The choice of lime for whitewashing walls is due to the fact that this coating has antiseptic properties and does not deprive the surface of its ability to breathe. Whitewashing is quite simple without the involvement of a specialist, and the material is quite easy to work with. Lime whitewashing of walls allows you not to worry about the formation of fungus or mold. The only nuance that should be taken into account is the preparation of the composition in compliance with all the nuances. The most popular is considered to be fluff. It is a white powder that has undergone a quenching process and requires the addition of liquid and various fixatives before application. Lime is sold in two versions - slaked, in the form of a dough (paste) or powder, quicklime, produced in the form of small or large lumps, as well as granules. The latter variety cannot be used for whitewashing. And if only this is available, the mixture is first extinguished. Quicklime is used as an additive in plaster and cement mixtures to improve plasticity properties and bind the components together.

How to properly slak lime?

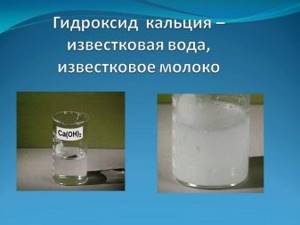

Hydrated lime, that is, slaked lime, is formed during the interaction of lumps or granules with a catalyst, which is water. A correctly carried out procedure is crucial, since, depending on the specific technique, you can get completely three different compositions: lime water, fluff - dry calcium hydroxide, suspension - lime milk.

The extinguishing process is accompanied by the release of a large amount of heat and is, in fact, a chemical reaction when a substance passes from one state to another. A person pouring calcium oxide with water must take all precautions to avoid getting burned. Along with a lot of heat, there is usually splash, so wearing personal protective equipment is a must.

To carry out cancellation according to all the rules, you need to follow a clear algorithm of actions. Each stage requires thorough execution, since it ultimately allows you to obtain high-quality fluff for whitewashing the surface of the walls. The difference between the compositions is not significant, but it does affect the quality of the work performed, so the recipe should be followed.

First stage

It is necessary to prepare the container. It should be washed well. It's best to take a saucepan. Water should only be used when cold. It is taken in large quantities. Limestone is poured into a prepared clean container and filled with water. For 1 kg of potassium oxide you need 1 liter of liquid. Additives are not always introduced, but it is thanks to the additional components that it is possible to obtain a better quality whitewash. Extreme caution must be used at this stage. The mixture will begin to heat up, bubble, and splash. Therefore, you should initially work with gloves and glasses. Otherwise, the hot solution may burn your skin and get into your eyes. The reaction takes more than half an hour. You cannot touch the composition until it completely “calms down”. Next, it is mixed with a previously prepared stick. The latter should be wooden.

Second phase

Slaked lime is not used immediately. It must be left to infuse in a cool place. The longer the preparatory solution sits, the better the adhesion properties become. The optimal holding time is considered to be from 5 to 10 hours. Some sources say several weeks, which is quite a long time. Usually a few hours are enough to get a fairly good whitewash, which will then fit perfectly onto the wall surface.

Subtleties of use

The product is also effective when carrying out repairs, for example, for whitewashing walls. In these cases, a hydrator is often used for slaking - a device for automated slaking of lime and producing hydrated lime (fluff). The required composition is prepared in advance, a day or two before the main operations. In order to obtain rich and light tones of diluted fluff, the proportion is 1: 1. A thoroughly mixed solution is applied to the material with a brush or using a sprayer in 2-3 layers.

Fluff is often added to various formulations. So, added to cement, it forms a viscous consistency that does not crack even after drying.

Lime is a caustic substance, so when working with it, it is important to adhere to safety measures:

- work in special glasses and gloves;

- during the extinguishing process, you should stay away from the container where the reaction is taking place, since the latter proceeds so actively that you can get burned from flying splashes;

- protect the respiratory system with a cotton-gauze mask;

- in case of contact with the skin, it is necessary to remove the drops with cotton wool soaked in vegetable oil, and place a compress of gauze pre-treated with 5% vinegar on the injured area;

- If the mixture gets into your eyes, rinse them immediately with water and, if necessary, go to the doctor.

