Previously, bathhouses were built only from natural wood; no additional internal or external cladding was made. The wooden walls “breathed,” which allowed them to constantly maintain optimal relative humidity values. In addition, during washing, the internal surfaces of the walls were heated to high temperatures, which prevented the appearance of dew points on them even at a relative humidity of 100%. All building structures (not only wooden ones) are afraid not so much of steam as of water, and water is condensation.

Vapor barrier for a bath

Why is vapor barrier necessary?

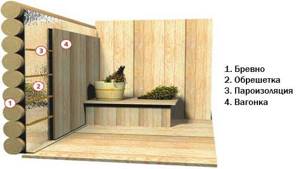

Currently, most bathhouses have interior walls lined - this is beautiful, useful and prestigious. The walls are usually covered with natural clapboard. From the designer’s point of view, everything is great, but from the builder’s point of view, there are big problems.

- An additional “heat-protective” wall is formed between the load-bearing wall and the steam room. This is good, it minimizes heat losses, but it causes condensation.

- Due to the low thermal conductivity of wood, the temperature difference between the lining and the wall is large. This situation needs to be looked at from two sides. The good thing is that the steam room retains heat. The bad thing is that steam easily passes into the forcing joints, and the relative humidity of the wood increases.

Now we come to the main problem. If the temperature of the lining is so high that condensation does not form given the existing humidity, then the wall temperature is below the dew point. Condensation forms on cold walls and is absorbed into all materials of external walls: wood blocks, brick. Due to the fact that natural ventilation between the sheathing and the wall is almost completely absent, water does not evaporate. As a result, the wood begins to rot, the red brick crumbles, and the concrete materials transfer moisture through micropores to all adjacent structures.

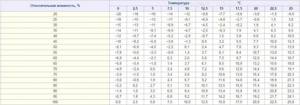

Dew point table

Dew point in the wall

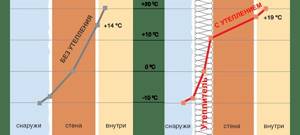

Here you can clearly see how the dew point in the wall of the house will shift

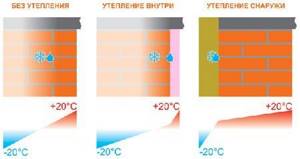

Vapor barrier and wall insulation

But these are not all the reasons why you should use a vapor barrier. Let's touch on the issue of insulating the bathhouse. Insulating the outside is a waste of money and time. Until the insulation “shows its effectiveness,” no one will wash in the bathhouse. The heating time for the sheathing and walls is several hours. Only then will the internal heat “reach” the insulation outside the external walls and it will be able to “work”. The effect will no longer be during the heating of the steam room, but during its cooling after washing. To “enjoy” the effectiveness of external thermal insulation, you need to stay overnight in the steam room.

It is necessary to insulate the bathhouse from the inside

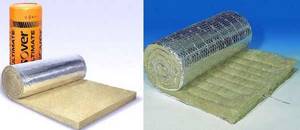

This means that for steam rooms, insulation needs to be installed only inside. But here too a problem arises. Most often, mineral wool, glass wool or polystyrene foam are used as insulation. The latter is not environmentally friendly and emits harmful chemical compounds, especially during heating. Sanitary authorities categorically do not recommend using it for steam rooms. What remains is mineral wool or glass wool.

Mineral wool has two “unpleasant” properties. First, with increasing relative humidity, thermal conductivity characteristics decrease significantly. This is what some “experts” write, although the characteristics increase, thermal conductivity increases, and heat saving decreases. Do you feel the difference? Three times - cotton wool takes a very long time to dry, there is almost no air movement in it. Which is natural, otherwise the heat would not be retained in the room. Insulation is always attached to the walls, regardless of the material they are made of. And prolonged contact with wet wool has an extremely negative effect on all building materials. Here is another reason why you need to use a vapor barrier in a bathhouse.

If you understand these issues, you can familiarize yourself with various vapor barrier materials and their physical characteristics.

Operating principle

The work of the vapor barrier material is as simple as the pendulum of grandma's walker. A water molecule, an air molecule and a steam molecule have different sizes. In an array of absolutely impenetrable material, calibrated perforation is performed, that is, holes of a certain size are made that freely allow an air molecule to pass through, but block the penetration of a steam or water molecule. That is, ideally, high-quality material guarantees the notorious “breathing effect”, when air circulates freely and moisture is cut off.

Attention! The pore size of the material determines the specificity of blocking water or steam molecules, hence the specialization of insulating materials. This is either a vapor barrier or waterproofing. Each one works in its own way and the effect of the work is different.

Types of insulation materials

As mentioned above, a high-quality insulated steam room is economical, practical and, most importantly, durable. The modern construction industry offers three main types of thermal insulation materials:

- Styrofoam. Convenient, lightweight, effective. But it's not suitable for the bathhouse. When heated, there is a high probability of releasing highly toxic volatile compounds, which will not ozonize the air in the steam room;

- Glass wool. Affordable, easy to install, quite effective;

- Mineral wool also has good properties, quite applicable in a steamy room.

However, both cotton wools, despite all their positive properties, are very hygroscopic, readily absorb condensation and are extremely poorly ventilated and, as a result, take a long time to dry. Contact with wet cotton insulation of any building material is very unpleasant for the latter, and sometimes fatal.

In general, insulation is needed, and its insulation is even more necessary.

Vapor barrier and its diversity

The market is saturated with various vapor barrier materials, each of which has, albeit insignificant, feature or specificity:

- Single-layer vapor barrier materials such as high molecular weight polyethylene film. One of the most affordable and fastest solutions. Available in two-layer sleeves of sufficient width, which ensures quick and easy installation. Due to the specific structure of polyethylene fabric, it reliably blocks water, steam and air. Builders call such films with the slang expression “grouse”;

- Anti-condensation multilayer vapor barrier. It has several layers of material with a set of strictly calibrated pore holes in each working layer. It works selectively and delicately, ensures sufficient gas exchange and air convection, but requires precise installation on the “front” and “back” sides, otherwise it will not work correctly;

- Combined heat-steam-waterproofing based on metallized aluminum foil. Provides not only protection from water and steam, but also exhibits a significant heat-accumulating effect. A complex, but quite expensive remedy;

- Glassine, rolled roofing felt and other materials based on modified bitumen. They are good, but not for a bath, because at high temperatures they tend to scorch and release volatile substances with a pungent and unpleasant odor, which, like polystyrene foam, also do not ozone the air;

- Insulation based on liquid synthetic rubber and caoutchouc. They have excellent insulating properties and are extremely convenient to apply to any surface, including curved and radius ones. However, roads and in premises such as baths must be used very carefully, primarily due to their synthetic origin.

