A humid environment poses a great danger to buildings and renders even large-sized structural parts of buildings unusable. The roof and foundation are considered to be the most vulnerable to the influence of water.

The roof primarily suffers from rain, snow and melt water. The foundation is from groundwater. A foundation with a porous structure without an additional protective layer will not be able to effectively withstand aggressive influences.

For this reason, special protective substances and solutions are used to waterproof the roof and foundation. Today, one of the most popular and reliable protection options is welded moisture insulation.

What is built-up waterproofing?

This is a subtype of adhesive insulation, which is applied to the surface by melting and gluing the outer layer under the influence of heat.

Protective raw materials are applied to the base quite simply. After hardening, a reliable protective layer appears that can last for decades. It has good resistance to external pressure (compression), but adaptation to internal loads is worse. Therefore, the material is more often used for roofing.

| —Installation of fused roofing— |

The substance can also be used as a roofing coating

,

foundations

of buildings, for horizontal and vertical protection from water, including shut-off,

for the floor

it is necessary to subsequently install a pressure screed. In addition, it can be used to protect OBS materials. Rarely used for ceilings and walls.

| Roofs | Foundation vertical, horizon | Paula |

Internal structure of built-up waterproofing (sectional diagram)

| Roofing on corrugated sheets | Foundation | Floor |

| 1 — Fused material 2 — Waterproofing material 3 — Insulation layer 1 4 — Insulation layer 2 5 — Vapor barrier film 6 — Telescopic fasteners 7 — Profiled sheet 8 — Double-sided tape | 1 — TECHNOELAST TERRA 2 — Primer TechnoNIKOL No. 01 3 — PLANTER geo membrane 4 — Foundation wall 5 — Drainage pipe 6 — Transitional side (fillet) 7 — Engineering preparation 8 — Fasteners for fixing slabs 9 — Swelling cord 10 — Backfill soil | 1 - Reinforced concrete floor slab 2 - Waterproofing under the screed 3 - Tile adhesive 4 - Tiles |

Types of built-up waterproofing

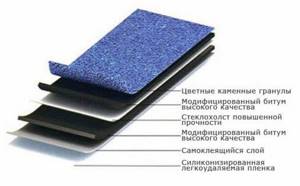

This type of waterproofing has several polymer layers, compositions made of bitumen or containing bitumen, applied to the base.

Fused moisture insulation impregnated with pure bitumen is the least durable and easily collapses under the influence of UV rays and sudden temperature changes. Bitumen becomes brittle, loses its plasticity, and begins to crumble.

Such disadvantages are absent in bitumen-polymer insulating materials. Here, bitumen is strengthened with the help of additional polymers, which makes it possible to maintain the strength characteristics and ductility of the base under the influence of external negative factors.

For polymeric materials, thermoplastics and rubber that have undergone a vulcanization procedure are used. They are highly resistant to the influence of chemically active substances, UV radiation, rain, snow, frost, etc. They are practical and easy to use, ensuring the durability of the protective coating.

The materials are produced in the form of rolls of built-up moisture insulation, which consists of several layers: 1. Protection is located at the bottom. 2. Next comes a bitumen, bitumen-polymer or polymer binder layer. 3. There is fabric raw material in the middle of the material. 4. After that, layer “2” again. 5. And finally, protection is placed, as in layer “1”.

Waterproofing can be made from fiberglass fabric or polyester fiber.

Fabric with fiberglass comes in two types: - Woven (fiberglass);

— Non-woven (fiberglass). Fiberglass raw materials are affordable, yet they are very durable and have high resistance to tearing. The downside is that the elasticity is not the best.

Polyester materials are included in the category of non-woven substances. Another name for the raw material is polyester. The substance has excellent tensile strength and ductility. One of the advantages of raw materials is the high price.

All types of deposited materials from TechnoNIKOL Corporation.

Properties and characteristics of rolled roofing

The built-up roof is held on the surface due to the bitumen that is applied to the underside and the heating of the primer.

Positive qualities of euroroofing material:

- long service life;

- durable and elastic material;

- waterproof;

- resistant to temperature changes and deformation.

Allows you to protect the building from precipitation, reduce heat loss, and also reduce the degree of heating during the hot seasons of the year. Can be used even in harsh climatic conditions.

