wall, it must be finished with non-combustible material, and the passage itself must be sealed in the same way as a ceiling passage.

It should be remembered that the industry does not produce asbestos-cement pipes specifically for chimneys and the owner himself bears responsibility for their use in the heating system.

Feasibility of use

The natural porosity of asbestos cement can earn it a negative reputation, since a chimney made from this material will quickly absorb condensation and moisture and, as a result, transfer it to the surrounding wall surfaces and ceilings. External manifestations of this phenomenon will look like streaks, stains and an unpleasant odor. The occurrence of problems in the system can negatively affect not only the gas duct, but also the entire structure. Insulating the chimney will not give the desired effect.

The use of asbestos pipes for chimneys is only relevant in heating equipment with low power. The final choice of material for installing a smoke duct may also be influenced by the fact that asbestos does not tolerate high temperatures, and its increased absorption of condensate helps to reduce draft in the entire system. In contrast to the characteristics listed above, only its cost remains attractive. This forces us to pay attention to other materials for chimney construction that have better characteristics and a longer service life.

For solid fuel boilers and stoves, heating indicators are presented in the following table. These data must be taken into account if you decide to build a chimney from an asbestos pipe with your own hands.

Disadvantages of asbestos pipes

Despite its popularity in private construction, a chimney made from this material has many disadvantages.

Defects appear almost immediately or after some time, depending on factors such as the fuel used, climatic conditions and frequency of use of the boiler.

The quality of the pipeline installation also matters. Let's consider the characteristic disadvantages of asbestos-cement chimneys and the reasons for their occurrence.

Burnout and bursting

Initially, the products were developed for mass production for use in land reclamation, construction of sewers and low-pressure gas pipelines. The designers did not provide for their operation at high temperatures. Emphasis was placed on tightness and ease of installation of highways.

The basis of the material is cement, and it is a porous material. It absorbs creosote, which is a flammable material. With strong heating, the process of its combustion begins, as a result of which the structure of the walls changes, they become thinner and burn out.

What temperature can asbestos cement pipes withstand: their limit is + 300 ºС.

With further heating, the pressure of the air enclosed in the walls of the purlins increases. Products crack, burst and even explode.

Maintenance difficulties

The high strength of asbestos cement is a myth that many people want to believe. Working with links requires increased caution and accuracy. The lack of steel reinforcement makes them extremely brittle and brittle, regardless of diameter and type. And that's not all...

Chimney maintenance is associated with the following difficulties:

- the need for regular cleaning, since pipes literally attract soot;

- the inability to make inspection windows to reach hard-to-reach areas;

- sensitivity of products to shocks and loads;

- Frequent replacement of insulation, which is destroyed by chemically aggressive condensate.

Humidification of the pipeline is fraught with unpleasant consequences, both for communications and for the building as a whole.

Condensate

The main purpose of the products was the laying of open and underground water pipelines of various lengths. Asbestos-cement pipes are resistant to water, but quickly collapse when in contact with chemically active liquids. They are the ones that form on the surface of the chimney during the interaction of soot and condensate.

The aggressive solution flows onto the roof and is absorbed into its surface. As a result, stains, unpleasant odors and cracks appear. Watching the video below will help you understand the extent of the damage caused by condensation. This issue can be resolved with the help of properly carried out insulation.

Why were they popular in the past?

During Soviet times, there was an acute shortage of all types of building materials. Asbestos pipes were a real boon for private developers. The purlins met all safety standards, had no worthy alternative, and were distinguished by their strength, tightness and affordable price. The links were used in furnace making, arrangement of water supply systems, sewerage systems and construction of wells.

Over time, GOST requirements were replaced by TU. Changes were made to the production technology, which negatively affected the quality characteristics of the products.

Modern products are no longer designed to remove combustion products with temperatures above + 300 ºС.

They can only be used for a gas boiler, installed in the middle and end of the chimneys of saunas and baths. But, it is better to abandon this idea and use pipes made according to specifications for arranging low-pressure communications and protective structures for laying cables.

Which type is suitable for which chimneys?

