With the advent of biofireplaces, it became possible to admire a live fire in a modern city apartment, in which it is not possible to carry out a complex of construction work to build a wood-burning fireplace. A biofireplace consists of a fireplace, inside of which a special heating metal block is mounted. Biofuel is poured into this block.

What is biofuel?

Biofuel is an environmentally friendly material produced from bioethanol. It is a colorless and odorless liquid. It is highly flammable. During combustion, it breaks down into water and carbon dioxide, so it is safe for indoor use.

The properties of biofuels are as follows:

- Ethanol, which is part of the liquid, during combustion breaks down into steam and carbon monoxide and is accompanied by the release of energy. Absolutely harmless to the human body and does not smell.

- There are no solid decay products (soot, ash) during the operation of the eco-fireplace.

- Combustion efficiency reaches 95%.

- Liquids with the addition of sea salt have the crackling effect of natural firewood.

- When fuel burns, the flames are similar in color and shape to the fire in a classic fireplace.

Ecofuel composition:

The basis of biological fuel is ethanol, of plant origin. It is obtained by fermenting the sugars of most plant crops, such as wheat, beets, potatoes, sugar cane, bananas and others. However, this type of fuel is not sold in its pure form, but is required to denature the alcohol.

For additional effects, dyes or sea salt are added to the liquid.

Ecofuel has the following characteristics:

- During combustion it does not form ash.

- Does not emit harmful gases.

- It is environmentally friendly.

- Has a long burning period.

- Easy to use.

Environmentally friendly fuels are produced all over the world. The leading positions in the production of this fuel belong to South Africa, India, and China.

The following types of biofuels are distinguished:

- Biogas - waste from garbage and production is subjected to pre-treatment and gas is released from it, an analogue of natural gas.

- Biodiesel is obtained from natural oils and fats of biological origin (animal, microbial, vegetable). The main raw materials for the production of this type of fuel are food industry waste or palm, coconut, rapeseed, and soybean oils. It is most widespread in Europe.

- Bioethanol is an alcohol-based fuel, a gasoline substitute. Ethanol is produced by fermenting sugars. The raw material for production is cellulosic biomass.

The advantages of environmentally friendly fuel include the following:

- During the combustion of fuel, smoke, harmful gases, soot and soot are not generated.

- The intensity of the flame and heat transfer during biofuel combustion can be adjusted.

- The fuel block and individual structural elements are easy to clean.

- The design does not require the installation of air exhaust structures.

- Biofireplace fuel is easy to transport and store.

- No waste during storage, unlike solid fuel.

- There is no need to create a separate room for storing large amounts of fuel.

- Heat transfer during fuel combustion is 95%.

- During the combustion of ecofuel, the air in the room is humidified due to the release of steam.

- Flame return is excluded.

- Thanks to the design of the bio-fireplace and the structural features of the biofuel burner, the design is fireproof.

- Low fuel cost with low consumption.

Using environmentally friendly fuel is easy in everyday life. Using the gel, you just need to open a jar of gel and install it in the bio-fireplace structure, hiding it in decorative elements or containers. When using liquid fuel, simply pour it into the fuel tank and light it. However, despite all the positive qualities, this substance has several disadvantages.

Disadvantages of biofuels:

- It is prohibited to store containers with fuel near open fire;

- Do not add fuel while the biofireplace is operating; you need to extinguish the device and wait for it to cool completely;

- Lighting the fireplace is permitted only with a special lighter or using electric ignition.

Rules for working with ecofuels

It is not recommended to ignite biological fuel with paper and logs; special iron lighters are used for this.

Some people believe that biofireplaces are easy to use. Units running on biofuel are fireproof. But manufacturers recommend taking the following precautions:

- The fireplace burner must be completely cool before use.

- Eco-fuel cannot be filled to the brim. The metal container is filled only one third.

- There should be no sources of fire near the fireplace.

- To ignite, you need to use a long lighter, which comes with the bio-fireplace.

- Do not add liquid while the fireplace is running. First you need to put it out, and then add it.

- Bioethanol must not be lit with paper or wood.

- Do not add a lot of essential oil to the fuel.

- After use, the remaining liquid must be drained. It is not reused.

- If biofuel gets on the floor or other surfaces, you must immediately wipe the area dry.

- In case of contact with skin, wash the affected areas under running water and soap.

- The container with the product should be kept away from the fireplace.

- Children and pets should not be allowed near the fuel.

Eco-fuel is produced in cans, from which it cannot be poured into other containers, as this is dangerous. It is prohibited to dilute bioethanol with kerosene or other flammable mixtures. If a person has diseases of the respiratory system, before purchasing a biofireplace for home, you should consult a doctor.

Biofuel for biofireplaces and its properties

Eco-fireplaces owe their appearance to the discovery of bioethanol. This is an alcohol obtained from grains and legumes, as well as from potatoes or sugar beets, cane.

Advantages of using bioethanol in biofireplaces:

- absence of soot, soot and burnt smell;

- absence of unpleasant alcohol odor (it is possible to use aromatic additives);

- no sparks or burning splashes;

- decomposition into water vapor and a small amount of carbon dioxide;

- economical consumption.

Biofuel production technology requires precision and constant monitoring. You can make biofuel yourself, but its quality is very different from the factory one, as is the chemical composition. All this can lead to equipment failure and costly repairs. Therefore, you should not consider such savings - as a result, you are unlikely to win.

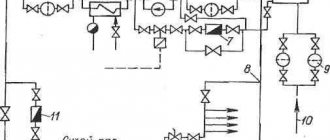

Rice. 6. Example of automatic control of a biofireplace

Description and fuel consumption for biofireplaces

Fuel for biofireplaces is produced in one and a half liter and five liter containers (bottles and plastic canisters).

