Izolon is considered an almost universal material used for heat, steam and waterproofing. During the production process, the ISO standard is necessarily taken into account. Finished products are used in almost all industrial sectors, which is possible due to their excellent performance characteristics.

Features and types

Izolon is an insulating material created in accordance with special technology. The main raw material is foamed polyethylene, which, under high pressure, obtains improved performance properties. Sometimes izolon is additionally covered with a layer of aluminum foil. This material has excellent elasticity and thermal insulation properties , thanks to which the product can be used in any room.

The use of special technology can significantly extend the service life of the finished material. 2 varieties of isolon on sale .

- PPE, that is, cross-linked material. Its structure resembles polyethylene, and it does not change during heat treatment. The product does not pose a danger to the environment or human health. The slight specific smell disappears in literally 2–3 weeks.

- NPE or uncrosslinked material. It is characterized by its unbound molecular structure. Accordingly, the products are more resistant to aggressive environments. Overall this material is more durable. It also does not require special care.

Specifications and Benefits

When purchasing such an insulating material, you need to remember that its properties will differ depending on the type.

PPE:

- thickness from 1 to 50 mm;

- sound absorption about 68%!;(MISSING)

- water absorption up to 1%!;(MISSING)

- density 30–200 kg/m³;

- reflection level 95–97%!;(MISSING)

- permissible temperature from -60˚С to +75˚С.

NPE:

- thickness from 1 to 16 mm;

- sound absorption 3–13%!;(MISSING)

- water absorption about 0.2%!;(MISSING)

- density 19–35 kg/m³;

- permissible temperature from -80˚С to +80˚С.

The service life of both varieties is approximately 90 years . At the same time, isolon tolerates negative external factors well, including chemicals and precipitation.

The main advantages include:

- high quality;

- environmental friendliness;

- non-exposure to UV rays;

- minimum weight, due to which the walls and foundation will not suffer from the load during installation.

It is important to note the thermal insulation properties. The main feature is the low thermal conductivity coefficient .

All cells of the material are closed, which means the surface will be protected from steam and moisture. Although the insulation is quite thin, it provides excellent sound protection. Most insulators are not used in various fields due to chemical activity, which cannot be said about isolon. It does not react with petroleum, oils and various chemical compounds .

The only drawback of the product is its high cost, as well as the need for careful transportation and proper storage. In addition, the product should be installed carefully so as not to damage its structure.

Areas of use

Isolon is very common in the modern building materials market. This popularity is explained by its good performance properties , which affects the scope of applications. Today, insulation is widely used in the following industries:

- medical industry;

- arrangement of housing and industrial premises, namely insulation of foundations, roofs, floors, production shops, utility rooms and warehouses;

- repair and production of vehicles;

- production of thermal blankets and various packaging;

- assembly of refrigeration equipment, air conditioners, heating systems;

- construction of shops, baths and shopping pavilions;

- creation of arch supports, insoles and other inserts for shoes.

Laying isolon

As mentioned earlier, isolon is easy to install. Accordingly, no special tool is required. To complete the work, it is enough to prepare the glue. You will also need nails or a construction stapler. During work, it is necessary to seal the seams. Aluminum tape is used for this purpose. It will help create a truly uniform reflective surface . After completion of the work, the insulation is painted or covered with a layer of polymer film.

It is important to remember the ventilation that walls need.

If you perform internal insulation, the surface will begin to deteriorate. This can be avoided by ensuring there is a ventilation gap .

Izolon is the best choice for insulating various structures. This material is quite expensive, but it will last for 90 years, protecting the room from heat loss. At the same time, the insulation does not have a negative impact on human health.

Izolon

Isolon is a polyethylene foam complex insulation with a wide range of capabilities.

It has excellent sound-absorbing properties, high heat, hydro and vapor barrier characteristics. Izolon technical characteristics and properties. Available uncoated and laminated on one or both sides with aluminum foil, which is protected by polypropylene film, Izolon foil insulation acquires the qualities of reflective thermal insulation. Ideal for both keeping warm and cold.

The material is produced by foaming polyethylene using hydrocarbons. The output is an elastic elastic fabric of a porous structure with closed cells.

Due to its low price, good insulation and strength properties, and ease of installation, it is widely used in construction and other industries.

Izolon, obtained in different ways and therefore differing in properties, is divided into two types:

- cross-linked – Izolon PPE (polyethylene foam);

- uncrosslinked – Izolon NPE (uncrosslinked polyethylene foam).

Izolon PPE

Production using this technology involves cross-linking (cross-linking) of foamed polyethylene molecules and the formation of a cross-mesh structure. Thanks to cross-linking, the cell walls become resistant to loads, retain strength without losing elasticity. Such products have a long service life and high resistance to destruction.

The creation of transverse intermolecular bonds of foam can occur by chemical and physical (radiation) methods.

In a chemical process, initiator substances (porophores) participate in the construction of the structure. With radiation, cross-linking is carried out by a beam of energy.

Properties

Izolon PPE has a smooth surface, elastic, durable microporous base with a cell size of less than 1 mm. The material boasts excellent elasticity and wrinkle resistance, and after compression it completely restores its shape.

