Good afternoon, dear reader! To vent the mixture of gas and fuel combustion products outside, stoves, fireplaces and boilers must be equipped with smoke exhaust ducts. Their head is covered with a special visor or umbrella. At first glance, these products seem to be only decorative elements. But in fact, the cap on the chimney pipe performs a very important function in the chimney system. It can significantly increase the energy efficiency of the heating system as a whole, and also eliminate any risk of smoke in the home.

Form and function

The main tasks of the chimney cap:

- Increased air draft;

- Protection against birds accidentally flying into the pipe;

- Preservation of the chimney masonry;

- Protection from snow and rain.

Please note: the use of a hood increases the efficiency of the chimney by almost 20 percent.

The pommels differ in geometry, shapes and sizes. Their varieties are determined by the style of the facade of the house and the peculiarities of the weather vagaries of the area.

- Umbrella (cover) – protects the pipe from rain and snow. Can be made in the form of a weather vane, flat cover or gable cover.

- Drip cap - removes moisture from the pipe walls and stops the formation of ice.

Caps are made from materials that are resistant to the destructive effects of weather conditions. This product is fixed in a very hard-to-reach place, so it is better not to save money and purchase stainless steel or sheet copper.

Some features of the use of caps:

- The semi-circle shaped deflector is more suitable for European design;

- An umbrella with a flat top will look natural on a cottage in the Art Nouveau style;

- A wind vane with a weather vane installed can be equipped with a damper, which will make the pipe work effectively even in the absence of wind;

- A weather vane with a gabled top promotes intensive ventilation;

- Hoods with a movable roof make it easy to clean the chimney.

How does a chimney cap work?

The air, entering the wall of the lid, turns upward and with its movement draws up the smoke. The chimney begins to work more efficiently and draft increases significantly. When the wind is angular or vertical, an umbrella also helps increase traction. To avoid problems when lowering, you need to install a reverse cone on the lid. In addition, by protecting the pipe from moisture, the deflector prevents the development of fungus and saves fuel.

Please note: a properly made and securely fastened cap should not make noise or vibrate even in a stormy wind.

Expert advice

- When there is a low wind, vortex phenomena are formed under the hood, which impair traction. If you install a reverse cone under it, it will reflect the air flow, cut it and lead it out;

- if a round cross-section device is installed on a brick pipe, then the installation of a corresponding adapter is additionally required;

- the chimney must be located no lower than the roof ridge, ventilation exhaust pipes and other structures, if they are located close to the chimney.

Making your own chimney cap

Making a cover for a fireplace or chimney yourself is not difficult.

To work you need to prepare:

- Sheet of galvanized metal, copper or stainless steel;

- Cardboard and markers;

- Metal scissors;

- Devices for bending sheets;

- Welding machine.

Before starting fabrication, it is important to carefully measure the chimney pipe. Then you need to make a model of an umbrella from cardboard. Pattern drawings:

The umbrella should fit onto the pipe without much effort, so when drawing up the drawing you need to leave an overlap of half a centimeter.

After trying on the layout, the drawing is applied to a metal sheet. The workpiece is cut out with scissors. Using bends, the material is given the desired shape. The joints are fastened with 3-4 rivets. Making droppers is similar.

The brackets are cut from metal plates and attached to the apron and top by welding. Welding points must be treated with a primer. The entire cap is additionally coated with anti-rust compound and paint.

Afterwards all that remains is to put it on the fireplace chimney. All joints must be treated with fire-resistant sealant.

The umbrella must cover the entire plane of the chimney. Some structures have a half-brick protrusion, which also needs to be covered from rain.

Please note: in winter, ice or snow may form on the cap. It is important to choose the thickness of the metal so that it does not get pressed under such a weight.

An excessively high or too low lid will not fully remove smoke, so it is worth making drawings taking into account all the necessary parameters. It is not difficult to use a cap to correct defects in the chimney, for example, if it is not of sufficient height.

You can decorate the deflector using a forged weather vane. This will be a durable and practical solution.