Attention! Coating vapor barrier of the “liquid rubber” type, based on synthetic rubber, is well suited for floor vapor barrier, forming a plastic polymer film resistant to mechanical stress.

Attention to joints: installation and installation features

The principle of operation of a system such as bathhouse vapor barrier is to carefully adjust and seal seams and joints. Violations of the integrity of the vapor barrier mass are a direct path to the formation of local breakdowns in the protection, which will then become the focus of future problems.

Main events:

- Purchase of material with an insurance premium of about 10-12% of the covered area of the bathhouse.

- Preparation of wall and ceiling surfaces to avoid damage primarily to film materials. Particular attention to the elimination of sharp, protruding elements, chips and other things.

- Careful and accurate cutting of material.

- Thorough joining of seams or overlap of insulation sheets at their junction.

- Sealing seams using tape, preferably double-sided metallized or adhesive.

- Application of a double-sided insulation protection system. On the outer wall side from condensation, on the inner wall from direct exposure to steam.

- Leaving an air gap between the insulation, vapor barrier and wooden cladding of the steam room for free air convection in the internal space. As a general rule, an air gap of 25-40mm will normally provide satisfactory convection.

Important! The vapor barrier for a sauna must meet the same principles and requirements, despite the significantly lower absolute humidity in a thermal room of this type.

Types and characteristics of vapor barrier materials

There are quite a few of them; we will focus only on a few of the most frequently used ones. Let's start again with a little “educational education”. Some amateur builders do not fully understand the difference between vapor barrier and waterproofing materials. After all, steam is the same as water. Why should some materials be used for vapor barrier and others for waterproofing?

Vapor barrier and waterproofing. Differences and Similarities

The fact is that water molecules and steam molecules have different sizes. Based on these characteristics, manufacturers produce materials with different micropore diameters. Some do not allow steam molecules to pass through (vapor barrier), while others do not allow water molecules to pass through. This means that vapor barrier materials can also be used as waterproofing, but the latter cannot be used in the same way. Recently, the production of vapor-waterproofing fabrics has begun; they consist of two layers with different micropore diameters. When installing such materials, you need to monitor the location of these sides so as not to install “exactly the opposite.”

What vapor barrier materials are produced?

Ordinary polyethylene film.

| Material | Description |

| The cheapest, but pretty good option. It has another significant advantage. The films are produced in sleeves with double walls, the sleeve width is up to three meters. By cutting the sleeve in half, you get a sheet of continuous film more than five meters wide - quite enough to cover the wall of a bathhouse with a continuous material without overlays. | |

| Glassine, roofing felt and other bituminous materials. | They are rarely used in baths due to the likelihood of unpleasant odors. |

| Pure aluminum foil and aluminum coated multi-component materials. | Used most often, multi-component materials have a small layer of thermal protection or special fibers to prevent condensation from draining. |

| An excellent vapor barrier material that can be applied to surfaces of any complexity and configuration. | |

| Liquid polyurethane foam insulation. | In addition to their main tasks of insulation, they have a sealed outer surface that does not allow steam to pass through. Universally applicable, characterized by high performance characteristics. |

Waterproofing materials

Heat loss through the ceiling and walls of the steam room can be prevented using modern building materials, or using those materials that our ancestors used for the same purposes. The latter option is beginning to become increasingly popular due to the desire of the population to use environmentally friendly materials and technologies that are harmless to human health.

Our ancestors carried out vapor barrier of the ceiling and walls using the following materials:

- red moss;

- cuckoo flax;

- flax fiber;

- tow.

Red moss and cuckoo flax were used to caulk the gaps between individual ceiling elements. They have good thermal insulation properties and prevent the formation of mold, as well as bacteria, which cause rotting. Linen fabric and tow were used to upholster the ceiling.

Note: These materials are 100% environmentally friendly, but have low efficiency.

Modern building materials used for hydro-, vapor barrier and insulation make it possible to much better reduce heat transfer. However, most of them are completely safe. In addition, they have another very useful property - high fire safety. They ignite very poorly, unlike natural materials, which is extremely important in buildings such as a bathhouse, where elevated temperatures are constantly observed.

For ceiling vapor barrier it is best to use:

- wax paper or cardboard, kraft paper;

- membrane films;

- foam glass;

- foil and metallized films;

- laminated films;

- clay;

- clapboard

Note It is not recommended to use oilcloth for vapor barrier of the ceiling - under the influence of high temperatures it easily ignites and melts, releasing substances harmful to the body.

- Paper and cardboard , additionally treated with special primers and mixtures or simply waxed, is the cheapest way to vapor barrier the ceiling and walls. Due to its low price it is very popular. However, paper and cardboard have very poor thermal and waterproofing properties.

- Membrane films are a modern material. Unlike other materials used for waterproofing, it does not just stop the passage of steam, but only limits it to the required extent. That is, membrane films allow the bath to “breathe”. Different models of such films have different properties, so you can choose the most suitable material for your case. Experts advise using this particular material for such an undertaking as waterproofing a bathhouse.

- Foam glass has much in common with foam plastic, but unlike the latter, it is characterized by greater fire safety. It is achieved through the use of quartz sand, which does not ignite or melt. Its main disadvantage is its rigidity, which makes it difficult to work with.

- Foil , as well as insulation coated with foil, is the best option. It combines good vapor and heat insulation properties. It's easy to work with and relatively cheap too.

- Metallized films are covered with foil on one or both sides. Often, one of the sides is adhesive, which makes it easier to attach to the ceiling and walls.

- Laminated films have much in common with foil films, the only difference being that in this case it is coated not with a metal coating, but with a polymer composition. It is a good waterproofing agent, but is rarely used, since it is believed that under the influence of hot steam the coating begins to release harmful substances.

- Clay and lining are materials that have been tested by generations of bathhouse builders, which is why even in our time they are very often used. They have good heat, hydro and sound insulation properties.

Some general tips for laying vapor barrier materials in a bathhouse

You can find advice from “experts” who encourage making small holes in vapor barrier materials through which air will pass, and the structure supposedly will not suffer from high humidity. There is nothing to say, it is better to remain silent. When installing a vapor barrier, the main condition for effectiveness is the complete absence of gaps ; overlapping materials must be sealed with ordinary tape (cheaper option) or special metallized tape (more expensive option). The presence of any cracks nullifies all activities.

Laying the material strictly without gaps

The fewer holes the material has during fixation, the better the protection. If possible, try to use double-sided tape or silicone glue. Of course, the choice of adhesive composition must correspond to the physical characteristics of the vapor barrier material. Now we will consider two options for performing the work: for a bathhouse with brick walls and for a ceiling.

