When is it worth insulating and when not?

Wood protects well from the cold. But to keep the house warm, it is necessary to build thick-walled houses. But usually for construction they use timber with a section of 200x200.

Inside the walls are insulated:

- when they don’t want to spoil the façade or it’s prohibited by law;

- it is impossible to carry out work, access to the walls from the outside is limited;

- want to save money;

- if necessary, increase sound insulation.

Important to remember. It is better to refuse internal insulation if it is possible to perform the procedure outside.

Experienced calculators, when determining the thickness of the insulation, warn about the appearance of moisture and the walls getting wet. They are categorically against carrying out such work.

But if you follow the rules, then this is the simplest option that a home craftsman can do.

Insulation of timber houses

Before starting the insulation process, it is necessary to invite a specialist who will give a professional assessment of the condition of the walls, ceiling, floor and ceilings. For this purpose, the entire building is inspected from the outside and inside. As a result of the inspection, you will be given a recommendation - re-caulking will be enough, or the house needs to be insulated with insulating materials.

Caulking a timber wall Source hi.decorexpro.com

If you decide to insulate the cottage from the inside, you need to choose a good insulator for this, which has the following requirements.

- Efficiency

. After installing the insulation, the house should become much warmer and more comfortable, and heating costs should decrease by an order of magnitude. - Environmental friendliness

. This indicator is especially important for internal insulation. They should not emit substances harmful to humans. - Fire resistance

. Most effective insulation materials ignite when exposed to open fire. You need to choose a material that either burns weakly or tends to fade out altogether. - Durability

. Sheet and roll insulators must be replaced periodically. But the less often you have to do this, the cheaper and easier it will be to maintain your home. - Easy to use

. The simpler the installation technology, the cheaper each replacement of insulation will cost.

Insulation for interior walls Source advancedhomenow.com

Recommendations for material thickness

To determine the thickness of the material, mathematical calculations and building codes are used. If there is not enough knowledge for this, then order services from professionals. Carrying out work based on the idea that the thicker the better is risky.

What affects the thickness of the insulation:

- Climatic zone of construction.

- Thermal conductivity coefficient, k. Appendix 3 of SNiP describes the thermal parameters required for the calculation.

- Wall heat transfer resistance, R. The value is determined by natural conditions. SNiP recommendations will help you find the correct value.

The minimum thickness of the insulation can be determined using the formula: the thermal conductivity coefficient is multiplied by the required heat transfer resistance: t = k x R. The thickness of the wall is also taken into account.

We need to pay attention. The thermal resistance of a wall is the sum of the resistance values of all layers of the structure.

On average, it turns out that 5 cm of thermal insulation material replaces 15 cm of wood. Builders advise adding a correction factor = 10% to the resulting value, which takes into account air humidity.

As air humidity increases, the thermal conductivity of some materials increases.

Competent builders rarely resort to meticulous calculations. They are guided by experience and intuition. They offer a simple scheme: the thickness of the insulation depends on the diameter of the timber, climatic conditions and the heating system.

Example. Required layer of insulation:

| Thickness of a wall made of timber, pine wood, in m | Insulation thickness, m |

| For the warm climate of the Russian Federation | |

| 0,15 | 0,05 |

| 0,2 | 0,025 |

| Middle lane | |

| 0,15 | 0,1 |

| 0,2 | 0,05 |

| Northern regions | |

| 0,15 | in the range 0.150 - 0.200 |

| 0,2 | 0,125 — 0.150 |

Recommendation . If you have a choice, it is better to use two layers of 50+50 insulation than one 100 mm.

Interior decoration

Decorating a house made of timber from the inside with clapboard

After installing the second layer of vapor barrier film, the walls are finished. The film is secured using staplers, and 30x40 mm bars, which are sold everywhere, are mounted on top.

Before finishing, the walls are plastered and primed. Materials for thermal insulation are perfectly combined with a variety of putties and primers.

