Insulation for a Frame House - Choosing the Correct Insulation for the Walls of a Frame House

Content

- Choosing insulation for a frame house

- Mineral and fiberglass wool

- Foam and EPS

- Ecowool Comparative characteristics of insulation materials

Frame construction technology makes it possible, at minimal cost and in a short time, to build a house that can comfortably accommodate a large family.

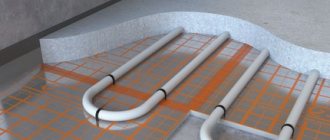

The walls of such a house consist of a frame, covered outside and inside with finishing materials, between which there is insulation. The energy-saving characteristics of a building depend on the insulation. This article will talk about how to properly insulate a frame house .

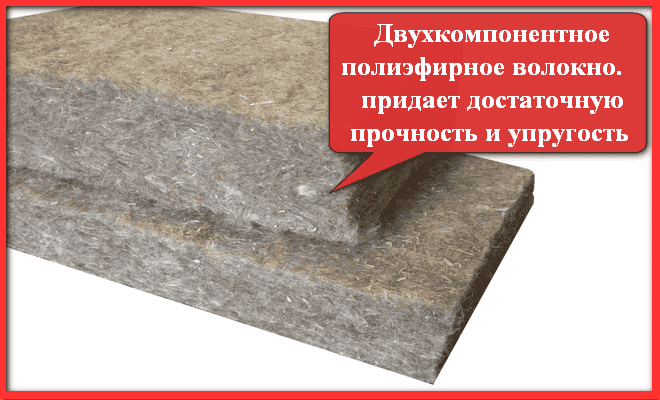

Ecotherm

Ecotherm is an eco-insulation material that consists of 70% flax and 30% two-component polyester fiber. This fiber is the one that gives it sufficient strength and elasticity. The ability to hold its shape well is an additional advantage during installation - the slabs can be installed between beams and joists without additional fasteners.

The main advantages of linen insulation:

- Durability – expected service life 60 years.

- Safe insulation. This means that it is absolutely hypoallergenic, leaving a pleasant feeling when touched.

- Not subject to electrification.

- Antiseptic - it does not harbor parasites, perfectly absorbs odors and purifies the air.

- Breathable - absorbs and releases moisture well, regulating heat exchange and humidity.

A natural antiseptic, it absorbs excess moisture well and prevents the formation of fungus and mold. The properties of the fiber are close to wood, and the use of linen thermal insulation in a frame house will help you easily achieve the effect of a “log house” - the material allows the walls to breathe.

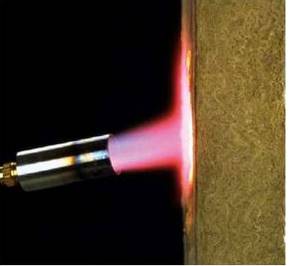

Flax is non-flammable, difficult to ignite, and even when burning does not emit hazardous substances. In terms of fire safety, it is comparable to good quality basalt wool. Has excellent sound insulation. The use of plant fiber makes linen one of the safest insulation materials. Available in the form of slabs with a thickness of 50 and 100 millimeters.

The qualities and properties of linen insulation allow you to work with it without fear, even when installing thermal insulation in children's rooms.

Cellulose insulation (ecowool)

In principle, the composition of the material is completely clear from its name. It is made up of 81 percent recycled wood, while the remaining 19 percent is antiseptic and fire retardant. The thermal conductivity here is excellent, it can reach 0.041 watt/m*K.

Cellulose insulation

Previously, we talked about the features of this material, its advantages, disadvantages and technical and operational characteristics; in addition to this article, we advise you to read this information and read about it here

This heat insulator differs from others in that it is applied to the surface using seamless technology, therefore, no “cold bridges” appear either. Air permeability is low, which also has a positive effect on heat transfer. As for the advantages of ecowool, they are as follows.

- It is not toxic.

- It contains no carcinogens or other toxic volatile substances.

- Ecowool weighs little, which allows you to save at least 30 percent on construction.

- The material penetrates into all crevices due to its special structure.

Note! Let's give a small comparison. The thickness of cellulose insulation of 10 centimeters corresponds in its thermal insulation properties to 55 centimeters of foam concrete or 145 centimeters of brickwork.

Also this environmentally friendly insulation:

- protects against corrosion;

- easy to install;

- resistant to bacteria and fungi;

- doesn't shrink.

The fire safety class here is G1, which is very good. The heat insulator is used everywhere; it adheres perfectly to any surface made of any material.

The average cost is from 1,500 to 3,000 rubles per cubic meter.

Types of environmentally friendly insulation

The very concept of environmentally friendly insulation, as you might guess, means that the material is made from environmentally friendly materials and, of course, has low thermal conductivity. Among them, the most popular in our time are the following types of insulation:

The most common types of environmentally friendly insulation

Below we will take a closer look at the features of insulation of all these types.