Extinguishing rate

Lime is divided into varieties not only according to the recipe, but also according to the time of the procedure. The quenching period is calculated depending on when the temperature subsides, that is, heat ceases to be produced when combined with water:

- fast pace - from 5 to 12 minutes;

- average pace - from 13 to 22 minutes;

- slow pace - 25 minutes or more.

The extinction period has a direct impact on the quality of the resulting solution; it is prepared with some differences. It is necessary to decide in advance at what rate the extinguishing will take place. Otherwise, the quality of the whitewash may suffer.

Slaked at fast and medium rates

The pan is filled halfway with limestone and then filled to the brim with water. Lumps or granules begin to dissolve when steam appears. Stir it with a wooden stick and add a little more liquid. They continue to dilute the substance to obtain the desired consistency even when the extinguishing has already been completed. It is recommended to pour the resulting composition into a working container in which it will be used for whitewashing. Lime that is slaked at an average rate is no different from lime that is slaked quickly. The proportions are also one to one. The difference is that dilutions are not carried out until the chemical reaction process is complete.

Slowly produced lime

The pan or other container is also half filled with potassium oxide, and water begins to be poured rather slowly. When the lime finishes cracking, continue to add liquid in small portions. The result is milk, which is carefully mixed. The disadvantage of this preparation is that not all the pieces will dissolve. It is quite difficult to eliminate lumps after the end of the chemical reaction, so they are simply removed. If this is not done, firstly, the amount of “useful” whitewash will be difficult to calculate, since lumps will create the misleading impression of a larger volume, and, secondly, the quality of the work performed will sharply decrease, since the mass will not be homogeneous.

Kinds

There are two types of lime, which are distinguished by the amount of calcium silicates and aluminoferrites they contain: air and hydraulic. They perform various functions, for example, air accelerates the hardening process of concrete, and hydraulic accelerates reactions in water.

It is important that all fragments of the substance are the same size. This moment indicates that the raw material has been completely calcined in the oven.

If pieces are too large or too small, they may not be completely heat treated, and this will reduce the quality of the finished material.

Based on the type of processing, there are several types of material:

- quicklime lump (boiling liquid);

- quicklime ground (powdered);

- quenched hydrate – Ca (OH) 2;

- lime dough;

- lime milk.

Lump lime

Lump lime is a mixture of lumps that differ in size. It contains calcium oxide and magnesium, as well as materials such as calcium carbonate, aluminates, and silicates. Magnesium or calcium ferrites, which are formed during firing of raw materials, can be added.

The good strength of concrete is ensured due to the fact that lump lime requires very little water (due to the fine grinding of the material) and produces virtually no waste.

Ground lime

Ground lime has the same composition as lump lime, but the difference is that the lumps of raw materials are ground much stronger and more thoroughly.

The main advantages of ground lime:

- strength;

- water resistance;

- fast hardening.

To increase or decrease the hardening rate, calcium chloride or sulfuric acid is often used (gypsum material is also suitable).

Hydrated lime

Hydrated lime (also called fluff) is a slaked type of material with a highly dispersed composition. Slaking occurs by adding water to the lime raw material. To prepare such a solution, add from 70 to 100% water to the powder.

In order for the lime to completely go through the slaking process, it must be placed in a special pit for 2-3 weeks. This way it will gain optimal strength and ductility. The minimum cancellation period is 36 hours. To prevent the raw material from burning out, it is advisable to add water gradually until steam stops being released.

Lime paste is formed when sufficient water is added to form a plastic material. You can also find a solution such as lime milk (mainly used for whitewashing tree trunks). Lime milk is made by adding excess water to lime dough.

What should a high-quality whitewash be like?