After installing the timber, decide how you will decorate the house: wood paneling or plank. If, when deciding how to insulate a house made of timber from the inside, you prefer wooden lining with a pronounced texture, you will be able to preserve the original interior of the house.

It will also be successful to choose a plank located horizontally. This material looks like a small beam.

What methods are used?

Wood “dries out” over time, so insulation should be done a year after the construction of the house.

Walls can be insulated using different methods. Here are the most popular ones:

- Slab insulation directly on the walls.

- Installation of the base on profiles, followed by laying mineral wool. Quite often used.

- Seamless spraying using innovative technology. Perspective view of wall insulation. But there is a significant drawback - the price. To perform the work you need a special device.

Thermal efficiency is achieved not by increasing the thickness of the warm layer, but by the correct ratio of the type, size and location of the thermal insulation layer.

What should you consider when choosing insulation?

Range of insulation materials

To choose insulation that is as safe as possible for health, you need to pay attention to the combination of material and wood. The insulation must not only be well ventilated, but it must also be in harmony with the properties and vapor permeability of the wood.

Attention : Many people prefer polystyrene foam. But it is worth noting that such material does not allow moisture to pass through well, so it should not be used for internal or external thermal insulation of a room (condensation will drip onto the wood, which will lead to rotting of the timber).

Despite the fact that basalt and fiberglass are non-natural materials, they have excellent vapor-permeable properties. If there is a ventilation system, moisture will not accumulate.

But it is worth noting that such materials emit harmful substances, which enter the room during ventilation. As a result, a person breathes them. Of course, if you install the film, then no harmful particles will enter the room, but the beneficial microclimate of the tree will also disappear.

As for flax fiber and fiberboard, they are best combined with the properties of wood.

Materials and tools

They offer four types of insulation with excellent technical properties for interior decoration:

- Mineral wool. The main property is low shrinkage of the material. Good air permeability. Has high vapor permeability. The material is non-flammable, chemically and environmentally friendly. When working, safety glasses and a respirator are required.

- Cellulose material, ecological wool. High environmental safety is confirmed by sanitary rules.

- The Penoplex slab almost does not absorb water. During installation, it is necessary to especially think through the ventilation system so that condensation does not get inside the wall. Negative properties - the walls do not breathe. The material is flammable or melts at high temperatures.

- Polyurethane foam provides a 100% guarantee of seamless thermal insulation. Non-flammable, thermal conductivity of various grades: 0.02 - 0.03. Applies well to the surface. The negative parameter is the high cost.

Additional construction accessories:

- Wooden slats.

- Foiled polyethylene foam.

- Plasterboard for walls.

- Construction adhesive.

- Notched trowel.

- Sheets of plywood or plastic for finishing cladding.

- Acrylic paint or wallpaper.

Internal or external insulation?

For example, when a frame house or a monolithic reinforced concrete structure of some structures requires insulation, internal insulation is an integral part.

In any other case, insulation placed indoors will adversely affect the condition of the walls.

All this is due to the fact that the dew point in the thickness of the wall moves deeper into the room, and with large differences in external and internal temperatures, it is likely that condensation will begin to accumulate in the gap between the wall and the insulation, and the external wall will completely freeze.

Such circumstances lead to the destruction of the wall material.

To prevent such situations, it is also important to follow the rule that the vapor permeability of the wall must increase from the inner layer to the outer layer in order for moisture to evaporate and escape outside. In the case of timber, the risk of freezing and condensation between it and the internal insulation leads to the formation of rot and destruction of the wood. In the case of timber, the risk of freezing and condensation between it and the internal insulation leads to the formation of rot and destruction of the wood

In the case of timber, the risk of freezing and condensation between it and the internal insulation leads to the formation of rot and destruction of the wood.

Such damage is extremely difficult to repair.

The only adequate option for a house made of timber is external insulation, and it is also important to ensure sufficient ventilation of the insulation layer and its vapor permeability.

The last requirement is realized by the correct choice of insulation.

