Such unpleasant moments as leaks should not be associated only with roof damage. The reason may lie in the lack of proper ventilation of the under-roof space. This article will help you understand the nuances of natural ventilation. Since the ventilation system plays an important role in the life support of the entire house. With proper roof ventilation, there will be no unpleasant odors, fumes or condensation in your home. Understanding that modern construction at the planning stage immediately provides for a ventilation system for more complex structures, compared to analogues of previous years. The question arises: is it possible to do roof ventilation with your own hands?

Purpose

When arranging the ventilation outlet on the roof, you should know about the main subtleties of the upcoming work, understand the types of structures and their purpose. Roof ducts can be used in different types of ventilation systems:

- 1. In the interior rooms of the cottage.

- 2. In the drain pipe of the sewer riser.

- 3. In the attic under-roof space.

Moreover, sometimes these passages are necessary for laying smoke shafts and television antennas. At the end of the air exhaust system there is a special ventilation outlet, which is equipped taking into account all the requirements for the system.

The purpose of such a design is to ensure effective exhaust of air from the room and prevent any leaks. At those points where it is necessary to make a ventilation passage through the roof, special passage elements are placed that correspond to the specific roofing material.

Currently, it is possible to buy ready-made sets of ventilation outlets for their further installation on roofing structures made of hard and soft materials. Such products allow you to quickly and efficiently build a ventilation riser to protect the roof from possible leaks, as well as maintain its aesthetic appeal. Moreover, such devices are a natural protection of ventilation ducts from the penetration of various dirt and precipitation.

The height and shape of the passages through the roof are determined by the individual characteristics of the roof structure. In addition to pipes with a round cross-section, rectangular structures are used.

To ensure that the ventilation pipe does not lead to a violation of the roof’s tightness, it is necessary to follow a certain sequence of actions and take into account the established requirements.

Components and installation

To install air ducts, it is best to use factory models. They are designed for installation in metal roofing, can provide the proper level of tightness and have a long service life

What should you pay attention to when choosing such elements?

First of all - on the diameter of the air duct. The optimal value of this parameter should be 50 mm. Also, the design must have a deflector - protection from moisture. Depending on the location of the channel (horizontal or vertical), this function can be performed by a housing or a cap on top of the pipe

It is also important to distinguish the purpose of ventilation

Roofing ↑

Designed to stabilize the temperature only in the air gap of the roof. It is an air outlet with a relatively small passage opening. It is best to choose ventilation through metal tiles with grilles. The main problem with operation in such structures is the high probability of ice formation. This significantly reduces air exchange, in some cases stopping it completely. Therefore, it is recommended to install a different type of ventilation.

Through ↑

The operating principle is almost completely identical to the coaxial chimney pipe of a heating boiler. The main air outlet for metal tiles through a through hole is mounted through the entire roofing pie, providing ventilation to the attic space. The double housing, insulated from the internal air duct, removes excess moisture from the roof space. Installation of such a structure is more labor-intensive; navigation from operation is much higher than that of a roofing structure.

For installation, it is necessary to make a corresponding hole in advance on the roof surface. Its outer diameter depends on the type of duct. Many factory models have special rubber seals along the edges to ensure tight joints. When passing through the waterproofing and thermal insulation layers, plastic adapters are installed. They will protect the insulating materials from rupture in case of possible displacement of the air duct housing.

In addition to the condition that one channel is needed for every 60 sq.m. roof, its installation should be carried out at a distance of no more than 60 centimeters from the edge of the ventilated ridge for metal tiles. To improve air exchange, they are also made ventilated.

How does a roof ventilation system work?

Ventilation of the under-roof space is of two types:

- Natural.

- Forced.

Natural ventilation operates without the use of mechanical devices, only thanks to the laws of physics. Air movement here occurs due to the difference in pressure in the interior space and outside the house. Through the exhaust openings, air from the under-roof space is drawn out along with the steam particles filling it.

The air exchange rate is directly affected by the difference in the height of the supply and exhaust openings. The larger it is, the stronger the resulting thrust will be. Therefore, exhaust ducts are often installed at a height exceeding the location of the ridge, and the supply openings are located in the eaves.

In forced ventilation, ventilation devices are used to create a directed air flow. They can be located at the exhaust or supply openings, or at both points simultaneously. Such modifications are more efficient compared to natural ventilation systems.

Attention! In order for roof ventilation to work in a balanced manner and as efficiently as possible, the volume of supply air must correspond to the volume of exhaust air. This indicator is regulated by selecting the correct cross-section of the supply and exhaust openings.

Forced ventilation

Supply valves together with a ventilation grille are the main method of effective supply ventilation.

They are designed on the front part of the room. The valve, equipped with a thermostat, reacts to fluctuations in outside temperature and automatically changes the air flow. Of course, the thermostat can be adjusted manually as needed.

Other methods for eliminating condensation

Option 1

Perhaps the option with insulation is not suitable for someone, so you can do it differently. The vent pipe that runs through the attic becomes disconnected. A tee with a conical plug is inserted at the disconnection point. It is into the place of the cone that the condensate will flow. The disconnected part of the ventilation pipe that goes outside should be installed in a tee. This method is called condensate removal from exhaust ventilation ducts. It is not expensive and does not require much effort, the main thing is to install the tee correctly in the air duct. Next, you need to insulate this structure, and instead of draining the condensate, you can install a tube through which the condensate will flow.

Example

The private house has 2 bathrooms, each of them equipped with exhaust fans in the ventilation ducts. For ventilation, metal pipes with a cross-section of 125 mm were chosen. Ventilation pipes in a horizontal position pass through an unheated attic (the length of one pipe is 7.5 meters, the length of the other pipe is 9 m), then they go outside. The pipes are insulated with mineral wool. In winter there is condensation, what should I do? Moreover, its quantity is very large, water flows out even through the fans.