Peat thermal insulation block

Option 1: peat blocks

Peat blocks appeared on sale not so long ago, however, their popularity is rapidly increasing, which is associated with the following advantages:

- resistance to moisture, so it does not require waterproofing;

- low thermal conductivity - 0.047-0.08 W/mS;

- low cost - about 3,000 rubles per cubic meter.

- durability - up to 75 years or even more;

- peat has bactericidal properties, due to which harmful microorganisms do not multiply on the surface of the material;

- capable of reducing the level of penetrating radiation by five times;

An example of the use of peat blocks in frame construction

- has high strength - thanks to this, the blocks can be used even for the construction of load-bearing walls of one or two-story houses;

- has vapor permeability;

- easy to process - you can cut the block with a regular hacksaw;

- It is light in weight - the mass of one cube is about 400-450 kg;

- fireproof, as it is not subject to fire.

Peat and wood shavings are used as raw materials for peat blocks. Accordingly, there is no doubt about its environmental friendliness.

In addition to building walls, peat blocks can be used for arranging partitions, insulating floors, insulating external walls, etc.

Option 2: cork insulation

This environmental insulation, as you might guess, is made from cork, or more precisely, the bark of the cork tree. During the manufacturing process, the bark is crushed and then treated with steam under high pressure. In this case, the cork resin secreted by the bark serves as a link between the crushed granules.

The resulting mass is pressed and cut into slabs or thin sheets. In this form, the material reaches the consumer.

Due to its porous structure, cork insulation has low thermal conductivity - only 0.03-0.04 W/mS . Of course, there are other advantages:

- has good elasticity, as a result of which it returns to its shape even after severe deformations. Thanks to this, the insulation can be used not only for thermal insulation of walls, but also floors. As a rule, it is used as a substrate for various types of finishing floor coverings;

- has the ability to absorb noise;

- has an original appearance, as a result of which many designers use the material as a finishing coating;

- does not support combustion;

- does not accumulate static electricity;

- is a natural antiseptic, due to which the cork does not rot and mold does not form on it.

When exposed to moisture, cork granules swell, as a result of which the material can become deformed.

The scope of application of cork is quite extensive. It can be used as insulation under wallpaper, as well as for complete insulation of internal walls, floor insulation, etc.

As for the cost, the price per square meter of a 20 mm thick slab is about 900 rubles. Thus, cork insulation is a fairly expensive material .

Eco-friendly ecowool insulation

Option 3: ecowool

This material is made from recycled paper products to which wood fiber is additionally added. Thus, ecowool also contains no synthetic substances that are harmful to humans. Hence the name of the material.

Among the advantages of insulation, the following points can be highlighted:

- has low thermal conductivity - 0.032-0.041 W/m*K, in addition, the material absorbs noise well;

- due to the elasticity and resilience of cellulose fibers, cotton wool does not settle on horizontal surfaces;

- accumulates and releases moisture without losing its thermal insulation properties;

- Ecowool contains boric acid, which prevents insects, rodents and microorganisms from growing in it;

- In the event of a fire, the material does not ignite, but only smolders. After the source of fire is eliminated, it quickly dies out.

Mechanical application of ecowool to walls

The disadvantages include the fact that ecowool can only be applied to vertical surfaces, for example, on walls, using a wet method using special equipment. Accordingly, it will not be possible to do the work yourself.

But the floor or, for example, the attic can be insulated independently using the dry method. The cost of dry ecowool averages 450-500 rubles per bag weighing 15 kg. The density of wool is 35 kg/m3.

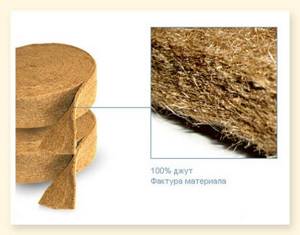

Option 4: linen insulation

The thermal insulation properties of flax have been used by mankind for a long time. Currently it is presented on the market in the form of felt and tape tow.

Linen boards are also called eco-fiber. Its characteristics are quite high:

| Options | Meaning |

| Density | 32-32kg/m3 |

| Thermal conductivity | 0.038W/mK |

| Vapor permeability | 0.4 mg/m*h*Pa |

It must be said that eco-thermal has a high level of moisture absorption, however, even if wet, it retains its thermal insulation qualities. In addition, they release moisture fairly quickly.

As a rule, I use eco-insulation to insulate floors, attics, ceilings between floors, etc. It can also be used to insulate walls from the inside.

As for tape tow, it is excellent for thermal insulation of crown joints. It can also be used to insulate other types of cracks.

There are environmentally friendly insulation materials made from hemp and other plant materials. They have approximately the same characteristics as linen insulation.

The cost of eco-thermal is about 1,200 rubles per package of 0.5 m3.

Sheep wool insulation

Option 5: sheep wool insulation

An alternative to linen eco-insulation is environmentally friendly sheep wool insulation. It is a canvas with a thickness of 20 to 120 mm.