Steps to do it yourself

In total, 4 stages can be distinguished. Let's look at each in detail.

Preparing for work

Before insulation, the tree must be carefully inspected and the surface area examined. Carry out the following work:

- Remove dust and dirt from the walls.

- Check the joints between the beams and seal the cracks.

- Level the protruding parts of the surface.

- Soak the wood with an antiseptic.

Note. During internal thermal insulation measures, you should monitor the electrical wiring. For safety, it is advisable to hide the wiring in decorative covers.

Ventilation and moisture protection

To protect wood from accumulating condensation, provide a gap for air ventilation and install a windproofing membrane.

The gap for ventilation is made at least 30 mm. Wind insulation removes water vapor outside, leaving the wall dry.

The sheathing is mounted on the prepared surface, a step smaller than the size of the insulation is selected by 2 cm. The wood is first treated with a fire retardant solution.

A windproof film is nailed onto the wooden lattice on top. Use a stapler. The rough side of the insulation is turned towards the wood.

To complete this you will need:

- wooden slats 40x50 mm;

- nails, staples and carpentry tools.

Insulation with mineral wool

The record holder among thermal insulation materials for wooden walls is mineral wool. There are three types with different technical parameters. Basalt wool is suitable for internal use.

Mineral wool does not emit harmful chemicals. But it often causes allergies. When working, you must follow safety rules.

The walls are covered with antiseptic and lathed. To do this, use wooden blocks or make a metal sheathing. Metal and wood are pre-treated with an anti-corrosion agent.

To install the insulation, a wooden frame is equipped. The heat-protective material is installed between the bars very tightly, by surprise. The frame cells must be smaller than the size of the insulator, minus 2 cm.

Important! Wooden blocks are installed around the perimeter of windows and doors. When lathed correctly, the wool fits tightly. No additional fixation is required.

Vapor barrier and finishing

Install the protective material. The vapor barrier protects the insulation from moisture and condensation. If the insulation has a foil surface, then a vapor barrier will be unnecessary.

Attach the film with an overlap of about 15 cm. Place it tightly to the insulation. Joints and fastening points are taped with construction tape. When using foil material, reinforced tape is used.

The use of vapor barrier worsens the microclimate of the room due to the accumulation of moisture. Therefore, you need to take care of the ventilation system inside the rooms.

For decorative finishing, plasterboard sheets and OSB boards are used. Attached to the sheathing using screws.

For bathrooms, moisture-resistant material is used: gypsum plasterboard. The final finishing is done according to your taste: wallpaper is glued, painted with acrylic paints, plastered.

What is needed for insulation

To insulate a house made of timber from the inside, you need to understand the condition of the walls, floor and ceiling. You can check this by conducting a thorough inspection around the entire perimeter, inside and out. If the beam has dried out, then voids will appear between the links, cracks in the material itself, and in some places the beam may twist. The problem of insulating a house made of timber inside can be solved in several stages:

- Carry out secondary caulking.

- Insulate with roll or matte insulation.

It happens that the first stage is enough to give the walls sufficient thermal insulation. This mainly applies to chamber-drying timber. The second stage begins with the selection of material.

Thermal insulators for timber walls

When choosing a heat insulator for insulating a house made of timber from the inside, you need to choose a material that meets several of the following characteristics:

- Environmentally friendly.

- Low or difficult to ignite.

- Easy to install.

- Durability.

- Non-toxic and does not cause an allergic reaction.

Among the most commonly used for finishing the inside of a house are: mineral wool, ecowool, polystyrene foam, polyurethane foam. I would like to highlight ecowool, which is applied directly under the gypsum board; there is no need to lay a vapor barrier. Ecowool is made of cellulose and can easily absorb and release moisture. The timber walls of the house never stop breathing. And various additives, for example, boric acid, prevent the development of mold, fungi and rodents.

One of the new materials is foamed polyethylene with a foil top layer, with penofol on one or both sides. The price of the material starts from 200 rubles/m, so it is expensive to decorate the entire house with it. But the material is thin and the usable area of the rooms is minimal.

