Timely thermal insulation accumulates heat in apartments, creates a comfortable microclimate, allowing owners to save on alternative heating methods.

Insulation of external panel walls also protects the wall structure from negative external environmental influences (temperature changes, frost, precipitation), helping to preserve the operational life of the building. Read more about thermal insulation for panels, step-by-step work, difficulties, price and other nuances in this article.

Do you need thermal insulation on the outside?

Panel buildings that are classified as secondary housing require thermal insulation. Modern buildings also need to be insulated , these include:

- expanded clay concrete;

- arbolite;

- polystyrene concrete;

- monolithic;

- buildings made of SIP and sandwich panels.

It is imperative to insulate them, especially if they are built in a region with harsh winters or high humidity.

Thermal insulation will protect the wall structure from freezing and external factors - accumulation of condensation, getting wet due to rain and snow. Thanks to such protection, the walls will not collapse, they will be free of fungus and mold, and there will be no need for constant repair work due to depressurization of seams or the appearance of cracks.

In addition, thermal insulation will additionally strengthen the supporting structure of the panel, preserve the usable “area” of the housing inside, increase the temperature, help the walls warm up and accumulate heat, significantly reducing its losses. The advantages of external insulation also include sound and noise protection.

Thermal insulation of panel houses

makes sense in all cases, except for the following factors :

- the house is subject to demolition;

- the walls require major repairs and replacement of spans;

- Preparatory work and plastering of the surface were not completed.

Insulation can be done with your own hands in private one-story buildings. In multi-apartment housing or 2-3-storey buildings, industrial climbers from construction companies providing thermal insulation services are invited to work.

The wall pie of the facade wall with insulation complies with GOST R 53786-2010. The insulator slabs are securely attached to the prepared wall surface using glue, then secured with fasteners with a wide head. In the process of work, they use the regulatory instructions of SNiP 23-02-2003.

Panel structures can be insulated externally all year round. But at the same time, it is advisable to choose dry days so that the glue sets well. Experts recommend carrying out thermal insulation work after the seams between the panels are properly sealed with sealants, the wall surface is cleaned, primed, and does not require repair.

Insulation for panel houses must be selected taking into account the characteristics of a particular residential building, the wishes of the owners and their financial capabilities.

Our offers

Our experienced specialists offer a full range of high-quality and reliable long-lasting insulation for the walls of a panel house. To ensure reliable thermal insulation and an ideal microclimate in the apartment, such work must be carried out comprehensively: insulating the walls and then sealing the seams between the panels.

The insulation process is quite complex and therefore it must be trusted exclusively to real professionals in this matter.

Very often in this matter it is impossible to do without professional climbers. Ours offers a full range of services necessary to ensure a warm and comfortable atmosphere in any room: insulating walls, sealing seams using exclusively high-quality reliable building materials, carrying out all types of high-altitude work. At the same time, we are ready to carry out work anywhere - a country house, an office, an apartment in a multi-storey building - any room that is located in a panel building. Before starting to fill out an application for work, you will be briefed by our specialist; after completing the documents for access to the roof (the company decides this issue independently and free of charge for the customer), a full assessment of the cost of the work will be carried out, taking into account the specifics of the object.

What is the best way to insulate?

Modern insulation materials are made using special technologies that provide them with “non-flammability” and the ability to repel water.

In addition, a special antibacterial impregnation of products provides them with sanitary resistance against pathogenic flora - fungi and mold. The advantage of any modern insulation is that it ideally adheres to any panel surfaces, and can become a good basis for any type of finish.

Thermal insulation materials are classified by GOST 4.201-79. The criteria for dividing into varieties are indicated according to the following criteria :

- Raw materials (created exclusively on natural components) – organic, inorganic.

- Structural (appearance, size, composition) - piece (fibrous and cellular), rolled, granular, corded, loose.

Roll and tile insulation options are very popular , and the latter are considered the most preferable for panel walls. The square or rectangular shape of the slabs means ease of use (compactness + lightness) and high speed of installation.

For external insulation of panel houses, various heat insulators are used - polystyrene foam, mineral wool, polystyrene foam, polyurethane foam. These four are among the most effective insulators. Their brief description is presented below.

Expanded polystyrene

Expanded polystyrene can be regular or extruded . Affordable - 1 tile product, depending on the thickness of the layers (30-50 mm), costs 70-200 rubles. a piece. The approximate dimensions of the slab are 20 x 600 x 1200 (mm). The material has good quality characteristics, the first of which is a high coefficient of water repellency.