During the production of insulation, the raw materials undergo special processing, as a result of which they become resistant to all kinds of biological influences. In addition, this solves the issue of fire safety. At the same time, the canvas remains environmentally friendly.

Other advantages of sheep wool insulation include:

- low thermal conductivity - about 0.033 W/(m K);

- durability;

- practicality.

As for the cost, it starts from 400 rubles per kilogram.

Option 6: mineral wool

Mineral wool is perhaps the most common environmentally friendly insulation material today. However, it should be noted right away that not all types of mineral wool can be called environmentally friendly. In particular, the well-known glass wool contains formaldehydes, despite the fact that their amount is minimal, it cannot be called completely environmentally friendly.

Basalt wool does not contain any harmful substances . Of course, its high popularity is associated not only with this, but also with many other advantages:

- low thermal conductivity - 0.077 - 0.12 W/mK;

- fire safety and resistance to high temperatures - the material can withstand up to 1000 degrees Celsius ;

- has vapor permeability;

- has sufficiently high strength, due to which it can be used for insulating floors under screed, as well as for insulating external walls using wet facade technology.

Materials of direct plant origin

Such materials include:

- linen;

- cotton;

- moss;

- hemp;

- other natural materials used in the production of thermal insulation boards and created directly from plant fibers.

During production, not only stems can be used, but also plant seeds (for example, if we talk about cotton), which are combined with a binder component and treated with a special fire retardant.

A distinctive feature of these materials is their solid-fiber structure, which makes it possible to obtain noise and thermal insulation with excellent characteristics, as well as achieve high-quality vapor permeability, thanks to which the walls will “breathe”. A huge number of capillaries in the structure ensures the material’s immunity to isolated cases of moisture penetration (the latter is quickly released through these capillaries, and the insulation dries out).

It is worth noting that when choosing a particular material, one should take into account the fact that the effectiveness of insulation will depend on both thermal conductivity and the quality of the installation. It is very important here that the insulating boards and mats are made from plant components, due to which they adhere tightly to the working surface. As a result, the notorious “cold bridges” do not appear, and heat loss, in turn, is minimized. To get a more detailed look at the issue, let’s look at the parameters of the materials in more detail.

Hemp

Hemp itself is an excellent antiseptic, so when it is grown, no pesticides are used. During operation, the material does not rot or become moldy; moreover, it protects the walls of the house itself from these troubles. Due to the high strength of hemp slabs (and it averages 40 kilograms per cubic meter), they can last quite a long time, and without shrinkage.

The material is universal, therefore it can be used to insulate roofs, walls, interfloor spans, floors, as well as frame buildings. In addition, it can be used to soundproof partitions. The insulation is suitable for any location or structure, and its high cost is more than offset by additional air conditioning and savings on heating.

As for the composition, the material consists of 85 percent hemp fibers. Flame retardants, at about 4 to 5 percent, are added to improve fire resistance; The binding element is polyester (10 percent). The material can be produced not only in slabs, but also in rolls with a thickness of 30-180 millimeters. According to the standard, the dimensions of the slabs are 62/62.5/58/100x120/240 centimeters. Roll sizes are 58/60/62.5x120/240 centimeters with a thickness of 3-8 centimeters. What is typical is that, if desired, the material can be ordered according to your own sizes.

As for the advantages, there are quite a lot of them. We list only the most basic of them.

- Increased thermal conductivity (up to 0.5 watt/m*K). The indicator is stable regardless of the humidity level, which cannot be said about mineral wool.

- High thermal inertia, which allows you to keep the house warm in winter and cool in summer.

- Excellent sound insulation.

- Harmless during disposal (carbon dioxide is practically not emitted into the atmosphere).

- Easy to install, tight fit to the surface.

The cost of insulation is on average 1,200 rubles per cubic meter.

Video - Hemp insulator

Linen

A decent environmentally friendly insulation for wooden houses is created from flax, which is placed between the crowns and prevents rotting (and also prevents the penetration of cold). As a rule, felt and tape are used for this. Linen rolls and slabs can be installed on almost any surface, regardless of its purpose, because the material, as far as we know, is completely harmless.

Linen-based insulation can be of several types:

- slabs;

- flax-jute;

- felt;

- tow.

Jute insulation

Previously, we talked about the features of this material, its advantages, disadvantages and technical and operational characteristics; in addition to this article, we advise you to read this information and read about it here

Each of them is extremely easy to install, does not accumulate moisture and significantly speeds up the building construction process. The binders in this case are the same as for hemp insulation. Borax is used for fire protection. The heat insulator has a fairly high heat capacity.

As for specific characteristics, the density of the material can reach 34 kilograms per cubic meter, the average thermal conductivity is 0.38 watt/m*K, the sound absorption coefficient is a maximum of 0.98. The service life is at least 75 years.

The price of such material is on average 135 rubles per square meter.