You can check the resulting composition with a wooden spatula. A thick white film should remain on the instrument. This mixture is diluted with cold water, if necessary, so that the solution is homogeneous and opaque. From a kilogram of potassium oxide after slaking and diluting with cold water, approximately 10 liters of whitewash are obtained.

Be sure to check that there are no lumps in the lime. To ensure that there are no remaining small particles that did not dissolve during the slaking process, you should pass the whitewash through a mesh. You should also take into account what tool is supposed to be used to apply the composition. If you decide to use a spray gun, then the solution is passed through gauze. Otherwise, it will not be possible to carry out high-quality whitewashing.

Safety precautions when obtaining a pure mixture

Small particles of lime easily rise into the air and therefore penetrate the respiratory tract. Due to the high humidity of the mucous membranes, the material begins to be extinguished directly in the body.

When extinguishing, a drop of lime can cause severe burns, so you need to adhere to safety precautions:

- respiratory protection. To do this, you need to ensure good ventilation; it is better to extinguish outdoors. A respirator or at least a dust-proof bandage is applied to the mouth and nose;

- protection of the skin and mucous membranes. To work with lime, you need to use elbow-length rubber gloves, as well as safety glasses, and clothing should cover your entire body.

How to increase the durability of the resulting whitewash?

To ensure that the whitewash not only adheres well to the walls, but also does not crumble for a long time, soap or wallpaper glue is introduced into the solution. Lime is also used for exterior wall finishing. Facades are exposed to the harmful effects of atmospheric precipitation, so it is necessary to increase the durability of the composition, which can be achieved by drying oil, which prevents the whitewash from quickly being washed off, repelling moisture. Another disadvantage of lime that worries many is the ability to stain anything that touches the whitewashed surface. To eliminate this disadvantage, ordinary table salt is added to the solution. Its quantity is 1 kg per 10 liters. The amount of drying oil is about 100 ml per bucket of ready-to-use whitewash. Laundry soap must be passed through a grater and then poured with hot water to obtain a solution, which is poured in during the preparation of the mixture. If you don’t have wallpaper or PVA glue, you can use carpenter’s glue. It should be pre-cooked in a steam bath. A similar hot admixture is added before the actual whitewashing, that is, into the already prepared lime whitewash.

Facts to note

- Treatment should not be carried out more often than once every 4-5 years. On soils with an intensive type of agriculture, it is carried out once every 2-3 years, in accordance with the results of control measurements of pH in the areas.

- The use of lime is most rational on heavy (clay) soils, due to its high acidity and high density. The fact is that lime destroys the clay structure, making the soil looser and lighter.

- To neutralize excess acidity, lime can be fully replaced with ash from tree species. It just requires 3-4 times more ash compared to lime.

- Liming is best done in the fall. This will give time for calcium dissolved by rain to penetrate into the deep layers of fertile soil, it will have time to enter into all the necessary reactions with the formation of soluble and easily digestible minerals by plants, and possible excesses under the influence of winter cold will be neutralized.

- The appearance of mosses on the edges of fields, as well as wormwood and horsetails, indicates that it is time to liming the soil.

Adviсe

Liming not only improves the soil structure, but also attracts beneficial earthworms. These living organisms do not like acidic soil, but readily develop slightly acidic soils. All gardeners know about the importance of earthworms for the well-being of the soil.

Ground limestone can be replaced with wood ash, which also contributes to alkalization of the soil. In addition, ash is a source of important microelements - potassium, calcium, phosphorus. To free the soil from acidification, ash must be added in larger quantities than ground limestone.

Is it possible to replace slaked lime for soil with gypsum? This is a big mistake that inexperienced gardeners can make. Gypsum helps free the soil from salt, but not from high acidity.

Constant fertilization of the fertile layer with agrochemicals negatively affects its structure - the soil inevitably acidifies. Therefore, on soils fertilized with chemicals, liming must be carried out more often. If organic fertilizer is used, frequent liming is not necessary. Perhaps it doesn't need to be done at all.

