Expert answers: 0

Chimney passage through a soft roof Flexible Tilercat tiles Underlayment carpet for a soft roof Installation of a roof window in a soft roof

A soft roof is not metal, it does not conduct heat. But just a thin layer of bitumen coating is not enough to keep the house warm. How to insulate a soft roof?

It makes sense to install a cold roof if the house is used exclusively during the summer season. In other cases, a soft roof with insulation is installed.

How to insulate a soft roof?

Regardless of the type of roof (flat or pitched), it is preferable to insulate a soft roof with basalt wool. Its distinctive property is non-flammability.

This is important because:

- in the private sector wooden buildings predominate;

- the rafter system of a pitched roof is usually wooden;

- Most roll coverings for flat roofs are either fused or laid on heated bitumen.

Expanded polystyrene insulation for roofs is not the best option: all types of EPS are flammable to one degree or another and emit toxic substances when burned. Also, complete insulation with this material is impossible!

The downside of mineral wool is its hygroscopicity. But if you use an absolutely sealed bitumen coating and install full ventilation to remove condensate, this drawback will not appear.

The advantages of basalt insulation for soft roofs include affordable price and ease of installation.

Types of roofs

There are two types of roofs - used and unused. If insulation is carried out on a roof that will subsequently be frequently used, then after completion of the thermal insulation work it will be necessary to make a concrete screed.

Conventionally, insulators can be divided into three types according to the degree of development of the construction industry. The material of the past is mineral wool, which, however, is often used today. The most popular thermal insulators are polystyrene foam and extruded polystyrene foam. The future lies with polyurethane foam - it has been used in the West for a long time, but in our country it has not yet gained much popularity.

Using polyurethane foam for insulation.

How to insulate a soft roof made of flexible tiles

When installing complex roofs (round, curved, attic), the most suitable material is flexible tiles. It is plastic and follows the contour of the base. When designing attic superstructures, installation is achieved with a minimum of waste. But insulating an attic with a roof made of soft tiles is even more important than roofs with any other configuration, because... Due to attic windows, heat loss increases.

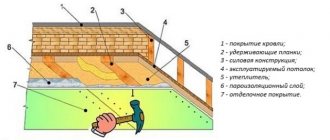

Using the example of an attic, let’s look at the structure of a roofing pie with insulation:

- top layer - tiles;

- underlay carpet;

- continuous base for covering - sheets of moisture-resistant plywood;

- sheathing, boards 10 by 2.5 cm or 7.5 by 2.5;

- counter beam 5 by 5 cm. Necessary for complete ventilation of the under-roof space, because the absolute tightness of the bitumen shingles prevents the free drainage of condensate from the house;

- windproof (aka waterproofing) membrane;

- rafters with insulation placed between them;

- if you are laying additional insulation, you need to put another 5 by 5 beam on the rafters from the inside;

- vapor barrier film;

- ceiling panels.

Installation sequence:

1. The slabs are installed between the rafters, spaced apart, close to each other.

2. Lay a hydro/windproof film on top. Adjacent strips are laid with an overlap, the joints are taped with mounting tape. Fastening - with a stapler to the rafters.

3. Counter battens are filled along the rafter legs. With this installation direction, air will move freely under the roof from the overhang to the ridge.

4. Sheathing boards are laid parallel to the ridge. The total thickness of the board with counterbeam is 10 centimeters.

5. Moisture-resistant plywood or OSB is placed on top of the board with joints spaced apart. Fastening with galvanized nails or self-tapping screws.

6. An underlay carpet and covering are laid on top of the plywood in accordance with the instructions for the model.

7. An aerator is installed on the ridge and covered with ridge tiles on top.

8. From the attic side, a vapor barrier film is sewn to the rafters - with an overlap, the joints are taped.

9. Sew up the attic ceiling with clapboard, boards or other material.

note

For pitched roofs, it is recommended to choose basalt insulation 15 centimeters thick, with a density of 30-40, so that the layer does not sag over time.