Bioethanol consumption is about 0.36 liters per hour (1 liter is enough for 2-5 hours).

Efficiency > 95%.

Thermal power (one heating unit) 4 kW/hour.

Compound

Approximate percentage of substances included in biofuels:

- bioethanol 96%;

- methyl ethyl ketone 1% (denaturing agent);

- water 4%;

- bitrex - less than 0.01% (1 gram per 100 liters of fuel).

Biofuel properties

During denaturation, ethanol becomes environmentally neutral. It does not cause harm to human health, since during combustion it releases heat and some carbon monoxide. The use of biofuel allows you not only to maintain health, but also to obtain beautiful and even flames when burning in a fireplace.

Biofuels are absolutely safe for health and the environment. During combustion, it does not produce smoke or soot. This allows you to build a fireplace without a hood or chimney. When burning, a lot of heat is released, which remains in the house for a long time. The efficiency of biofuel reaches 95%. If you compare the flames from burning such fuel and wood, there are practically no differences.

Another advantage in favor of using biofuel is its release form. It comes in gel form, which is very convenient to use and store. It also contains sea salt. It allows you to achieve crackling, like regular firewood, during combustion.

Biofuel is absolutely safe for the health of people, animals and the environment

At the same time, the outlines of the fire are quite colorful, the flames are even, bright, and saturated in color. The color of the flame is, of course, a little different from normal, it is not as orange, since burning ethanol releases carbon dioxide and water. To get a more natural fire, natural, environmentally friendly additives are added to liquid fuel for fireplaces, which color the fire the desired orange color.

But what’s even better is that the heat generated during combustion is not lost, but is completely released into the room. Thus, the efficiency of such an installation reaches 95-100%. At the same time, in terms of the type of flame, ecofuel for fireplaces is not much different from ordinary firewood, which allows you to see a real fire. A fireplace gel based on ethanol with the addition of sea salt allows you to create the complete illusion of burning real wood, since in addition to a similar fire, a characteristic sound will appear in the form of crackling.

A biofuel fireplace during its operation, as we have already said, practically does not emit soot and soot. Experts compare its emissions into the indoor atmosphere with the burning of one ordinary candle. At the same time, the bio-fireplace liquid does not emit carbon monoxide during combustion, which can be dangerous in large volumes.

Bioethanol used for fireplaces can also be poured into a regular kerosene lamp. In this case, during combustion there will be no soot and odor emitted, as when burning kerosene, and the device will perform its original functionality perfectly, illuminating the room.

Rules of use and precautions

- Never add fuel to an open flame or a fuel tank that is not cool. Before refueling, it is necessary to extinguish the device and wait for it to cool (about 15-20 minutes).

- It is prohibited to use straw, paper, wood or other flammable materials to ignite biofuel. It is allowed to use only a special long metal lighter, electric ignition or long match.

- It is prohibited to store fuel canisters near a burning fireplace or other source of open flame.

- It is recommended to store biofuel out of the reach of children.

- If fuel is spilled during the process of refueling the biofireplace, it must be thoroughly wiped off with an absorbent cloth.

General operating rules:

- It is necessary to store the container with biofuel in a place away from open fire and heating devices.

- Ignition of biofuel in the burner should be done with a special lighter.

- If biofuel gets on the surface of the biofireplace, the floor or any other surfaces, the drops must be thoroughly wiped with a dry absorbent cloth.

- Biofuel can only be added to an extinguished and cooled eco-fireplace.

In order for an eco-fireplace to please its owners with an even and pleasant burning, it is necessary to properly supply it with high-quality fuel.

There are several criteria that will make it extremely difficult to make a mistake with your choice.

First of all, you need to choose fireplace products that have been on the market for more than one year and have proven themselves well. The seller must have the necessary documents for biofuel on hand. It is also worth paying attention to the performance indicator and choosing a biofuel that will meet the needs of the fireplace owner. When opened, the liquid should not emit unpleasant odors that sharply hit the nose

It is important that the expiration date indicated on the label has a sufficient period before expiration. Only by choosing high-quality products can you be sure that an ecological fireplace will decorate your home and will operate as safely as possible.

Only by choosing high-quality products can you be sure that an ecological fireplace will decorate your home and operate as safely as possible.

Do-it-yourself biofuel for a fireplace

The simplest biofuel fireplace, also called an “eco-fireplace,” is a large alcohol stove. The principle of its operation is simple: the alcohol lamp is filled with flammable fuel and set on fire. Such eco-fireplaces are decorated in different ways: for some, the flame comes out directly from the hole, for some, the flow of fire is covered with decorative decorations (ceramic logs, stones, sculptures).

No matter how safe such a fireplace is, it has its own operating rules. For example, it is often equipped with heat-resistant glass on both sides. It protects walls and interior items from fire and does not allow children and animals to get close to the source of the flame. And although such a fireplace has no exhaust, the room with it still needs to be regularly ventilated.

Biofuel that shines and does not heat

The fuel for a modern fireplace is ethanol. Due to the chemical properties of ethanol and the presence of special additives in the final product, the fuel does not emit soot, and during the combustion process it decomposes into carbon dioxide and water. To make your own biofuel, you will need ethanol sold in pharmacies. If you have high-quality purified moonshine at your disposal, then you can actually use it. To produce moonshine you will need a special unit. You can buy it at a specialized store or design it yourself. But for cleaning, the simplest substances are used: from birch charcoal to potassium permanganate.

Ethanol biofuel is used to achieve decorative combustion of eco-fireplaces. It is not suitable for heating a room. To make an ethanol fire burn the traditional orange color, gasoline is added to the fuel. The gasoline itself must be of the highest possible quality. Ethanol biofuel for eco-fireplaces has a simple composition: 20 parts of ethanol to 1 part of gasoline.