Lime is contraindicated for the following crops:

- tomatoes;

- zucchini;

- sorrel;

- parsley;

- potato;

- carrot;

- peas;

- pumpkin.

The following crops also like acidic soils:

- garden strawberries;

- chokeberry;

- garden raspberries;

- gooseberries and blueberries.

Ground limestone is used not only to correct the composition of the soil and protect the bark from harmful insects and rodents, but also to treat cellars from mold, and gazebos and wooden supports from destruction by animal pests. The bases of benches and wooden fences are treated with lime - this will protect them from premature destruction and rot.

To obtain a high-quality solution, add water to the powder in portions. Bring the mixture to a batter, and then dilute with the rest of the water to the consistency of milk.

Bottom line

Slaked lime has long been used for gardening and gardening. This is a unique substance that has disinfectant and protective properties. It’s not difficult to prepare the composition; any summer resident can handle it. Since ground limestone is caustic, you need to work with it very carefully. Dilute the working mixture only outdoors, or better yet, in the fresh air.

Slaked lime is used to treat the trunks of fruit trees and all wooden surfaces in a summer cottage. This prevents the destruction of wood by pests and extends the life of fences, garden gazebos and benches. Liquid limestone is used to sanitize garden tools and disinfect the internal surfaces of greenhouses and cellars.

Deoxidation of soils, enrichment of the fertile layer with calcium and other microelements makes it possible to obtain a good harvest from the site. Lime drives away harmful insects and rodents, protects trees from freezing and promotes rapid cleansing of dead bark. Ground limestone is an indispensable substance in household farming, the importance of which is very difficult to overestimate.

Varieties

All limestones are divided by origin, color, chemical composition, physical properties, structure, and application features.

The most common colors of this breed are:

- White or greyish. Chemically pure limestone rocks, consisting almost exclusively of calcium carbonate, have this color.

- Brown and yellow colors are due to the presence of iron compounds.

- Red, pink and brown limestone is obtained in the presence of an admixture of manganese compounds.

- The green color of this rock is given by the remains of seaweed.

- Dark and black colors are associated with the presence of heavy hydrocarbon fractions in this rock. These types of limestone are very rare.

In the first case (the most common option), the reason for their formation is the accumulation of calcareous shells and other fossils in the thickness of the seabed. In the second - chemical transformations during which calcium carbonate is formed. In the latter case, the formation of new strata is associated with the natural transformation of previously destroyed limestones.

Based on the time of occurrence, Jurassic, Triassic, Cretaceous limestones and other types are distinguished. The name of limestone corresponds to the geological period within which its formation took place. Since natural conditions were different in different eras, the limestones themselves were not the same. The composition of the imprints of ancient organisms also depends on the time of their origin, since different types of living beings predominated in different geological periods.

Limestones are also classified by variety. The following types are common:

- Dolomitized. Contain a significant admixture of magnesium oxide. At its maximum content, dolomites are obtained.

- Coral. They are formed in modern warm seas and form the basis of coral reefs. They have a porous consistency.

- Clayey. Such rocks contain a significant admixture of clay. As it increases, marl is formed.

- Marbled. Relatively dense limestones of light or gray-blue color. May also contain fossils.

The technology for processing natural raw materials determines the division of construction lime into two types:

- quicklime containing CaO;

- slaked (hydrate), the main component of which is Ca (OH) 2.

The distinctive features of fatty lime are:

- high extinction speed;

- heat generation;

- plasticity of the composition.

This material is added to mortars to increase the elasticity of the mixture and ease of use. A lean composition has a higher extinguishing rate, and much less heat is released. As a result of processing, the composition turns out to be granular and heterogeneous, and the dough itself has low plasticity.

Lime that tends to harden in air is called air lime. A mixture that can harden in air and water is called hydraulic. In airy lime, up to 12% of the composition is made up of silicates and calcium aluminoferrite, in rare cases this figure reaches 20%. This mixture is widely used when painting porous surfaces of concrete, brick, plaster and natural stone.