One of the most popular waterproofing materials is TechnoNIKOL Uniflex HKP slate. It has excellent performance characteristics, a long service life (15-25 years) and is laid using simple technology; it is absolutely waterproof.

On the reverse side there is an indicator showing the degree of heating. As a result, it is impossible to make a mistake with the temperature during installation. In order for the service life to be as long as possible, a roof slope of more than two degrees is required.

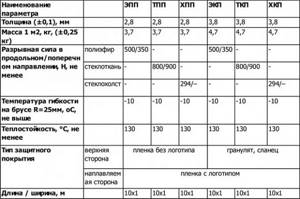

Markings are used to differentiate waterproofing materials. Depending on the type of base, TechnoNIKOL overlay coatings are of the following types:

- E – polyester;

- T – fiberglass;

- X – fiberglass.

This designation appears first. After it comes a description of the component used as the top coating. It could be:

- P – film;

- K – coarse crumb;

- M – fine-grained sand.

In third place is the type of coating applied on the underside of the material being deposited:

- P – film;

- C – self-adhesive layer;

- B – ventilated layer;

- M – fine-grained sand.

For example, CCP means that the waterproofing is made of fiberglass, covered with coarse chips on top, and a film is glued to the back side.

Euroroofing material, on the upper side of which there is a film, can only be used as a substrate. For the finishing coating, insulation with coarse granular coating is used.

How to transport and store rolled material

Storage conditions for deposited coatings: - vertical placement;

— protect from UV radiation; - do not overheat the material; - keep away from moisture. If you do not adhere to storage rules, the moisture-proof properties of the protection may be impaired.

An example of storing material on a roof and installing a roofing pie.

Transportation of rolled material must be carried out in a horizontal or vertical position in a truck with a closed body. When transporting rolls horizontally, no more than five layers are allowed. Vertical - no more than two.

Technology for laying fused roofing "TechnoNIKOL"

Laying a soft roof from materials from this manufacturer can be done mechanically or by fusing onto a pre-prepared base.

The first of them is used to cover pitched roofs. The finishing layer is fixed with polymer-bitumen mastics and galvanized steel nails.

The fusing method is used when installing flat roofs and consists of melting the bitumen layer with a gas burner while simultaneously rolling it onto the surface to be covered with rollers. Laying is done from the lowest point of the roof. These are usually drainage areas.

The roll is rolled onto an insulated surface

Video: how to install a fused flat roof

https://youtube.com/watch?v=wofS8o7z9E4

Requirements for the surface under a fused roof

The base for installing such a finishing coating must meet certain requirements. Low-slope and flat roofs are most often built on a concrete base. The requirements for their surface are:

- Thermal joints must be installed between the roof slabs to compensate for thermal expansion when heated during operation. The gap size must be at least 5 mm; the gap must be filled with plastic waterproofing material.

- There should be no protrusions on the roof surface more than 5 mm high, but only smooth ones. All elevated surface elements must be cut down mechanically.

- Cracks or potholes must be carefully repaired with cement-sand mortar after preliminary cutting and cleaning of the damage.

- Oil stains are not allowed. If any are found, they must be removed with a solvent.

Sheets of moisture-resistant plywood, OSB boards and other similar materials are often used as a base for the finishing coating. Laying a fused roof over such substrates is dangerous due to the high risk of fire. Therefore, before starting work, careful surface treatment with fire retardant compounds is necessary. Before installation, it is recommended to ensure that you have a fire extinguisher.

Find out more about the design, installation technology and operation of the Technikol soft roof from our article - The Path to Perfection: DIY Technikol soft roof.

Before fusing the roofing material, the roof surface must be thoroughly cleaned of dust and debris using an industrial vacuum cleaner.

Work can be carried out in dry, windless weather at temperatures from -5 to +25 degrees. The roof surface must be clean. The ideal air temperature is 6 degrees with a humidity of about 80%. If this rule is not observed during work, it is permissible to use a hair dryer to additionally heat the surface of the slabs.

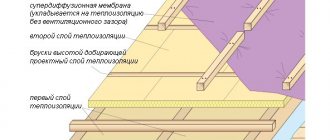

The roofing pie includes insulation, vapor and waterproof films

Forming a roofing pie with TechnoNIKOL film

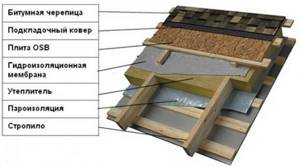

The roofing pie is a multi-layer structure designed to reliably protect the interior of the house from precipitation and wind. It is formed depending on the characteristics of the base. For a wooden roof, the pie may consist of the following elements (from top to bottom):

- Soft roofing material "TechnoNIKOL".