Mineral wool and foam plastic have been used for a long time and have shown only the positive side. The biggest disadvantage of polystyrene foam is the high risk of fire at home. But if the wiring is done correctly, that is, not inside the finish, but along the top, and insulated with high-quality materials, the danger is minimal.

To lay polystyrene foam or any type of mineral wool, you must purchase a vapor barrier. It will protect the insulation from condensation and prevent moisture from penetrating inside the structure.

Mount from the inside onto a wooden or metal frame. For lumber, it is better to take wood, only the bars must first be dried and soaked in antiseptics, for example Senezh.

Advantages and disadvantages

Experts believe that internal insulation should be used only in extreme cases. Insulating the walls inside keeps the house warm. When performing work, the principles of insulating external walls are maintained. But the technology of indoor insulation is much more complicated. The main thing is to choose the right thickness and avoid mistakes when installing the insulation.

Positive points:

- Repairs can be carried out at any time of the year. When you want to.

- To work, you will need a stepladder; there is no need to build additional scaffolding.

Negative sides:

- The area of the rooms is reduced. During renovation, the area must be cleared of residents and furniture.

- When using a vapor barrier film, the humidity inside the rooms increases. To avoid this, it is enough to carry out additional ventilation measures.

- Poorly protected places, “cold bridges,” appear at the junction of the walls with the ceiling and base. You should caulk the joints between the wall and other surfaces and prevent heat from escaping. Insulate the floor, ceiling and roof.

Thermal insulation

The main causes of cold indoors:

- Errors during installation or selection of heat insulator thickness;

- Gaps between beams due to improper installation, shrinkage, etc.

The sequence of work indicated in our photos:

- prepare the surface;

- caulk the cracks;

- We create a vapor barrier;

- we install the sheathing on load-bearing walls;

- we lay and seal the insulation;

- We competently create a ventilation system;

- We carry out interior finishing.

Before carrying out work, prepare everything you need. To complete the work you will need:

- necessary tool;

- experience in external wall insulation;

- high-quality materials for thermal insulation;

- vapor barrier film.

The video in this article will help you to efficiently insulate your home.

Surface preparation

First of all, you need to assess the condition of the walls and the quality of previously completed work on insulating the house. It is necessary to carefully examine the condition of the corners, joints, and joints of the beams, and evaluate the compaction of the surface of all walls. If you find any defects, be sure to correct them.

Before you start insulating a log house from the inside with your own hands, you must:

- Clean load-bearing walls from possible dust.

- Then the surface is carefully treated with a special emulsion against insects that live in wood.

- Apply a special liquid to the surface that protects it from rotting and burning.

Also, when preparing the surface, special attention must be paid to electrical wiring. If there is surface wiring on the wall, it must be separated from the wall surface.

Installation of lathing on load-bearing walls

The lathing, which is designed to hold mineral thermal insulating wool, is made of timber. It can also be made from a metal profile, if you then line the inside of the house with moisture-resistant plasterboard.

By telling us how to insulate a timber house from the inside, we will try to help preserve the appearance of wooden walls, so for finishing it is better to choose wooden lining or plank.

- To obtain the correct, even corners, you must first make corner posts.

- You need to measure the height of the house and cut a beam with a section of 100x50 mm of the same length.

- Then cut a 50x50 mm block of the same length and place it along the edge of the 100x50 mm block and secure it using self-tapping screws. You will receive an L-shaped stand.

- Such racks, one for each corner, are secured with self-tapping screws directly into the corner, controlling the vertical position of the racks with a level.

- Having installed the corner posts, bars with a cross section of 50x50 mm are mounted vertically on the wall between them at intervals of 500-600 mm.

Selection and installation of insulation

The choice of insulation for a home is largely determined by its price. You can use expensive imported or domestically produced materials, which will perform well.

But keep in mind that for insulation of houses made of timber it is strictly not recommended to use:

- dimensional thermal insulation materials;

- expanded polystyrene (for example);

- Styrofoam.