There are several options for solving the problem; the pipe must be insulated completely, right down to the last section facing the street. You can mount the ventilation pipe outlet directly on the roof without horizontal sections, equipping it not with a duct fan, but with a turbo deflector. The last best option is to install a drain in a place where the ventilation in a private house drips condensate, through which the water will quietly drip, for example, into a sewer drain.

Option #2

A plug is made on the old ventilation and a new forced ventilation system is installed. An exhaust fan is installed in the room where the most evaporation occurs. Often the mechanical device is mounted in a window vent. The supply of fresh air can be provided by a supply valve, which is installed near the battery or behind the gas boiler. Installing supply valves near heating equipment will heat the winter air and heat loss in the house will be minimal. This expensive option allows you to permanently remove condensation from the ventilation.

The correct approach to insulating ventilation pipes solves the following problems - increasing the operation of ventilation ducts. Noise insulation during the passage of air masses. Reducing heat loss in winter. Condensation does not drip from the ventilation in a private house. Prevents the spread of fire in case of fire.

Today, insulation materials in stores are presented in the form of cylinders, cords, and half-cylinders. The diameter must also be selected individually. The thickness of the insulation is also different. It is advisable to approach the issue of insulation of ventilation ducts at the stage of building a house.

Roof ventilation methods

There are several variations of the mechanisms by which roof ventilation is carried out in country houses:

- ventilation of ridges on a roof consisting of two slopes;

- ventilation of eaves and chimney;

- roof exhaust fan;

- single components with holes for ventilation;

- skates equipped with a special design;

- clearances for ventilation provided when installing roofing material;

- dormer windows in attics.

Each material has different designs, which you should familiarize yourself with before purchasing.

Ventilation installation options

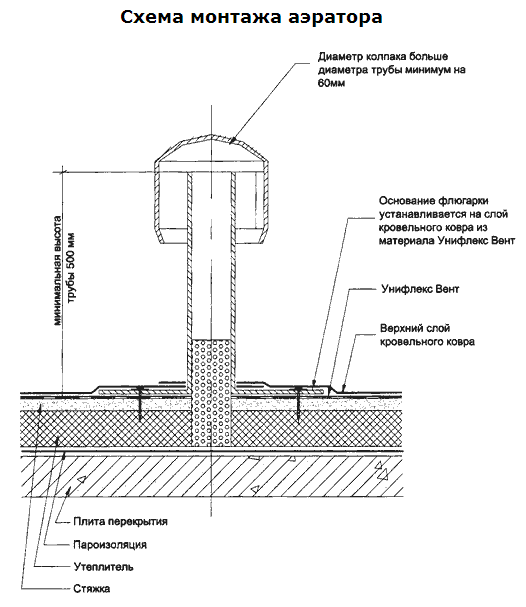

For this purpose, exhaust outlets can be provided at or near the ridge. Such outlets are called roof aerators. They can be placed pointwise or made into a continuous gutter. The greatest efficiency will be ensured if they are located along the entire edge of the roof. Roof aerators can be combined with the general ventilation system of the house.

Roof aerators will not spoil the appearance of the house, since the main covering is laid on them. When constructing this type of ventilation, sealing cannot be done using polyurethane foam or special tapes. This will block air access, making natural ventilation of the roof impossible. To make a roof with 2 gaps, you will need to cut holes in the film, since it will also block the access of air from the outside.

For almost any roofing covering, there are functional elements that can be used to create ventilation. These elements include:

- plates with air channels;

- aeroelements;

- ventilation rolls.

With the help of these roofing elements, you can ensure ventilation of the roof of the house. The greatest efficiency is achieved by a ventilated ridge system created using these elements, rather than installing them separately.

Arrangement of a ventilated eaves is an opportunity to provide an area for air penetration sufficient for effective ventilation of the roof. Eaves ventilation can be of several types:

- soffit, which is the gaps between the wall of the building and the eaves board;

- in the form of ventilation grilles embedded in soffits;

- using a special material that includes vents placed slightly above the level of the eaves overhang.

In order not to block access to air, it is necessary to refuse to lay heat-insulating material in the eaves or place plantings on it. You can provide effective protection for ventilation ducts located on the eaves:

- special grilles and aeroelements;

- location of drainage system elements under the roofing;

- installation of snow guards.

Scheme of attic ventilation through dormer windows.

The roof valley or roof valley is a more complex option for ventilation. If the eaves overhang is too short and there are 2 ventilation gaps (or long gutters) on the roof, then certain difficulties may arise with the ventilation outlet.

It is possible to ensure ventilation of the roof if you make ventilation openings in the film in each span of the rafter system. Instead of an opening, you can make a continuous channel for ventilation along the gutter.

In such difficult cases, aerator elements can be placed along the valley. This is very convenient on roofs with a slope of 45°. If the roof is flat, then such ventilation will not be effective. In this case, the best option is roof fans powered by electricity, high ventilation nozzles, inertial turbines, etc. However, the cost of such ventilation is much higher than when arranging ventilation naturally.

The most common way to create ventilation is to create a dormer window. This element carries not only a functional, but also a decorative load. A roof with a dormer window looks very attractive. You can make a hole for a dormer window of various shapes.

A single-pitched dormer can be installed on any roof. The base of the gable roof should be a roof made of metal or soft covering. But if desired, you can also install windows with a more complex design.

Thus, roof ventilation is an essential element that serves to remove warm and humid air from the house. With the help of a ventilation system, you can prevent rot and mold on floor beams and roof supports. There are several ways to arrange ventilation on the roof. One method or another may be more or less effective depending on the roof design. In some cases, it may be necessary to include special devices in the ventilation system that operate from the electrical network. This will make ventilation more efficient, but will increase energy consumption. It is recommended to resort to this method of arranging ventilation only in cases where the roof structure prevents natural ventilation.

Features of roof ventilation organization

Under-roof ventilation systems come in several types, differing in design features and the range of ventilation devices used.

