Professional builders value such thermal insulation, which, in addition to its immediate function, has a number of additional characteristics. In particular, environmental safety, moisture resistance, sound insulation. Surprisingly, today, all of the above qualities are combined only by isolon.

This is a unique domestic development, which is in consistently high demand in Russia, Europe, and the CIS countries. There are no high-quality analogues of isolon yet, so it makes sense to consider in detail the key features and technical characteristics of this material.

What it is?

The term isolon appeared thanks to the developments of the Izhevsk Plastics Plant. The material is foamed polyethylene with a porous structure. This feature provides isolon with high quality heat and sound insulation. It should be noted that the material is quite elastic, which greatly simplifies the installation process.

How polyethylene foam with a uniform cell structure is produced

The technological process of isolon production can be divided into three stages:

- All components involved in the process are mixed in one container, adhesion agents and foaming agents are added.

- The finished mass is heated to high temperatures, melts, forming finished sheets.

- The material is sent to the oven, where it undergoes additional heat treatment. At certain temperatures, foaming agents react, creating pores on the surface of the sheets.

If we are talking about the production of foil material, at the final stage, one side of the sheet is covered with thin aluminum foil. Lamination technology is used here.

Release forms of isolon

Universal fabrics izolon

This category of materials includes rolled and sheet products of different thicknesses, from various types of isolon, designated by digital indices 100, 300 or 500, with the possible addition of alphabetic symbols.

Izolon 100

This material is considered to be the most affordable, which does not mean its low quality. It’s just that its production does not require any complex technological processes. Recycled raw materials may well be used for production. But at the same time, the operational characteristics of the resulting insulator will fully satisfy many requests.

The previously used name for this variety was “Izolon NPE”. The abbreviation meant that this was ordinary, so-called non-crosslinked polyethylene. That is, it does not undergo special processing to create additional intermolecular bonds.

Izolon 100 in sheet form

The average density of such material is 25 kg/m³. and at the same time it shows, of course, far from a record, but still quite decent thermal conductivity coefficient of 0.045 W/(m×℃).

The material is produced on extrusion lines with physical foaming of the raw material melt. The result is a structure with a closed gas cell, and the cells are quite large in size.

The difference from other types of isolon, made from cross-linked polyethylene, is not only, of course, in price. This material is good for thermal insulation or noise reduction only in conditions where it is not subject to compressive loads. The problem is that after deformation, the cells are, so to speak, reluctant to return to their previous shape. That is, in such conditions, isolon will “caking”, losing thickness, air content, and thermal and sound insulating qualities.

For example, insulating a wall and then covering the frame with clapboard - Izolon 100 is perfect. But using it as an elastic insulating and noise-absorbing substrate, say, under the finishing floor covering, laminate or linoleum, will not work. it will quickly wash out and lose its advantages.

The release form of conventional isolon 100 depends on the required thickness of the material.

Canvases with a thickness of 1 to 10 mm are sold in rolls up to 50 meters long. The width of the rolls is 1050, 1300 and 1600 mm.

Izolon 100 with a thickness of more than 10 mm (up to 50 mm inclusive) is sold in sheets. The standard sheet size is 1000×2000 mm (an example is shown in the illustration above).

During production, pigment dye can be added to the melt - multi-colored canvases are readily purchased by interior designers and craftsmen.

IZOLON NPE

Izolon 300

The name of this material, which has fallen out of official use, is Izolon PPE NH. This means that the products are made of cross-linked polyethylene, and the cross-linking process itself was carried out using chemical technology.

Let us repeat right away - the compression of polyethylene means the creation of cross-links between the linear molecules characteristic of this polymer. That is, the molecular lattice takes on a three-dimensional structure, which immediately has a positive effect on the characteristics of the material.

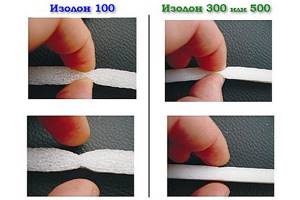

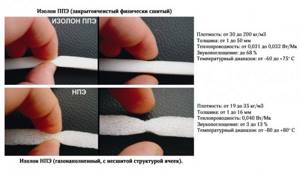

Even visually, the cells of cross-linked and non-cross-linked polyethylene foam are different. Izolon 300 has smaller bubbles, more regular shapes and all of approximately the same size.