Even novice craftsmen can make a chimney cap on their own. It is important to take measurements carefully and choose high-quality metal. A well-made deflector will correct shortcomings in the operation of the chimney and provide constant draft in any weather. And if you apply a little creativity in your work, the product will become a decoration for the facade of the house.

Purpose and functions of the chimney cap

The cap on the outer part of the chimney pipe is a rather important element that performs several functions at once. A correctly selected pipe part complements the appearance of the building well, emphasizing the design style. At the same time, the cap has compact dimensions, is easy to install and increases the efficiency of the chimney.

A chimney cap can become an original decoration for the roof of a residential building

The chimney cap is made of metal, as this material ensures the strength and durability of the product. The simple design performs the following functions:

- protection of the inside of the chimney from moisture, debris and dust;

- increased draft in the pipe for efficient combustion of fuel in the furnace;

- aesthetic addition to the building design;

- extending the life of the chimney as a result of its protection from precipitation.

A rectangular or square shaped cap is the most common option. Such an element provides effective draft and complements the chimney design well from an aesthetic point of view.

Materials for the chimney

The cap is located outside the chimney and is exposed to climatic factors and ultraviolet rays. Therefore, for the manufacture of the chimney, only high-quality, durable materials that are resistant to various factors are used.

Metal is a practical basis for a chimney

To make a cap, various types of metals are used, each of which has different properties and characteristics. The main options are:

- sheet steel;

- sheet aluminum;

- rolled copper metal;

- stainless steel in sheets;

- zinc - titanium alloy.

Depending on the material that served as the basis for the cap, the characteristics of the product differ. For example, the service life of steel chimneys is about 5 years, and models made of sheet aluminum can be used for 8 years. The most durable caps are made of stainless steel, zinc-titanium alloy and copper, the service life of which reaches 50–100 years.

Design options

There are many options for chimney caps that differ in appearance. Moreover, the design of all types of products includes a base, an upper roof and vertical posts. This cap is simple and protects the chimney well from precipitation. More complex options are deflectors, one of the main functions of which is to enhance traction.

Deflectors are varied and can be either simple or more complex.

Among the most popular smoke vent options, the following are especially noteworthy:

- cap with opening lid;

- flat chimney for pipe;

- cap with weather vane;

- cap of multi-slope design;

- deflector with ventilation holes.

The choice of a specific option is made depending on the type of roof, the design of the house, the shape and design of the chimney. For example, for a round metal pipe, metal deflectors are optimal, providing enhanced traction.

Photo gallery: types of chimney caps

Choosing a hood depending on the chimney

The correct choice of a chimney cap is the key to effective heating of rooms in the house and the absence of chimney breakdowns. The choice of chimney type is made depending on the type of pipe and heating system. For example, for the chimney of a gas boiler, only elements in the form of a nozzle with an open top are used. This model eliminates the possibility of ice covering the entire surface of the hood during the winter season.

Products in the form of a pipe are optimal for a gas heating system

For brick outlets, multi-slope, rectangular or square elements are often used. Precipitation does not accumulate on the surface of such caps and therefore the chimneys are not subject to significant load. The shape of the deflector is selected depending on personal preferences and the design of the building. Many cap options can be easily complemented with a forged weather vane or twisted elements.

Criteria for calculating chimney pipes

When determining the height of the pipe based on the ridge level, you should keep in mind all the factors that may be important when calculating the chimney draft.

Important. The length and diameter of the pipe affects not only the safety of using heating boilers. The efficiency of boilers depends on these parameters. Too strong a draft does not allow combustion products to transfer the maximum amount of thermal energy; it is removed outside. This situation significantly increases the material costs of maintaining the house during the heating period.

The height of the pipe above the ridge depends on the following factors.

- The angle of inclination of the slopes.

Roof angle

The larger it is, the greater the air flows resulting from the turbulence. They can not only reduce the speed of air movement in the chimney, but also cause so-called backdraft. After its occurrence, the toxic products of fuel combustion are not removed outside, but enter the room. If such a phenomenon occurs at night, the consequences can be very tragic.