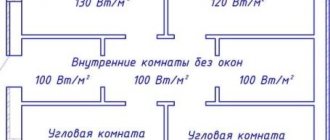

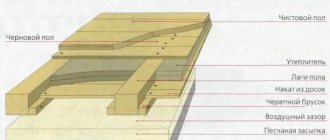

A typical moisture-heat-protective roof pie consists of several layers, each of which is protected from the accumulation of condensation. Therefore, the design of the “pie” directly affects the choice of ventilation devices and the nuances of organizing the ventilation system.

The materials used to construct the roof of a building differ in their performance and technical qualities. The modern building materials market offers a large number of roofing coatings - metal (corrugated sheeting, metal tiles), asbestos-cement (slate), polymer (soft tiles).

Each of the listed roofing materials has different thermal conductivity indicators, which affects the intensity of condensation formation in the attic.

A correctly selected and installed under-roof ventilation system should provide:

- Stable temperature balance throughout the attic space.

- Effective removal of steam entering under the roof from residential premises.

- Reducing the level of heating of the roof under the influence of sunlight.

- Increasing the service life of both the roofing structures themselves and the entire building.

To create air exchange in the under-roof space, the following devices and devices are used:

- Vents located in the eaves and ridges of the roof.

- Aerators.

- Roof fans for forced air circulation.

- Exhaust holes in roof slopes.

- Dormer windows of attics.

- Ventilation ducts. Relevant for residential attics and attics, divided by partitions into separate rooms.

Note! Incorrectly selected ventilation devices, installation with technological errors, incorrect location of ventilation ducts and exhaust devices - leads to a decrease in the efficiency of the entire ventilation system.

Consequences of poor installation

Do not ignore the rules that apply to roof ventilation. If you neglect the rules of arrangement, you may encounter unwanted processes that can destroy the entire building.

Warm air flows from the living quarters under the roof. Outside, the roof is exposed to cold air masses. Due to the difference in temperature, condensation begins to accumulate under the roof, which can only be removed by ventilation. If a vent is not provided, condensation will accumulate in the attic, destroying the roof.

Concrete roofs are not so susceptible to the effects of condensation, however, harmful fungus can appear on their surface, which negatively affects the human body.

Improper air venting to the roof can also negatively affect soft roofing. In most cases, soft roofing materials are located on a concrete base or continuous sheathing. The presence of excess moisture that penetrates from the inside will cause the material to begin to delaminate. In the future, the roof will leak.

Iron roofs can corrode, reducing the protective properties of the roof. Shedding of hard material from the roof can injure people below.

Ventilation of the under-roof space

Moisture is always absorbed in the under-roof layer. This happens due to:

- water condensation inside the living space,

- absorption of moisture on the inner surface of the metal roof,

- accumulation of moisture from the external environment.

The service life of the roofing substructure is reduced due to the negative influence of excess humidity, which causes the spread of mold and harmful fungi.

Differentiation of pressure and air flow is the basis of ventilation. In this regard, it is recommended to create a sufficient supply of air from under the eaves and gable overhangs of the roof.

It is necessary to take into account the type of roof covering when choosing ventilation for the under-roof space.

The components of the roof covering include: KTV valves, ventilated ridges and ventilation outlets with a deflector cap.

Functions

A universal ventilation outlet must be installed on roofs made of metal tiles, since this material is produced in the form of large-area sheets, the seams between which are sealed during installation. There are 3 good reasons why you should install roof ventilation:

- It prevents the insulation from getting wet, thereby maintaining the high thermal insulation properties of the material. Please note that when the humidity of the thermal insulation layer increases by only 5%, the thermal conductivity of the material doubles and remains the same even after drying. Therefore, the installation of ventilation outlets, the installation price of which does not exceed several thousand rubles, can delay the complete replacement of the thermal insulation layer.

- Roof ventilation prevents increased humidity and premature wear of the rafter frame, which consists almost entirely of wood. Wood is a material of natural origin; when humidity rises, it suffers from rot and mold, which are the result of the activity of harmful microorganisms.

- This simple measure, the price of which is less than 1/10 of the total cost of constructing a roof, optimizes and equalizes the temperature of the roof covering. Thanks to the ventilation outlets, an ice crust does not form on the roof surface, overloading the rafter frame and damaging the metal tile covering when sliding.

Professional roofers claim that for a roof with a slope of 20-30 degrees and an area of no more than 60 square meters. m, one ventilation outlet with a diameter of 50 mm is sufficient. The larger and steeper the slopes, the more pipes will be required. The universal kit includes the pipe itself, an elastic casing, a plastic penetration, a protective deflector, a template and fasteners. The output price is 700-1500 rubles, depending on the material and functionality of the model.

What is needed to install a roof ventilation outlet

To perform installation work on a ventilation pipe above the roof, you need to have all the necessary tools. It is recommended to prepare them in advance so that no unforeseen circumstances arise during installation.

Pipe installation is carried out using the simplest tools

List of materials and tools that will be needed when installing the ventilation pipe:

- scissors for cutting metal;

- insulation;

- Screwdriver Set;

- marker (for marking);

- special sealant;

- self-tapping screws;

- sealing elements;

- passage unit;

- work gloves.

- drill or hammer drill;

- level;

- electric or manual jigsaw.

When is box installation necessary?

The influence of natural factors (wind, precipitation, etc.) leads to the gradual destruction of the chimney. For example, brick absorbs moisture well, which gradually accumulates inside and freezes when the temperature drops, compromising the integrity of the material. The box allows you to protect the pipe, slow down the process of destruction and give the pipe a more aesthetic appearance.

The main function of the box is to protect the ceiling from fire.

Installing a metal casing allows you to extend the service life of the pipe.

Additionally, the box gives the pipe a more aesthetic appearance and allows you to avoid periodic repairs.