Recommendations from experts on the use of asbestos-cement pipes in heating systems are brief. Purlins manufactured according to modern technical conditions should not be installed indoors or directly on brick kilns. At any moment, pipes can crack and dangerous carbon monoxide can fill the room.

As for the use of different types of products, they can be installed in the following places:

- Non-pressure. They have thin walls and low resistance to loads and impacts. It is better to install them inside auxiliary rooms and attics. That is, in places where people are not constantly present and there is no likelihood of mechanical damage to the highway.

- Pressure. The products are more durable and pressure resistant. It is advisable to install purlins on the roof where there is wind load. Pressure pipes can be used for fireplaces and stoves, provided that they are heated with wood.

How to properly make a chimney from asbestos pipes

One of the reasons why the asbestos pipe has become widespread is that the installation of a homemade chimney from an asbestos pipe can be easily done with your own hands. During installation, fire safety requirements and standards, as well as current SNiPs, are taken into account.

Reliable fastening, heat and waterproofing are carried out, and also, if the pipe is cracked, smoke is prevented from entering the room. Below are the most common mistakes and solutions that take into account the characteristics of asbestos-cement pipes.

How to fix an asbestos-cement chimney

One of the most difficult things to do when installing a smoke exhaust system yourself is the accurate calculation and arrangement of external chimneys made of asbestos-cement pipes. Existing standards stipulate in detail what parameters a chimney pipe must meet in order to provide sufficient draft and be able to resist wind loads.

To secure the external chimney, special clamps and braces are used. When installing a free-standing pipe, or its part above the roof, adhere to the following recommendations:

- Calculate the diameter and height of the chimney from an asbestos pipe. The higher the chimney, the greater the wind load it experiences. To secure the pipe on the roof, raised above the ridge by more than 2 meters, roof braces are installed. The height is calculated depending on the distance of the chimney from the ridge of the building, the diameter according to the volume of the combustion chamber (recommended cross-section is at least 120 mm).

- A free-standing chimney is fixed to the wall every half meter using pipe clamps. To securely secure the pipe to the roof, a special roofing base is used. Sealing against leaks is mandatory.

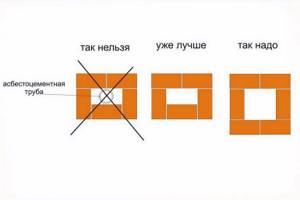

- When installing an asbestos pipe in a brick channel, the pipe is securely fixed using special spacer fittings. The minimum distance between the pipes of a multi-channel chimney made of asbestos-cement pipes is at least 10 cm. A plate is installed on top of the structure, covering the channels from moisture. If you do not fix the asbestos pipe in a brick chimney, then over time the pipe at the joints will lose its tightness, which will result in the appearance of oxides and destruction of the walls.

- When passing through the roof and interfloor slabs, a fastening bracket made of asbestos cement is used. A distance of at least 10 cm is left between flammable materials and a very hot surface; a non-combustible chimney support is installed on the wooden floor.

- In a house made of aerated concrete blocks, it is not recommended to install free-standing chimneys. The wall to which the pipe is attached will not be able to withstand the wind load. The optimal solution would be to install an internal smoke exhaust system. If it is necessary to make an external connection, the use of guy wires is chosen as a method of attaching an asbestos-cement chimney pipe.

It is extremely important to secure the pipe to the roof to reduce the effects of wind loads. When heated, asbestos loses its strength. Any gust of wind can lead to loss of integrity of the chimney walls.

How to build up an asbestos-cement chimney pipe

The regulatory documents regulating the use of asbestos-cement pipes as chimneys, in particular SP 60.13330 (formerly SNiP 41-01-2003), indicate that asbestos chimney pipes are designed vertical. It is allowed to use asbestos-cement materials or prefabricated structures in which the top layer is made of stainless steel.

When laying chimneys, free-flow pipes are used. Stainless steel sleeves can be used as adapters when connecting to heating devices. To connect an asbestos pipe to a metal pipe, CAM type couplings are installed. The design of the adapter includes machined grooves, which ensures maximum tightness of the joints.

There are heat-resistant sealing gaskets on both sides of the coupling. To extend the pipe from the side of the asbestos chimney, remove the rubber band and fill the groove with a heat-resistant mixture to connect the asbestos-cement elements of the chimney pipe. If two asbestos pipes are connected, the sealing compound is used on both sides.