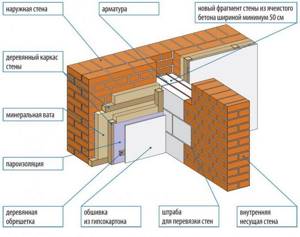

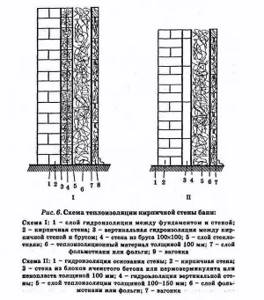

Vapor barrier for brick walls

Such baths are very rare and belong to elite and expensive buildings. Their vapor barrier is quite complex, in most cases two-layer. Brick baths must have insulation on the walls, and it is highly desirable on the interior. We have already explained why this is so.

Brick wall insulation scheme

Step 1. Selection and calculation of the quantity of materials. The quantity is easy to calculate: measure the quadrature of all surfaces and increase the resulting number by ten percent. It is more difficult with the selection of materials. As we have already noted, only materials that are safe for health can be used for thermal insulation of indoor baths. Not “environmentally friendly”, as it is now fashionable to say, but safe.

What is it for?

The main purpose of this structural element of the ceiling cake is to protect its remaining elements from getting wet.

Everything seems to be clear. However, a logical question arises: is it needed in the entire bathhouse or can it be limited to the rooms that are the most humid - the steam room and the washing room?

The answer to this is simple: no, you cannot limit yourself to a steam room and a washing room, because vapor barrier is part of the standard ceiling pie, regardless of the room in which it is being built. Why is that?

Because the main element that needs protection is the thermal insulation material , which lies at a higher level. Since in most cases this is mineral wool, the mats of which are most affordable and easy to install, one must also take into account the property of this material, such as sensitivity to the accumulation of condensate in its thickness.

The fact is that moisture accumulating between the fibers of stone wool significantly reduces its thermal insulation properties. After all, the main heat insulator is always air. We simply create a heat-resistant environment for it in the form of thin mineral wool fibers or clay partitions in expanded clay balls. Water, on the contrary, connects the fibers (this does not apply to expanded clay, the clay is baked there, and water does not get inside the balls), improving the conductivity of heat through this medium .

Condensation forms not only when the room is very humid, but also when there is a temperature difference between what is inside and what is outside. And humidity is present in any room and outside it; it is a natural component of the air.

In the Russian steam room

In terms of the amount of steam, the Russian steam room is second only to the Turkish hammam, but it is usually finished with tiles or mosaics, which makes it less sensitive. The Russian steam room is traditionally finished with wood, and if its surface layer, for example, lining, is inevitably sacrificed and takes on all the blows of increased temperature and humidity, then the inner layers can (and should) be protected.

We will talk about the methods of vapor barrier of the ceiling in a bathhouse a little lower, but for now it is important to draw conclusions - a Russian steam room clearly needs a well-thought-out and powerful vapor barrier. Does the same apply to the sauna?

In the sauna

It is not for nothing that the Finnish sauna is called “dry air”. In the orthodox version, the humidity in the sauna is minimal, amounting to no more than 5-15%. The Finns don’t pour much water on the stones, which is understandable - they either lay them out in a mound on top of the stove, or in a mesh covering the body, and this does not give the stones the heat needed to produce light, fine steam. Instead, the steam is thick and heavy.

In addition, the high temperatures of the Finnish steam room do not allow a person to easily absorb excess steam.

The third essential property of a sauna is vigorous air exchange , which is achieved using natural or forced ventilation.

Let's summarize: the sauna has good ventilation and high temperature, both of which help eliminate excess moisture, so even the surface layer of the ceiling will not suffer much during the procedures. However, insulation of the ceiling is mandatory, which means you need to make sure that the insulation does not accumulate condensation even due to temperature differences. Therefore, it still needs to be insulated , except that the vapor barrier itself can be standard, but (since the temperature in the sauna is high) it must be designed for exposure to heat.

Proper waterproofing of the top of the insulation will also help, but more on that later.

Principles of vapor barrier

To begin with, it should be noted that this type of protection is significantly different from waterproofing and uses completely different materials. At the same time, you need to understand that it is mainly the walls and ceiling that are exposed to vapors, which means that it is not worth considering types of floor protection. However, it is worth saying that the vapor barrier of the bathhouse is also done on the floor, but here again materials are used to protect against direct contact with water.

The film cannot be called practical

Film

- This material is very popular among modern builders. It has a fairly low cost, tolerates moisture well, and at the same time has a long service life.

- However, if the vapor barrier of the bathhouse ceiling is done in a steam room, then the film should not be used. The fact is that it does not tolerate high temperatures at all and even with moderate heating it begins to lose its shape. Considering this, they prefer to install it in the rest room.

- The installation process is quite simple. This vapor barrier is fixed to the bathhouse using special heat-resistant tape along the entire perimeter of the surface. At the same time, if joints are formed, then they must be placed, overlapping and gluing on both sides.

Using a special film to create a vapor barrier

- Some craftsmen use a stapler to fix the material onto the sheathing, but this will break the seal, which will greatly weaken the protective functions of the film.

- It should be noted that there is a special vapor barrier for the bathhouse made from similar materials. However, its cost is so high that, in combination with insulation, it forces builders to look for other methods of moisture protection.

Advice! The film must be purchased without seams. It is in these places that it is most vulnerable and can tear.

Appearance of the steam room after installation of foil on the walls

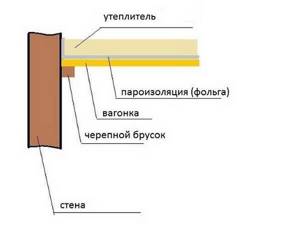

Foil

- This type of insulation is of great importance for a bathhouse, namely for a steam room. Not only does it perfectly impermeable to moisture, but it also reflects infrared radiation. This allows the room to be heated much faster.

- This material is especially effective at the moment when vapor barrier is being applied to the ceiling in the bathhouse, since this is where the largest accumulation of moisture and infrared radiation is located. However, professional builders advise using it to work in all rooms and on any planes.

Aluminium foil

- Bath foil is applied to the surface in the same way as film. In this case, fixation is carried out exclusively with heat-resistant tape.

- All work must be done very carefully, since this product breaks very easily.

- It is also necessary to remember that the vapor barrier of the walls in the bathhouse is made on top of the insulation, but it should not come into contact with it. Otherwise there will be no air gap between the two materials. This will lead to condensation accumulating on the insulation, and it may lose its qualities.