- Lining made of chipboard, plywood or OSB.

- Lathing, the design of which depends on the type of the previous layer.

- Waterproofing made of membrane or polyethylene film.

- A layer of insulating material with a thickness that depends on the climatic conditions of the construction region.

- Internal lathing for thermal insulation.

- Vapor barrier material.

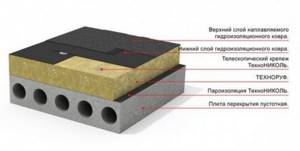

When installing a roof over a concrete slab, the roofing pie is formed differently:

- Finish coating from TechnoNIKOL.

- Slope (creation of guaranteed slopes in the required directions) using expanded clay concrete or cement-sand screed.

- Thermal insulation.

- Vapor barrier membrane.

Fused roofing is effective only if there is a roofing pie

Video: installation of a roofing pie under a fused roof

Installation of built-up moisture insulation

Welded hydraulic protection guarantees reliable and durable operation only if the installation rules are followed and preparatory work is carried out.

Preparation of the base: 1. The working base should be as level and smooth as possible. 2. It is necessary to cut out and polish all protrusions, angularities, concrete sagging, remove protruding reinforcement, etc. 3. Microcracks, cracks, cavities must be filled with cement-sand mixture and leveled. 4. The smoothness of the base is controlled using a rod and a measuring tape. The differences should not be more than 0.5 centimeters along the slope of the base and 1 centimeter at an angle of 90 degrees to the slope. 5. Before installation, the base is well dried.

After drying, the surface is checked by covering it with plastic film. If condensation appears on the film during the day, then the surface is not dried enough. If this is not done, the moisture-proofing coating will swell and quickly become unusable.

To speed up drying, it is recommended to use: - acetone (can be applied with a rag) and drying with a hair dryer; — blowing off the base using an air gun; — deformation seam areas are equipped with heating laces; — blowing the surface with air from the compressor unit.

After leveling and drying, the surface must be treated with a primer. Often a ready-made primer made from bitumen is used. You can make a primer yourself; for this you use bitumen and a volatile solvent. You can also use bitumen mastic, which is diluted to the desired viscosity.

To apply the primer, use a brush, roller or spatula. The thermal insulation layer of protection is primed using hot bitumen mastic. The primer material becomes dry within a period of 30 minutes to 24 hours (depending on the level of humidity and ambient temperature).

Laying technology step by step

In order for the roof to last as long as possible, it is recommended to buy TechnoNIKOL fused roofs made from polymers and fiberglass fabric. Products coated with large and small grains are used as a finishing layer.

You can install euroroofing felt on the following types:

- reinforced concrete slabs (without screed);

- lightweight concrete;

- mineral wool (without screed);

- cement-bonded particle boards, asbestos-cement sheets with a thickness of 8 mm or more and other building materials laid in 2 layers;

- monolithic screed.

The technology requires careful preparation of the roof and all the parts on it - ventilation pipes, parapets, and so on. If there are elements built from brick or other block materials, then they should be plastered with a cement-sand mixture of grade M150 at a distance of 25 cm from the base.

Before laying TechnoNIKOL, the roof is cleaned of debris, dirt, old coatings and oil stains. Protruding parts, reinforcing bars and others are removed as they can damage the waterproofing. Deep potholes and cracks are sealed with cement-sand mortar grade M150, small ones are covered with bitumen mastic.

Work begins only after the base has become completely dry. You can check the humidity level with special equipment, for example, a moisture meter, or put plastic film on it for 12 hours or 24 hours. If there are no drops of water on it, then the roof is ready for treatment.

Installation should only be carried out on a completely flat plane so that the material adheres tightly to the entire surface. In areas where vertical structures are adjacent, it is necessary to install fillets with an inclination angle of 45°. They can be made from mineral wool or cement-sand mortar.

Technology:

- The cleaned surface should be treated with a primer. It will increase the degree of adhesion to euroroofing felt. To do this, you can buy a ready-made bitumen primer and apply it with a roller or brush. Installation begins only after the base has completely dried.