To connect asbestos-cement pipes to each other in a brick chimney, an inspection hole is made at the joining site, allowing installation work to be performed on site.

An adapter from an asbestos-cement pipe to a metal one compensates for the difference in heating and the ability of the material to expand. It is prohibited to use improvised means as a transition coupling.

How and with what to insulate an asbestos chimney

The asbestos-cement chimney pipe can withstand temperatures up to 300°C. At the same time, the material has high thermal conductivity and instantly transfers heat to the environment. The heating of the chimney surface is almost identical to the temperature of the exhaust flue gases. Surface insulation with non-flammable thermal insulation material is required for several reasons:

- Insulate the asbestos chimney pipe from wood or any other combustible wall sheathing.

- Reduce the amount of condensate produced and avoid freezing.

- Waterproof the pipe.

Modern insulation technologies can significantly reduce the volume of condensate in an asbestos pipe and significantly increase the service life of the chimney.

As practice shows, it is not enough to simply wrap an asbestos pipe with thermal insulation material in order to achieve good thermal insulation characteristics; work is carried out according to the following installation diagram:

- Choice of insulation - basalt wool or any other non-flammable thermal insulation is suitable for the work. It is better to choose a material that has a low water absorption coefficient. If necessary, it is possible to insulate with mineral wool insulation.

- Fixing the thermal insulation - the insulation is wound onto the pipe and secured using special clamps. Alternatively, tie wire can be used.

- Protective layer - insulation is carried out on top of the mineral insulation with foil insulation. A layer of foil protects the basalt wool from moisture and serves as additional protection against fire.

- Frame - the rules for installing and insulating asbestos-cement pipes provide for the use of a metal frame that protects a free-standing chimney or the outer part coming out of the roof. As an alternative, it is possible to use sandwich systems, with an outer layer of stainless steel and an inner layer of asbestos.

Should asbestos pipes be used for chimneys?

But that is not all. Like brick, asbestos begins to absorb condensation. Having become saturated with it, he begins to transmit it to the entire structure. Hence the stains on the walls and the unpleasant smell. Continued use of such a system will lead to complete destruction of the chimney.

Insulation as a panacea

Draw conclusions about what is cheaper and more convenient for you.

As a rule, chimney insulation, when using boilers with high efficiency, does not give the desired result. However, if you still insulate the chimney, it will last a little longer.

The result of insulation

Should I use asbestos-cement pipes for the chimney?

You should not listen to the advice of visiting “experts” from nearby countries: “my mother-in-law has had an asbestos pipe for thirty years and, most likely, it will outlive her mother-in-law.” It's probably true! But there is a small addition: the mother-in-law does not have a modern, economical boiler installed, but a clay hut from the beginning of the last century.

Briefly about asbestos: what kind of material is it?

Asbestos is one of the fine-fiber minerals belonging to the class of silicates (in other words, a mineral). This material is distinguished by its relatively low weight, extremely high strength and resistance to chemical influences.

Asbestos cement pipes

Asbestos has long been used in construction, in the production of rockets, and in the automotive industry. The main disadvantage of this material is its toxicity to the human body, and therefore it is classified as a Category I carcinogen according to IARC.

Is it possible to use asbestos pipe for chimneys?

Considering the health hazards, pipes made of asbestos cement (if it is not chrysotile) are now used much less frequently than 30-40 years ago. But whether it is possible to use it now is an open question; many experts do not recommend doing this and advise using more modern materials.

However, the use of asbestos chimney pipes is possible and, in principle, not prohibited, but it must be taken into account that such pipes are not suitable for constant use. They are relatively effective only in cases where they operate periodically, but are generally poorly suited for organizing a smoke exhaust system .

Which boiler is it suitable for?

You should immediately take into account that asbestos pipes are designed for temperatures not exceeding +300 degrees. This means that they are not suitable for solid fuel boilers. Therefore, asbestos chimneys are ideal for modern boilers with high efficiency and an output temperature of about 100-150 degrees.