Advice! Some craftsmen claim that any metal foil can be used for these purposes. However, professionals advise using only material made from food-grade aluminum. The fact is that when heated, it will not emit harmful substances, which is typical for some other products.

Sealing joints using special reflective tape

Special materials

- Currently, materials for vapor barrier of baths based on foam insulation have become extremely popular.

- The fact is that such buildings are made mainly from timber or logs. If they use brick or other material to create the walls of the bathhouse, then it must be insulated from the outside. Thus, the entire structure is sufficiently protected from the cold and does not require internal insulation.

Appearance of foamed polyethylene with a foil layer

- However, the steam room should be equipped with a coating that contains a reflective surface, since in this case we are talking about savings and energy conservation.

- Taking this into account, many craftsmen prefer not to insulate the structure of the bathhouse from the inside, and they install roll insulation in the steam room, which is a foam base coated with foil.

- This Izospan vapor barrier for a bathhouse has a thickness of no more than one centimeter, which allows great savings on space.

This material is also sold without a reflective surface, but for installation in a bathhouse it is better to use the option with such a layer

- Also, its base is a kind of insulation, which of course cannot be compared with mineral wool or expanded polystyrene, but it does its job perfectly, considering that the walls are wooden or are also protected from the cold from the outside.

- Special attention is paid to the fact that the price of this material together with the work is much lower than the cost of insulation, film and foil combined.

- To install such insulation, special tape is used. It also has a shiny surface and perfectly reflects infrared rays.

- Before purchasing such products, the installation instructions recommend paying attention to their quality certificate. The fact is that recently many fakes have begun to appear that do not meet the stated characteristics. Their foam lining not only does not tolerate high heat, but also emits harmful substances.

Surface ready for stitching

- The same requirements must be applied to the quality of adhesive tape.

- Given this situation, professionals always purchase only from trusted sellers, trying to purchase goods from one manufacturer. At the same time, they will always try its quality with their own hands, since with constant work, some of them have learned to determine it by touch.

Advice! To save money, you can install insulation with a layer of foil in the steam room, while in other rooms you should use polyethylene foam. The fact is that a reflective surface is needed only where there is a source of infrared radiation. Otherwise it will cause cost overruns.

Several types of heat-resistant tape that can be used during installation

What is the difference between vapor barrier and waterproofing

Now this is an interesting question. In essence, in both cases we are talking about the effect of moisture, it’s just that in the first case an increased temperature is added to it. Therefore, it would be correct to use these concepts and related materials something like this:

- vapor barrier is done from the inside of the room so that water vapor that arises inside does not turn into condensation when faced with the cold of the external environment;

- waterproofing is done primarily to protect against moisture coming from outside, and it can be in the form of water vapor or precipitation.

When it comes to ceiling insulation, vapor barrier is the bottom layer, waterproofing is the top layer. However, if the bathhouse has a second floor with a residential attic, then the term “waterproofing” becomes somewhat arbitrary, because protection is carried out from the same vapors, only found in the insulation.

Hence, probably, the constant confusion that can often be found in descriptions.

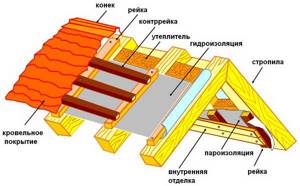

Everything is clear with the roof: the layer located directly under the roofing material is waterproofing, because precipitation can seep into it, and the layer that is made from the inside on top of the insulation is a vapor barrier . See the article When is it necessary to insulate the roof of a bathhouse and when is there no point? Roof thermal insulation technology

In which particular bath rooms are vapor barrier materials needed?

A typical bathhouse includes three rooms: a steam room, a shower room and a relaxation room. The humidity level in each of them is different:

- The steam room has the highest concentration of steam, because there is hot air and stones that are periodically watered.

- Shower room - the temperature in this room is lower, and therefore the humidity is lower.

- The rest room is the “dryest” place, but steam and soda still penetrate through the doors.

Materials for the vapor barrier must be selected taking into account the listed factors. If you need to save money, then high-tech multilayer membranes are installed in the steam room, and inexpensive films can be used in the relaxation room.

Why do you need steam protection?

The barrier, first of all, prevents the thermal insulation from being moistened by moisture-saturated vapors formed inside the bathhouse. Similar measures are used when insulating balconies or living rooms. In the absence of vapor protection, the insulation quickly becomes moistened and loses up to 10-15% of its properties annually.

It must be taken into account that the material for vapor barrier of walls should always be installed only on the inside of the building. Why is this so? The fact is that steam moves in the direction from warm to cold. Temperature changes occur inside the insulation, which leads to the formation of condensation. Therefore, a sealed barrier should be made in the path of the steam.

Another function of the membrane is to block the decomposition products of the heat insulator. Even high-quality basalt wool after several years of use dries out and forms fine dust. It has a harmful effect on human well-being. The film prevents dust from entering the room.

What types can be found on sale?

And again, it’s interesting to figure out what a vapor barrier film for the ceiling is, what can they offer us in the store? In general, it’s probably worth clarifying right away that the class of vapor barrier films is not all that can be found on sale. It is worth talking about such a popular foil, and about foil materials, and much more.

Vapor barrier films

There are polyethylene and polypropylene. The difference, as you understand, is in the polymers. Polypropylene is more expensive, its melting point is 40 degrees higher than polyethylene (better for a bath), but it is more fragile and can withstand frost 10 times worse (PE - up to -50, and PP - up to -5), PP more elastic, but still less durable.

Also, the film may or may not have perforations. Since we are talking about vapor barrier, it cannot be perforated and single-layer. Therefore, perforation is allowed only in the second layer.

The advantages of perforation are questionable - during operation, these holes are easily clogged with dust.

Reinforced and not reinforced . An ordinary film is not reinforced with anything, but you can easily distinguish a reinforced film - it has a thread base made of a different material. The film is reinforced for the sole purpose of increasing its strength. And this really helps, it is more difficult to damage mechanically.

Reflective foil vapor barrier film

Another way to improve the properties of conventional films is foiling. A thin layer of metal makes such a film reflect infrared radiation. On the other hand, fragile foil with a polymer base becomes more durable.

As for anti-condensation films, they are not for vapor barriers and not for ceilings - they are for roof waterproofing.

Foil

But this is generally a favorite of those bathhouse owners who want to both retain heat and provide a reliable barrier to steam. Aluminum foil is completely impenetrable to steam. However, the rolls have a limited width, so you have to overlap and seal the joints, and the seams are always imperfect. So, if any moisture penetrates into the insulation, it will not be the fault of the foil itself.