These materials quickly begin to release carcinogenic substances that can cause many diseases. The use of such thermal insulation materials will completely disrupt the environmental friendliness of a house made of timber.

Use only modern certified insulation materials. Do not forget that the manufacturer's installation instructions must be strictly followed.

Laying and sealing insulation

After making the sheathing, mineral wool is laid. First, unwind the roll, then cut a strip of cotton wool to the height. The width of the strip should be 1-2 cm greater than the distance between the vertical slats.

What difficulties might you encounter?

Freezing of corners is a common problem if construction rules are not followed. At sub-zero air temperatures, condensation appears inside the room. It is he who is the culprit of mold and mildew on the walls.

The correct solution to the problem is to reliably seal the seams from the outside. Builders suggest using “liquid thermal insulation” in case of such troubles. Sealing is done along the perimeter, starting from the bottom corner.

Insulating a home is a responsible undertaking. It is imperative to follow the technology to avoid the appearance of rot, rotting wood and other problems.

Typical mistakes made due to inexperience:

- before work, the condition of the timber was not inspected, the surface was not prepared;

- construction materials were not transported and maintained according to regulations;

- all cracks have not been sealed;

- the building material was chosen incorrectly;

- The insulation is not tightly secured.

Advice. Do not use foam for interior work. Although it is cheap, it is not suitable for interior work.

Timber as a building material for cottages

Wooden building materials make it possible to build beautiful, comfortable, reliable and environmentally friendly country houses. Modern timber is easy to use and practical to use. It exists in several versions:

- Planed . An ordinary log is given a square or rectangular cross-section, and the result is a planed beam. It is cheap, but during the process of natural shrinkage it can become deformed and crack. In addition, such material is not protected from rot, mold and blue stains.

- Profiled . It differs from the planed one by the presence of a recess on the working side, which allows the frame to be assembled using the “tenon in groove” or “comb” technology. Thanks to the presence of samples, it is possible to build ideal walls without cracks and defects.

- Glued . The most expensive, but also the highest quality material. It is created by connecting thin, well-dried lamellas. A special harmless glue acts as a connecting substance. Glued laminated timber practically does not shrink, does not crack, and is not exposed to the negative effects of moisture and insects.

In low-rise construction, laminated veneer lumber with a cross-section of 150x150 mm is most often used.

This wood option attracts with its optimal price-quality ratio. But in regions with cold winters, walls of this thickness may not be warm enough. This problem can be solved with the help of basic insulation of a house made of 150x150 timber from the inside.

How much will it cost to order work?

There is a decent selection of necessary materials for insulation on the construction market.

The average cost of turnkey work on wall insulation is 5,250 rubles. sq. m. The work includes the full range of services. The price includes the total cost of materials and delivery.

Price without consumables:

| Types of installation work | Cost per sq. m, in rub. |

| Installation of guides | 30 |

| Horizontal lathing | 50 |

| Vertical lathing | 150 |

| Windproof membrane | 30 |

| Insulation t=50 mm | 70 |

| Insulation t=100 mm | 120 |

| Vapor barrier | 100 |

| Plates | 200 |

| Impregnation of the surface with a protective layer | 70 |

Work progress

To ensure complete thermal insulation, one caulk is not enough. It is necessary to insulate the walls of the entire structure. The modern market offers a wide selection of various thermal insulation materials, the most affordable of which are mineral and stone wools; it is quite possible to install them yourself.

Lathing

To attach soft or lightweight hard insulation with your own hands, you must first equip the frame. To do this, a vertical or horizontal sheathing is placed on the wall surface, in which the guides are placed at a distance of 40 - 50 cm.

Depending on the thickness of the insulation layer, the geometry of the bar or board for the frame ribs is also selected. So, to lay a layer of 50 mm, it is best to make a frame that protrudes from the wall by 70 mm, which ensures the formation of a ventilation gap.

