In the cartoon about Alyosha Poppovich, he had three paths. Today there is more choice when choosing insulation. However, it is THREE manufacturers that especially stand out: Knauf, Rockwool and our guest today, TechnoNikol insulation products.

The TechnoNikol company was founded in 1993 and today, almost 24 years later, it is the market leader in the field of building materials, in our case thermal insulation. The photo below shows how mineral wool production increased from 2003 to 2015.

Someone will immediately say that in the case of well-known brands you need to overpay for the name, but in an era of crisis this is a very controversial issue. In general, the premium for time-tested quality is worth the nerves and extra effort spent on “fighting” with bad materials made “on the knee”. But, in an era when every manufacturer is fighting for every customer, such markups are becoming a thing of the past.

The company produces materials that are used at very serious facilities:

- Alexandria Theater; Saint Petersburg;

- Torgovy, Nizhny Novgorod;

- Drama Theatre, Omsk;

- St. Petersburg State Technical University, St. Petersburg;

- Trade St. Petersburg;

- Konstantinovsky Palace, St. Petersburg;

- Crimean Bridge, Moscow.

The company produces thermal insulation from two main materials:

- Mineral wool;

- Expanded polystyrene.

Basalt wool, names

Insulation materials made from cotton wool are produced in ten main directions:

- AXI,

- BASALT,

- TECHNOACUSTIC,

- ROCKLIGHT,

- TECHNOBLOCK,

- TECHNOVENT,

- TECHNOLIGHT,

- TECHNORUF,

- TECHNOFAS,

- TECHNOFLOOR.

Of course, each direction represents a material for a specific application. Some types are more or less universal insulation materials. For example, Technofas, as the name suggests, is a slab for facade insulation from TechnoNikol.

Stone wool is produced at factories in Cherkassy, Rostov-on-Don, Zainsk and Chelyabinsk. [flat_ab id=”33"]

Types and features of TechnoNIKOL mineral wool

TechnoNIKOL products are available in two varieties:

- Basalt wool, which looks like slabs.

- Expanded polystyrene, which is formed during extrusion.

Expanded polystyrene is often used as an insulation material for buildings due to its excellent characteristics, which ensure heat retention indoors at a high level. Only wood with 10 times greater thickness than the layer of insulation material used can be compared in efficiency.

Expanded polystyrene is lightweight enough to reduce shipping costs. It has significant hardness and rigidity, allowing it to be used in places where flexible materials have absolutely no or little effect.

A significant disadvantage of these products is their high flammability, which releases substances hazardous to health. In this regard, when arranging extruded polystyrene foam, fire safety precautions should be followed.

TechnoNIKOL basalt wool has individual technical qualities. They consist of a thin layer of stone fibers that have mountain raw materials. Between the strands of rock there are numerous layers of air, due to which the degree of thermal insulation of the material is at a fairly high level.

Due to the still air inside, mineral wool has significant resistance to heat transfer.

The product has excellent performance in both cold and hot weather. Basalt wool is quite fire-resistant compared to expanded polystyrene.

Mineral wool does not burn up to 1000°, which minimizes its ignition, even near a nearby fire source that will not cause a melting process. In the event of a fire, the insulator will not allow fire to spread across its surface, and no hazardous substances or gases will be released.

Characteristics of stone wool

In general, the features of TechnoNikol stone wool and its technical characteristics are very similar. Basically, when choosing a material, it is worth considering:

- Manufacturer's recommendations;

- Density (hardness);

- Material type.

The manufacturer initially recommends certain types of insulation for specific tasks. For example, Technoacoustic slabs are used to soundproof interior partitions. In the video below, at 6 minutes 31 seconds, the manufacturer recommends Rocklight for attic insulation.

And TechnoNikol recommends Technofas as facade insulation. If there is a need to insulate the foundation, TechnoNikol recommends Technoruf. In general, foundation insulation should be carried out using hard mineral wool slabs.

Density is the second important factor that affects the area of application of cotton wool. There are three main types of wool layout:

- Mats (rolls);

- Soft slabs;

- Rigid slabs;

Mats or rolls are used to insulate the floor in the attic or it can be laid between floors. Insulating the walls of balconies and loggias may require the use of rigid slabs if there is no possibility or desire to use lathing.

Technical characteristics of mineral wool

This type of modern thermal insulation materials has unquestionable advantages and excellent technical parameters in comparison with conventional insulation:

- minimal absorption of water and moisture;

- ability to withstand high loads;

- long service life, which reaches 50 years, thanks to the use of extrusion;

- easy and convenient installation work;

- excellent sound insulation performance, which is achieved due to the unique structure of the fibers;

- saving heat for a long period of time;

- basalt wool is capable of restoring its original shape after compression.