Many people do not like to cover the ceiling in a bathhouse with foil in its pure form because of its fragility - it breaks easily, in addition, it is easy to cut yourself on it; this material requires great care in working.

combined on sale - foil increases the operating temperature range of the films used, and they, in turn, protect it from ruptures. In addition, the presence of a polymer backing allows you to make the foil layer thinner - in its pure form you simply would not be able to lay it with such a thickness.

Many film companies have expanded their range to include foil materials, so when we get to specific names, just keep in mind that they most likely have them.

Now is not the time to argue about whether foil is needed in the bathhouse or not. In essence, all questions of this kind can be reduced to one thing: does a person know the materials enough to get exactly the desired effect or does he not know. And the circumstances can be very different.

Ruberoid or glassine

Both are the result of impregnation of cardboard with petroleum bitumen . Both can, in principle, be used for vapor barrier of a bath ceiling, but we still would not recommend these two materials over the steam room .

However, you may not listen to our opinion, because the temperatures in the steam room are different for everyone, and the ceilings themselves will not be the same, so in some cases such a vapor barrier may turn out to be quite acceptable.

Since we are talking about fairly cheap materials, they can be used in budget construction, when, for example, a flat ceiling scheme is used. In this case, roofing felt or glassine is placed directly on the flooring boards from the attic side and serves as a backing for the insulation.

Kraft paper

This is an excellent option for those who decide to insulate themselves with ecowool. Vapor barrier kraft paper is a type of cardboard that can be single-layer or double-layer. The coating with a polymer film can be on one side of a single-layer cardboard or between two layers of a two-layer cardboard. , reinforcing mesh can be added , which is also located between the layers of cardboard.

This paper is produced in Finland and is intended for insulating environmentally friendly insulation materials made from cellulose or flax fiber.

Can kraft paper be used with other types of insulation, such as mineral wool? Yes, you can.

Izospan

We inquired about the recommendations given by the manufacturer of these products. Izospan RS (aka B) as a vapor barrier there

Well, let's see what he is. This is a material that consists of three layers of polymers, two of them are exactly polypropylene. The first layer of polypropylene is a regular film, it is smooth. In the middle (second layer) there is a reinforcing mesh, the material of which is not specified. The third layer is non-woven material, all made from the same polymer. Non-woven materials (= something like felt) are usually used to create an anti-condensation layer, in this case its use is not entirely clear.

Izospan B for a bath on the ceiling

However, in addition to vapor barrier of ceiling insulation, this type of film can also be used for waterproofing, for example, floors and roofs. Let's classify the rough third layer as waterproofing. Although this is a little strange - if the film is vapor barrier, then it is impenetrable to vapors, if it is waterproofing, it is permeable. What is a universal film, suitable here and there? Mystery. At least for us.

The technical specifications say that Izospan B is vapor-tight, its temperature range is -60+80 degrees. In terms of temperature characteristics, it is not particularly suitable for a steam room. In other rooms, if desired, you can use it.

A little about the manufacturers and their products

Armitex-75 is an analogue of Izospan V. Only without reinforcing mesh, apparently. It has smooth and rough sides. The manufacturer advises facing the rough side towards the insulation.

The Czechs produce films under the Jutafol . They have several types of films only as a vapor barrier, they are all included in the Yutafol N . Among other things, you can find films with a reagent that leads to the extinction of the flame, preventing a fire. Some are reinforced, some are foil.

The Luxembourg company DuPont produces a foil vapor barrier called AirGuard® Reflective .

The Poles make Folder in the following varieties: Minima H 98, Silver H 98 and Alum H 90. The numbers mean grams per square meter. The latter is foil, suitable for baths and saunas. Others, however, are also suitable. Minima is not as durable as Silver.

Russian-Polish film Optima B is suitable for insulating insulation. This is a two-layer film with a density of 75 g/m2, with smooth and rough sides.

The company that produces the popular roofing material ondulin also produces roofing films. There are also vapor barrier ones among them. These are Ondutis R 70, RV, RS and Thermo. The latter is foil, RV does not have reinforcement, but RS does, and RS can be considered an analogue of Yutafol standard 110. Thermo is suitable for steam room ceilings, because the foil there is protected by a layer of polyester with a melting point of 200 degrees!

Vapor barrier for a bath - foil, on the ceiling and walls

For a Russian bath, one of the main tasks is to retain steam. After all, it is high humidity that we need to create the desired atmosphere. Its second task is to protect the heat insulator from getting wet: when wet, it protects the premises much less well from heat loss.

What does it look like

Foil vapor barrier is the best choice for a steam room

If this is a regular vapor barrier, it is a milky, white, blue film. There are them “checkered” with reinforcing fibers, and there are homogeneous ones. They feel dense to the touch and can have surfaces of different textures - smooth and rough. There are vapor barrier membranes. They are nonlinear - they have a corrugated surface or with spiked protrusions.

Especially for baths and saunas, vapor barriers with a heat-reflecting coating are produced: it can be made of foil or metallized lavsan.

What is it for?

High humidity and temperature in the steam room of a Russian bath require a special approach. It is important to protect the heat-insulating layer from moisture. Why protect him? The fact is that basalt wool is most often used for thermal insulation of premises. In a dry state, it has good heat-insulating qualities, is made from natural materials, and tolerates high temperatures well. But in an important state, its thermal conductivity increases greatly, and it protects less well from heat loss. And if it freezes when wet, it will completely crumble. That is why it is necessary to protect it from moisture in any condition. Both from liquid (waterproofing) and from steam:

- From moisture coming from the room. The humidity in the Russian steam room is very high, the air is oversaturated with moisture, so the steam tends to flow into other rooms and outside (through the heat insulator). And we need to avoid this.

- From moisture formed due to temperature changes in the steam room and in the attic and on the street (and on the interfloor ceiling and on the walls). It condenses even before steam begins to be supplied, during the heating of the air in the steam room.

Laying rules

In order for such material to fulfill its tasks, it is necessary:

- ensure the best possible tightness of seams and joints;

- make sure there is a ventilation gap between the foil and the finish.

How to ensure tightness

You can either buy metallized tape and glue the joints on the outside, or double-sided tape and fasten the panels together

It will probably not be possible to create complete tightness of the seams and all the material to protect against steam, but it is possible to significantly reduce the amount of steam entering the insulation. To do this, the panels are laid with one over another by several centimeters (5-10 cm).

The joints are glued either with double-sided tape, which allows you to tightly fasten the two panels, or with special foil tape, which is sold in the same place where the foil material is sold.