Cotton

Cotton insulation is also completely harmless, since it is made from old jeans in the form of mats or slabs. Installation can be done with your own hands, and no protective equipment is required. A distinctive feature of the material is considered to be excellent sound insulation, which is why it is often used in cinemas.

Cotton itself is flammable, so it is treated with fire retardants during manufacturing. It is worth noting that cutting the material is quite difficult, and the installation procedure takes longer than if other environmental insulation was used.

Types of materials for insulating frame houses

Currently, the following three types of materials are used for heat and sound insulation of frame houses, but not all of them can completely insulate frame houses:

Information block: What kind of insulation, and where it can be used, read below, in the description of each insulation.

Basalt wool

Basalt wool is the main insulator of natural origin, which is made from molten basalt rocks.

The binding components are environmentally friendly resins. The use of this material for frame buildings can significantly reduce space heating costs and minimize heat loss.

The porous, chaotic structure of basalt wool provides the material with low thermal conductivity and a good degree of sound insulation.

Basalt insulation is perfect for insulating walls, floors, roofs and partitions. It will not slide off over time, as glass wool will, due to the lack of rigidity of the mats. The only negative is the higher cost compared to other types of thermal insulation, but it is reliable.

Mineral wool (glass wool)

Mineral wool (glass wool) is a fibrous, non-flammable material that is made from blast furnace slag, rocks or glass production waste.

The material is made by melting raw materials at high temperatures, after which the mass is placed in a centrifuge to form fibers. Then the finished material is compressed.

As insulation for frame structures, they use not rolled material, but slabs, since they are convenient to work with, they do not change their shape and do not cake.

Glass wool is perfect for insulating floor joists, roofing and interior partitions. It can be used as an economy to fill voids only in non-loaded surfaces.

Due to the lack of the required rigidity of the slabs, the glass wool begins to cake and slide over time, as a result of which cracks form and the frame house becomes leaky.

Foam plastic (expanded polystyrene)

Polystyrene foam (expanded polystyrene) is a cheap, durable insulation material that is sold in the form of slabs of different sizes and thicknesses.

Polystyrene foam is a frozen foam mass consisting of 98% air and 2% polystyrene itself, resulting in a very light material.

Plates made of polystyrene foam and extruded polystyrene foam are not used for wall insulation, due to the release of toxic substances during the operation of the house and vapor permeability. They can only be used to insulate the foundation if they plan to pour concrete under the house.

Other types of insulation (ecowool, sawdust and polyurethane foam)

These types of insulation have not been used in frame construction technology for a long time due to inefficiency or high cost (polyurethane foam), although there is a lot of reverse information on the Internet.

Therefore, when ordering the construction of a frame house, we would recommend that you pay attention to how your house will be insulated.

The best polyester fiber insulation

Here is another group that was included in our rating of the best insulation materials according to a group of experts. What is polyester fiber, what is it made from, and how well does it work as home insulation? Polyester fiber comes from recycling plastic containers and other similar raw materials.

And this is important if you are a fighter for the ecology of the planet. Further, using recycled material, multidirectional synthetic fibers are produced

These fibers perfectly allow steam to pass through, but resist heat transfer. To give you an idea of the material, let’s say that in terms of characteristics and appearance it is very similar to padding polyester.

Insulation Shelter Eco Stroy (SHES) arctic

This product appeared not so long ago, so it can be considered a new product. This material is produced using MicroFiber technology. The insulation material has a structure of multidirectional fibers, which create an elastic layer and maintain its shape. The fiber effect is due to the fact that steam easily passes through such material. The fibers in this material are hollow inside, so this gives good heat and sound insulation properties. The substance itself is completely environmentally friendly, hypoallergenic and does not contain phenol. Thanks to the thermal conductivity indicators, which amount to 0.031 W/(m*K), as well as the fact that the insulation does not rot and is absolutely not interesting to rodents, it has found many fans. Its popularity is beginning to gain momentum.

Insulation Shelter Eco Stroy (SHES) arctic

It’s not for nothing that the word Arctic appears in the name; this insulation is recommended in harsh climates. Professionals say that 100 mm of this material replaces 125 mm of mineral wool, which means you can save a lot of space and achieve excellent thermal insulation.

pros

- Excellent thermal conductivity.

- Not afraid of water.

- Does not rot and is not afraid of rodents.

- Long service life, about 50 years.

- Takes up less space compared to other insulation materials..

Why should you choose environmentally friendly insulation for your home?

Natural insulation materials, in addition to their non-toxic properties, also have the following positive qualities:

- Excellent thermal conductivity (0.04 – 0.04 W/m•K), and even changes in the degree of humidity do not affect this indicator;

- They contain such a quality as thermal inertia, which will help keep the house cool in the summer and warm in the winter;

- Excellent sound suppression capabilities, and material such as hemp can even reduce carbon dioxide emissions into the environment;

- Installing most environmentally friendly insulation is easy, since the material fits tightly to all structures.