Backdraft leads to disaster

All modern boilers must have special equipment that automatically stops combustion in the event of insufficient draft. If certain coincidences occur, the air movement in the chimney may be reversed; this is an extremely dangerous situation.

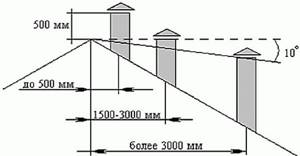

- The distance between the pipe and the ridge. Building codes and regulations have special tables indicating the dependence of the height of the chimney on its removal. If there are no tables, then the values can be calculated independently. We will describe how this is done below in this article.

Removing the pipe from the ridge

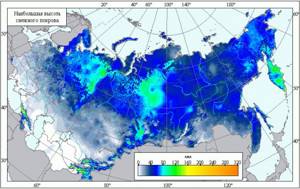

- Wind rose, maximum snow cover height, climatic zone of the building location. As an additional factor, the proximity to high-rise buildings that impede the free movement of air masses must be taken into account.

Maximum snow depth map

Climatic zones of Russia

The more factors are taken into account when performing calculations, the safer the operation of heating boilers, the higher their efficiency, and the more comfortable the living conditions in the house.

It is important to calculate and know the roof slope before the roof construction stage. The design of the rafter system, as well as the choice of the final roofing covering, depends on this value. The slope angle of the slope is also important when choosing the height of the chimney above the ridge level. Read the article on our website about roof slope in degrees and percentages.

Making a cap with your own hands

The most common and universal option is a rectangular cap with four slopes. Such a product is easy to purchase, but you can make a simpler, but no less effective semicircular version with your own hands.

The semicircular smoke vent is simple and easy to use

To do this, you will need a sheet of galvanized metal with a thickness of 1 mm, rivets, and metal scissors. A set of devices complements the marker for marking. The dimensions of the structure are preliminarily determined and a life-size drawing is made on cardboard. You can make a drawing yourself or take a ready-made diagram as a basis and adjust its parameters.

For a semicircular chimney, you can use a drawing of a pitched structure by changing the shape of the lid

The complex of works for the manufacture of a chimney involves the following stages:

- A rectangle is cut out of a sheet of metal, which will become a semicircular roof of the chimney. To do this, transfer the drawing to the metal and cut out the element with scissors.

Galvanized steel is easy to process

Metal strips or profiles allow you to make a frame for attaching the cap

The frame can have a stepped shape

Making a cap for a chimney pipe with your own hands is not difficult, but precise determination of the parameters of the product is important. High-quality materials are also the key to creating a durable structure.

Installation stages

Installation of the chimney box begins from the bottom, before the pipe itself is laid. The process is divided into stages:

- A frame is created for the opening in the ceiling. To do this, U-shaped elements are installed alternately on opposite walls. The rectangular halves are overlapped, forming a continuous metal insulation. Then screw the bottom to the ceiling with self-tapping screws.

- After this part of the casing is assembled, the chimney is passed into it and fixed on 4 clamps bent in the central part of the rectangle.

- The upper parts are installed and secured, thereby reaching the top of the pipe.

- At the end, the empty space is filled with expanded clay, dry earth or other insulating material. The end is covered with a metal lid.

Before installing the facing covering on the roof, the place where the chimney comes into contact with the passages must be insulated with roofing felt or plastic film. Install it overlapping the casing and the overlap plane. To prevent the waterproofing from being visible, it is covered with a decorative corner around the entire perimeter.

Cap function

Before starting work, you need to know exactly the full range of functions that the cap can perform in order to take into account all the subtleties during manufacturing.

It is installed in order to:

- the following did not enter the pipe space: debris, snow, rain, birds;

- for a long time the pipe itself did not collapse under the influence of temperature changes, moisture, or icing, because in most cases the pipe is laid out of brick;

- strengthen the top layer of the chimney masonry;

- increase traction up to 20%;

- create a windproof exhaust gas outlet;

- decorate the highest point in the house structure.

Atmospheric phenomena put pressure on waste gases, even if the ventilation pipe is made according to technological requirements.