Mineral wool is produced in sizes convenient for installation; it is resistant to high and low temperatures, which significantly increases its service life. Does not contain any hazardous substances that may pose a threat to health.

How much does TechnoNikol mineral wool cost?

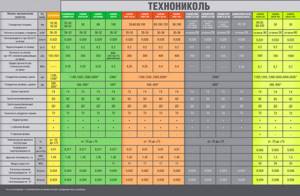

The characteristics of TechnoNikol insulation also include cost. In this section we provide the approximate cost of the most popular TechnoNikol stone wool insulation.

| Name | Size | Thickness | Number of slabs per package | Square | Price | Price 1 sq. meters |

| Rocklight | 1200Х600 mm | 50 mm | 12 | 6,91 | 514 rub. | 74 rubles |

| Technoblock PROF | 1200Х600 mm | 80 mm | 6 | 6,91 | 918 rub. | 133 |

| Technolight Optima | 1200Х600 mm | 50 mm | 12 | 8,64 | 603 | 70 |

| Technofas Optima | 1200Х600 mm | 50 mm | 6 | 4,32 | 951 | 220 |

| GreenGuard insulation | 1200Х600 mm | 50 mm | — | 5,76 | 400 | 69 |

Mineral wool thermal insulation cylinders TechnoNikol brand CF 80 measuring 1200 by 20 mm and a diameter of 18 mm cost 50 rubles as of January 2021.

It is easy to notice that materials are available in different price segments. On the TechnoNikol website there is a division into three types of basalt wool: economy, standard and premium. Of course, everything depends not only on financial capabilities, but also on the needs of a particular home.

Meet: TechnoNIKOL products

This company, which today ranks with the largest European manufacturers (more precisely, one of the five largest of them), produces not only thermal insulation. It produces the following products.

Roofing materials:

- Roof tiles;

- roofing felt;

- membranes made of polymeric materials;

- primers;

- mastics.

Insulation:

- Expanded polystyrene made by extrusion;

- mineral (basalt) wool, made in the form of slabs.

Basalt wool: composition and features

The finest stone fibers of this material consist of processed gabbro-basalt rocks. Between these fibers there is a large number of air layers. As a result, the level of thermal insulation of the material is simply excellent. It is no secret that it is the air, being without movement, that has great resistance to heat transfer.

But this is not all the advantages of insulation - it is good not only in cold weather, but also when the temperature rises critically. A very impressive characteristic of TechnoNIKOL mineral wool is its fire resistance. This material does not burn, easily withstanding temperatures of even 1000 degrees Celsius. At the same time, it doesn’t even melt! Even if, unfortunately, a fire occurs, basalt wool will protect your home, preventing walls and ceilings from collapsing. It will block the path of fire, without releasing a drop of harmful substances in the event of a fire.

- You can find out more about the characteristics of basalt wool insulation in the article: Technical characteristics of basalt insulation, advantages, disadvantages and scope of application.

Extruded polystyrene foam TechnoNIKOL

This type of material is increasingly used for insulating houses both here and abroad. After all, it holds heat very well. For example, to achieve an equivalent effect, you need to take a layer of wood 10 times thicker than polystyrene foam (twenty centimeters versus two). So EPS is cheaper. And it is much lighter than other insulation materials, which reduces transportation costs and facilitates installation. Strength and rigidity allow it to be used where softer thermal insulators cannot cope. But this material is afraid of fire - it not only burns, but also releases toxic substances. So it is necessary to comply with fire regulations by providing adequate protection.

Polystyrene insulation

The products consist of expanded polystyrene granules and look like uniform layers with closed pores. They are mainly intended for insulating structures and buildings for private and public purposes.

The following types of polystyrene foam from Technonikol are in demand on the domestic market: XPS CARBON ECO DRAIN (characterized by the presence of grooves with drainage functions, used for insulating roofs and foundations), XPS CARBON ECO FAS (used for plinths and facades treated with plaster), CARBON ECO SP (used for insulating foundations).

Installation of expanded polystyrene

If it is necessary to insulate the ceiling, layers of at least 5 cm thick are used. The ceiling is leveled, primed, then insulator sheets are glued to it. After the glue has hardened, the gaps are filled with polyurethane foam and the insulation is strengthened with dowels. An insulating film of foil is glued on top, a sheathing with a thickness of bars of 2 cm is installed, onto which sheets of plasterboard are attached.