Organic insulation Kamka - manufacturing details

Thermal insulator Kamka is an example of organic insulation obtained from zoster algae washed up on the Black Sea coast during a storm. As a thermal insulation material, Kamka justifies itself in all respects. Just like mineral wool, it does not rot, retains its performance properties throughout the entire period of use, does not burn or melt at temperatures below 1000 degrees.

In rooms with high humidity levels, the material absorbs moisture; in dry rooms, it moisturizes, thus maintaining a comfortable microclimate.

Among all natural insulation materials, Kamka is the cleanest and safest; moreover, it has a healing effect due to the special composition of iodine, zinc, cobalt and amino acids contained in algae. Fukondak polysaccharide included in the material prevents cancer and has a beneficial effect on the nervous and respiratory systems.

Calculate the insulation of your home

Two parameters are taken into account: the temperature zone of the area, the heat transfer resistance coefficient (R). If you need to decide which insulation is best for the walls of a brick house or wooden building, take into account the area where the thermal insulation will be installed: walls, ceiling, floor, ceiling, etc. Then you should determine the heat transfer resistance coefficient of the supporting structure and insulation.

To obtain the value of this parameter, it is necessary to divide the thickness of the wall covered with thermal insulation, partition or floor by the thermal conductivity of the material from which the supporting structure is made. Using the same principle, the value of the coefficient of resistance to heat transfer of insulation is obtained: divide the thickness by the thermal conductivity. You need to add up 2 R indicators and compare them with the table value of this parameter. According to this scheme, types of insulation are selected for a house that is being built using frame technology.

Installation features

Having studied the main types of environmentally friendly insulation, you need to analyze the methods of their installation. Plates, rolled materials and mats are attached like ordinary mineral wool. In any case, you need to choose the most environmentally friendly insulation for buildings and install it in stages.

Stage 1. Preparation

First of all, prepare the work surface. To do this, remove the old casing and thermal insulation from it. In this case, chips and other defects need to be plastered.

You also need to clean the coating from dirt and dust. After which they take on the main work.

Stage 2. Lathing

For maximum thermal insulation of a building, a frame of wooden slats or iron profiles must be made on its external walls. Its thickness is equal to the thickness of the insulation. The distance between the frame elements is made according to the width of the thermal insulation boards.

Stage 3. Installation

Installation is performed differently depending on the type of insulating material used.

Laying environmentally friendly insulation

Mats and slabs made of natural material are placed tightly between vertical profiles (from bottom to top). A cladding is installed on top of the material. If the attic is being thermally insulated, then environmentally friendly insulation is placed between the rafters.

Installation of cellulose insulation

There are 2 ways to install cellulose insulation:

- Dry.

- Wet.

You need to insulate inclined surfaces using the first method. A hole is made in closed cavities and ecowool is blown into the structure with a compressor. It is also possible to manually fill the cavities with material.

The second method of installing ecowool is optimal for frame structures. I wet the material with water, after which it is blown onto the surface. This allows it to adhere well to any surface. Thanks to this, the required thermal insulation layer is created on the surface, the excess of which is cut off.

In these simple ways, you can quickly insulate your home with environmentally friendly materials, which will create a healthy climate and comfort in your home.

By choosing the most environmentally friendly insulation for finishing your house, as well as properly installing it, you can make your house very warm, cozy and economical in terms of heating costs.

Insulation materials

Insulating a home means achieving comfortable living conditions and saving the family budget. Recently, consumers are increasingly choosing environmentally friendly materials as thermal insulation.

Among the natural eco-insulation materials for the home, the following can be noted:

1. Peat blocks - are made from sawdust, shavings, chopped straw, and the binder is peat processed into paste. The disadvantage of peat is its ability to accumulate moisture.

- Easy to process;

- Has high thermal conductivity (0.046-0.07 W/m K);

- Good sound insulation properties;

- Durability over 70 years.

What is fibrolite and how does it work?

Eco-friendly fiberboard for thermal insulation contains, in addition to wood fiber, Portland cement and liquid glass. The peculiarity of the material is that the temperature of its surface changes only 11 hours after the temperature outside changes.

The main advantages of insulation include resistance to moisture and low temperatures, practicality, and resistance to mechanical damage. In addition, the material is not subject to natural decay processes and is not a favorable environment for the development of fungus. External walls can be insulated with fiberboard even in winter at sub-zero temperatures.

Main types of insulation

Progress in all spheres of human life does not stand still, including in the construction industry, so every year new types of insulation for walls, floors and ceilings, foundations, etc. appear on the building materials market. If just a couple of decades ago, only mineral wool, sawdust (shavings), and expanded clay with slag were available to the average person, today the choice of thermal insulation materials is much richer. In addition to the above, these include:

- Expanded polystyrene in slabs;

- Ecowool;

- Sprayed polyurethane foam.