Everything is clearly visible in the photograph: at the top is the “anarchy” of non-crosslinked polyethylene foam, at the bottom is the seemingly denser structure of the crosslinked material.

But the main thing is different: the structure of cross-linked polyethylene foam will always fail to restore its configuration after deformation, regardless of what and how long the load is applied.

It’s easy to verify this by doing a simple experiment yourself. You can try to squeeze the Isolon 100 and Isolon 300 (or 500) fabric with your fingers as hard as you can, and watch what happens then.

After compression, a dent will remain on the isolon made of non-crosslinked polyethylene foam, and on the second sample the same deformation will quickly “overgrow”.

What's the conclusion? And the fact that such isolon, made of cross-linked polyethylene, can be used as insulating substrates, anti-vibration gaskets, damping layers that limit the spread of impact noise, etc.

Thus, to all the capabilities of the previously discussed isolon 100, the indicated functions are also added.

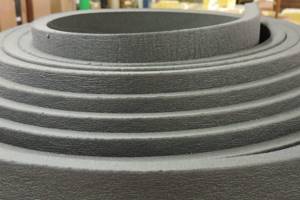

Isolon 300 sheets (panels) of different thicknesses in black and white colors

One more important detail should be emphasized. In the production of foamed cross-linked polyethylene, technologies make it possible to control the process, achieving the required level of gas saturation, or, as they call it, the foaming ratio of the feedstock. Therefore, the characteristics of the output materials (density and operational parameters) can differ quite significantly.

I won’t give a table here - we’ll just say that with a foaming ratio of 5 to 40, the density of Izolon 300 can vary in the range from 185 to 25 kg/m³. The thermal conductivity coefficient at a foaming ratio of 15 times (67±10 kg/m³) is equal to 0.042 W/(m×℃), and at a foaming ratio of 30 (33±5 kg/m³) - 0.037 W/(m×℃).

Release forms of isolon 300:

- Rolls of canvas with a thickness of 0.8 to 15 mm, a width of 1500 mm, a length of up to 150 m.

- Sheets with a thickness of 15 to 50 mm, a width of 1000 or 1400 mm, a length of 2000 mm.

IZOLON 300

Izolon 500

Isolon 500 is considered the most “advanced” option, combining unique physical, chemical and operational characteristics.

According to the old classification, the material was called Izolon PPE NR or Izolon PPE-7. This is also cross-linked polyethylene, but only the creation of transverse intermolecular bonds is carried out by a physical method - by irradiating the material with an electron flow. The result is a very high cross-linking density, and the resulting isolon itself acquires unique qualities. In terms of the combination of excellent thermal insulation ability along with high elasticity, “volumetric memory” - the desire to return to its original position after removing the load, the ability to absorb vibration and noise - it simply has no equal.

Izolon 500 can be used on any construction site, without restrictions, where effective insulation, vibration damping, and noise insulation are required.

A large number of materials with some differences in their properties are produced under the brand name “Izolon 500”. In particular, the density can range from 25 to 200 kg/m³, and the thickness can range from less than 1 mm to 50 mm. More precisely, after foaming, the resulting webs can reach a thickness of up to 5 ÷ 10 mm, and then they are duplicated (glued together) into webs up to 15 mm thick or sheets up to 50 mm.

Just as in the case of Izolon 300, there is a gradation in the frequency of foaming - from 5 to 40. In addition, there are certain differences in manufacturing technology and even in the material used.

It’s not difficult to understand which material is in front of you if you know the current markings.

The following alphanumeric scheme is usually practiced:

IZOLON 500 XXXX LL

(X – numbers, L – letters).

Four numbers mean: the first two are the foaming ratio of the material, the second are the thickness of the finished product. For example, if the tag says Izolon 500 4020, then this is a material with forty-fold foaming and a thickness of 20 mm.

By the way, if the frequency of foaming is known, then it is easy to “estimate” the so-called apparent density of isolon. To do this, you just need to divide 100 by the factor. In our example it turns out 25 kg/m³

But with letter symbols some “interesting variety” is possible.

- Izolon 500 XXXXX AV

This index marks isolon, made on the basis of foamed cross-linked polyethylene, the production of which is carried out by vertical foaming (meaning the location of the furnace in the production line and, accordingly, the longitudinal vector of the direction of movement of gas bubbles in the process of formation and hardening of the structure of the material.