Interior walls are finished by gluing polystyrene sheets to the wall. For reliability, they are reinforced with dowels, and the gaps are filled with polyurethane foam, the remains of which are cut off. Then the foil film is attached, and on top of it is lathing and drywall, ready for finishing.

When insulating external facades, the walls are cleaned, leveled, primed, then an adhesive mixture is applied to them and polystyrene sheets are mounted on it. After this, the cracks are sealed, an adhesive is applied to the insulator, then a reinforcing mesh is installed, on top of which another layer of glue is applied. After it dries, the walls can be finished with plaster, primer and paint.

When insulating floors, a film is laid, then a heat insulator, which is mounted end-to-end from one wall of the room to the other. The gaps are sealed with polyurethane foam.

Selecting a location for installing the thermal insulation layer

Initially, you need to decide how best – from the inside or outside – to fix the mineral wool. In this article I will talk about the second type - external insulation and give some subtleties of the technology.

| External insulation |

| When installing mineral wool on building facades, there is no need to dismantle and subsequently restore the interior decorative finish. |

| If “wet” technologies are used to insulate a house, the wall can only be insulated in the warm season. |

| Facade insulation allows you to protect enclosing structures from freezing. The timber wall will not be subject to successive cycles of freezing and thawing, which significantly extends its service life. |

| A wooden wall, in contact with the heated air of the room, accumulates thermal energy, which it then releases back when the air temperature outside decreases. |

External insulation has more advantages than internal insulation.

Of course, how to attach mineral wool - from the inside or outside: which is better is up to you to decide. But, in my opinion, the only negative in external insulation is the loss of decorative functions by the facade of a timber house. But I will fix this with the help of a block house mounted on top of the insulation.

Insulation of a private house - floor.

The floor will be constructed using wooden joists using TechnoNIKOL Floor Light technology. The floor, which is located on the first floor, gives us up to 15% heat loss. Therefore, floor insulation in a private house must be treated as responsibly as possible. In private housing construction, laying floors along joists is the most common option. Undoubtedly, the advantage of this floor is its simplicity of design and the absence of complex robots. By using insulation in the form of stone wool, you will also provide yourself with additional protection from noise.

So, let's start insulating the floors:

The basis of the structure are wooden floor joists. The recommended distance between the logs inside is 580 – 590 mm.

If you make such a distance, you will be able to lay the insulation tightly and it will press well against the joists. You will not have empty spaces that can form cold bridges, which can significantly worsen thermal insulation. Also, this distance will simplify the installation of insulation.

A particle board in the form of OSB or plywood should be hemmed underneath the joists with self-tapping screws. It is possible to use other similar materials.

If there is a room with high humidity under the floor, for example, a bathroom or basement, then you will additionally need to lay a vapor barrier film. Typically, membrane vapor barriers are used for such purposes.

Then you can lay the thermal insulation material. If you use Technonikol products, then for these purposes you need to use Technoacoustic and Rocklite slabs. The thickness of the material is selected according to thermal engineering calculations. On sale you will find slabs with a thickness of 50 and 100 mm. If necessary, installation can be done in several layers. Keep in mind that the height of the logs must be matched to the thickness of the insulation, then it will fit comfortably into the gap - it will not protrude and will not form a void.

If you are laying a second layer of material, then you need to keep the seams shifted by 100-150 mm. This will avoid the appearance of cold bridges.

To avoid moisture condensation on the insulation on top, a vapor barrier film is laid closely. The edges of the film should overlap, which should be 100-150 mm. The seams are taped with acrylic tape to ensure sealing of the film.

Next, large-sized load-bearing materials are laid on the wooden logs; these can be OSB, chipboard, plywood and even wooden boards, there is even special drywall.

The next step is laying the substrate and laying the topcoat.

Extruded polystyrene foam - application features

Expanded polystyrene insulators are combined into one series - Carbon. The materials have similar characteristics, but differ in release form. The type of execution largely determines the scope of use of EPS.

Material characteristics

The insulation is produced by extrusion. As a result, many sealed cells are formed. The composition and structure of expanded polystyrene endowed the heat insulator with the following properties:

- Low thermal conductivity. An indicator of 0.028-0.035 W/m*C puts the material among the leaders in terms of thermal efficiency.

- Hydrophobicity. EPS does not absorb moisture and retains its characteristics in a humid environment.

- Moderate combustion. The use of carbon made it possible to minimize the flammability of polystyrene foam - when the material melts, burning drops do not form .

- Insulation thickness – 20-120 mm. The choice depends on the area of use.

- The thermal insulator is resistant to fungus, mold, and pests.