Below is a little more detail about each of them. And on the forum you can read reviews.

Mineral wool as insulation

Mineral or basalt wool is one of the most popular insulation materials for frame residential premises. This material is resistant to combustion and high temperatures, environmentally friendly, and has good sound insulation. The last property is very important in frame buildings. To understand the thermal insulation characteristics of mineral wool, it will be enough to say that a layer of this material 50 mm thick is equal in properties to the thickness of brickwork of 580 mm.

Regarding the insulation technology itself, the construction of the frame is carried out initially with the expectation that slabs of mineral (basalt) wool will be used. A distance of 60 cm is left between the racks of the wooden frame, which is equal to the standard width of the insulating material.

Basalt slabs should be laid tightly so that there is not too much free space between them and the outer and inner walls, but they should not be pressed too hard, as over time this can lead to damage to the material and the formation of “cold bridges.”

Expanded polystyrene boards

Expanded polystyrene (EPS) in boards is a foamed thermoplastic, which consists of fused granules. This may seem surprising, but the insulation boards themselves consist of 98% air, which fills both the granules themselves and the space between them, and only 2% polystyrene. Of all types of insulation for frame structures, polystyrene foam boards are the lightest.

With prolonged exposure, polystyrene foam is affected by vegetable, animal and paraffin oils, fats, diesel fuel and petroleum jelly. EPS is unstable to various types of organic solvents, but it does not dissolve or swell in water, practically does not absorb moisture, is durable and resistant to rotting. This material is not digestible by animals and microorganisms, therefore it is not used by them as food and does not provide a breeding ground for bacteria and fungi.

Ecowool or cellulose insulation

Ecowool, which consists of 80% cellulose and 20% various components (binders and fire retardants), in our country relatively recently began to be used as insulation for frame houses, although, for example, in the States this material was widely used back in the 70s. -s of the last century. For comparison, it must be said that a layer of ecowool 130 mm thick is equivalent in its thermal insulation characteristics to a 600 mm thick aerated concrete wall.

Essentially, ecowool is paper production waste that has been treated with brown acid or ammonium sulfates (prevents burning) and boric acid (prevents rotting). It is resistant to combustion, harmless to the health of people and animals, does not rot and rodents are not very fond of it.

However, when choosing this material, you need to take into account this feature: ammonium sulfates and phosphates, when interacting with boric acid, lose their flame retardant properties over time. In addition, these compounds can cause an unpleasant odor. Therefore, you should purchase ecowool that uses only brown acid (borax) as a fire retardant, which does not lose its properties and is odorless.

Insulation with sawdust

Another bulk insulation material is waste from wood processing plants - sawdust. Perhaps this is the cheapest way to insulate a house. Some furniture production shops give away sawdust free of charge if a person independently removes the waste from the territory.

However, it should be remembered that for insulation you can only use sawdust of a fairly coarse fraction, and that remaining after cutting the primary wood.

Thus, sawdust from chipboard, fibreboard, MDF panels and other materials, in the production of which various binding components are used, are not suitable not only for reasons of environmental safety, but also because they are too small and are, in fact, fine dust .

Any questions?

If during the process of placing an order you have any questions about the application, calculation of the required volume of Flaxan insulation, configuration, delivery, pricing policy, etc., our specialists will be happy to answer them by phone. or by mail

- Discounts

- Description

- Application

- Visualization

- Installation

- Those. characteristics

- Construction stages

- Materials

- Media

- Reviews

Flax insulation FLAXAN (Flaxan) consists of flax fiber and jute 85% and 15% lavsan. Natural, environmentally friendly insulation creates a warm, biopositive atmosphere in the premises. FLAXAN regulates (balances) the humidity regime and maintains a healthy microclimate in the house. Low thermal conductivity allows flax and jute insulation to keep the house warm in winter and cool in hot summer. Possessing excellent thermophysical characteristics, Flaxan insulation belongs to premium-level building materials.

Use as heat and sound insulation in all horizontal, inclined and vertical structures: - external and internal walls; — floors, ceilings, ceilings; - interior partitions; - pitched roofs and attics;

FLAXAN flax boards are easy to install; they can be installed without any special skills and without any personal protective equipment. Thanks to its elasticity, the material easily “stands up” and fits tightly to joists, posts, rafters, etc.

Advantages of FLAXAN compared to other alternative mineral insulation materials; basalt; glass wool: - absolute safety and environmental friendliness; - excellent sound insulation properties; — the ability to “breathe” and regulate humidity creating a comfortable microclimate; — biostability and durability; — convenience and practicality of installation.