Traditionally, materials such as stainless or galvanized steel are used to make boxes, as they are resistant to moisture, corrosion, and temperature changes. The materials have a long service life.

A variety of color options makes it possible to choose the best option without reducing quality characteristics.

Some types of coating do not match the style of a chimney made of brick. Installing a metal box would be the right solution in such a situation.

It is not in all cases possible to make a brick pipe on a sandwich made of galvanized or stainless steel. A galvanized pipe against the background of the roof will look like a separate element. A metal box of the same color as the roof covering can save the situation.

The sight of a collapsing pipe is hardly pleasant. Therefore, it is worth installing a metal box that will hide the consequences of destruction and stop them.

Pipe destruction reduces the safety of using the heating system, negatively affects the functional characteristics, and reduces the level of draft. Therefore, a metal casing would be a good option for protecting the chimney.

Return to contents

What to consider when installing a ventilation pipe on the roof

The ventilation duct exits to the roof so that water does not get under the roof covering. Reliable sealing of the joint is a very important undertaking. If it is not done correctly, problems may arise in the future due to the fact that water will flow down the ventilation structure into the house. The sealants needed in this case can be purchased at any hardware store.

Particular attention should be paid to sealing the pipe where it exits through the roof.

Important! The upper end of the pipe must be covered with a protective cap, which will prevent precipitation from entering the system. There is a more functional way - equipping the end of the pipe with a deflector.

The lower end of the ventilation structure, which goes to the roof, is connected to the air duct. Docking is usually carried out using connecting flanges. To improve the tightness, you can equip the outlet with a special support ring. In addition, a valve is mounted directly into the pipe body, which will regulate air movement.

Ventilation pipes on the roof are mounted using auxiliary elements, which are offered in a huge range. If you wish, you can consult with specialists who will tell you which parts to choose in order to simplify the work as much as possible.

Features of UP for chimney

For houses that have stove heating or fireplaces, the construction of a control unit for the design of pipes and chimney will be required. Such designs have their own characteristics: when installing a chimney pipe, it will be necessary to create auxiliary rafters in the attic so that snow masses do not accumulate on the chimney duct.

Auxiliary fastening of rafters and corrugated sheeting will be required if the roof penetration is placed through the ridge. This arrangement complicates the installation of a mansard roof in the attic.

Features of UP for chimneys:

Organization of UE for chimneys will require compliance with fire safety

Particular attention should be paid to wooden structures. Non-flammable products must be used for work. This will prevent the roof from heating up and catching fire.

It is also necessary to comply with the requirements of SNiP, which indicate the size of the gaps between pipes and wooden parts in the CP. The popular UP design, which protects the chimney pipe from heat, looks like a box around the pipe. The box must be filled with non-flammable materials. You need to install a special umbrella over the chimney, which will prevent water from getting inside and minimize the blowing of winds into the attic roof. Since the tightness indicators in joints on a seam roof may be compromised, installing a UP in the valley is not recommended.

Types of roof ventilation outlets

Ventilation outlets operate in conditions of high humidity. In winter, this causes a lot of condensation to appear on the inner walls of the pipes, and under certain conditions it freezes, which reduces the effective diameter and negatively affects the technical parameters of ventilation systems. In addition, condensate flows through pipelines and can accumulate in large volumes. Such operating conditions are taken into account during the design and manufacture of devices; manufacturers make every effort to ensure stable and reliable functionality of roof ventilation outlets. Which ones exactly?

- The actual capacity of the exits significantly exceeds the design requirements for ventilation systems. The reserve is created to minimize the negative consequences of condensate freezing in the winter.

- The inner surfaces of the walls create minimal resistance to the movement of air flows. This also has a positive effect on the cost of maintaining the ventilation system.

Air flows through elements with minimal resistance

- Light weight and high strength indicators reduce the operating forces. Currently, roofs made of metal sheets are often found: profiled or metal tiles. The thickness of such coatings is only 0.45 mm; the material cannot withstand significant additional loads. Moreover, if they stagger under gusts of wind and create multidirectional dynamic forces.

- Resistance to negative climatic factors. The material used to make the outputs should not oxidize and withstand significant temperature fluctuations from minus to plus values. Do not be afraid of harsh ultraviolet rays, do not react to aggressive chemical compounds.

The material used to make the exits is extremely resistant to most negative factors.

Only a few manufacturers enjoy well-deserved respect among numerous consumers.

| The company's ventilation outlets are widely known in many countries around the world and fully meet stringent requirements for quality, safety and reliability. The company is located in Finland, and Vilpe Vent roof ventilation outlets have been on the market since 1998. They have a modern design and various color schemes, the elements are interchangeable, and special autonomous noise dampers are installed. This is very important when installing equipment on metal roofing. The manufacturer's minimum warranty is 10 years, but in practice the devices last 15 years or more. |

| Made from modified types of plastic with increased resistance to hard ultraviolet rays. The polymer has the ability to maintain plasticity even at significant negative temperatures - ventilation outlets are allowed to be installed in the Far North. The systems have an excellent appearance and are compatible with many architectural styles of buildings. They can be insulated or non-insulated, with electric fans, ordinary or rotary. The diameter and height are selected taking into account the initial data. |

Functional purpose and technological features

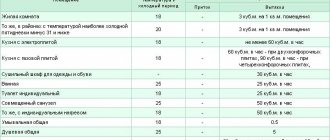

The task of any ventilation system is to maintain a fresh atmosphere in the house, remove foreign odors and substances that do not meet sanitary standards. Forced ventilation is rarely used in residential buildings. And for the natural movement of air to work correctly, it is necessary to create good draft in the exhaust air line. It is ensured by the optimal location of the outlet pipe above the roof and the correct calculation of its height.