To make ethanol biofuel for your fireplace with your own hands, pour ethanol and gasoline in the indicated proportions into a container of suitable volume. Mix the liquids thoroughly until they become as homogeneous as possible. Please note that this biofuel is not suitable for long-term storage. It is better to do it immediately before use (pouring into the fireplace). Why? While at rest, the ethanol and gasoline will separate again and will have to be mixed again.

Ethanol fuel consumption is low: a medium-sized eco-fireplace consumes about half a liter of fuel in one hour of continuous burning. Excess biofuel can be poured into kerosene burners - an excellent decorative decoration for an interior in Provence or country style!

Fireplace biofuel for heating

How to make biofuel for a fireplace, the purpose of which is to both heat and light? To start, you will need raw materials. Further design or purchase of a processing plant depends precisely on the type of raw material. Manure is considered the most optimal for fuel production. Which manure to use depends on your resources:

- horse manure with peat and straw/leaf;

- a mixture of horse and cow manure in proportions 1:1;

- cow manure with sawdust in a ratio of 7:3.

The operating principle of an installation that processes manure into biofuel is simple: during the fermentation of animal waste products, biogas is released. Using special equipment, this gas can be converted into a liquid with flammable properties. If you have a sufficient amount of raw materials, then it makes sense to buy or make such an installation. This way you will receive biofuel not only to power the fireplace, but also for domestic needs. This gas is used for heating rooms and for cooking.

There is an easier way to get biogas - dig a hole and place manure in it. The pit is covered with an impenetrable tarpaulin from above - as soon as the manure begins to ferment and release gas, the tarpaulin will immediately tighten. Tubes are connected to the pit, through which your biogas circulates. If your fireplace can operate on the principle of a gas burner, then this biofuel is quite suitable. This method is relevant for owners of private houses and farms.

How to make biofuel yourself

It is noteworthy that you can make biofuel for the fireplace with your own hands directly at home. To do this you will need:

- 96% ethanol, sold in pharmacies. Unfortunately, you won’t be able to make bioethanol for a fireplace with your own hands.

- Gasoline of high purity, for coloring the flame, which is used to refill lighters. It is desirable that the gasoline has no odor and is completely transparent in color.

The ingredients must be mixed in the following proportion: per 1 liter of ethanol, approximately 50-100 ml of gasoline. Then the resulting composition must be thoroughly mixed and poured into the fireplace. It is advisable to make fuel for a biofireplace with your own hands immediately before use, since the substances may separate from long-term storage.

Smokeless fuel for fireplaces can be used in rooms where there is no special chimney or ventilation, that is, in almost any apartment, house, office, or country house. At the same time, you can enjoy a real fire right in your home, because this fuel is suitable for almost all types of interior fireplaces.

Types of biofuels and their features

Today, there are 3 types of biofuels:

- liquid;

- hard;

- gaseous;

Liquid biofuel

It is the most discussed species. After all, the life of modern man depends on oil; without it, humanity cannot survive, and oil is a fossil resource and at some point its reserves will run out.

Liquid biofuels have the potential to replace this fossil resource.

Liquid biofuels include:

- alcohols (ethanol, methanol, butanol),

- biodiesel,

- biofuel oil,

- esters;

Solid

Includes biogas, hydrogen.

Also, biofuels can be classified by generation. There are biofuels of 1st, 2nd, 3rd and 4th generations:

- The 1st generation includes biofuels obtained by processing agricultural plants into biodiesel and ethanol.

- 2nd generation – biofuel obtained from food waste.

- The 3rd generation of biofuels includes biofuels obtained using introduced technologies as a result of the destruction of biomass.

- The 4th generation of biofuel is produced on lands unsuitable for agriculture and without destruction of biomass.

Another classification of biofuels is the division of biofuels into primary and secondary. Primary biofuel refers to biofuel that has not been processed. To the secondary – processed. Recycled biofuels undergo a variety of modifications before use and can be in solid, liquid and gaseous forms.

Advantages

The advantages of biofuel are as follows:

- Mobility. Biofuel has the ability to be produced anywhere in the world, regardless of climatic conditions and topography, because this type of fuel can be produced from various organic compounds.

- Renewability. Since biofuel is obtained from a variety of organic compounds of plant or animal origin, for example, manure, its quantity will not run out.

- Environmentally friendly. It is a cleaner type of fuel and, when burned, emits fewer harmful substances into the air than fossil fuels.

- Caring for the environment. Biofuel production solves problems associated with waste disposal.

The prefix “bio” in the name of the fuel determines its environmental friendliness. After all, renewable natural resources are used in the production of this type of fuel. The main components used in the production of environmental fuel are grains and grasses with a high content of sugar and starch. Thus, cane and corn are the most suitable raw materials for creating biofuel.

Biofuel for biofireplaces, produced from natural components, is not inferior in its energy characteristics to the following less environmentally friendly analogues:

- biogas, which is a product of specific processing of various waste waste, like natural gas, is used to create thermal and mechanical energy;

- bioethanol, almost entirely consisting of alcohol, can replace gasoline;

- Biodiesel is made from vegetable oil for fueling cars and other purposes.

For lighting bio-fireplaces, preference is given to bioethanol, a colorless and odorless liquid. Among its advantages the following are noted:

- Environmental friendliness is due to the complete absence of carbon monoxide, soot and soot production.

- Easy to clean burners.

- High fire safety and reliable use of fuel due to thermal insulation of the fireplace body.

- No need to install ventilation devices.

- Convenience of transporting the fuel itself and ease of installation of the device.

- Possibility of adjusting combustion intensity.

- High heat dissipation.

- There is no need to prepare firewood or clean up dirt, debris and ash near the fireplace.

- The vapors released when ethyl alcohol is heated help normalize the humidity level in the room.

Types of product

Fuel for biofireplaces is a product made from environmentally friendly raw materials that can be renewed.