Installation elements

The design of a single-layer system includes the following elements:

- floor slab on which vapor barrier is laid;

- roof insulation and roofing material are laid on top;

- The last layer is the telescopic roofing fastener.

The two-layer soft roof system has the following structure:

- floor slab on which vapor barrier is laid;

- bottom and top layers of insulation;

- roofing material and insulation fasteners are placed on top.

Installation of a soft roof is carried out with a special type of tile - flexible tile, which is also called “shingles”. This material comes in the form of flat sheets 1*0.33 m in size and with curly cutouts along the edges. Tiles can be of different shapes and colors, which makes the roof interesting in design. The basis of the tiles is felt or fiberglass impregnated with bitumen. The upper part of such tiles is covered with basalt granulate (mineral chips), which protects from UV rays.

Installation of soft roof insulation is carried out as follows. First, the base is prepared - an exhaust hole is created at the top and an opening for air flow at the bottom of the roof. Such ventilation is necessary to remove moisture from the insulation and roof, and regulate temperature (protection against hypothermia and overheating). With a slope of 15%, the roof is laid in 2 layers, with a slope of 5-15% - in 3 layers.

Next, you need to lay the base in the form of moisture-resistant plywood or bridging boards with a moisture content of no more than 20%, and the length of the boards must be at least 2 spans between the supports - the joints are located on the supports.

The lining layer is laid on the surface of the roof with an overlap of at least 10 cm, the seams are sealed with glue, and the edges are hammered with nails at a frequency of 20 cm. The next stage is the installation of eaves strips, which protect the eaves overhangs from moisture and are fastened with an overlap of 2 cm with roofing nails frequency of 10 cm.

The waterproofness of the lining layer is ensured by laying a valley carpet - the edges are secured with bitumen mastic and roofing nails. Finally, after these measures, a rolled soft roof is laid.

When laying, to remove steam and prevent condensation, a roof aerator is installed - a pipe with a diameter of 63-110 mm, covered with an umbrella, which protects from precipitation inside the pipe. A hole is made in the roofing carpet and ties to the insulation.

Mastic is applied to the lower base of the aerator and the aerator is attached to it to the roof, and then further strengthened with self-tapping screws. Waterproofing is additionally laid on the base of the ventilation pipe.

Our works

Installation of flexible tiles in Vidnoye

Reconstruction of the roof in the Serpukhov region

Cottage community "Losiny Park"

Installation of soft roofing in Myshetskoye

Types of roofing pies for soft coverings

Soft coverings are installed on various buildings and structures; they can be rolls or shingles. For residential buildings, asphalt shingles are most often used. Depending on whether the attic space will be residential (attic) or non-residential, a specific type of roofing pie is selected. Each type has its own characteristics, installation technology and design features.

Bituminous shingles

Table. Types of roofing pie.

| Type of roofing pie | Brief description and technical specifications |

| Cold | The simplest and cheapest pie, used during the installation of cold roofs. Provides reliable waterproofing of the building, but does not retain heat. |

| Warm | Used during the construction of attic spaces, it requires strict adherence to the technologies recommended by the manufacturers. A warm pie consists of several layers, each of which performs its own tasks. The cost is several times higher than the price of a cold pie. |

The article will give step-by-step instructions for making both types of pies for soft roofing.

Models and sizes of bitumen shingles

Prices for various types and manufacturers of bitumen shingles

Bituminous shingles

Technology of rolled soft roofing with insulation

The base of a flat roof can be made of reinforced concrete slabs, thick corrugated sheets with high corrugation, wooden boards:

- corrugated sheeting should be galvanized and corrosion-resistant;

- wooden floors must be treated with antiseptics;

- on a reinforced concrete slab, in order to avoid its further destruction, all cracks, cavities, and irregularities must be repaired.