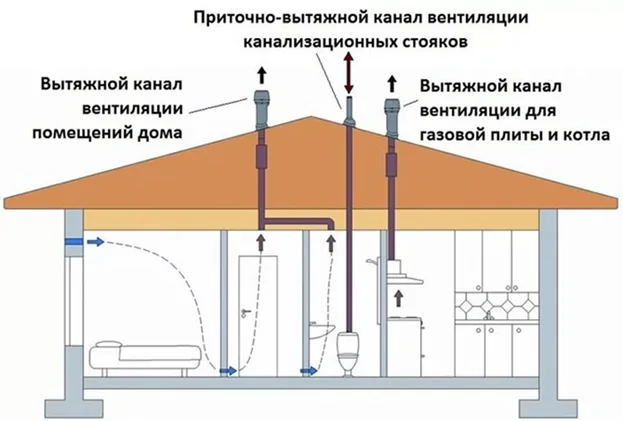

Complete ventilation of the house should perform the following tasks:

- ventilation of all rooms in the building;

- air removal from household appliances (gas stoves and boilers);

- sewer line ventilation.

It is optimal for each task to create a separate ventilation circuit with its own exit to the roof.

Functions of home ventilation

General recommendations for the placement of ventilation elements

Let's look at some general rules that are recommended to be followed when installing roof ventilation.

- When installing embedded elements, waterproofing aprons are used; the junctions between them and the roof surface are coated with mastic. Poorly performed waterproofing can lead to leaks in the future.

- Be sure to install protective grilles to protect the roof space from birds and debris.

- It is recommended to think through the number of necessary components in advance; it is also advisable to purchase them from the same manufacturer as the roofing material.

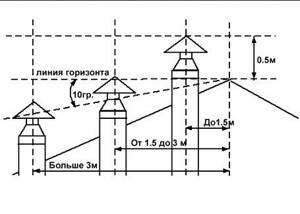

- The height of the ventilation pipe above the roof must be at least 50 cm. If the pipe is located at a distance of more than 3 m from the ridge, then its length must be at the same level as the ridge.

Determining the height of the pipe relative to the roof.

- In cold regions, it is recommended to insulate ventilation elements to avoid the formation of condensation and icing.

- Roofs with complex shapes require a large number of ventilation elements.

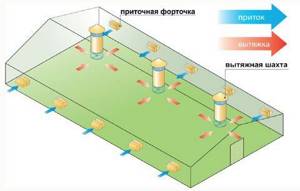

Ventilation shaft arrangement

The structure is usually similar to a cylindrical trunk. It is located strictly vertically and contains three parts:

- one large one – about 300x600 mm;

- two small ones - about 150 mm.

It is the large part that is the trunk, which crosses all floors of the building, from the basement to the attic. The design may be non-standard. Increased dimensions must be taken into account when selecting fans.

Through special windows located in rooms such as the kitchen or bathroom, polluted air enters not very large channels and, rising through them to a height of about three meters, ends up in a common shaft. Thanks to such a device, the spread of used air through the air duct from one room to another, for example, from the kitchen to the bathroom, and then into the rooms, is practically eliminated.

In outbuildings, say, farms or poultry farms, an ideal design for air circulation is considered to be a ventilation shaft near the ridge. They run the entire length of the building's roof in the direction of the ridge.

To block access to raindrops, an umbrella is mounted above the outlet of the box. As a rule, in natural air exchange structures a deflector is mounted directly at the mouth. When there are gusts of wind, a vacuum is created here, which contributes to increased traction. But first of all, of course, the deflector prevents the air flow from “tipping over” in the box. When calculating the system, the vacuum created by the wind is not taken into account.

Options with artificial air exchange, which help remove aggressive air impurities of the first and second classes, work somewhat differently: polluted air is emitted to a fairly significant height. This type of emission is also called a flare emission.

Pipe height

The size of the pipe located above the roof is indicated by SNiP:

- When installing a ventilation outlet next to a chimney, its height should be equal to it.

- On a flat roof, the height of the pipe must be selected taking into account its diameter, but within 50 cm.

- For a pitched roof, the distance of the ventilation outlet from the ridge is important: if the pipe is located further than one and a half meters, then its height should be 50 cm or more.

- If the ventilation unit is located at a significant distance from the roof ridge (from 3 meters and further), it is necessary to draw an imaginary line from the top point of the roof down along the roof. The top of the pipe should touch the conventional intersection line from the ridge to the horizon.

Choosing a location for the pipe

The installation of the pipe outlet to the roof must be thought out in such a way that it has a minimum slope or bend.

Ideally, the pipe should be installed strictly above the internal riser of the ventilation shaft. If this is not possible for any reason, it is advisable to use a flexible corrugated pipe to connect the nodes.

Fire safety

When organizing ventilation of a building, all rooms and floors are connected to each other by a network of channels and air ducts, which in itself is dangerous from the point of view of fire safety. Therefore, these elements themselves and the gaskets between them are made of materials that meet SNiP, according to which explosion and fire safety is ensured. In particular, the shaft is separated from the air duct by a partition made of non-flammable and moisture-resistant material.

Technical factors

The quality of functioning of the ventilation system depends not only on the materials that were used for its construction. Of great importance is the extent to which the completed design complies with existing standards and regulations. First of all, it is necessary to take into account the most important aspect - fire safety.

Metal roof ventilation

View of a metal roof

Ventilation of the roof of a metal tile house has some features.

Continuous ventilation is ensured during the installation of the roofing pie and consists in leaving a gap of up to 5 cm between the roofing material and the thermal insulation. The bottom layer of insulation is ventilated thanks to a 5 cm thick gap up to the sheathing. To prevent the wood from getting wet, a sealant is placed under the ridge.

The area of the ventilation slots at the eaves should be equal to the area of the ridge vents (the volume of inflow is equal to the volume of outflow). The total area of the vents should be 1% of the roof area. If during the design and construction of a house the ventilation of a metal roof is not thought out, there is an express method for ready-made roofs.