According to the parameters of the oxide in the composition of lime, we can roughly distinguish:

- calcium – contains up to 2% MgO;

- low magnesium – contains 2–5% MgO;

- magnesia with a magnesium oxide content of 5–20%;

- dolomite, including 20–40% of this component.

Depending on the type of processing of natural raw materials, the following options for pneumatic lime are conventionally distinguished:

- quicklime lump or boiling liquid, which mostly consists of Ca (OH);

- quicklime ground - this is a material obtained by crushing lump lime, characterized by a powdery structure;

- slaked lime is formed by slaking lump lime;

- lime body is another material produced as a result of slaking of a lump composition with a dough-like structure;

- milk of lime is light-colored lime; calcium hydroxide is present in it both in a dissolved state and in the form of particles.

Based on the rate of extinguishing, the material is divided into three types:

- fast-extinguishing (extinguishing speed no more than 8 minutes);

- moderately extinguishing (reaction time ranges from 8 to 25 minutes);

- slow-burning (requires 25 minutes or more)

Water purification

To purify water, bleach is used, which has high disinfection properties. Chlorination of water allows you to avoid outbreaks of intestinal infections and other epidemics.

Constant consumption of such water leads to allergic reactions and contributes to the formation of carcinogens in the body. In water, chlorine can combine with other substances, which affects the appearance of intoxications.

In order to reduce the effect of chlorine on the body, it is necessary to drink water that has been passed through carbon or other high-quality filters. At the same time, bleach is considered one of the most effective means; it prevents the occurrence of cholera and dysentery. Bleach must be used to disinfect wastewater.

Where is slaked lime used?

Lime is considered a binder that gives plasticity to cement mortar. Slaked lime can be used to whitewash ceilings and walls in the bathroom, basement, garage, swimming pool, and closet. It is also used for treating surfaces in agricultural buildings, that is, chicken coops, cowsheds or pigsties. The protective film that appears on the surface after treatment is resistant to moisture and environmentally friendly. Lime is also used to treat trees against pests, and it is used to whiten curbs on highways.

This material also has disadvantages; after application, stains or streaks may remain on the surface. But such problems arise if the technology for preparing the composition is violated.

Help with burns

A lime burn is a chemical damage to the skin that is fraught with the most unpleasant consequences. Quicklime is an alkali that emulsifies and dissolves sebum, penetrating into the deep layers of the epidermis. Externally, the burn looks like complex necrosis of off-white tissue with the formation of loose scabs. When it comes into contact with the skin and mucous membranes, the alkali penetrates in all directions, so the lesion is much larger than the area of contact with lime. Damaged tissues partially lose their ability to regenerate and wounds take a very long time to heal.

In case of injury, medical assistance should be provided immediately. It is necessary to promptly call a doctor, and while she is on her way to try to improve the victim’s condition. If slaked lime gets on your skin, you should rinse the affected areas with cold water for at least 15 minutes, and then treat with chamomile infusion or anti-inflammatory ointment.

But if a burn occurs with quicklime, then rinsing the skin with water is strictly prohibited, because this can aggravate the situation and cause irreparable damage to health. Most of the substance will come out along with tears, and its remnants should be removed with a cotton cloth and lubricated with oil or grease. By the way, this is the only type of chemical damage when their use is allowed. For any other types of damage, such reagents are strictly prohibited. The wound should be covered with a sterile cloth and then immediately taken to the hospital.

The situation is more complicated if lime gets into the eyes. It causes quite dangerous consequences, including partial or complete loss of vision. Small and medium fractions are not so dangerous; they can only cause conjunctivitis. Large parts literally stick to the mucous membrane of the eye and actually corrode them, penetrating inside and causing sharp pain, burning and spasm of the eyelids.

First aid includes:

- instillation of disodium salt, which binds metal ions;

- use of painkillers, including local ones.

To learn how to extinguish lime with your own hands, see the following video.