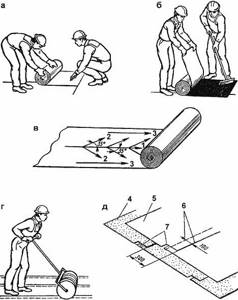

- Laying the first roll of TechnoNIKOL overlay coating begins from the bottom of the roof. First, it is rolled out and the position is adjusted. After this, one edge is heated with a burner so that it sticks tightly and rolled back.

- While heating the insulation and roofing, slowly roll out the roll, moving forward, and press it down with a soft roller. The edges need to be heated especially well. The burner is held at such an angle that it simultaneously heats the euroroofing material and the roof.

- After placing the first sheet, check the quality of adhesion. If there are peelings, they are lifted with a spatula, heated again and pressed down. It is not recommended to walk on newly laid material, as this will leave dents on it.

- The next sheet is mounted on top of the previous one with an overlap of 8 cm at the edges and 15 cm at the end. The joining is carried out so that water does not stagnate or flow in the places of overlap.

If the roof has already been covered with euroroofing felt and it remains in good condition, then it is enough to put 1 new layer on top. 2-3 layers are fused onto foundations without waterproofing. When laying in several layers, it is necessary to ensure that the joints do not coincide.

You can make a primer for processing yourself. To do this, mix bitumen with a solvent (gasoline) in proportions 1:3 or 1:4.

If a bubble has formed on the surface of TechnoNIKOL, it is carefully pierced and air is released, after which it is heated and pressed firmly. On old coatings, blisters are removed by making a cross-shaped cut. The hole is cleaned and left to dry, after which the cut site is covered with bitumen mastic and sealed back.

Cost of work and materials

The price of a built-up roll roof depends on its brand and characteristics. The cost is greatly influenced by the type of base. Polyester is more expensive than fiberglass fabric products. The lower the prices, the shorter the service life.

| View | Price per m2, rubles | |

| Technoelast | TCH | 160 |

| EPP | 170 | |

| HPP | 115 | |

| Uniflex | HKP | 110 |

| ECP | 140 | |

| EPP | 130 | |

| HPP | 100 | |

| Bikrost HPP | 60 | |

| Linokrom HPP | 65 | |

| Cost of work per m2 | ||

| Installation in 1 layer | From 110 | |

| In 2 layers | From 220 | |

| In 3 layers | From 330 | |

| Flooring for parapets and walls, height up to 50 cm | From 120 per 1 linear meter | |

You can install a fused roof from TechnoNIKOL yourself, the main thing is to strictly follow the instructions from the manufacturer. The quality of the final result largely depends on preparation. If the base is thoroughly cleaned and properly primed, the waterproofing will be installed as tightly as possible.

Safety rules must be followed. The operator should wear gloves, goggles and clothing not made of synthetic fabrics so that if hot bitumen or fire accidentally gets in contact with it, a fire does not occur, this will help avoid burns. Work is carried out in dry weather. Euroroofing material should be stored only in a vertical position and at a remote distance from heaters; it should not be exposed to water or sunlight.

Welded roof waterproofing

When creating a waterproof coating using weldable raw materials, it is important to consider what type of base it will be installed on.

Traditionally, the base is: - reinforced concrete slabs with seam sections filled with a high-grade sand-cement composition; — thermal insulating sheets made of mineral wool; — a heat-insulating homogeneous layer of concrete (or vermiculite, perlite, which is bound by a bituminous substance or cement); — homogeneous cement-sand and asphalt concrete screeds; - dry screeds arranged in 2 layers, made of asbestos-cement slabs, cement particle boards, glass-magnesium material. It is necessary that the materials of the prefabricated screed are homogeneous and monolithic. Self-tapping screws must not be allowed to protrude.

An example of what a built-up roof waterproofing looks like.

To increase the service life of the roof, it is recommended to slope the surface when installing built-up moisture insulation. To do this, you can use bulk thermal insulation material (perlite, vermiculite, expanded clay). Lightweight versions of concrete made on a base are used: foam, expanded polystyrene, expanded clay, perlite. It is possible to use wedge-shaped insulation sheets and cement sand compositions. To completely level a surface with a large fraction, sand is used.

You can create a slope on metal or profiled flooring only with sheet materials. Concrete and crumbly compounds are not allowed to be used in this case.