The basis of roof ventilation in this case is ventilation pipes and ventilation outlets. The height of the pipe should be 50 cm or more. For every 60 sq. meters of roof area, 1 pipe is installed as close to the ridge as possible. By the time of installation of the point ventilation outlets, the video of which we present, the metal tile roof must be completely assembled.

In areas with heavy snowfall in winter, pipes up to 65 cm long are installed. The junctions of the pipes with the roof are hermetically sealed. When the roof is flat and the slopes are more than 6 m long, ventilation connections are installed. The height of the junctions is from 40 cm above the roof. Instead of a regular pipe, it is sometimes more effective to use deflectors, shown in the video of metal roof ventilation.

Ventilation of the roof ridge under the metal tile is provided by a ridge board separating the two roof slopes. On one side, air flows out freely, preventing the formation of condensation.

Natural draft is used to ventilate the space under the roof. And it will work only if the number and location of ventilation outlets are accurately calculated.

Installation of point ventilation outlet

Point exits are suitable for ventilation of hip and pitched roofs of a small area. Complex roofs with several ridges are equipped with an exit at each ridge. The distance to the ridge should not be more than 0.6 m. It is not advisable to install two exits on one sheet of metal tiles so as not to weaken the structure.

When purchasing a ventilation outlet for a metal tile roof, the following parameters are taken into account:

- the profile of the lining must match the profile of the metal tile;

- pipe color;

- temperature restrictions for this instance;

- the kit should include installation instructions, linings, a template, fasteners, the pipe itself, as well as a passage element;

- The diameter of the pipe depends on the roof area.

The most important point in installing spot ventilation for a metal tile roof is cutting a hole of the required size and sealing the pipe. If the device is assembled correctly, in accordance with the instructions, then the junction with the roof will be insulated from rain or snow.

The tightness is ensured by silicone, which is used to treat the sealing circle. Next, the passage element is attached with screws from the kit and a pipe is inserted into it. The passage element is necessary to fix the pipe. To make the fastening reliable, a hole is cut in it a quarter smaller than the diameter of the pipe. Sometimes this unit is sold already assembled. The pipe must be installed vertically, which is checked by level. Now it is secured with screws and covered with decorative overlays.

Step-by-step installation instructions

The procedure for installing a ventilation duct on a roof structure is not too complicated. Anyone can easily do it, but to do this you need to follow these instructions:

- First of all, you should figure out where to install the passage unit on the roof.

- On the upper wave of the metal tile, you need to draw the contours of the future hole, applying the template that comes with the element itself.

- After this, you should cut a hole on top with a chisel and metal scissors, and also make several holes in the lower layers of the roofing pie.

- Following the template, you need to drill several holes for the screws.

- Then all that remains is to clean the roof surface from any remaining moisture and dust.

- A layer of sealant must be applied to the bottom of the sealing gasket.

- Then you need to place the gasket in the right place and secure the passage element in it. After making sure that the structure is secure and correctly positioned, you can begin fixing it. Screws are used for this.

- Finally, it is necessary to ensure the tightness of the ventilation outlet to the roof from the attic.

By following the above guidelines, you can perform high-quality, reliable and durable installation of the ventilation outlet. In this design, it will serve the owner of the premises for a long period of time.

Based on the above, there are practically no difficulties in installing a ventilation duct on the roof. If you draw up the correct project in advance, carry out calculations and study the installation instructions, the future ventilation system will work best. At the same time, the service life of the roof, which has gone through a lot of changes due to the appearance of a new unit, will not be reduced in any way. But for this you need to take the upcoming work responsibly and follow the basic installation rules.

Making a box

Some people are hesitant to make a chimney device themselves. However, there is nothing complicated about it. Therefore, anyone can make a metal casing. To do this, you can use step-by-step instructions.

Before work you need to prepare:

- Scissors for working with metal.

- Galvanized sheet.

- Drill.

- Compass.

- Regular self-tapping screws.

First you need to measure the hole between the rafters

and cut it out. If you intend to lead the pipe through the wall ceiling, then a hole must be made in it. After that, follow the instructions below.

- When the hole is cut, it is recommended to further strengthen its edges with support bars.

They will act as a support for the future box. - Cut a couple of blanks from a galvanized sheet, which should be 5 cm

.

The edges of the blanks must be bent at a distance of 5 cm at an angle of 90 degrees.

As a result,

two U-shaped metal strips will be ready. - These strips must be secured with self-tapping screws on both sides of the prepared hole in the ceiling.

- At the next stage, you need to prepare two more U-shaped strips,

which are fixed in the hole

overlapping

the already installed metal sheets. The result will be a continuous frame around the cut hole in the ceiling. - After this, you need to prepare the bottom for the structure. You need to cut a piece from a galvanized sheet, the dimensions of which correspond to the ceiling hole. Then, using a compass, mark a circle in the center for the hole for the chimney.

- From the center to the edge of the bottom you need to mark 4 fasteners with a 2-centimeter width.

Then cut them out and bend them at an angle of

90 degrees.

The result should be a metal plate with a hole and four strips for fixation. - At the next stage, the bottom is attached to the walls. A chimney pipe is inserted into the casing through the hole and secured with a clamp. The free space between the chimney and combustible materials is filled with a layer of insulation.

If you follow these instructions, it will not be difficult to make a box with your own hands.

In order not to disturb the overall design of the building, the box on the roof must be beautifully decorated using. To make it, you can use various materials, which are then decorated.

Exterior finishing

allows you to improve the appearance of a brick or metal chimney.

It should be noted that in such a design you can hide the ventilation and protect it from natural precipitation.

Metal chimney

.

But here you need to understand that the material can collapse at only a temperature of 40 degrees.

To avoid this, the metal pipe must be wrapped in foil insulator. And leave a small layer between the chimney and the pipe.

After this, the structure can be finished with stone, tiles or plaster. It should be noted that a metal chimney will last no more than ten years, after which the box will need to be dismantled. The device can also be made from wooden boards.