- The operating temperature range is comparable to that of basalt insulation - from -50°C to +75°C.

Weaknesses of EPPS: vulnerability to gasoline, solvents, UV rays, fire.

Carbon: variety of product items

Types of extruded polystyrene foam TechnoNIKOL Carbon:

- Eco - slabs of various thicknesses (20-100 mm) for insulation of low-rise buildings and cottages.

- Drain – one side of the EPS has drainage grooves. The holes provide improved ventilation when insulating a flat roof or draining rainwater when insulating a foundation.

- Eco Fas – arrangement of house plinths, plastered facades. Milling on the outside ensures good adhesion to various surfaces.

- Eco SP – suitable for insulating foundations using the Swedish plate method. The foundation includes communications and a floor heating system. Eco SP has increased rigidity and very low thermal conductivity .

- Prof – maximum strength. Application – insulation of floors on the ground, various foundations, flat roofs.

- Prof Slope is a combination of five slabs forming a wedge-shaped insulation.

- Solid – high strength due to closed cells. Used on an industrial scale: insulation of highways, floors under load, railway tracks.

Facts about the manufacturer

The TechnoNIKOL concern, which has been successfully operating in the global market for more than 20 years, began its activities with the opening of an office in Moscow in 1992. By the beginning of 2000, the corporation entered the Ukrainian market and opened several large factories in Russia for the production of waterproofing materials, the technical characteristics of which stood out favorably against the general product range.

Having survived all the crisis moments, TechnoNIKOL continues to successfully conquer the international market of insulating materials. Currently, the company has expanded its scope of activity to 35 factories and official representative offices in 33 countries.

Material calculation

Differences in the dimensions of mineral wool elements can mislead you. Professionals try to save working time. The price of a mistake is the same for everyone - budget overruns and loss of time.

To perform calculations, use an online calculator. It will take into account all the necessary quantities, parameters and conditions. A small reminder on using the calculator:

Please note that not all Russian settlements are represented in the list of cities

Therefore, try to choose options that are minimally distant from the location of your home. This is important because... this parameter determines the average winter temperatures; all numerical values (thickness) are displayed in millimeters

Just in case: 1 m is 100 cm or 1000 mm; We recommend looking at the detailed characteristics of insulation on the manufacturers’ websites. There you will also find recommended prices for this type of product; All calculations are approximate, so it would not be superfluous to add 10% to the results obtained.

Having obtained the thickness of the thermal insulation as a result of calculations and knowing the area of the walls, it is easy to calculate the volume of insulation. We hope this is helpful.

Innovative PIR insulation TechnoNIKOL

The mats are made of polyisocyanurate foam. The structure of the plates is hermetic cells, the external insulation is covered with a layer of foil. This solution improves thermal efficiency - the thermal conductivity coefficient is reduced to 0.021 W/m*C. An innovative polymer is used to insulate the fuel tank of rockets.

A 1.6 cm layer of PIR insulation is equivalent in thermal efficiency to a 1.34 m concrete wall.

Polyurethane is considered the toughest elastomer - a compressive strength of more than 120 kPa. The excellent characteristics of insulation make it popular when installing flat roofs. Reviews about PIR insulation are positive - the material is lightweight, easy to install, durable, and the aluminum layer increases its fire resistance.

Technonikol products are in active demand. Main advantages: wide range of choice, high quality and loyal pricing policy.

Thickness of mineral wool for attic insulation

Due to different regional climate conditions, figures may vary. For example, for areas with a temperate climate, it is enough to lay mats 150 mm thick. Whereas for the northern regions, the thickness of the product reaches 200 mm or more. Southern regions do not require dense insulation, and in this case 100 mm of mineral insulation is sufficient.

Also, the parameters are affected by winds. If the house is located in an open space with constant winds, then the coefficient increases by 1.5. The dimensions of the attic and its internal layout play an important role. When equipping an attic for living space with vertically positioned walls and additionally located heating devices, the thickness is reduced to 150 mm.

Work order

Now let’s look at how to insulate the outside walls of a private house. All necessary actions can be divided into several mutually dependent stages, which are presented in the illustration below.

Scheme of external wall insulation.

Now in more detail about each stage separately.

Stage 1 - Preparing the walls

Before installing insulation for the walls of a house outside, it is necessary to properly prepare the external surfaces of the walls. This is done this way:

- I cleaned the timber walls from dust and debris that had accumulated over two years of operation. The main thing is to remove decorative finishes from surfaces that prevent air infiltration through the walls (for example, oil paint). After this, it is advisable to vacuum the walls to remove dust from the inter-crown cracks.