It is equally important to maintain its integrity when installing a foil vapor barrier. In those places where the film is attached to the bars, holes form. Minimal damage during installation is ensured when using staples from a construction stapler. For those who love perfection in everything, you can additionally cover the places where they are attached with tape on top.

The second good way is to fix the panels with wooden clamping strips, into which nails are driven at intervals of 150-200 mm. Here the protection against steam penetration is immediately improved.

How to make a gap for vapor barrier ventilation

This gap is provided by the counter-lattice bars, to which the lining is subsequently attached. The gap size is at least 2 cm. Having selected the appropriate bars, nail them on top of the vapor barrier. And already attach the lining to them. When fixing it, do not forget about the need to maintain the integrity of the foil.

What happens as a result: part of the rising steam condenses on the vapor barrier film. Hanging droplets are dried by a flow of air that passes between the film and the lining. If everything is done correctly, there are no problems with rotting.

The gap between the vapor barrier and the finishing is provided by counter-lattice bars

Materials

For a steam room, the best vapor barrier materials are foil materials. They simultaneously do not allow steam to pass through and reduce heat loss by reflecting heat waves back into the room. Some believe that this is a sales trick, but in fact the foil does not affect anything except the cost of finishing. But in practice, they prefer to use foil or foil-coated materials.

Simple thin foil is difficult to use: it breaks easily. Paper-based construction foil is much more convenient. Here are some materials:

- RufIzol S. Foil mounted on waterproof kraft paper. Operating temperature range from -60°C to +120°C.

This is what materials look like on kraft paper - Alucraft. This material consists of three layers: a layer of polyethylene film is placed between kraft paper and polished aluminum foil.

- Izospan FB. This is kraft paper with metallized lavsan. This means that it is not metal. Therefore, using it in a sauna steam room raises questions (in other rooms - easily). Although the manufacturer says that it can be used up to +140°C.

- MEGAFLEX KF. This is also metallized lavsan on kraft paper.

- YUTAFOL N170 AL (Czech Republic) is a four-layer vapor barrier membrane with a foil coating. Can be used for baths and saunas.

There is also foil based on fiberglass. It is more durable, also less flammable, but more expensive. According to the manufacturers, this material can withstand up to +450°C (peak load up to +600°. This is more than enough for use even near chimneys. This material, along with steam protection, has thermal insulation properties. This does not mean that without You can get by with thermal insulation, but it’s easy to use a smaller layer.

According to the manufacturers, it can be used in baths: it does not emit harmful substances. Price: approximately 3 times higher than on kraft paper.

By brand: almost all materials are nameless. There are only a few with the name:

- Thermofol ALST - temperature range up to +400°C;

- Folgoizol is a heat-resistant vapor barrier;

- ARMOFOL - can withstand up to +150°C, there are different types, even with a self-adhesive base.

If you want to see the description and characteristics of the “nameless” ones, search for “foil on fiberglass.” And then choose

These are fiberglass-based materials. In addition to vapor barrier, they also have quite significant thermal insulation properties.

There is also a combination of a heat insulator covered with foil. It is laid like a regular heat insulator - spaced between the beams of the sheathing, and the joints are taped with foil tape. When using such material, installation time is saved. If this is important to you, you can use this material. Despite the fact that the material appeared relatively recently, there are more proposals here:

- Isover Sauna;

- Ursa (Ursa) foil;

- SAUNA BUTTS from ROCKWOOL.

These are heat insulators covered with foil

There is one important nuance: when choosing a material, pay attention to its flammability. It is advisable to choose either non-flammable or low-flammable materials. After all, a bathhouse is a fire-hazardous building and it’s better to play it safe.

Bath ceiling vapor barrier

The figure shows a general diagram of the thermal vapor barrier of the steam room ceiling. Please note that at the junction of the wall and ceiling, the vapor barrier material is laid with an “approach” to the wall. This minimizes steam penetration. For reliability, the edges of the material need to be secured, ensuring tightness if possible: if possible, you can use the same double-sided tape, or press the material tightly against the wall with a strip.

Scheme of vapor barrier for the ceiling of a steam room in a bathhouse or sauna

Often, another layer of waterproofing material is laid on the side of the attic (or second floor). It is, in fact, necessary there: it will protect the heat insulator from drops of condensation that may drip from the roof, from precipitation that may seep in, from spills on the floor of the second floor. Doesn't matter. This is the option when it is better to play it safe. Only this time we need vapor-permeable waterproofing. This is so that the steam that does get into the insulation can escape into the under-roof space and evaporate there.

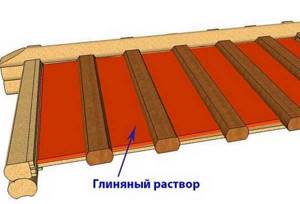

There is also the option of vapor barrier of the steam room ceiling using the “old-fashioned” method and publicly available materials. In this case, the ceiling beams are hemmed with a thick board (at least 50-60 mm), often unedged, and a vapor barrier is laid on the boards from the attic or roof side. In the most budget option, it can be cardboard impregnated with drying oil, waxed paper, glassine or any modern material with the appropriate properties. Its edges and joints also require careful sealing. On top of this layer they lay clay soaked to a paste-like state, to which straw or sawdust is sometimes added - for greater viscosity and also so that cracks do not form or are small.

Steam room ceiling vapor barrier using clay

After the clay layer has dried, the cracks that appear are covered again and the material is allowed to dry again. Then a layer of thermal insulation is laid (read what materials to use for thermal insulation of a bath here), and lining or boards are stuffed on the side of the steam room.

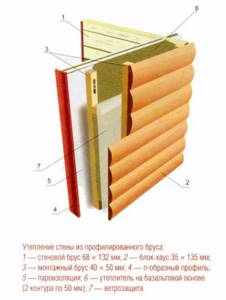

Vapor barrier of walls

The vapor barrier scheme for the walls of the steam room is practically no different from the “pie” on the ceiling. The whole difference is in the thickness of the thermal insulation layer (for the ceiling it is twice as large). It is also recommended to lay a foil film or membrane on the walls in the steam room (do not forget to ensure that it “fits” onto the ceiling and floor).

The vapor barrier must be taped at the joints

It is also necessary to glue the places where the vapor barrier material meets window or door openings, other structural elements - the less vapor penetrates under the film, the better the protection will be and the longer the service life of the bathhouse without repairs and replacement of insulation elements.

Vapor barrier of a bath: sequence of laying materials for the ceiling and walls

Vapor barrier in the washing department

In order for the bathhouse to stand for many years without problems and the need for repairs, it is also necessary to make a vapor barrier in the washing room. The humidity here is not so high, the temperatures are also non-critical, but still the conditions are far from normal: at times there is quite a lot of moisture, both in the form of steam and in the form of water.