Expanded polystyrene is able to protect the wall structure from freezing, gradually accumulate and distribute heat in the room. It is easily secured with polyurethane foam and mounting hardware. Suitable for all panels. It has the only drawback - low sound insulation. But this factor is nothing compared to the warmth and comfort of home.

Mineral wool

It is considered the most inexpensive among facade insulation materials. The material is produced in the form of rolls and plates. Rolls per 1 m2 are offered at a price of 1,200 rubles.

Packages of slabs, each containing 16 pieces of cotton wool, with a thickness of 50 (mm) and a dimension of 600 x 800 (mm) - from 720 rubles; with a thickness of 100 (mm) and the same standard size (600 x 800 mm) - from 1200 rubles.

The composition of the wool is made with an improved composition of the incoming elements , one of which is expanded polystyrene foam. Thanks to this, the slab gained rigidity and resistance to high humidity.

Mineral wool is considered not only a thermal insulator, but also a noise insulator. Its only drawback is that it requires ventilation, but only when installed inside houses. On the streets, in the fresh air, this disadvantage is quickly eliminated.

Styrofoam

The material is used for external insulation in the form of slabs, which can be with crushed or foamed granules. The price of 1 m3 of foam plastic in the Russian Federation averages from 1,400 rubles. The thickness of the material is 50 (mm) and 100 (mm). The insulation has ideal insulating and soundproofing properties.

Its only disadvantages are that it is

fragile and rodents like it . Therefore, care is required when working with it. It is not suitable for private houses, as well as the first floors of multi-apartment buildings.

Polyurethane foam

It is considered the most expensive insulation , but the easiest to work with. It has the best thermal conductivity (0.025). Available in cylinders up to 870 ml or special plastic containers, the contents of which will need to be loaded into a construction sprayer (spray gun).

The structure of the material is cellular, it allows air to pass through well. At the same time, the surface will never be wet, since the insulation has strong water-repellent qualities.

Spraying on a prepared wall panel surface has its advantages. Polyurethane foam can be used as a final layer when sealing seams between panels. That is, after the slabs have been installed with construction adhesive, spraying polyurethane foam over their surface will seal the seam, reliably sealing even in hard-to-reach places.

This will also eliminate existing imperfections or unevenness of the panels. The thickness of the polyurethane foam layer of only 25 (mm) is capable of providing protection against freezing and temperature changes .

The material dries in a few seconds. It can be used at low temperatures (down to –12°C). The only drawback of polyurethane foam is the price, which ranges from 495 rubles for 1 cylinder.

According to the regulatory data of technical documents, the wall thickness should be at least 40 (cm) in the central regions of the Russian Federation, and at least 60 (cm) in the northern regions. At the same time, the thickness of the insulation should be from 25 (mm) to 200 (mm).

Features of room insulation in a panel and brick house

It makes sense to insulate only one wall in a room - the one that faces the street. If this is an end room, then two walls will need to be protected from the cold. The choice of insulation thickness depends on the size of the room: the smaller it is, the thinner the layer should be.

A universal option is mineral wool or foam materials. In a brick house, it is better to use those insulation materials that have a minimum thermal conductivity coefficient due to its high value in brick.

Consumables and tools

Of the consumables and devices used in thermal insulation work, you may need :

- Selected type of insulation.

- Glue for the material.

- Reinforced mesh.

- Fastening elements (angles, profiles, disc dowels).

- Drill with a set of drills.

- Construction knife and levels.

- Container for solutions.

- Spatulas, brushes.

- Work clothes, safety glasses and gloves.

This list may be supplemented, depending on the complexity of the work or the characteristics of the insulation. The main thing is to buy a high-quality heat insulator and glue for it. If sprayed insulation is used, the set of tools will be minimal, especially if the substance is in a cylinder.

It is worth paying attention to the instructions and guarantees from manufacturers . Also, the purchased material must be well packed in polyethylene and have the appropriate markings on the product.

When collaborating with a construction company, you don’t have to worry about tools, and the materials, most often, are provided by specialists themselves, after examining the panel surface, according to the contract estimate. Industrial climbers perform work quickly and efficiently.

Step-by-step installation instructions

When creating an outer insulating layer in panel houses with your own hands, the stages of work for a wall structure are as follows :

The surface is being prepared. It should be dry, clean, with seams sealed, and primed with two layers of primer.- Additionally, you can treat the walls with any antiseptic. Let the wall dry.