However, according to the physical law of aerodynamics, when a flow of cold air comes into contact with the hood and goes around the installation, a discharged area is obtained, then the air begins to move at a higher speed, which increases the draft in the chimney and allows heating devices to operate more efficiently.

Ensuring proper operation of the ventilation system

The quality of the natural ventilation system directly depends on the approach to the installation of hoods. Ventilation pipes must be manufactured in strict accordance with building codes. The efficiency of the system is ensured by the flow of the required amount of fresh air into the room. If there is a weak supply of air entering the house from outside, the draft in the ventilation ducts will be low. In some cases, a backdraft effect occurs. The most effective method of solving the problem of poor air flow into the house may be to install supply fans in walls and windows

This is especially important if the house is built using modern materials that do not allow a “breathable” effect. This is why often after installing plastic windows, air draft can drop significantly

Ventilating the room also has a small effect. But it is short-term, as it ends immediately after closing the windows or doors.

Materials and tools used

Among people, the cap is called a visor, a chimney, a fungus. Its scientific name is deflector.

Forged deflectors are very original, but their price is not always justified. After all, you can make a cheaper structure from the following metal material:

- galvanizing;

- stainless steel;

- steel with paint and varnish coatings;

- aluminum;

- copper

The most convenient, practical and cheapest is galvanized sheet.

You need to have the right tool. List of what you may need during work:

- rubber or wooden hammer;

- small iron hammer;

- screwdriver;

- electric drill;

- drills of the required fastener diameter;

- rivets;

- fastenings;

- roulette;

- marker;

- construction corner;

- bends;

- special clamps;

- metal scissors;

- metal ruler;

- iron corner up to 1 meter in size.

Deflector shapes

The shapes of the deflector or head can be striking in their diversity.

Therefore, you need to decide which shape of the deflector will be ideal for the ventilation pipe, while still looking neat.

- round,

- square;

- hip;

- conical;

- tent;

- standard hipped;

- with a flat umbrella;

- with a semicircular umbrella;

- gabled with four slopes and a high roof;

- with weather vanes.

Types of exhaust hood

The types of exhaust hood also have a variety, but the most popular are:

- tsags are a simple model that can be made in a workshop;

- Grigorovich;

- It is difficult for a beginner to make a spherical “Volper” with his own hands, since machines are required;

- H-shaped;

- star shape "Shenar";

- ASTATO open.

You can find plastic hoods on sale; they are best used for basements and garages; for high-rise structures they are fragile and do not last long.

Manufacturing technology of the Tsaga deflector with drawing

Manufacturing drawing of the Tsaga deflector. (Click to enlarge)

First you need to decide on the dimensions of the external and internal pipes. Measurements must be accurate.

The outer diameter of the stove hood fits tightly onto the chimney pipe.

The main parts are made in proportion to the internal diameter:

- the inlet pipe is placed on the pipe;

- the outer cylinder is a diffuser, its size should be approximately 30% larger than the internal diameter of the pipe;

- cover, its size should be about 90% of the pipe diameter.

In order to correctly calculate the dimensions of the deflector, a table is provided.

- A drawing is made on paper to match the shape and dimensions of the cap.

- The patterns are applied to a metal surface and cut out with metal scissors.

- The resulting parts must be bent according to the design and connected with rivets.

- The finished parts of the deflector are assembled in the workshop, and at a height they are only fixed above the pipeline.

Make it yourself or buy it

You can make a standard weather vane, which looks like a house with a hipped roof, from galvanized steel yourself. It is easy to cut and bend using simple tools.

If you do not have any skills and tools for the manufacture of such metal structures, then you can buy a ready-made device that is in harmony in style with the overall appearance of the roof.

The approximate price of the simplest cap model starts from 1100 rubles. The cost of TsAGI, Volpert-Grigorovich or Khanzhenkov galvanized deflectors does not exceed 3,500 rubles.

A rotating model made of stainless steel will cost much more - from 8,000 rubles. Well, the most expensive ones are exclusive forged products.