Brick chimney

To finish a brick device, you can use artificial stone: shell rock, sandstone, limestone and others. However, you need to have some experience working with such material. It is also necessary to take into account that not every stone is able to withstand high temperatures, so it is not recommended to do such finishing with your own hands, but to entrust it to a professional specialist.

A brick chimney can be decorated with tiles. Ceramic tiles are often laid on the roof, so this option is the best. To do this, you need to make a wooden frame onto which a special tile is attached using self-tapping screws. This finish will have a thickness of about 35 cm.

plaster to line the chimney.

, which is sold as a ready-made mixture. If cement slabs are used for the roof, the chimney can be decorated with the same material. The boards are resistant to UV rays and do not lose their color over time. In addition, cement slabs tolerate temperature changes well, which is very important.

It is important to understand that the protective casing for the chimney on the roof is an important part of the bathhouse and any other room. Fire safety will depend on the quality of work

steam room. If necessary, the manufacture and installation of the structure can be entrusted to qualified craftsmen who will quickly complete all the work for a small fee.

Technological roofing structures made from modern materials have high tightness and a long service life. They differ from less advanced predecessors in the absence of gaps, cracks and holes, which were not only the causes of leaks, but also served as natural ventilation. Therefore, multilayer roofs made of profiled metal, the construction of which includes thermal insulation, vapor barrier, and waterproofing, require the installation of a forced ventilation system. In this article we will tell you how to equip a ventilation outlet for metal tiles in order to extend the life of the roof covering and wooden elements of the roof frame.

The ventilation outlet for the roof is a device in the form of a small tube made of metal or plastic, the diameter of which is in the range of 30-100 mm, and the length is up to 50 cm. It is installed in close proximity to the roof ridge (no further than 60 cm) to provide heated air saturated with water vapor has a free exit from the interior of the house to the street. For forced equipment, 2 types of circuits are used:

- Roof ventilation. This system is designed to optimize the temperature and humidity in the roof ventilation gap. It solves the problem of dampening of the thermal insulation material and the wood of the rafter frame. Although the price of such a solution is low, it is rarely used to organize a ventilation outlet for metal tiles, since due to heating of the inner surface of the roof, an ice crust forms, which completely stops air exchange. To arrange roof ventilation, pipes are used, equipped with an elastic penetration and a deflector, of such a length that they reach the rafters.

- Cross ventilation. This scheme differs from the roofing one in that the ventilation outlets pass through the roofing pie and exit into the attic. The pipes used for the installation of through ventilation operate as coaxial ones; the price for such products is higher, but the high efficiency justifies these costs. The pipes have a special design - 2 independent circuits remove excess moisture from the roofing pie and ensure air circulation in the attic.

Important! A universal ventilation outlet for a metal tile roof is a plastic or metal pipe with a diameter of 50 mm with a protective deflector at the head. The price of such products depends on the material, size and additional functions offered by manufacturers. Ventilation outlets equipped with mechanical or electric fans and air filters are considered effective.

Methods for calculating pressure loss in a ventilation pipe

In addition to the height of the pipe, the pressure loss occurring in the duct is also calculated. Several formulas are used for the calculation:

- Air pressure loss can be calculated using the formula P = R*L + z . In this case, R is the pressure loss directly due to friction, z is the pressure loss due to local resistance, and L is the length of the air duct.

- To calculate the pressure loss for a round duct, you need to use the formula Ptr = (x*l/d) * (v*v*y)/2g . The notation in this formula is deciphered as follows: x is the coefficient of frictional resistance, g denotes the acceleration of gravity (it is equal to 9.8 m/s2), d is the diameter of the air duct, y is the air density and v is the air flow velocity.

Operating principle and secrets of mine efficiency

The principle of operation is quite simple, but at the same time very effective - through special windows, the exhaust air enters small channels, where, rising about three meters, it smoothly passes into a large shaft. Such a device almost completely eliminates the transfer of polluted air from the room to other rooms with subsequent distribution throughout the building.

To prevent snow and raindrops from penetrating into the air duct, it is covered with a special umbrella on top. Designs with natural air exchange are additionally equipped with a deflector, which, during gusts of wind, creates a vacuum that enhances traction. In addition, it prevents the “overturning” of air masses inside the box.

It is worth remembering that when carrying out calculations, the vacuum created by the wind is not taken into account. If the ventilation of the mine is carried out forcibly with the removal of impurities included in the first and second categories, then the exhaust air is emitted to a significant height. This technology is also called flare technology.

Types of chimney boxes

Diagram of the roof passage assembly.

Removing a pipe is a rather complicated process, since improper installation of ventilation can lead to unpleasant consequences, including a fire. Therefore, before removing a pipe, it is worth deciding on its design and how to carry out the withdrawal safely.

Many developers forget about such an important detail as the box. This term refers to two completely different elements of the roof: a device for installing a chimney and a decorative component.

The pipe that allows smoke to be removed from the room is installed both inside and outside the room. In some cases, for example, when installing a heating system in a steam room, it is more appropriate to use the first option: this way more heat will be retained. But then the pipe will have to be brought out through the roof. That's why a box is needed.

Thanks to this device, the temperature will not affect the ceiling rafters, the coating of metal tiles and hydro- and vapor barrier films. It’s good if the hole is planned during the construction of the house, in this case you can make a separate rafter system for the outlet pipe.

The distance from the surface of the pipe to the combustible material depends on the height of the pipe, but in any case it is within 15-25 cm. Then the free space around the pipe can be filled with dense basalt wool or other material that is resistant to high temperatures. This will eliminate the need for additional waterproofing.

Return to contents

Why does the check valve sometimes not work and close?

On the kitchen side, a check valve is mounted on the tee. In the factory version it will be quite long. In this case, it is better to shorten it so that this “gun” does not stick out too much.

The valve is inserted inside a section of a standard air duct d-125mm, and this air duct is put on and siliconized onto the tee.