Parameters of plates (mats) and packaging: Parameter

| Packaging material | Plate length | Slab width | Slab thickness | Material area in packing unit (m2) | Volume of material in packaging (m3) |

To produce the material, two types of algae are used - dwarf eelgrass and seaweed. Both of them are perennial tall grasses that grow in the coastal waters of warm seas. Local residents call the plant Kamka and have been using it for their needs for a long time. Algae are distinguished by a number of useful properties: – Long service life of materials made from this plant material. Danish scientists conducted a study and claim that properly collected and processed damask retains its properties for 150 years. – Hypoallergenic and environmentally friendly. Algae do not emit toxic substances and do not provoke allergy attacks. Moreover, the iodine they contain saturates the air, which is very beneficial for humans. – High thermal insulation characteristics. They are comparable to those of stone wool. The damask retains heat well. – Fire safety. The plant contains silicon, which makes it difficult to ignite. When exposed to fire, the material smolders and collapses without releasing substances hazardous to humans. – Sorption properties. Kamka absorbs moisture quite well - up to 30% of its own weight. It also gives away excess water just as easily. The material has the ability to regulate the amount of moisture. – High biostability. Algae contains a large amount of tannins, which prevents the growth of fungi and mold. In addition, it has a beneficial effect on the roofing elements in contact with it. Prevents them from drying out and rotting.

Damask not only retains heat, but also retains sound waves well. It is considered a good sound insulator. Three different shaped thermal insulation materials are produced from damask. The easiest to produce is loose seaweed. These are rolls or bales consisting of pressed sea grass. This option is also the most budget-friendly. In addition, the advantage of hanging damask is the ability to install it in the most complex areas. |

Natural insulation materials

To find out which is the most environmentally friendly type of insulation, you should pay attention to a number of specific factors by which the degree of safety of the material is determined.

Base and structure

Fibrous structure of natural insulation

Eco-friendly insulation materials are made from natural fibers of plant origin:

- linen,

- hemp,

- wood,

- and others.

They do not cause any allergic reactions and are completely safe for the human body, and their soft fibrous structure prevents the components from being dispersed into the surrounding space.

This distinguishes them favorably from such analogues as mineral wool and glass wool insulation - they are also based on natural components, but their use can cause significant harm to health.

Insulation of this type has a crystalline structure, which leads to the spraying of tiny fragments of glass and stone into the room. Solid particles of insulation, entering the respiratory system, can settle in the lungs for a long time.

Components

In addition to the plant base, fire retardants and binding components are also used to form insulation boards - the first reduce the degree of fire, protect against insects and fungi, and thanks to the second component, individual fibers are transformed into a solid surface.

The most commonly used antipyrine is borax, a natural mineral that does not pose a serious health hazard and at the same time effectively prevents fire.

Impregnation with borax allows the insulation to resist open fire and resist rotting. The benchmark for this material is moderately flammable.

Lingin, a natural material contained in wood, is used as a binding material, through which the insulation is shaped into a slab. With its help, the fibers are connected to each other and maintain the correct geometric shape. Some manufacturers use vegetable starch for this purpose.

Combustion and smoke formation

There are a large number of conditionally safe materials, both natural and synthetic. The prefix “conditionally” is attached due to the fact that their safety for human health is maintained only under certain conditions. When heated, burned or exposed to ultraviolet radiation, they release various toxins that can lead to severe poisoning.

The smoke from such products is extremely toxic, as it contains formaldehydes, phenols, cyanides and other extremely toxic substances.

Natural-based products are environmentally friendly insulation that does not emit toxic substances when burned or heated. In this regard, we can conclude that insulation made from flax, cellulose, cotton or hemp is the most environmentally friendly insulation today.

How to identify a truly environmentally friendly material among analogues?

To find the best insulation for your home, you need to rely on the following factors:

Natural composition. The product should be based on natural components and fibers. It is unacceptable for thermal insulation to release toxins or carcinogens. Even the decorative layer used in the future is not able to protect residents from pathogenic chemical fumes. Over time, any finish will become thinner and become permeable; coatings and paints are not able to protect against aggressive components. Thermal conductivity. Optimal performance is shown by options made from natural fibers, mainly plant fibers. When choosing which insulation is the most environmentally friendly, you need to pay attention to the heat transfer coefficient: the ideal range is 0.032-0.040 W/m∙K. This range is sufficient to ensure a healthy microclimate in the house. Moisture resistance It is necessary to find a sufficiently dense material that can repel liquids, since when wet, the fibers lose their thermal insulation properties and the heat transfer coefficient increases. In conditions of excess humidity, fungi and mold develop, which can cause the spread of pathogenic microorganisms. Natural breathable materials, having absorbed water, dry out with good ventilation and retain all their useful parameters. Flammability

This property is especially important in the decoration of buildings; natural raw materials do not contribute to combustion, are vulnerable only when in contact with an open flame and die out when the latter is localized. Environmentally friendly materials, even when burning, do not produce dangerous toxic substances, unlike common insulation materials containing formaldehyde (it releases phenols).

The specialized market offers a rich variety of safe materials; their characteristics will be discussed in more detail below.