Manufacturing technology of a rectangular exhaust unit with a weather vane

Drawing of a rectangular chimney cap. (Click to enlarge)

- Cut a rectangle out of a sheet of iron, taking into account when bending it so that there is 10 cm for the chimney to fit.

- Oblique cuts are made on the sides at equal distances; when joined, these cuts will produce trapezoidal segments.

- Next, four posts are made, attached to the corners of the rectangle, secured with rivets.

- Bend the ends, you get a hole, as in the drawing.

- Separately, cut out a rectangle: bend it into an arch, fasten it - this is a ready-made hood; for originality, you can make a weather vane.

- The finished structure is installed in the chimney pipe.

The pipe is attached to the installation according to what the chimney is made of.

Node of passage of a chimney through a flat roof

When installing a chimney on a flat roof, it is important to remember that its height above the roof surface must be 500 mm in accordance with SNiP standards. A round pipe, a rectangular chimney duct, or a brick chimney itself can be discharged through a concrete floor slab. The round pipe passage unit will be considered separately, and for other cases two basic installation principles are used

The round pipe passage unit will be considered separately, and for other cases two basic installation principles are used.

Features of arranging a passage through a pitched roof

How to fix a chimney on the roof? On the chimney pipe on the inside of the roof, it is necessary to mount a flange that is rigid enough to absorb the loads from the sheathing - the chimney outlet forces the dismantling of part of the purlins, and without installing the flange, the structure will remain suspended.

The flange is usually a steel sheet with stiffeners welded to it. The sheet thickness should be at least 2-3 mm. A non-flammable heat insulator – basalt cardboard – should be placed on the flange. This will prevent heat transfer from the chimney to the sheathing. If the chimney structure is not reliable enough to take on part of the load on the roof, a rafter structure or additional racks are installed around the perimeter of the opening so that the load is transferred to the attic floor.

Around the pipe, all layers of the roof must be cut into a gap that complies with the standards specified in SNiP (depending on the type of pipe and the degree of its heating). The resulting gap must be filled with a non-flammable heat insulator - basalt or glass wool, basalt cardboard.

The principle of sealing the junction of the roofing material to the chimney pipe depends on factors such as:

To ensure that the chimney exiting through the pitched roof is not damaged when snow melts, it is recommended to install snow guards higher up the slope. If the width of the chimney (across the slope) is over 800 mm, above it on the slope a special structure should be installed to divert the water flow.

Output through the roof of a pipe with a circular cross-section

It is very difficult to waterproof the junction of the roof to a round pipe without the use of special roofing penetrations. The construction market offers a wide selection of pipe assemblies, differing in diameter and material of manufacture.

A universal option is an aluminum flange equipped with a silicone or rubber corrugation. These elements are available in several standard sizes, so you can choose a penetration for a chimney pipe of any popular diameter. The working surface of the flange is covered with a material similar to the corrugation material and is equipped with grooves for filling with sealant. The top of the corrugation cone is cut to the required diameter, after which the penetration must be pulled onto the chimney. The flange must be coated with sealant and attached to the roof with self-tapping screws, which are included in the kit. If the roof covering is not made of metal, the flange is attached with dowels or long screws directly to the sheathing.

For roofs with different slopes, penetrations are offered in which the corrugation is located at different angles to the flange. You can purchase a detachable design, which is used if it is not possible to stretch the corrugation onto the pipe due to the presence of protruding parts or the large height of the installed chimney. This penetration is equipped with clamps, thanks to which the corrugation is tightly pressed around the pipe.

Fastening the chimney to the roof can be done using penetrations in which a hinged segment is used instead of corrugation. This is a universal option for roofs with any slope angle: the surfaces of the connecting elements are spherical in shape and can be fixed relative to each other at any angle.

Manufacturers of roofing materials often offer ready-made chimney penetrations with a flange pre-formed to match the appropriate roofing covering. This penetration is attached to the roof sheathing with the necessary overlap. To achieve matching diameters, the apron cone is cut off. Penetrations from roofing manufacturers have several standard angles of inclination. To seal the joint, a second conical apron is installed, overlapping with the first.