In the washing section of the bathhouse, vapor barrier is also necessary, but there is no need to use foil materials. In this case, it is more advisable to use diffusion membranes, which, on the one hand, prevent the penetration of steam into the insulation, and on the other, retain the moisture present in the insulation cake (if the membrane has a hygroscopic coating on the inside).

In this case, a drop of water is retained on the membrane, on its rough side, until it is dried by air currents. For this to work, there needs to be a ventilation gap between the vapor barrier and the finish.

Scheme of heat and vapor insulation of a bathhouse wall made of profiled timber

How to mount it on a wooden floor (and even on a panel ceiling) and on walls is demonstrated in the video. Pay attention to which side the vapor barrier is laid on the walls. It is easy to mix up the side, but as a result, nothing will work, and after a while repairs will be needed to replace the casing.

Is it necessary in other rooms?

Whether or not to make a vapor barrier in the remaining rooms of the bathhouse is your choice. But even in the locker room when using a bathhouse, the humidity level is always significantly higher than normal. If your bathhouse is built of wood and will not be insulated either from the inside or from the outside, then you can do without this layer - drying will occur due to the fact that the wood “breathes” and has the ability to remove vapors. But even in this case, it is already desirable to have a well-thought-out ventilation system in the bathhouse.

If the bathhouse is made of brick or foam block, then vapor barrier in all rooms is required. Moreover, when creating ventilation and insulation/steam/waterproofing, you must keep in mind that you will have to dry not only the insulation, but also the walls themselves due to the hygroscopicity of the material.

Schemes for vapor barrier of a brick bath

Therefore, in addition to the vapor barrier layer from the inside, a layer of wall waterproofing is required. The diagram shows two methods of insulating the walls of a brick bath, which necessarily include foil material, which plays the role of a vapor barrier and at the same time reduces heat loss.

You might be interested in “Do-it-yourself insulation of bathhouse walls from the inside”

Vapor barrier for bathhouse roof

Making a vapor barrier on the walls and ceiling of a bathhouse is not enough. To ensure the safety of walls and roofing materials, roof vapor barrier is also necessary. To do this, on the side of the attic, on the sheathing, a vapor barrier membrane is laid, a layer of insulation is placed on it, and waterproofing is placed on top, along which a counter-lattice is made, and the roofing material is attached to it.

Roof vapor barrier

When choosing materials, you need to accurately understand the difference between vapor barrier and waterproofing. This video clearly and thoroughly examines the processes, their features and differences, as well as the requirements and characteristics of the materials used.

Traditional insulation methods and materials

Progress has both disadvantages and advantages. But when it comes to vapor barriers, traditional methods of making ceilings vapor-tight turn out to be very questionable when compared with what modern technology has given us.

Just for reference: in Russia, ceilings in log buildings were made on three beams attached to opposite walls of the log house. Poles were placed across these beams - these were logs or half-logs. They formed the basis of the then ceiling. Of course, gaps formed between the poles .

So, the only analogue of a vapor barrier in the construction of floors at that time could be covering these cracks with clay . Yes, but as insulation they put everything on top of them - straw, and even hay, and yarn, and hemp, and flax, and twigs, and dry leaves... In general, they put what was at hand.

For reference, we studied part of an archaeological book about construction in Rus' in the 10th-11th centuries. Now think for yourself - why bother so much when even with the smallest budget you can buy plastic film and protect the attic space from steam with it?

Useful video

This video will help you distinguish between different types of film materials for protecting ceilings and roofs:

Let's summarize: if we had insulation at our disposal that would not suffer at all from moisture getting into it, the entire technology for constructing a standard ceiling and roof in a bathhouse would change. But while we are relying on mineral wool, we will have to do vapor barrier and waterproofing. Foam plastics, of course, do not suffer from moisture, but they try not to use them in the bathhouse.

In order for a bathhouse, and especially a steam room, to hold steam well, the ceiling in the bathhouse must be insulated and vapor-proofed. Wood is a “breathing” natural material, so vapor barrier for a ceiling in a wooden floor has a number of specific features that are characteristic only of this type of structure.

The principle of heat retention for a bath ceiling

The bathhouse can be classified as a building with special operating conditions. Due to the fact that this is most often an unheated room, with occasional heating of air masses to high temperatures and a large amount of steam, the ceiling, which absorbs maximum temperature influences, can quickly become unusable.

Depending on the budget and capabilities of the owner, the bathhouse can be a whole complex of several rooms for undressing and relaxation and a steam room itself, or a small building with a steam room and a dressing room. Regardless of the area, the ceiling must be properly insulated with a mandatory vapor barrier device.

The most common method of producing steam for a Russian bath is the construction of a heater stove. A large amount of steam released due to temperature changes and excess humidity will settle in the form of condensation on the ceiling lining, up to the formation of large drops that fall down. An unsuccessful vapor barrier in a wooden house will lead to soaking of the insulation, loss of its qualities, and ultimately to excessive fuel consumption and an uncomfortable stay in the steam room.

Due to the design features of the roof, log baths or baths made of timber can be divided into two types: with and without an overhead “attic” space.

Depending on this, the vapor barrier device will be designed differently.

The hottest: which vapor barrier is best for the ceiling of a bathhouse?

The ceiling surface is designed to withstand a real assault of heat and steam. That is why it should be insulated with materials that can withstand high temperatures. Oddly enough, along with insulating the floor with sawdust , the old-fashioned method of coating with a mixture of clay and sawdust is still popular. However, there are also modern materials.

Fiberglass

A vapor barrier material that, having the properties of glass, is flexible and durable. It is better to use it in a steam room, since it does not release toxic components when heated, unlike bituminous materials.

Foil mineral wool

In fact, it is a heat insulator covered with a moisture-resistant heat-reflecting layer. An excellent material for organizing a vapor barrier cover for the ceiling plane in a sauna or bathhouse. For cladding, a coating with a thickness of at least 50 mm is suitable; it is mounted with insulation on the inside and foil on the outside.

Protecting a wooden ceiling from excess moisture - which vapor barrier is better

The air gap under the roof slopes will prevent heat loss, but without additional insulation with a vapor barrier, the bathhouse ceiling will get wet from excess humidity and the wood will deteriorate. This can cause individual deck boards to dry out due to temperature changes and cause mold to form. A properly executed vapor barrier for a bathhouse ceiling involves installing two vapor barriers on both sides of the insulation with a small air gap between them.