Which material to choose

So, there are a lot of materials, so it’s difficult to say which is the best insulation for thermal insulation of a frame house. All options considered have different characteristics, cost and appearance. Some have a limited scope of application, others have a high cost, the need to attract professionals, and low environmental friendliness.

You need to weigh which characteristics are priority and make the final choice. For example, according to the author of this article, basalt stone wool is the best insulation for the walls of a frame house. Perhaps the tips from the video, the authors of which tested products from different manufacturers, will help you.

Why is vapor barrier and wind protection of insulation important?

Vapor barrier is necessary to protect the thermal insulation layer of mineral wool from the influence of moisture and fumes coming from inside the room. The effectiveness of the entire thermal insulation system largely depends on the quality of the device and the performance of the vapor barrier. It is advisable to entrust its implementation to professionals or, at least, to strictly follow all the recommendations of manufacturers of vapor and heat insulating materials.

Mineral wool insulation also needs protection from the outside. A thick woolen sweater cannot always protect its owner from the wind. But as soon as you put on a windbreaker made of thin but not breathable fabric over it, you immediately feel warm and cozy.

Similarly, a layer of insulation will reliably retain heat only when it is protected by a reliable hydro-windproof membrane fixed outside. At the same time, wind protection not only helps to save heat inside the building, but also prevents the weathering of the fibers of the insulating material, and also protects it from atmospheric moisture.

Expanded polystyrene

It looks a lot like white foam. They are even made from the same raw materials. The only way they differ is in the manufacturing technology.

Expanded polystyrene is made using extrusion. That is, for this, its raw materials are combined with freon or carbon dioxide. After this, the mass is heated and passed under pressure through the extruder nozzle. As a result of this process, slabs are formed that have a high density of insulation for a frame house.

But polystyrene foam, on the contrary, has a more porous structure. This is due to the fact that it is produced by foaming raw materials.

The main and main advantages of these insulation materials are:

- Low thermal conductivity coefficient.

- And also light weight.

- Insulation can be used both on the inside and on the outside of the frame.

- The materials are inert to biological influences.

- These materials have a very good level of sound insulation.

- You can also do the work yourself.

- The price is affordable.

The main disadvantages of these materials include:

- Flammability.

- These insulation materials are incompatible with organic solutions.

- Insulation materials are also unstable to direct sunlight.

- The materials are very toxic.

Sawdust

During construction, it is very important to determine what insulation to use in a frame house. You can use sawdust. This material continues to be laid, despite the fact that more modern synthetic insulation materials have appeared. In addition, sawdust is one of the most environmentally friendly insulation materials for a frame house.

To ensure that the house has good thermal insulation, it is recommended to choose sawdust exclusively from hard wood. Such trees include maple, beech, alder, oak, and pine.

In addition, it is worth noting that this material is one of the cheapest insulation materials for a frame house.

If sawdust is not treated with special compounds, but used in its pure form as insulation, then you may encounter the following disadvantages:

- The material is flammable.

- Both insects and various rodents can live in it.

- At high humidity, the material may begin to rot.

- And if sawdust is moistened, significant shrinkage can occur.

Therefore, to avoid such situations, sawdust is most often used in combination with something. So, for example, in order to make an insulating mixture, you need to purchase:

- vitriol or boric acid, which are antiseptic;

- clay, lime, cement as a binding component of the mass.

Properties of thermal insulators

So, first of all, the heat insulator must have the following qualities:

- Low heat conductivity;

- Fire safety;

- Low water absorption;

- No or minimal shrinkage;

- Environmentally friendly.

Let's look at them in order.

Low heat conductivity. The lower this indicator, the less heat passes through the insulation. Accordingly, the smaller it is, the better. With low thermal conductivity, the house will be warm in winter and cool in summer. In addition to the fact that this makes the room more comfortable, it also significantly reduces the cost of heating or cooling rooms with electrical appliances.

Water absorption is the ratio of the amount of water that is absorbed by the material to the weight of the heat insulator itself. If moisture gets through the outer walls of the building, the insulation must absorb its excess and prevent it from penetrating inside. This indicator is important because it greatly affects thermal conductivity - moisture conducts heat well. And if this happens during the cold season, the water may freeze completely and turn the insulation into ice, thereby losing all its useful properties.

Fire safety means the strength of resistance to ignition and combustion. There are several GOST categories that meet this indicator.

The best insulation materials, naturally, should be non-flammable.

Shrinkage. Also an important indicator, which should be the most insignificant. If this number is high, after some time after completion of construction the material will settle, holes and cracks will appear between it, which will lead to the appearance of cold bridges and increased heat loss.

Environmentally friendly. During production, some materials are treated with substances harmful to the body, such as formaldehyde. They can damage a person’s respiratory tract, and completely unnoticed. Other materials, such as glass wool, during operation emit very small particles into the air, which also settle on the lungs and bronchi. Such materials are categorically not recommended for insulating children's rooms, and are not very useful for adults.