First, the corner elements of the sheathing are created. A 50x50 mm timber strip is attached to the rib at an angle of 90°. Such elements are placed in all corners of the room and, after checking the location according to the level, they are attached to the walls. The remaining space is marked for the selected number of sheathing ribs. It is advisable to treat all frame elements with antiseptics to prevent rotting.

Moisture protection

Before installation, the entire frame is covered with waterproofing film, which is attached with the smooth side to the wall. The film is laid horizontally and the seams between the cuts are insulated with special adhesive tape.

Then insulation is placed in the frame and a vapor barrier is applied on top of it to protect against internal moisture. Before installing any type of waterproofing, you must carefully study the instructions, since an error in the location can lead to the insulation getting wet and losing its properties.

The gap left will facilitate natural ventilation and evaporation of condensate. Next, the entire frame is covered with any finishing material.

Laying insulation

After creating the frame, the heat-insulating material is cut into strips or sections 2–3 cm wide greater than the distance between the guides and placed between the frame elements. Sometimes additional fastening of the insulation with special polymer anchors is used. This technique ensures a tight fit of the material to the frame and reduces its subsidence.

Pros and cons of timber insulation

Internal thermal insulation can be carried out at any time of the year, but the procedure has disadvantages:

- due to the construction of sheathing for fastening the insulation, the usable area of the room is reduced;

- the natural beauty of the walls is hidden;

- the dew point moves inward at the base.

External insulation is more suitable for a wooden house. It does not lead to a reduction in the area of the rooms and helps protect the façade of the building. Installation work is carried out in dry and warm weather.

External insulation of the house.

Methods of external insulation with a description of the work

To insulate the facade, different methods of attaching the material are used. The most popular technologies are curtain and wet façade and “well” thermal insulation.

Wet facade technology

The installation of a “wet” facade involves installing insulation boards on the base surface using self-tapping screws. After this, an adhesive composition is applied to the layer and the reinforcing mesh is fixed.

First, strengthen the corners, and after a day - the remaining surfaces. Decorative plaster is applied over the reinforcing layer. If paint is used to finish the facade, then its surface is leveled with putty. To fix the insulation, special metal plumbs are used.

Wet facade on a frame house.

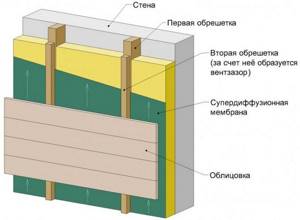

Ventilated curtain façade

A curtain wall is used to simultaneously insulate and decorate a home. The design has a long service life, is quickly installed, and is characterized by a wide range of colors. When installing panels, the dew point moves outward.

Installation of products involves the following steps:

- Treatment of the base with antiseptics and fire retardants.

- Attaching the sheathing. A windproof membrane and waterproofing are fixed on it. This will allow for efficient condensate drainage. When screwing wooden planks, you need to monitor the horizontal and vertical levels of the structure.

- Installation of slats. The step between them is equal to the width of the insulation and is at least 70 cm.

- Laying the heat insulator. If mineral wool is used, dowels with round heads are required to fix it.

- Screwing the bars for laying the facing layer. A gap is left between it and the insulation.

Siding and lining are used for finishing.

With a ventilated curtain wall, there remains a gap between the insulation and the cladding.

Insulation with a “well”

The “well” insulation method involves finishing the house with brick. Insulation is laid between the facing and outer surfaces of the wall.

During installation, follow the following procedure:

- Prepare the base and materials.

- Roofing material is laid on the foundation, which extends 15 cm onto the load-bearing wall.

- Install the first row of insulating boards. They are secured using hangers or dowels. At the same stage the brick is laid.

- Mount metal rods along the upper edge of the insulation. The material is pre-treated with an anti-corrosion compound and launched onto the brickwork with the free end. The installation step is 40-60 cm. The rods will prevent the cladding from collapsing, moving outward or inward.

All manipulations are repeated with the second row of heat insulator.

Insulation using brickwork.