When burned, it does not release harmful substances or smoke into the air, and there is no soot or soot on surrounding furniture and decor. Biological raw materials can be of plant or animal origin. Read also: making a bio-fireplace at home.

There are several types of biofuels:

- biogas;

- biodiesel;

- bioethanol

The first type of fuel is a direct analogue of natural gas , only it is not extracted from the depths of the earth, but is produced from organic waste decomposed by bacterial cultures. It is mainly used to generate heat and electricity in industry.

Pay attention to the following video, which will tell you. How to make an alcohol burner yourself:

Biodiesel is made from vegetable fats and some components of animal origin. The input is usually coconut, palm, canola, soybean or other oil. The raw material is often waste from the food industry. Biodiesel is often used in the transport sector.

Biofuel for fireplaces is the best type of fuel that does not require the presence of a chimney

Most often, bioethanol is purchased for eco-fireplaces, which is considered an environmentally friendly analogue of gasoline. Fireplace fluid contains high levels of carbohydrates, which come from potatoes, beets or sugar. The product is also obtained by hydrolysis of straw, wood and other resources that contain a high cellulose content.

Advantages and disadvantages of biofuels

Using a biofireplace, even a tabletop one, you can enjoy a live fire at home that is safe for the environment. You just need to choose the right type of biofuel, because the sharpness and color of the flame depend on it

To do this, you need to pay attention to the following important points

Biofuels should:

- burn to the end;

- have a sufficiently high heating capacity;

- have genuine quality certificates.

Biofuel has the following advantages:

- It is an environmentally friendly product, since its combustion does not emit any harmful substances, smoke, soot, etc.;

- possibility of adjusting combustion saturation;

- no need to install special hoods;

- ease of maintenance (burners are very easy to clean);

- bioethanol is easy to transport;

- When bioethanol burns, water vapor is released, resulting in humidification of the air in the room;

- when burning biological fuel, the return of the flame is excluded;

- biofuel has a low cost, and this is essential for the family budget.

Bioethanol formula for biofuel production

In addition, there are no difficulties in using biofuels. If the fuel is gel, then you just need to open the can and put it among the stones or in an armful of artificial firewood, and then set it on fire. One such can of biofuel is enough for 3 hours of continuous burning of the fireplace. To get a larger flame, you need to light several cans of fuel at once.

To put out a fire, you only need to cut off the oxygen supply to the flame by closing the fuel cans. If liquid fuel is used, it must be poured into the fireplace heating unit and set on fire. This biofuel is usually produced in five-liter cans, which have a consumption scale. One such canister is designed for 18-20 hours of uninterrupted burning.

The disadvantages of biofuels are as follows:

- To add fuel, you first need to turn off the fireplace and let it cool; this cannot be done while the fireplace is operating;

- Do not store fuel near an open fire;

- You cannot ignite biofuel with paper and logs - only with special iron lighters.

Consumption and application features

Fuel for biofireplaces is sold in plastic containers in volumes from 1 to 5 liters. The thermal power of one heating unit averages 4 kW/hour. You can ensure continuous combustion for a period of 2 to 5 hours using 1 liter of fuel.

When using biofuels, it is advised to adhere to certain precautions:

- After using fuel, the container with it must be closed;

- keep fuel away from a lit fireplace and any other source of fire;

- refueling of the device is carried out only after the burner has gone out and the housing has completely cooled;

- The fireplace is ignited using special lighters;

- If fuel gets on the floor or other surfaces, wipe the drops with a dry cloth.

It is recommended to fill the fuel tank of the fireplace only 1/3, and not to the brim, otherwise the entire fireplace may catch fire. It is better to extinguish the flame during operation, add liquid and re-ignite the device. To prevent alcohol fumes from accumulating in the room, bioethanol residues after using the fireplace must be constantly removed.

If the fireplace fuel runs out, replacing it with improvised materials, such as gasoline or kerosene, is strictly prohibited. Their vapors can harm the health of those living in the house, especially those with allergies.

Advantages and disadvantages of biofuels

Biological fuels have their positive and negative sides. Interest in the use of this type of raw material is caused by its undoubted advantages. These include:

- Budget cost. Although at the moment the prices for biofuel are almost the same as the cost of gasoline, biological substances are considered a more profitable type of fuel because they produce fewer emissions when burned. Biofuel is suitable for use in various conditions, and it can be adapted to engines of different designs. Another advantage is the optimization of engine operation, which stays clean longer due to the small amount of soot and exhaust gases.

- Mobility. Biological fuel differs from other alternative energy sources in its portability. Solar and wind installations usually include heavy batteries, so they are most often used permanently, while biofuels can be transported from one region to another without much hassle.

- Renewable energy source. Although researchers believe existing crude oil deposits will last for at least several hundred years, fossil reserves are still finite. Biofuels, made from plants and animal waste, are among the renewable resources that are not in danger of disappearing in the foreseeable future.

- Protection of the earth's atmosphere. A major disadvantage of traditional hydrocarbons is the large percentage of CO2 that is released when burned. This gas creates a greenhouse effect in the atmosphere of our planet, creating the conditions for global warming. When biological substances are burned, the amount of carbon dioxide is reduced to 65%. In addition, crops used in biofuel production consume carbon monoxide, reducing its share in the air.

- Economic security. Hydrocarbon reserves are distributed unevenly, so some states are forced to purchase oil or natural gas, spending large amounts of money on acquisition, transportation, and storage. Various types of biological fuel can be produced in almost any country. Since its production and processing will require the creation of new enterprises and, accordingly, jobs, this will benefit the national economy and have a positive impact on the well-being of people.

Improving technology and developing new methods can enhance the positive effects of biofuels. Thus, the development of technologies using plankton and algae will significantly reduce its price.