Attention: Let’s make a reservation right away - the difference in the “direction of processing” mainly affects the external texture of the material and its resistance to mechanical loads of compression and tearing in the longitudinal and transverse directions.

Such webs (AV) or sheets usually have a very smooth outer surface.

This is what the texture of vertical foaming isolon looks like.

When foaming, sheets with a thickness of 0.8 to 5 mm are obtained, with a foaming ratio from 05 to 40. When duplicating (gluing), a material of the required thickness is obtained.

The thermal conductivity coefficient of the material at an average density of 33 kg/m³ is 0.036 W/(m×℃).

Release form:

– rolls with strip thickness from 0.8 to 15 mm, length up to 600 m, width from 800 to 1500 mm.

– sheets with a thickness of 15 to 50 mm, a length of 2000 mm, a width of 1000 or 1400 mm.

- Izolon 500 ХХХХ AN

This isolon is processed in a horizontal oven. The finished material of this type usually has a micro-relief, sometimes somewhat “velvety” surface.

The relief on the surface of sheets or canvases is a material of horizontal foaming.

This technology makes it possible to produce sheets (webs) up to 20 mm thick.

The release form is practically no different from AV. True, the minimum thickness of the sheet (canvas) is 4 mm.

IZOLON 500AH

- Izolon 500 ХХХХ SV

This is exactly the exception mentioned above. That is, isolon, obtained not from polyethylene foam, but from a modified analogue - penosevilene. Despite numerous similarities in parameters, this variety is still distinguished by increased softness and elasticity of canvases and sheets.

Otherwise, the characteristics and classification are similar. As you might guess, the letter symbol V indicates production in a vertical oven. Foaming thickness – up to 5 mm.

Release forms:

— fabrics in rolls with a thickness of 6 to 16 mm, a width of 800 to 2000 mm, with a roll winding diameter of up to 1000 mm;

- sheets with a thickness of 15 to 50 mm, width 1000 and 1400 mm, length - 2000 mm.

- Izolon 500 ХХХХ SН

As you might guess by analogy with the previously discussed samples, this material differs from the previous one in manufacturing technology and in some indicators of spatial strength. In addition, the maximum foaming thickness of the sheets here reaches 20 mm.

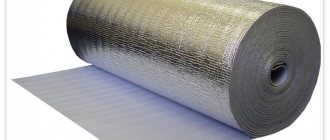

Isolon with reflective surface

It has long been known that insulation materials equipped with a reflective surface show significantly greater efficiency. The ability to direct the flow of thermal radiant energy in the desired direction provides significant cost savings for equal opportunities. Nothing surprising - just remember the well-known effect of a thermos, in which heat can remain for days.

Naturally, such abilities are necessarily “adopted” by manufacturers of thermal insulation materials. And isolon is no exception in this regard.

Any of the materials discussed above (Izolon 100, 300 or 500) is used as a base. And the reflective layer can be either aluminum foil or laminated lavsan film with a metallized surface. Materials with aluminum foil are marked with additional symbols LA, with lavsan film - LM.

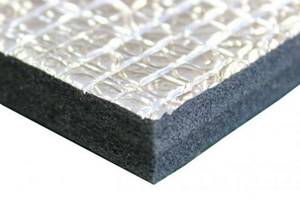

Foil-coated isolon 500

The foil or lavsan layer also provides a significant advantage to the vapor barrier ability of the material. That is, such sheets or sheets become an excellent solution, for example, for thermal and vapor barrier of steam rooms in a bathhouse. They are placed under a layer of wooden sheathing - and the heat is retained for a long time, and the load-bearing walls are saturated with moisture.

Foil can be called more resistant to moisture, but isolon with reflective lavsan film is preferable, for example, in the design of an electric heated floor. Simply for safety reasons, since the coating will not act as a conductor during a breakdown.

Laying isolon with a reflective layer before installing a “warm floor”

Such qualities of the material are especially in demand in conditions of limited space, where it is difficult or even impossible to use thick layers of insulation. A classic example is a balcony or loggia, where every centimeter of space counts. The combination of isolon with a reflective surface and other thermal insulation material gives a very significant effect. By the way, this can be easily verified if you calculate the insulation of a balcony using the proposed calculator. Try to calculate both options, with or without foil isolon - and the difference will be very eloquent.

By the way, the calculator allows you to calculate the insulation of any balcony surfaces (walls, floor, ceiling, parapet) and with any neighborhood (street, warm or cold balcony).