The use of such pipelines is justified in the following cases:

- To install an isolated chimney system - in this case, asbestos-cement pipes are installed as a separate system. To connect to a heating device, for example, a gas boiler, stainless steel connecting sleeves are used. To install a chimney outside the building, tees or adapters are used.

- To extend an existing chimney. Using asbestos, you can lengthen the chimney pipe if its draft is insufficient or if there is a constant accumulation of large amounts of condensate.

- Also, using a sleeve made from an asbestos-cement pipe, you can sanitize the existing smoke exhaust system.

Pros and cons of asbestos chimneys

This material has both a number of advantages and a number of disadvantages, which is typical of any building materials.

Among the advantages of asbestos are:

- simple production and, as a result, relatively low cost;

- simplicity of arranging a chimney (you can do it yourself, armed only with theoretical knowledge);

- can be used as a smoke exhaust system in several types of buildings - for a stove, for a fireplace, it can be installed for a bathhouse, a private house, but for any industrial purposes in this form it is not suitable.

Among the disadvantages are:

- unstable to high temperatures - high temperatures lead not only to deformation of the pipe, but even to its explosion;

- absorbs condensation that forms;

- there is no possibility of making a large draft in an asbestos chimney;

- due to the porosity of the material, it is not possible to clean it from soot accumulation (which is catastrophic when used for a stove, for example);

- It is impossible to install cameras to monitor the technical condition of the pipeline.

Prices for asbestos pipes

| Name (Diameter, Length, mm) | Unit change | Pipe weight | Cost (pieces), rubles |

| per piece | |||

| Asbestos-cement free-pressure pipes GOST 1839-80/31416-2009 | |||

| Gravity pipe 100 (3950) | PC. | 20,1 | 280 rub. Buy |

| Gravity pipe 150 (3950) | PC. | 27,2 | 472 rub. Buy |

| Gravity pipe 200 (3950) | PC. | 57,2 | 985 rub. Buy |

| Gravity pipe 200 (5000) | PC. | 72,3 | 1160 rub. Buy |

| Gravity pipe 250 (5000) | PC. | 91 | 1670 rub. Buy |

| Gravity pipe 300 (5000) | PC. | 114 | 2370 rub. Buy |

| Gravity pipe 350 (5000) | PC. | 154 | 3400 rub. Buy |

| Gravity pipe 400 (5000) | PC. | 237 | 3620 rub. Buy |

| Gravity pipe 500 (5000) | PC. | 360 | 7060 rub. Buy |

| Asbestos-cement pressure pipes VT-6 GOST 539-80/31416-2009 | |||

| Pressure pipe VT-6 100 (3950) | PC. | 30,8 | 650 rub. Buy |

| Pressure pipe VT-6 150 (3950) | PC. | 51 | 1060 rub. Buy |

| Pressure pipe VT-6 200 (5000) | PC. | 124 | 1750 rub. Buy |

| Pressure pipe VT-6 250 (5000) | PC. | 151 | 3200 rub. Buy |

| Pressure pipe VT-6 300 (5000) | PC. | 199 | 3400 rub. Buy |

| Pressure pipe VT-6 400 (5000) | PC. | 334 | 5620 rub. Buy |

| Pressure pipe VT-6 500 (5000) | PC. | 537 | 10180 rub. Buy |

| Asbestos-cement pressure pipes VT-9 GOST 539-80/31416-2009 | |||

| Pressure pipe VT-9 100 (3950) | PC. | 45,9 | 750 rub. Buy |

| Pressure pipe VT-9 150 (3950) | PC. | 67 | 1060 rub. Buy |

| Pressure pipe VT-9 200 (5000) | PC. | 142 | 2020 Buy |

| Pressure pipe VT-9 250 (5000) | PC. | 169 | 3670 rub. Buy |

| Pressure pipe VT-9 300 (5000) | PC. | 217 | 3990 Buy |

| Pressure pipe VT-9 400 (5000) | PC. | 390,5 | 6800 rub. Buy |

| Pressure pipe VT-9 500 (5000) | PC. | 623 | 10470 rub. Buy |

If we talk about prices for asbestos pipes, they depend on what parameters need to be purchased. Diameter, length and weight make up the price of such materials.