Procedure for assembling the pie:

1. Lay a vapor barrier membrane.

2. Lay basalt wool slabs. Fix to the base with dowels or self-tapping screws.

3. If there is a reinforced concrete slab at the base that can withstand the load of a cement-sand screed, a waterproofing film and screed 2-10 cm thick are placed on top of the insulation.

4. Lay a bitumen roof over the screed in 2-3 layers.

If the floor is wooden, it will not support the weight of the screed. In this case, it is recommended to choose a polymer membrane (PVC, EPDM, PVO) for the finishing coating. A layer of geotextile is placed on top of the insulation, and a membrane is placed on it. Fastening is carried out mechanically.

How to insulate a roof made of soft roofing in two layers? The same, just put it in two layers of slab. They should be laid with joints spaced apart. For the bottom layer, choose insulation of greater thickness, for the top layer - thinner, but with a higher density.

In addition to its main purpose, basalt insulation for soft roofs can be used to tilt a flat roof. In this case, the slabs are installed on a slatted frame. The slope is obtained by using slats of different heights.

If you want your warm soft roof to serve well for many years, order installation from us at STM-Stroy.

Our company has twenty years of experience in roofing work, we know all the subtleties and nuances of installing insulation. We will install a soft roof with insulation for you in full compliance with the technology, quickly and inexpensively.

+7(495) 241-00-59

Installation and repair of roofing and facade coverings from economy to VIP class

Calculate online

my experience is your saved money and nerves.

I advise everyone who contacts me, even if you later leave to join another brigade. Ask questions, don’t be shy, I answer everyone - it’s free

+7(495) 241-00-59 I am available for calls 7/24 - I will be happy to help you, please contact me!

Typical installation methods

Soft roofs are thermally insulated according to two standard schemes. The first is single-layer thermal insulation. The second is two-layer insulation. Let's take a closer look at each scheme.

A single-layer heating system is the destiny of old and restored structures.

This type of insulation is used mainly during renovation or reconstruction of buildings. The thermal insulation layer has a device made of materials of uniform density.

Operated roofs require the creation of a screed made of concrete.

Two-layer insulation systems are the standard for new buildings - today new buildings rarely get by with just one layer, as was previously the case. Such systems include two layers. The bottom layer is considered the main one and materials with the highest possible thermal resistance are used to create it. The thickness of the products ranges from 7-17 cm. Strength, on the contrary, is low.

The task of the upper heat-insulating layer is to redistribute mechanical loads. Moreover, this applies to the entire heat protection system being installed. The thickness of the material is 3-5 cm. But the compressive strength, which was discussed above, and the density are much greater than that of the lower layer.

The two-layer scheme is a vivid example of when each element performs a specific function, which makes it possible to significantly reduce the weight of the roof. The overall design does not place high loads on the building and at the same time prevents heat loss.

Additional materials on the topic

Lightning protection on soft roofs

More details

Cleaning soft roofs from moss

More details

Ventilation of soft roofs

More details

Your feedback, comments, questions

Dear visitors! We will periodically answer your questions in the comments as we are busy. In order for us to respond to you promptly (within an hour), you can: call, write a personal message or leave a request for a free consultation by phone.

Roofing pie: what is it?

A roofing pie is a basic structure of a soft roof, which in a roof fills the space between the outer and inner edges (in the rafter frame).

The roofing pie consists of various materials layered on top of each other. Each layer performs a specific function. The name of the structure is due to the layering.

Roof pie under soft tiles allows you to increase waterproofing properties and additionally insulate the roof. A special waterproofing layer increases the degree of moisture resistance.

The number of layers in the pie depends on the type of roof - for an insulated roof, more are required.

Types of roofing pies

There are several types of soft roofing. When arranging a roof, you need to have an idea of the features of each of them, since the designs for different materials can vary significantly.

More recently, there was one type of soft roof on the Russian market - roofing material, which does not have a very aesthetic appearance. Now the situation has changed.