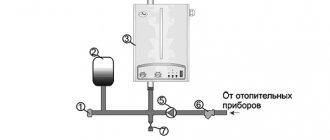

To work with the program, you will need to know the values of the normalized thermal insulation resistance for walls and ceilings. The attached diagram map will help with this issue.

Diagram map for determining the normalized heat transfer resistance of building structures (by region of the Russian Federation).

Balcony insulation calculator

Go to calculations

Varieties of special purpose isolon

As has been noted more than once, the main advantages of isolon are its thermal insulation and noise-absorbing characteristics. This prompted material manufacturers to produce some special varieties intended for specific construction or finishing areas.

Izolon EcoHeat underlay for underfloor heating

This reflective material is designed specifically for installation in underfloor heating systems. Such a substrate hides minor unevenness of the base well, while significantly increasing the efficiency of the heating elements. In fact, this is exactly the material that we reviewed a little earlier and were convinced of its usefulness.

Roll of special underlay for heated floors

In addition to its insulating qualities, such a substrate based on Isolona 500 meringue also provides a very significant anti-noise effect. Thus, a 2 mm thick canvas provides an absorption of 24 dB of impact noise, and for a 3 mm thick substrate this figure even reaches 30 dB.

Release form: rolls 8 m long, 1000 mm wide, 2 or 3 mm thick.

Izolon EcoHeat underlay for floating floors

A real disaster for residents of high-rise buildings can be impact or structural noise that travels through building structures over long distances. It’s not easy to fight them, but it’s still possible. And one of the effective schemes is an elastic damper (spring) between two massive parts. The parts can be a floor slab and a screed, and between them, preventing their direct contact, there is an elastic gasket.

It is for such a layer that the “Izolon EcoHeat” underlay under a “floating” floor is intended

A floating floor underlay effectively solves the problem of impact noise propagation.

With a thickness of 5 to 10 mm, such a substrate, separating the ceiling and the leveling screed, has the effect of reducing impact noise by 36 ÷ 44 dB!

Release forms - rolls 8 m long, 1000 mm wide, 5, 8 or 10 mm thick. All rolls are packed in shrink film.

IZOLON EcoHeat

Izolon EcoHeat underlay for flooring

The technology of laying many floor finishing coverings, including those belonging to the elite category, requires placement, provides high-quality interlocking connections, and increases the comfort of using the floor. Including not only “softness”, but also insulation, reducing the spread of impact and airborne noise, vibration.

An excellent solution would be to use a special “Izolon EcoHeat” substrate for these purposes. It was developed precisely for this application.

Izolon EcoHeat underlay for flooring

The material is resistant to deformation, practically does not absorb moisture, and with a thickness of only 2 or 3 mm, it demonstrates a reduction in the impact noise level by 18 ÷ 30 dB.

Release form - rolls of substrate based on Isolon 500, 8 m long, 1000 mm wide, with sheets 2 or 3 mm thick.

Izolon EcoHeat backing for wallpaper

A unique material that allows you to independently “include wall surfaces in the noise defense system.” A thin elastic gasket under the trim perfectly resists the spread of airborne noise.

In addition, such a substrate eliminates the very unpleasant effect of “wall coldness” that occurs. Another convenience is that the pre-glued layer evens out minor surface irregularities, allowing for a high-quality finish. An additional plus is that the wall will not be affected by mold or mildew.

Many have already appreciated the capabilities of the thin backing for wallpaper “Izolon EcoHeat”

The substrate itself is a thin layer of isolon, covered on both sides with a paper “wrapper”. Moreover, the quality of gluing is such that the paper is inseparable from the polymer. The paper layer has an even white tint, that is, it will not appear in any way even when gluing very thin wallpaper. On the contrary, it will set a very even foundation in this regard.

The backing is glued using the usual technology for “heavy” wallpaper. And after complete drying, it is ready for finishing.

It goes on sale in rolls 500 mm wide and 14 meters long. The thickness of the substrate can be 3 (Classic) or 5 (Premium) millimeters.

IZOLON EcoHeat for wallpaper

Video: Advantages of using Izolon EcoHeat substrate

* * * * * * *

We examined the most popular types of isolon in construction. But that’s not all. Thus, a lot of elastic tapes are produced under this brand, for example, for interlayers between walls and partitions erected indoors, say, from gypsum tongue-and-groove slabs. Or for the installation of frames, suspended structures - in order to prevent the transmission of vibration. In addition, many materials, including those that have been discussed, are equipped with an acrylic adhesive layer with very high adhesive abilities, which simplifies the work.