At the same time, at the present stage of development of science and technology, biofuel production is associated with a number of difficulties and inconveniences. First of all, these are natural limitations in growing plants. For the growth of crops used for biomass production, a number of factors must be taken into account, namely:

- Water use. Agricultural plants consume a lot of water, which is a limited resource, especially in dry areas.

- Invasiveness. Crops grown for fuel are often aggressive. They choke out the authentic flora, which can cause the biodiversity and ecosystem of the region to suffer.

- Fertilizers. Many plants require additional nutrients to grow, which can harm other crops or the overall ecosystem.

- Climate. Certain climate zones (for example, desert or tundra) are not suitable for growing biofuel crops.

Active cultivation of agricultural plants is also associated with the depletion of agricultural resources.

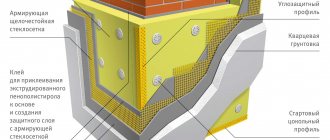

Preparing to make a biofireplace

To make your own fireplace, you first need to decide on its type, take the necessary measurements, and make a sketch of the future model. This will allow you to avoid errors during work.

Materials and tools

You can make a bio-fireplace at home using ordinary glass, for example, from an A4 photo frame, a glass cutter, silicone sealant, metal mesh, a mesh from a barbecue or oven, a metal box, pebbles or other heat-resistant stone, fuel and wick.

Do-it-yourself desktop biofireplace

The stages of its construction are as follows:

- We calculate the distance between the burner and the protective screen. It should exceed 15 cm to avoid damage to the glass. We measure the distance between the burners - it should be more than 16 square meters. cm.

- Preparing the fuel tank. You can use a simple square or rectangular metal box, keeping in mind the distance from the flame to the glass.

- Painting the drawer to increase its aesthetics. It is carried out only from the outside, as fire or release of toxic substances from the paint applied to the inner surface is possible.

- Creation of a protective glass casing. It can be made from ordinary three-millimeter glass or 4 glasses from a photo frame, which are adjusted to fit the metal box.

- The glass is glued together with silicone sealant, secured between supports, which can be any stationary objects, and left in this state for a day until the sealant dries.

- Excess sealant is removed with a blade.

- Biofuel preparation. Only a metal can is suitable for storing it, even if it was sold in a plastic one. The jar is placed at the bottom of the box. One standard container of fuel will support combustion for several hours, after which it will need to be replaced - you will need to remove the stones and mesh or fill in a new portion with a large syringe.

- Cutting a mesh to cover the box. This can be done in two layers. Its fastening will be more reliable if you use wire, but do not forget that the mesh must be removed to replace the can of fuel.

- Laying stones on the grid. They are needed not only as a decorative element, but also for uniform heat distribution between the grille and the screen.

- Ignition of a biofireplace with a torch lowered through a mesh into a container with fuel.

Do-it-yourself floor biofireplace

To design a floor biofireplace you need:

- Prepare materials: a sheet of drywall, 2 square meters of thermal insulation material, 2 square meters of tiles with glue, 8-9 meters of metal profile, a hundred screws and self-tapping screws, grout, stones or other decorative elements, heating unit.

- Assembling the frame using screws and a metal profile.

- Sheathing the frame with plasterboard and self-tapping screws, two layers on each wall, between which glass wool or other thermal insulation will need to be placed.

- Facing with tiles or other similar material. To do this, you need to carefully lay it out in accordance with the idea; for example, the fireplace can be made monochromatic or a pattern can be added.

- Grouting joints.

- Drying.

- Installing the heating unit in its place.

DIY bio-fireplace burner

The most reliable material for a burner is stainless steel. Its walls should be thick enough to avoid deformation when heated. You should also be very careful when assembling, since unreliable fastening or a defect will damage the bio-fireplace.

It is advisable that the burner be solid, so there is less chance that fuel will spill out. A paint can is best suited for this role, the main thing is to make sure that its size is suitable for the fireplace and that there are no cracks or holes in it.

Those who are not looking for easy ways can make the burner completely themselves; it is not difficult, since in appearance it looks like a large matchbox with an oblong hole in the top for pouring biofuel. Sheets of metal 1.5-2 mm thick are welded at the seams. You can add glass wool to it, which acts as a wick, and a damper, which will regulate the flame and extinguish it.

The burner is ignited with an ordinary wick, for example, a cord dipped into biofuel, the end of which will rise above the stones or other decorative elements.

Fuel for biofireplace

Bioethanol can be used as a fuel; it is sold in specialized stores, but can also be made at home, since it consists of gasoline, which is used to fill lighters, and ordinary medical alcohol, mixed 1 to 9. After mixing and shaking, the mixture is suitable for use.

Electric fireplaces

When talking about the absence of a chimney, many often mean the absence of any pipe as such. Until recently, it was believed that stoves without a chimney were a pipe dream. Today there are at least three ways to make this dream come true:

- electric fireplaces;

- biofireplaces;

- tiled stoves.

The most popular is the use of electric fireplaces. This option is suitable for a summer cottage, since you don’t have to count on a large heated area, and electricity can handle heating a small house. The heating element in such a stove is a nichrome spiral, which is placed in an insulated housing. The effect of heat transfer from such stoves is enhanced by the arrangement of convection channels in which the air is effectively heated and enters the room.

Electric fireplace option

Electric fireplaces do not require chimneys, with the exception of a dummy when creating a certain style. They simulate flames using a variety of technologies. The flame based on the work of a steam generator is a real miracle, as it is pleasant to admire, and the three-dimensional image conveys all the magical power of living fire. Electric fireplaces or heaters are the only possible heat source for the garage. Even installing a conventional solid fuel stove is difficult, as it takes up precious space.

Which biofuel is better for home

This term refers to natural materials. Bioethanol belongs to a small category of liquid biofuels, while solid fuels are the most commonly used.