Screeds, which are the basis for weld-on insulation, must have temperature-shrinkable seam sections about 0.5 centimeters wide. Seams are used to divide cement-sand screeds into sections of 6 by 6 meters, and asphalt concrete screeds into zones of 4 by 4 meters. It is necessary that the shrinkage seam sections coincide in projection with the seam sections of the reinforced concrete slabs of the base and the integral heat-insulating layer.

In the areas where the roof connects to the vertical parts, inclined fillets with a height of ten centimeters are made from a cement sand composition, asphalt concrete, or a mineral slab of the required rigidity. It is necessary that the fillet angle be forty-five degrees.

Before installing the weld-on insulation, the area is cleaned of dust and dirt particles.

The raw material to be welded is rolled onto the surface, then rolled towards the center. The lower base of the rolled material is gradually melted while simultaneously rolling out the roll and attaching it to the base using special glue. Next, the welded fabric is rolled using a roller.

Installation of built-up waterproofing of floors and foundations

The base of the foundation part also needs careful preparation: you need to level the surface, treat it with a primer, and dry it.

Before pasting the foundation part, you need to mark the bitumen mastic. You can roll out and stick the rolled weldable material following the “bottom up” principle. In this case, the process of melting the polymer film layer of the material must simultaneously take place. It is important that heating and gluing are carried out evenly and consistently along the axis of the roll using special equipment.

The melting temperature of waterproofing raw materials is about 151-161 degrees. This temperature regime helps the upper part become more elastic.

After proper gluing, a “roller” of bitumen should appear under the edge throughout the entire glued sheet. Bubbles or folds are not acceptable. Leveling and blowing air is done using special rollers and construction rollers.

Installation of the next sheet is carried out with an overlap of ten centimeters over the previous layer. In this case, the edge of the first layer is coated with bitumen-based mastic.

The foundation part is covered with waterproofing material up to 3-5 meters above the ground surface. The upper edge of the canvas is attached to part of the base using an edge strip.

Horizontal and vertical built-up waterproofing of the foundation in the photo. It is important to correctly combine the welded vertical and horizontal waterproofing sheets. A strip of raw material, which is thirty to forty centimeters wide, is glued to the seam areas and butt elements. Areas with a complex structure (non-standard corner elements, base bends, utility connections, etc.) are also finished with an additional layer.

Before processing with backfill, polystyrene foam boards are installed on the layer of built-up moisture insulation using rubber-bitumen mastic. The material helps protect the welded waterproofing coating from mechanical damage.

Backfilling is not required immediately after installing the waterproofing system. If a weld-on moisture insulation material is installed, it must be covered in advance with expanded polystyrene sheets. This will help protect raw materials from the negative effects of UV.

Popular built-up waterproofing TechnoNIKOL

TechnoNIKOL weld-on moisture insulation is in great demand today.

The material is classified as bitumen-polymer and is applied to surfaces made of polyester fibers, fiberglass or fiberglass. The binder composition that is applied to the surface includes: - bitumen; - butadiene styrene; - polyolefin; - polymer modifier. On each side of the waterproofing material, protective coatings are applied from fine-grained powder or polymer raw materials.

The following materials are also in demand: bicrost, technoelast EPP, uniflex EPP from Technonikol, etc.

The cost of TechnoNIKOL overlay insulation depends on the materials used. Thus, waterproofing based on polyester fiber has a higher price.

The installation of fused insulation requires certain knowledge, skills, the use of specialized equipment and high-quality materials. A profitable and optimal solution would be to entrust the work to experienced professionals who will promptly and at a high level carry out all the necessary waterproofing work of varying levels of complexity.

In the HydroPro company you can order work on waterproofing the roof using fusion materials; all the necessary specialists are available (contractor, engineer, installer, consultants). You can find out more details here on the website, by calling the hotline or sending a message by email - each client can use any convenient method and receive a detailed and comprehensive free consultation.

Roll roofing TechnoNIKOL: conclusions

TechnoNIKOL Corporation is considered one of the leading manufacturers of materials for fused roofing. The range of its roll products is very wide; you can choose from it what you need for specific operating conditions, taking into account your budget. True, it will take quite a lot of time to analyze the technical characteristics of the product. To save your time when choosing the right modification, it is better to turn to professionals.

Share the post “TechnoNIKOL roll roofing: types and applications, cost of a roll” by copying the link: https://kaksdelatsvoimirukami.ru/rulonnaya-krovlya-tehnonikol/