The leading manufacturer of materials under the IZOLON brand in Russia is the Izhevsk Plastics Plant. The company's products are of high quality and are constantly receiving positive reviews from consumers.

Scope of application of foamed thermal insulation

Due to its unique properties, isolon is widely used in many industries, construction and repair work. For example:

- Insulation of wall structures, floors, ceilings, floor slabs. Izolon has proven itself well in private and multi-storey construction, construction of garages, bathhouses, and outbuildings. Insulation of balconies and loggias without creating additional load on supporting structures.

- Vapor barrier for rooms with high humidity.

- Insulation of pipelines.

- Reliable insulation when installing self-leveling floors.

- Industry: packaging of medical equipment, production of thermal blankets, production of refrigeration chambers. It should be noted that life jackets are made on the basis of isolon, which help retain body heat during prolonged exposure to cold water.

- Protection of car elements from corrosion, additional body insulation.

It should be noted that no building material in the world has such versatility.

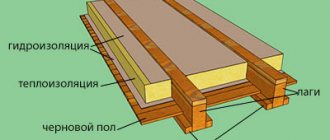

Use of cross-linked polyethylene foam

Thanks to its sanitary and epidemiological qualities and unique technical properties, the range of applications of this material is constantly expanding. The installation of such a product is often used in the engineering industry to insulate heat-reflecting screens, refrigerators, isothermal cabinets and climate control equipment. Isolon is also in demand in construction, where it is used for the following purposes:

- waterproofing of basements and foundations;

- protection of communications;

- heat and vapor insulation of rooms with high humidity (bathrooms, saunas);

- insulation and waterproofing of partitions, roofs, walls, ceilings, ceilings and floors.

This thermal insulation material is often used in the automotive industry. This product is used to cover the interior for sound insulation and also to reduce vibrations. Among other things, it is used as a sealant, a protective element against corrosion, and a damping gasket.

The material in question is used in medicine to make elastic products for specialized purposes, thermal blankets, insoles, as well as orthopedic products.

In addition, isolon is used to create packaging materials. They are used for the safe transportation of products and storage of various products for household and industrial purposes.

Isolon foil material has increased moisture resistance

A variety of things for tourism and sports are made from this versatile material. These mainly include gloves, mats, life jackets, punching bags, mats, helmets and swimming boards.

Types of material

Given the versatility of its application, several types of insulation are supplied to the markets. Conventionally, products can be divided into two categories:

- NPE is a “non-crosslinked” material produced by extrusion. Thanks to the use of modern equipment and technological processes, an environmentally friendly large-porous material is obtained.

- PPE is “cross-linked” polyethylene, which also foams at high temperatures, but here the technology of strengthening molecular bonds is used. The result is a fine-mesh sheet of insulation with sealed pores.

The difference between the categories is determined by tensile strength and resistance to dynamic loads, which are significantly higher for “cross-linked” isolon. This feature determines the scope of application of the insulation.

The products are marked as follows:

- A – one-sided coating of the sheet with aluminum foil.

- B – double-sided foiling.

- C – self-adhesive base.

- ALP is a self-adhesive foil sheet, the surface of which is covered with an additional protective film.

Knowing these features, you can easily select insulation, focusing on the scope of application and individual preferences.

Types and model range

There is cross-linked isolon (PPE) and non-cross-linked (NPE). Izolon PPE has higher technical characteristics (primarily strength properties) than NPE.

The main modifications of isolon used in construction:

- PPE 500 and 500L - polyethylene with a bonded transverse structure, cross-linked in a vertical oven;

- 500 HP - its analogue, processed in a horizontal oven;

- PPE NH – chemically cross-linked, foamed in a horizontal oven;

- PSEV – physically cross-linked with improved technical characteristics (increased strength to cyclic compression, etc.);

- NPE 100 – uncrosslinked, formed from extruded polyethylene;

- 100L – unstitched two-layer;

- single- and double-sided self-adhesive tape Isolon Tape.

There are also varieties modified for one or another characteristic:

- with a wetted surface on which adhesives and paints and varnishes are applied;

- with increased rigidity;

- colored;

- with fire retardant impregnation (fire resistant).