In addition to bioethanol, biofuels include:

- coal and peat;

- firewood and wood derivatives;

- compressed agricultural and woodworking waste;

- biogas;

- biodiesel.

These types of fuel are used in full-fledged heating devices, where the main requirements are high heat transfer, combustion duration and low cost. To obtain heat, various technologies are used, the most common of which is pyrolysis of the thermal decomposition of fuel under pressure, followed by afterburning of the resulting gases. Visually, this is not much reminiscent of a fire burning in a hearth, but no one demands an aesthetic flame from these types of biofuels: completely different tasks are set.

When using bioethanol, the heating function becomes secondary. The burning of vapors resembles the fire of a fire. Fuel has high efficiency with low heat transfer, so you should not consider bioethanol equipment as a heating device. An eco-fireplace cannot heat a room on its own, but such a fireplace can slightly increase the temperature of the room.

An analogue of bioethanol is isopropyl alcohol (IPA). It is obtained from fossils containing propylene. Such substances are oil, gas and coal. If we talk about combustion, there is no significant difference. The lower cost of isopropyl alcohol-based liquid is due to the absence of excise duty paid on ethanol-containing substances. IPS is used in the production of fuel in a gel consistency with the addition of various additives.

Which biofuel is better: bioethanol or isopropyl alcohol? Bioethanol wins in all respects, except price. If you want to save money, use IPA-based fuel.

<

Rice. 2. Bioethanol production scheme

Popular brands and manufacturers

Biofuels are produced in many countries around the world. Production is established in Spain, Germany, France, Italy, North and South America. Fuel is also produced on the African continent. About 5% comes from India and China. Brazil occupies the leading place. Also, several factories have been opened in Russia. All of these countries have sufficient quantities of plant materials needed to make ethanol. Fuel for biofireplaces is available for sale from the following brands:

- Kratki BioDECO - Polish fuel, produced in 1 liter bottles, which lasts up to 5 hours of combustion;

- InterFlame - country of origin: Russia, volume 1 liter, operating time 2-5 hours;

- BioKer - Russian biofuel is sold in economical 5 liter containers, which will last up to 20 hours of combustion at an average consumption of 0.3 l/hour;

- Planika Fanola is a German manufacturer and is available in bottles from 1 to 5 liters. Fuel consumption per hour is 2-6 hours depending on the intensity of combustion. Thermal power is about 3 kW;

- Vegeflame - fuel produced in France. A 5 liter canister lasts from 15 to 20 hours at a consumption of 0.3 l/hour;

- Bionlov is a Swiss biofuel for fireplaces without synthetic additives. A volume of 1 liter is enough for continuous burning for up to 5 hours;

- Bioteplo Slimfire - Italian quality biofuel allows you to provide a fireplace with fire for up to 5 hours. Material consumption is 0.36 l/hour.

As you can see, there is plenty to choose from. The cost of fuel depends on the brand, container volume, presence of impurities and fragrances. Some aromatic oils are quite expensive, although their quantity in the composition is extremely small. On average, you will have to pay from 300 to 700 rubles for 1 liter of raw materials.

Related Posts

- How to install a stove in the house?

- How to choose a wood-electricity combi boiler

- Which wood heating boiler to choose

- Review of models of stationary and portable gas fireplaces

- A stove with a water circuit for heating a house: features of stove heating + choosing the optimal option

- Fire-battery 7b (thermophor)

- Heating for home

- Fireplace stove with water heating circuit: selection and self-installation

- Wood burning boilers stropuva long burning

- Waste oil boilers

- Brick fireplace

- Pellet boiler for heating a private house

- Heating boilers using diesel fuel. we buy correctly

- Do-it-yourself stove-fireplace

- Why chimneys become contaminated with soot and how to get rid of it yourself

- Fireproof heat-resistant glass robax and ceran from the German manufacturer schott

- How to make a fireplace from plasterboard with your own hands

- Design and application of a mini gas burner

- Setting up a chainsaw carburetor. or how not to pay repairmen!

- Hydrogen heating boilers: why you should not choose a hydrogen fuel boiler for heating a private home, review and comparison of efficiency and economy, the best models and their prices

- Pros and cons of pressed sawdust for heating

- Requirements for a boiler for a bath

- And let all the fuel burn out to the end! cast iron grate

- We are talking about the gas generator design diagram

- Corner fireplace in the interior +70 photos

Read with this

- How to install a stove in the house?

- How to choose a wood-electricity combi boiler

- Which wood heating boiler to choose

- Review of models of stationary and portable gas fireplaces

- A stove with a water circuit for heating a house: features of stove heating + choosing the optimal option

- Fire-battery 7b (thermophor)

- Heating for home

- Fireplace stove with water heating circuit: selection and self-installation

- Wood burning boilers stropuva long burning

- Waste oil boilers

Review of manufacturers and prices

Modern manufacturers produce liquid for bio-fireplaces in canisters with a volume of 1, 1.5, 3 and 5 liters. Fuel in the form of a gel is poured into tin cans. They always indicate the dosage. The price per container may vary from different manufacturers.

Biofuel is suitable for all types of interior fireplaces

Among the popular brands of biofuel it should be noted:

- Kratki (Poland). This high-quality product perfectly humidifies the air without emitting smoke or odor. It is produced in 1 liter bottles. This amount is enough for 3-5 hours of operation of the biofireplace. Kratki has a wide range of fragrances. The price for fuel varies between 700-1,500 rubles.

- Bioheat (Russia). Canisters are produced in 1.5 or 5 liters. In an hour, the product is consumed in a volume of 0.36 liters. The average price for 5 liters is 1,250 rubles.

- Planika Fanola (Australia). When creating products of this brand, a special formula is used. 1 liter of eco-fuel of plant origin is enough for 3-5 hours of fireplace operation. One bottle costs between 250-400 rubles.