- Then thermal insulation boards are attached to the panels using glue and disc dowels. The products must be pressed tightly until they completely set to the surface.

- Existing gaps between the plates are eliminated using polyurethane foam or a suitable sealant.

- A reinforced mesh is attached on top of the insulation in the corners, onto which the plaster solution will be applied, and then the finishing will be done.

If the design provides for waterproofing, then insulation is applied on top of it. When installing the sheathing indicated in the drawing, the insulation is connected with fasteners to the structure.

It is advisable to carry out all work in the dry, warm season, adhering to a clear sequence of actions and strictly following the technology.

Advice from the experts

It also happens that the building borders on another house, which means that work cannot be carried out anywhere except from the inside. In this case, you will, of course, reduce the internal usable area, but will make the premises of your home much more comfortable and suitable for staying there. Interior work also has its advantages, including ease of work and cost savings, because you can carry out all the work yourself, without involving specialists and expensive equipment.

Difficulties and possible errors

The main mistakes that can be made when arranging the insulation of external walls with your own hands are as follows:

- Working with low-quality material . The heat insulator will not perform its functions, and all costs for consumables will be in vain. You need to buy insulation only from trusted manufacturers working with a range of Russian industrial products. The manufacturer must provide a quality certificate.

- Working with an unprepared surface . A dirty wall, covered in dust and remnants of masonry mortar, will contribute to poor adhesion of the insulating material to the adhesive. The adhesive composition will be detached from the surface. Therefore, high-quality cleaning of the panels and mandatory primer (double) are necessary here.

- Using wet insulation or working with a damp surface. A dry surface and the same material are required, otherwise it will not be able to adhere well to the panel.

- Applying insulation to plaster . It is best to use polyurethane glue, since the plaster composition will experience stress from the products during temperature changes, expand and contract due to condensation, and fall off.

Knowing about possible mistakes in construction, you need to try to avoid them. If you work according to the technology of GOSTs and SNiPs, then no difficulties will arise in the process.

It is best to order the services of professional specialists who almost never make mistakes, since they are certified, work under a contractual guarantee, have experience and qualifications.

Methods of external insulation of facades

In total, there are two ways to install insulation on the facade of a building:

- Dry method or ventilated facade.

- Wet method.

Each technology has its own advantages, so we will consider each option separately.

Insulation of facades ventilated facade

The dry method does not involve the use of mixtures with added water. In order to create a thermal insulation layer using this method, a thermal shield is made from insulation materials, which are covered with panel materials. The materials we have already discussed are used as insulation materials. The façade is called ventilated because a small air gap is left between the panel material and the insulation to ventilate the insulation.

Facade insulation wet facade

This method involves insulating the façade surface using specialized water-based mixtures. These mixtures can have different compositions. Recently, cellulose-based foam insulation has been increasingly used. The main advantage of this method: filling all cracks and holes. The wet method does not leave cold bridges through which heat can flow out of the room.

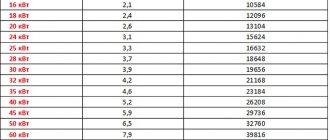

Price: how much does the work cost?

The cost of work on insulating external panel walls, on average in the Russian Federation, depends on the following factors :

Season. In the winter season, the price for the services of industrial climbers is always higher.- Urgency of work completion.

- Region of residence. In Moscow Region, St. Petersburg and Novosibirsk, prices for services and materials are always higher.

- Difficulty level (number of floors).

- Use of mechanical devices and vehicles.

- Total amount of work. Determined by the master, always indicated in the estimate.

Construction companies provide price lists for services on their websites , which anyone can view. When drawing up a contract, the cost of work is always negotiated between the customer and the company.

The average cost of work on insulation of panel buildings in the Russian Federation is from 380 rubles per 1 m2. If construction reinforced mesh is applied over the insulation (for further finishing work), the price for services starts from 200 rubles per 1 m2.

Is it possible to insulate walls indoors?

There is no direct ban on insulation. There are also no documents regulating how to insulate a cold wall from the inside in an apartment. The owner independently chooses the material, method of fastening, and place for insulation. If the resulting insulation does not protect well from the cold and condensation forms on it, then the owners will also have to solve the resulting problems themselves.

Note! Poor quality insulation will create an unfavorable environment in neighboring rooms, including other apartments. Therefore, when deciding to install internal insulation, remember the level of responsibility that you impose on yourself.