The isolon marking is deciphered as follows:

- two numbers at the beginning - foaming ratio;

- the second two are the sheet thickness;

- letter A – one-sided foil;

- B – double-sided;

- C – self-adhesive;

- ALP – reinforced reflective.

Pros and cons of elastic polyethylene foam

If you conduct a comparative analysis of the pros and cons of isolon, the advantages will be noticeably greater. However, as is the case with other building materials, insulation cannot be called completely ideal.

Advantages:

- Long service life without loss of original properties.

- Resistance to almost any aggressive environment.

- Immunity to ultraviolet rays and natural phenomena.

- Relatively low weight, which avoids high loads on supporting structures.

- Neutrality to any pathogenic microflora and fungus.

- Resilience and elasticity - easily takes any shape, quickly recovers even after prolonged compression. Curiously, the increased elasticity ensures that the material can be reused without losing its properties.

- Easy to install - absolutely anyone can handle the work, without exaggeration.

- Environmental safety: no chemically active or toxic substances are used in production.

It should be noted that the use of elastic polyethylene foam for insulation of residential premises allows you to save about 30% .

Flaws:

- High cost - so many people prefer to choose lower quality, but cheaper materials.

- Caution - if the foil layer is damaged, the thermal insulation characteristics are reduced to zero.

- Restrictions on finishing - izolon can only be covered with protective films and painted. Wallpaper, tiles and plaster create additional stress on the surface, which will invariably lead to damage to the material.

In addition, when installing isolon, you must strictly follow the instructions, do not forget about the ventilation gaps between the insulation and other materials, and avoid direct contact of the foil with electrical wiring.

Disadvantages of thermal coating

Due to its rather low strength, isolon can be easily torn or deformed

But in addition to the advantages described above, this material also has its disadvantages. Unfortunately, isolon also has negative aspects that you need to know:

- Low strength. Insulation covered with foil can easily be torn or pierced. True, this drawback is found in many modern insulators, except for polyurethane foam and penoplex.

- A ventilation gap is required. When overheated, the foil material begins to lose its properties. It is this gap of 1-2 cm that will help avoid this, but in some cases it is extremely inconvenient to do.

- Corrosion gradually begins to form on the aluminum coating of the material at high humidity, which negatively affects its effectiveness.

Technical characteristics of insulation

Izolon is manufactured in strict accordance with international standards, for which there are appropriate certificates. The characteristics of the insulation look like this:

- Thermal conductivity – 0.031-0.037 W/m*S .

- Vapor permeability – 0.001 mg/m*hour*Pa .

- Moisture absorption – 0.2-0.7%.

- Resistance to dynamic compression – 0.031-0.033 MPa .

- Soundproofing – 68%.

- Heat-reflecting properties – 95-97%.

The operating temperature range varies within -80/+80 degrees . Accordingly, the material can be used with equal success for internal and external insulation.

| Name | Unit | NPE | PPE |

| Density | kg/m3 | 19-45 | 33 |

| Specific Thermal Capacity | kJ/kg*s | 1,95 | 1,8 |

| Water absorption | % | ≤0,1 | ≤0,1 |

| Use temperature | °C | -80…+80 | -80…+80 |

Preparation before installation

Nowadays it is popular to lay insulation with a thickness of no more than 10 mm on the floor. Izolon can be placed in any room to avoid heat loss. But first you need to remove the old flooring and remove all debris.

Laying isolon insulation can be done independently without much difficulty

After this, you should inspect the underlying structure, where there should be no damaged screed. It is best to pour new cement mortar. In addition, it is necessary to check the reliability of the butt seams. Any holes on them must be sealed with foam. Before laying isolon, do not forget about waterproofing the base. To do this, the floor is covered with a primer, and when it dries, polyethylene must be laid on top of it. It is recommended to secure the film with tape.

Installation features of Isolon

It was already mentioned above that the installation of foil-coated polyethylene insulation does not require special skills and knowledge. The insulation technology may differ depending on the type of material, so we will focus on the general features of installation work. It is imperative to observe the following nuances:

- The sheets are attached to a dry, clean surface.

- The insulation is laid end-to-end, the seams are taped with a special tape.

- The foil side always “looks” inside the premises.

- If there is no self-adhesive film, the sheets are attached with a mounting stapler.