If the insulation is not made with fibrous or slab materials, but with bulk material, for example, expanded clay, the vapor barrier is laid on top of the intermediate wooden flooring, from the side of the above-ceiling space.

To lay slab insulation, it is enough to arrange a sheathing of timber with a two-layer membrane-type vapor barrier laid over it, with the rough (absorbing) side down.

It is not advisable to use the following as a vapor barrier for a bath:

- Polyethylene film, due to its excessive tightness;

- Roofing felt and its varieties under the general name “euroroofing felt”, due to the possible leakage of bitumen impregnation through the ceiling due to high temperatures;

- All types of coating vapor barrier, except for places where chimneys pass through the ceiling.

The best choice is breathable two- or three-layer membranes or foil membranes. The reflective layer of such a vapor barrier, due to the reflection of heat waves, will significantly improve the temperature in the bathhouse and reduce the cost of fuel for the stove.

An economical option is to lay craft cardboard impregnated with drying oil.

Vapor barrier of the ceiling in a bathroom in a wooden house is carried out using the same technology, but since maintaining a high temperature in such a room is less important, you can save on installing a foil vapor barrier.

Vapor barrier materials – which ones to choose?

The walls of the bathhouse can be protected with any traditional and more modern materials. The main thing is that they perform their task effectively. The easiest way to do a vapor barrier on walls with your own hands is to use an inexpensive polyethylene film. Firstly, it is completely waterproof, and secondly, it reduces the time required to heat the steam room.

Unfortunately, polyethylene deteriorates very quickly due to high temperatures in the bathhouse. Therefore, it makes sense to install films made from it as a vapor barrier only in a relaxation room after taking bath procedures. Moreover, it is allowed to use only polyethylene material that does not have seams formed when folding it. It is along these seams that the film literally begins to creep apart during operation. This problem can be solved (for a while) by gluing the folds of polyethylene with heat-resistant tape. But even in this case, the polyethylene vapor barrier will not last long.

Polyethylene vapor barrier for baths

The rest room in the bathhouse can be protected from steam with special construction cardboard - the so-called kraft paper. It has a high density, which makes it possible to slow down the process of moisture penetration into the walls. But, having been saturated with steam, it will also spread out and will have to be changed again. Some craftsmen perform vapor barrier with roofing felt, pieces of glassine and roofing felt. Theoretically, such materials are suitable for protecting bath elements from high humidity, but when the temperature rises, they release substances harmful to our body. And the “aroma” emanating from such vapor barriers leaves much to be desired.

Professionals advise using modern materials when carrying out protective measures in all bath rooms. These include:

- Aluminum foil. It does not emit unpleasant odors or harmful compounds when heated, and easily perceives elevated temperatures without changing its shape. It is placed overlapping on the walls of the bathhouse, connecting the joints between individual strips of material with heat-resistant tape.

- Vapor barrier films of different brands. They are truly innovative materials for protecting baths from moisture. Below we will take a closer look at films under the Izospan brand, which have recently become increasingly in demand both among construction professionals and among those who like to do housework with their own hands.

- Foamed foil polymers. They are also very popular, being an innovative combination of two materials at once - aluminum-coated foil and a foamed polymer compound. This vapor barrier is ideal for wall insulation. But it is not recommended to mount it on the ceiling - it may well melt under the influence of high temperatures.

Vapor barrier for the ceiling of a wooden bath

A bathhouse without an overhead space, usually a structure with a flat roof with a slight slope, due to the lack of an air gap, requires significantly greater efforts to insulate and vapor barrier the false ceiling. Let's take a closer look at this process.

- The vapor barrier is attached over the entire surface of the rough ceiling, extending onto the walls by 15-20mm. It is advisable to seal the junctions with the walls with sealing tapes. The vapor barrier can be installed directly on the rough ceiling or on wooden dies nailed to it in small (no more than 1 m) increments;

- If the width of the vapor barrier panels is not enough to cover the entire ceiling, they are attached with an overlap of at least 15-20 mm. For installation, nails with a wide head or staples of a construction stapler are used. It is advisable to place cardboard washers or any other sealing gaskets, for example, cut from the remains of a vapor barrier or any other film, at the fastening points, in order to prevent ruptures of the vapor barrier at the points of contact with the fasteners.

- Insulation is laid on top of the vapor barrier. This can be expanded polystyrene (cheaper foam for a bath is not desirable due to its high flammability and release of toxic smoke when ignited), mineral wool, glass wool, slab basalt insulation;

- The insulation layer must once again be protected by a vapor barrier to protect against internal moisture;

- A wooden sheathing is installed with a gap of 40-50 cm from the ceiling to secure the finishing ceiling lining.

A common finish for the ceiling of a wooden house is lining with wooden clapboard. It is also appropriate to use it in a log bathhouse. The only difference is that for lining the bathhouse ceiling it is better to use wooden lining made from hardwood.

Using coniferous lining, on the one hand, will give an unforgettable forest aroma due to the release of resin when heated, on the other hand, the release of resin will gradually lead to warping of the wooden lining. There are no such restrictions for other rooms of a wooden house.

How to attach the material?

The choice of method depends on the material used. Polypropylene films or polyethylene-based vapor barrier, fixed with a small nail or staples of a construction stapler. But again, based on the situation, additional protection is required here. If the sheets are large, they can tear under their own weight, on the same nail or staple. In this case, the material must be fixed with thin slats on a nail. In this regard, membrane insulators are simpler. Their structure is not so fragile and they can be easily attached with a nail or staple.

When using film vapor barriers, they are secured with slats to avoid tearing of the material.

The canvases are laid on the insulation, under the outer cladding of the walls in the bathhouse. The first sheet is fastened at the bottom, and the rest are laid upward from it, with an overlap of at least 10 cm, and each joint is glued with adhesive tape or reinforced tape. If foil materials are used as a vapor barrier, then the connections must be sealed with a similar material - foil-coated tape. Otherwise, up to 20% of the effect of the layer is lost. Manufacturers do not comment on how this is explained.

When hanging canvases, do not try to stretch them. All films tend to shrink and expand under high temperatures, and in order to avoid ruptures during operation, it is necessary to make a small margin, fixing the material loosely.

You need to pay special attention to the vapor barrier of hard-to-reach places. These are the corners of the walls, and the transitions from the load-bearing wall to the partitions in the bathhouse, blocking access to the steam room, etc. Any auxiliary means of protection will be useful here. You can cut an additional strip of material and use it to strengthen the insulation in the corner transition. All joints are taped with several strips of tape. Additionally, it is necessary to insulate areas near window or door openings. The films are brought over the edges of the frames and secured there.

Source