Biofuels are also produced in the USA, Canada, Europe, Brazil, China and India. Modern people are increasingly thinking about ecology and environmental protection, so fireplaces running on clean fuel are quickly replacing classic and gas models.

When choosing fuel for biofireplaces, the composition of which is environmentally friendly, you should check the certificates with the product seller. All liquids are characterized by the same components. They are distinguished only by fragrances. Pure and high-quality alcohol should not contain harmful impurities.

Types of environmentally friendly biofuels

The prefix “BIO” is now often added to labels based on the rules of successful marketing. Issues of preserving the environment and cleanliness are in fashion today throughout the planet. Bio-products, bio-cosmetics, bio-based detergents, purification and bio-energy stations and even bio-toilets. It also came to fireplaces and fuel for them.

Structurally, biofuel fireplaces are equipped with a standard burner and a tank for liquid fuel. Adjustment of the flame size and fuel combustion rate is carried out using a damper.

If it is completely closed, then the fire in the biofocus simply goes out by itself. In general, a bio-fireplace is a great way to heat a room and add a touch of coziness to it from the glow of the “bonfire”.

The biofireplace differs from its wood-burning ancestor in the fuel used to produce the flame - the logs in it are replaced with smokeless fuel in the form of a liquid

Obtaining biofuel for such a fireplace involves the use of renewable natural resources, environmentally friendly technologies and raw materials during production. Plus, burning it should not produce harmful emissions into the atmosphere. Humanity cannot yet survive without combustible fuel. But we can make it less harmful.

There are three types of biofuels:

- Biogas.

- Biodiesel.

- Bioethanol.

The first option is a direct analogue of natural gas, only it is not extracted from the bowels of the planet, but is produced from organic waste. The second is made by processing various oils obtained by squeezing oilseed plants.

As such, the fuel for biofireplaces is the third option - bioethanol. Biogas is mainly used to generate heat and electricity on an industrial scale, while biodiesel is more suitable for automobile internal combustion engines.

When burned, pure ethanol gives a blue, not very beautiful flame, so additives are added to fireplace biofuel to produce a red-yellow hue

Home fireplaces are most often fueled with bioethanol based on denatured alcohol. The latter is made from sugar (cane or beet), corn or starch. Ethanol is ethyl alcohol, which is a colorless and highly flammable liquid.

But most importantly, when burned, it does not emit odors, carbon monoxide and soot. Simply an ideal option for city apartments, in which it is almost impossible to install a chimney pipe.

Biofuels overview

Many manufacturers of biofireplaces offer their own fuel for operating the equipment. In most cases, it is advisable to choose products from one company - this guarantees full compliance with the properties specified by the developers. If for some reason you don’t like or are not satisfied with a brand’s biofuel, then there are many alternative options. Let's look at popular offers on the market.

Rice. 5. Eco-fuel from the popular company Bionlov

Bionlov

Premium biofuel developed by specialists from Poland and Switzerland. The liquid is produced using advanced filtration technologies using molecular purification. Selected raw materials are used to create fuel. Bionlov®Premium is uncompromising quality.

The brand’s bioethanol has undergone a series of tests at the factories of leading European manufacturers. Tests have confirmed the high quality of eco-fuel. The safety of the fuel has been proven by government research institutes throughout Europe, and biofireplace manufacturers recommend Bionlov®Premium on a par with branded fuel. The products have certificates of compliance with international standards. When 1 liter of fuel is burned, water and a small amount of carbon dioxide are released, as well as about 3 kW of heat, which is 10-20% more than its analogues.

Deep fuel purification guarantees equipment durability and ease of maintenance. The liquid is supplied in 1 and 5 liter containers.

Rice. 6. Biofuel from Fanola

Fanola

The producer of bioethanol under the FANOLA® brand is the well-known developer of biofireplaces – Planika. The American-Polish manufacturer occupies a leading position, exporting products throughout the world.

The fuel was developed in the company’s laboratories, and its formula is patented by the brand. The products underwent multi-stage testing and testing at the plant, where the safety of eco-fuels and the complete absence of harmful substances both in the composition and during combustion were proven. The results of the tests were confirmed by international experts.

Certificates:

- EcoLogo®;

- TÜV;

- CNBOP;

- PZH;

- OMNI-Test Laboratories Inc.

The tests revealed complete combustion without the formation of smoke, odor or soot. During combustion, a small amount of carbon dioxide is produced, comparable to human breathing.

The safety of Fanola has been confirmed by national research centers, thanks to which the brand’s biofuel is allowed to be used in biofireplaces located in rooms with children, public organizations, and crowded places. The fuel's complete safety for the environment has been confirmed. The liquid is suitable for use in biofireplaces of any production, regardless of its type and location.

The reason for Fanola's popularity lies in its consistently high quality and reasonable cost. The liquid is supplied in containers of 1 and 5 liters. Today, FANOLA® is the No. 1 fuel for biofireplaces on the domestic market.

Rice. 7. Kratki bioDeco - top quality biofuel

Kratki bioDeco

Another popular manufacturer of biofireplaces from Poland, the Kratki company, has its own offer. The company was founded in 1998, intensively expanding the list of products. Today, the brand supplies goods to 60 countries around the world, and its activities have been awarded at the state and international level. Kratki is a European-level production using modern technologies.

BioDeco closes the top three. The liquid is developed for the company’s own equipment and meets all safety requirements. Products are certified and verified through testing in reputable research institutes. The product’s compliance with international standards is confirmed by certificate Nr PZH/HT-3066/2015. This indicates compliance with all requirements regarding production, composition and application.

BioDeco comes in 3 variants:

- without smell;

- with the smell of the forest;

- with the smell of coffee.

The company also offers special odorless oils for adding to fuel. This product is designed for fans of aromatherapy.