For high-quality insulation, one layer 5 mm . For particularly cold walls, it is recommended to use a sandwich: isolon, mineral wool, isolon.

DIY crafts from isolon

Master class on making a lamp in the shape of an owl from isolon

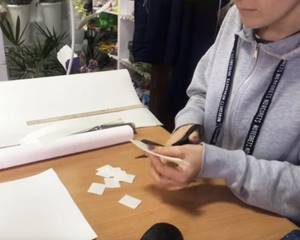

To work, we will need a thin sheet of isolon, which must first be prepared, namely, cut into squares, 3 × 3 cm², forming “feathers”.

The procedure can be seen more clearly in the photo instructions. To work, we will need a small lampshade, which must first be disassembled into 2 parts, isolon, scissors, and glue. In addition, we will need wire with which we will make the frame of the wings

Please note that the wire will have to support a fairly large number of feathers. Be sure to use an LED lamp as a backlight, it is more durable, and you will not need to open the structure often

| Illustration | Description of action |

| Cut the isolon into squares. It's okay if the squares aren't perfectly straight. To speed up work, it is best to roll the isolon sheets in several layers |

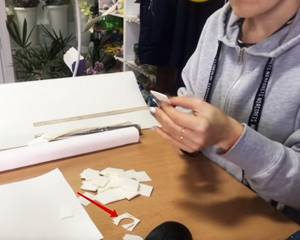

| Next, we give these squares a petal shape approximately like this. We cut each leaf so that we get a fringe. |

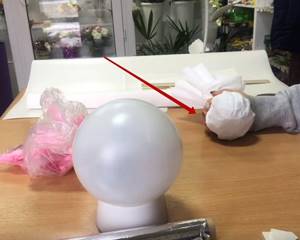

| To make the head we will need foil and corrugated paper. We roll the corrugated paper noodles, cut into thin strips about 1.5 cm wide, into a ball and wrap them with foil. We got this blank for the head |

| We wrap it with a sheet of heated isolon so that we get such a round blank, tighten the base with tape or an elastic band for banknotes. Cut off the excess. The diameter of our head for the owl turned out to be approximately 10-12 cm |

| We attach the head with hot glue, in fact, it turns out to be such a snowman. Carefully glue the workpiece in a circle |

| We begin to cover our blank with feathers from the bottom up so that we have a fluffy body. The higher you go to the head, the smaller the feathers should be. We glue the next row in relation to the previous one in a checkerboard pattern. |

| Having reached the head, we begin by gluing the area under the eyes. This needs to be done at the very beginning, otherwise you simply won’t be able to make them on top of the glued row later. |

| For the eyes, we chose a ready-made option, which can be bought on AliExpress or in any craft store |

| Next, we continue to work according to the usual pattern - checkerboard, trying to avoid gaps |

| Now it's time to start decorating the wings. We attach the blanks to the base. The process of creating voluminous feathers is similar to the design of the body. |

| Our owl is almost ready. Now it's time to make the ears. To do this, we wind the isolon tape into a small skein, glue the base and make a fringe |

| We attach our ears to glue, slightly fluffing the tops. Now all that remains is to complete the final finishing by covering the rest of the head with makeshift feathers. To give our lamp the appearance of natural plumage, you can slightly fluff the feathers by directing the warm jet of a hairdryer |

| This is how our volumetric lamp made of isolon in the shape of an owl turned out |

You can watch all the stages of work in more detail in this video:

Watch this video on YouTube

Lamps in the form of flowers from isolon

Izolon is most often used to make beautiful jewelry and decorative flowers. These masterpieces are almost indistinguishable from the real thing. Despite the apparent complexity of the work, giant plants made from isolon are the simplest craft that a novice craftsman can complete.

For work we use familiar objects:

- 5 strips of isolon 1 m long, 15, 15, 23, 30, 33 cm wide;

- plastic container with lid;

- cartridge;

- glue gun

Watch the video in which the author explains in detail how to make a flower from isolon with your own hands. He got a huge rose. You can decorate your garden plot with it. If you are starting a renovation, save some isolon to make this luxurious flower.

Watch this video on YouTube

Master class on making a lamp in the shape of a doll from isolon

Almost any lamp can be made in this way. For example, the author of the following video explains in detail how you can make an unusual lamp for a child in the shape of a doll. This idea will make your child absolutely delighted.