If this whole structure seems too cumbersome to you, and the protruding pipe with the valve is not very aesthetically pleasing, you can do it a little differently. You make the air duct not with a round pipe, but with rectangular channels.

In this case, you install the above check valve on a straight section, as close as possible to the turn.

You can't achieve a factory connection here, so you'll have to farm collectively. Buy a rectangular tee with a round outlet on one side. Next, this round timber is cut off and a check valve is glued in its place.

The valve is placed strictly at an angle (2 degrees). Otherwise, it will open every once in a while or not open at all.

Many people have encountered this problem and easily solved it this way.

The damper itself is also mounted with a vertical deviation. The upper turning point, based on the hour dial, is at 13.00 (1 o'clock), and the lower one is at 17.00 (5 o'clock). This is if your flow direction is from right to left.

Otherwise, the circle is placed at the 11 o'clock - 7 o'clock position.

For more reliable operation and stable opening of the damper, you can stick some kind of weighting material (no more than 2 grams) on one side. Glue it close to the edge.

By the way, do not throw away the previously cut round pipe. It is tightly inserted onto the valve from above, after which a decorative grille diffuser is mounted on it.

What nuances might there be with this method? If your hood stands exactly above the entrance to the ventilation shaft, and the duct pipe goes straight, without any turns in the horizontal plane, then the valve installed on such a straight section does not work normally, at least at 1st speed.

You will simply have nowhere to get the increased pressure to close it. The air will fly through this “turn” in a straight line. You definitely need an angle.

The valve cover and its rotating mechanisms are easy to clean and do not be afraid of them becoming overgrown with grease. For this to happen, you will have to fry huge wild boars on the stove and stew them in your oven for several hours a day, no less.

If you don’t want to see a protruding “hollow” under the ceiling at all, then, as an option, you can install a tee so that the middle elbow rests against the wall, otherwise, where the valve is located, it would look to the side. In this case, also close the hole with a decorative cover.

Everything will look much nicer. However, due to the additional rotation, the performance of natural ventilation will deteriorate slightly. And the grill will reduce it by another twenty percent.

In addition, it will no longer be possible to clean the channel by hand or with a vacuum cleaner. But many do this deliberately and even hide the entire structure in a wooden or plastic box.

As they say, beauty requires sacrifice.

Self-construction of chimneys

The technology for installing a smoke duct has much in common with the installation of a conventional air duct. The difference lies in the presence of more stringent requirements for the operation of the chimney. Therefore, the process of arranging pipes for furnaces requires accurate calculations, selection of building materials, fasteners, refractory putties and other things.

Modular pipe

In the case where the chimney is planned to be laid in the wall of the house, this nuance should be taken into account at the stage of wall construction, otherwise the hole will need to be punched using a jackhammer. It is possible to install a stove duct in an already equipped ventilation duct, but as a result, the fire safety of the smoke exhaust structure will significantly deteriorate.

To implement a hidden pipe scheme, you need to use the services of an experienced architect, since during the operation of the furnace, temperature deformations are possible - the dimensions of the channel increase from the influence of hot gas, thereby exposing the walls to destructive processes.

Chimney sections inside load-bearing structures can be constructed from multilayer blocks. They are placed over the entire surface of the wall, using a temperature-resistant adhesive for fixation. This material is able to level out thermal deformations, thanks to damper gaskets, and thereby ensure the integrity of the building.

The main advantage of this design is that there is no need to insulate the pipe on the roof of the house - the channel will go outside above the roof level inside the gable.

Mounted steel chimney

Installing steel chimneys does not require special skills or a lot of time, so they are often preferred by homeowners, and such structures are relatively inexpensive.

It should be taken into account that:

- Any metal pipe must consist of at least two parts and must be disassembled accordingly. After a few years, the first section burns out from high temperatures, not the entire structure will need to be replaced, but only a section of it.

- Where the chimney will be brought out through the roof and wall, fire-resistant insulation is laid, otherwise the building may catch fire.

- The section of the pipe located in an unheated room must be properly insulated so that cold air masses do not cool the gas and thereby affect the performance of the heating unit. As a result, condensate will not collect on the surface of the pipe and it will not rust.

- It is imperative to waterproof metal pipes using non-combustible materials.

Install the metal shell structure in stages:

- The first elbow is placed on the screen pipe or on the outlet of the furnace air duct.

- The second ring is brought out through the attic into the room and fixed on a fire-resistant spacer.

- Connect both knees.

- The third segment is led out into the attic through a through opening in the roof. The place where the pipe exits to the street is covered with a spherical casing.

Root brick pipe

This type of brick stove chimney will last for many years. The main pipe is installed on a foundation, which is laid separately during the construction of the basement floor.

The installation technology of this chimney is more complex than that of a mounted metal structure. The fact is that the main pipe must withstand the longitudinal load from the weight of the entire unit, so it is laid out from baked bricks.

Features of the structure:

- To build a chimney channel, leave a hole the size of a brick or half a brick. To lay one layer, 4-6 bricks will be enough.

- The layers are laid out so that the bottom joining seam of the row is under the whole brick.

- Before the chimney pipe is brought out through the roof, a special module is made in the place where it passes through the ceiling to shift the axis of the section piercing the roof relative to the axis of the part of the chimney located in the room.

The design of this type is complex, and it is installed when there are no other options.

External chimney

A pipe mounted from metal or asbestos-cement modules is installed along the facade of the building, moving in the direction from bottom to top.

External structures have the following features:

- in the place where the pipe enters the building, a hole is made, through which a horizontal segment of the chimney is then brought out;

- the junction of the horizontal and vertical sections is designed in the form of a tee, one part of which is closed with a plug. This element is used when cleaning the chimney;

- the pipe is attached to the facade using detachable metal clamps. The lower part of the chimney is strengthened with a superstructure specially erected on a separate foundation.