Rice. 8. Bioethanol from LuxFire

LuxFire and Good Fire

Ecofuel production has also been established in Russia. Confirmation of this is LuxFire fuel, produced by the manufacturer of biofireplaces Lux Fire RUS. The company has been operating since 2015, and develops equipment of any complexity: inexpensive eco-hearths are produced under the Lux Fire brand, and special limited edition models with an original design are produced under the Good Fire brand.

Taking into account its own experience, the company has developed its own fuel for biofireplaces. The production technology and formula of the liquid were developed in the factory’s own laboratory. LuxFire is a patented fuel with good performance characteristics. The product has a safety data sheet, as well as a TU certificate 2389-015-89167980-2016, indicating that the fuel complies with Evrazstandard.

Biofuel was developed for the needs of the domestic market, but the manufacturer is gradually expanding its presence in the CIS countries. The company offers liquid under the LuxFire brand in containers of 1, 1.5, 5 liters, as well as special premium fuel Good Fire in 1 liter packaging.

Rice. 9. Eco-fuels from ECOline

ECOline

Among the manufacturers offering liquid with aromatic additives, ECOline products stand out. The company offers high-quality bioethanol with and without additives. Compliance with quality standards is confirmed by a certificate obtained in a study by the National Research Institute of Poland, which puts forward serious requirements for products.

What flavors does the company offer:

- lavender;

- chocolate dream;

- stronger – chocolate dream;

- the smell of the holidays (Christmas);

- rose;

- vanilla;

- forest;

- coffee;

- cinnamon and orange.

In addition to bioethanol with odor, the manufacturer offers aromatic oils for individual addition to existing fuel, as well as bio-fireplaces, stoves and technical fluids.

The company's products are available in 1 and 5 liter packaging.

ZeFire

The brand has been operating for more than 5 years, and during this time it has managed to establish itself well. Initially, these were simple but practical manually operated devices. Today the company offers premium quality equipment at affordable prices. This also applies to fuel.

Types of ZeFire biofuel:

- Expert – an inexpensive solution of standard quality;

- Premium – elite liquid for bio-fireplaces;

- Premium with coffee scent.

The “Expert” version comes in a 1.5-liter package, while premium fuel comes in a 1.1-liter package. The liquid is absolutely transparent and has no sediment due to deep filtration of the mixture. ZeFire products have good user reviews.

Rice. 10. FireBird brand eco-fuel

FireBird

The trademark belongs to the Russian company Belfort Fireplace, operating since 2007. The company works closely with leading manufacturers of biofireplaces, producing its own solutions. The FireBird brand emerged relatively recently - in 2014, but has already established itself well in the market and is well recognized. The production of biofuels under this brand has been organized since 2015.

The FireBird assortment consists of:

- standard fuel in a 1.5 liter bottle;

- FireBird-EURO – 5 liter canister with an elongated neck;

- Aroma series – flavored liquid in 1 liter container.

Good value for money - this is how you can characterize the brand’s products.

basic information

This type of fuel is used only for eco-fireplaces. It received the prefix “bio” due to the use of only renewable biological products. The basis of fuel for fireplaces is denatured ethanol, which contains regular ethanol. This product is obtained through the fermentation of various sugar-containing crops.

The most common uses for ethanol production are:

- beet;

- wheat;

- sugar cane;

- potato.

Alcohol (ethanol) can be obtained by hydrolysis of raw materials containing a lot of cellulose. Straw or wood is used for this.

Types of fuel

Biofuel is produced mainly in Europe and America. But Brazil occupies the leading place in its production. All fuels produced in the world can be divided into several types:

- biodiesel;

- bioethanol;

- biogas.

The first type of fuel is made from vegetable oils. Biogas is a kind of replacement for conventional gas produced during the processing of waste and household waste. Biodiesel also contains ethanol and easily replaces regular gasoline.

Biodiesel is produced during the processing of waste and household waste

Biodiesel is the best choice for a fireplace. For its production, vegetable oils of animal or microbial origin are used. The main composition of biofuels for fireplaces includes oils from:

- soy;

- palm trees;

- coconut;

- rapeseed

Biofuels are made from foods that contain a lot of sugar and starch.

In the production of fuel, the technology of processing ordinary algae is often used. This is mainly practiced by European manufacturers.

Almost any biofuel found can be represented by bioethanol. This ingredient is an alcohol that is formed during the fermentation and processing of carbohydrates. For this purpose, products that contain a lot of sugar and starch are used. Cellulose-containing raw materials can also be used. The finished liquid is colorless and should be odorless.

Let's sum it up

The technology for producing biofuels was established at the beginning of the last century. The delay in the development of fuel was caused by the discovery of fuel for internal combustion engines based on petroleum products. With the worsening environmental situation, people again remembered the opportunity to obtain safe, environmentally friendly fuel from renewable resources. This contributed to the emergence of fireplaces with decorative functions, including biofireplaces.

Today, everyone can enjoy natural fire. There is no need to obtain approval from utility companies, install a chimney, or regularly clean the fireplace. Bioethanol burns completely in the firebox, releasing a small amount of carbon dioxide and water vapor, which is useful if necessary to humidify the air during the heating season. You can use a bio-fireplace even indoors with children, but do not forget about fire safety rules.

Modern production technologies make it possible to achieve deep purification of the composition from unwanted mixtures and substances. The liquid goes through many tests, and only after that it goes on sale. This is why it is so important to ensure that you have a certificate.

How to choose fuel for a biofireplace? The answer depends on many factors. The products proposed in the biofuel review are high quality products, tested by thousands of customers. Equipment manufacturers often organize their own production of fuel optimized for the company’s equipment, but there are exceptions. You can find out which biofuel is better experimentally, checking the criteria for proper operation. There is always the opportunity to contact an expert to make sure that the liquid matches the specific biofireplace model.