Watch this video on YouTube

Most popular manufacturer

OJSC Izhevsk Plastics Plant is the largest enterprise in Russia and the CIS producing material under the Isolon brand.

The plant supplies Izolon throughout Russia, as well as to the CIS countries and Europe. The company has existed for more than 50 years and produces isolon PPE and NPE in rolls and mats in accordance with GOST standards. The company's products have an excellent price-quality .

In conclusion, we can say that izolon easily tolerates temperature fluctuations, is not afraid of heat and cold, while maintaining its flexibility and elasticity . It takes up a small volume and saves space, the material is environmentally friendly and easy to process.

About the technical characteristics of isolon tape, watch the video:

Find out what isolon is like by watching the video below:

Areas of application of polyethylene foam

Cross-linked polyethylene foam is used in the following areas:

- construction;

- food industry;

- mechanical engineering;

- Automotive industry;

- tourism;

- production of leather goods;

- medicine;

- package.

Rules to follow:

- The sheets are placed end-to-end, “welding” them with a hot knife or soldering iron. Additionally, the connections are secured with aluminum tape.

- Foil material should not be placed close to electrical wiring.

- It is advisable to leave a ventilation gap. To create it, the insulation is mounted on bars 5-6 cm thick, and the same ones are attached on top, but in the transverse direction. Plywood is laid or nailed on top of them.

- For fixation, glue 88, Foam rubber-2, acrylic sealant, tape, screws or staples are used.

- It is not recommended to use PPE if linoleum is chosen as the floor covering.

Recommendations for selection

1. The thinnest isolon (2-3 mm) is suitable for installation under a floor heating system.

2. Under laminate, parquet, etc. you need to buy the option from 2 to 5 mm.

3. For wooden and concrete floors - a layer of 8 to 10 mm.

4. Insulation of pipes located underground requires the use of cross-linked polyethylene foam from 15 to 45 mm.

5. High-quality sound insulation of floors between floors can be obtained using isolon with a thickness of 8 to 10 mm. This layer is enough to drown out normal speech, soft music, and footsteps. If a high noise level is expected, then a thicker layer will be required.

6. For pipes and dry screed devices, only foil-coated Isolon is suitable. Thermal insulation for traditional “wet” is made of a product with foil on both sides.

7. When installing laminate or parquet on joists, it is recommended to use 1508 grade strips as gaskets. They are dense and effectively dampen noise when placed under the joists. Thin, loose insulation 3002 is laid directly under the floor covering.

8. If the covering (most often parquet, laminate, solid board) is laid directly on a wooden base, then Isolon is laid without a ventilation gap in one layer. The joints are connected with aluminum tape. Plywood is laid on top, secured with self-tapping screws. Then the finishing floor covering is laid.

9. Lay on the floor with foil facing up. If we are talking about insulating walls from the inside of a building, then they are placed with the reflective side facing the inside of the room.

10. Isolon is also mounted on bars on walls. Slats are placed across them on top of the thermal insulation, onto which plasterboard, plastic or wooden panels are mounted.

Sheet polyethylene foam can be purchased individually. The unit cost depends on the manufacturer, brand, and batch size.

Advantages and disadvantages

Advantages of insulation:

- Excellent thermal insulation characteristics.

- Low vapor permeability.

- Water absorption is less than 1%. Moisture is not absorbed into the internal structure of the material, so it does not need waterproofing.

- Excellent sound insulation.

- Easy to cut and install. You can insulate your home yourself, without hiring specialists.

- Increased flexibility and elasticity of the material.

- Environmentally friendly. Izolon PPE does not emit toxic substances and does not harm humans and the environment.

- Hypoallergenic. The material does not cause allergic reactions on the skin.

- Izolon is not very heavy.

- The service life of the material is up to 100.

- Recyclable.

What types of isolon are there?

How to properly lay laminate flooring with your own hands

When viewing this building material through a magnifying device, you can see what isolon is. The material has a foam base with closed cells.

- Based on the characteristics of the base, isolon is divided into two types:

- Polyethylene foam (PPE);

NPE, it has an unbound molecular structure, sometimes it is called non-crosslinked polyethylene foam Izolon.

Using a special technology called cross-linking, the service life of the product is significantly increased, thereby ensuring the constancy of the performance characteristics of this material. The type of a certain insulation can be easily determined by touching it or simply by assessing its appearance. For example, NPE has a larger cell structure and is not as elastic as the first type of isolon.