Has the following qualities:

- Effective thermal insulation. Retains heat better than mineral insulation. Operates over a wide temperature range.

- Low moisture and vapor permeability. It practically does not absorb water; the closed-cell structure filled with air creates a floating effect.

- Significant noise absorption. It has anti-resonance soundproofing characteristics and dampens impact noise.

- Chemical inertness. Resistant to petroleum products, gasoline, microorganisms, and atmospheric influences. Not afraid of UV rays.

- Elasticity and light weight. One of the lightest insulation materials, soft and durable at the same time. Very convenient for installation, quick and easy to process.

- Durability. The service life, while maintaining all operational characteristics, reaches 80 years.

Izolon technical characteristics

Technical parameters may vary depending on the thickness of the material, its type and density.

| Density | 25-200 kg/m3 |

| Thermal conductivity at 25°C, no more | 0.032 W/m*K |

| Water absorption by volume, no more | 1%! |

| Vapor permeability coefficient | 0.001 mg(m*h*Pa) |

| Specific heat | 1.35 W(m*°C) |

| Flammability group | G1-G4 |

| Ultimate strength, compression by 25%! | 0.035 mPa |

| Shrinkage when heated to 70°C, in 22 hours | 1.45%!p(MISSING)longitudinal size, 0.75%!p(MISSING)transverse size |

| Operating temperature range | -60°C to 75°C |

| Sound absorption coefficient at frequency 250 Hz and 6000 Hz, not less | 7%! and (MISSING) 60%! |

| Level of improvement of sound insulation against impact noise (Lw)³ 18 dB | for seamless cement floors 50mm |

We recommend: Sticking tiles to drywall

Application

The product is mainly used in construction, mechanical engineering, production of refrigeration units, and consumer goods.

Serves for thermal insulation of walls, partitions, and roofs of buildings. It is used as a sound absorber in the construction of floors and inter-concrete floors. As thermal and sound insulation, it protects ventilation pipes and air conditioning systems, and underfloor heating in systems.

Taking advantage of its buoyancy properties, it is used to fill flotation devices and life jackets.

Izolon NPE

This type of product is obtained using a simplified technology, when the polymer is foamed with gas mixtures under pressure. The expanding gas forms closed pores, where it partially remains. The gas-foamed material has a slightly wavy surface, the base consists of large cells.

Since the structure lacks cross-links between molecules, this insulation is not so strong and elastic. It wrinkles easily, loses elasticity and is prone to destruction of pore walls under stress and aging.

Many technical characteristics for this type of isolon have not been established due to their insignificance, since it is characterized by low thermal parameters, inability to bear mechanical loads and insufficient durability.

Application

Its density of 25-30 kg/m3 limits the use of the product within the low requirements of insulation areas. Often used as packaging and cushioning material.

Video

Source: constructionlinfo.ru

Composition of isolon and its characteristics

Izolon is made by foaming polyethylene, so its structure consists of many closed air pores in the synthetic material. The material is elastic, but very soft, so it can be laid on almost any geometrically complex surface. A special feature of the production of isolon is a thin foil layer of aluminum, thanks to which heat is reflected back into the room, and because of this, the main layer of insulation can be made much thinner than the usual 50-100 mm. Izolon has an initial thickness of 2 mm, and this parameter can increase to 100 mm, depending on the application. Thus, insulating a balcony with isolon will require a layer 20-30 mm thick, since the room is always located on the street. Foamed polyethylene is sold in rolls, sheets, strips or blocks.

According to the manufacturing method, isolon is of the following types:

- Foil-coated isolon NPE (the abbreviation stands for non-crosslinked polyethylene foam). It can be of different densities and thicknesses, with a regular and self-adhesive surface. Technology – method of extrusion and foaming with butane gas;

- Foil-coated isolon PPE (the abbreviation stands for cross-linked polyethylene foam). The technology for producing NPE material differs only in the use of another reagent - porofor, which makes it more environmentally friendly due to the absence of freon.

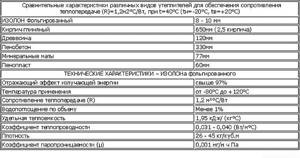

Technical and operational parameters:

| Characteristic | Foaming ratio | ||||

| 30 | 20 | 15 | 10 | 5 | |

| Density, kg/m3 | 33 | 50 | 66 | 100 | 5 |

| Nominal thermal conductivity, W/m•K | 0,031 | 0,033 | 0,036 | 0,039 | 0,041 |

| Water absorption, cm3/m2 | 0,7 | 0,5 | 0,4 | 0,3 | 0,2 |

| Operating nominal temperature | -60°С + 100°С | ||||

| Sound absorption | at 250 Hz -7%, at 2000 Hz – 38%, at 6000 Hz – 60% | ||||

| Thermal energy reflection coefficient | from 95% to 97% | ||||

| Moisture permeability | < 1% | ||||

| Product thickness | from 2 mm to 100 mm | ||||

Isolon vapor barrier is divided into the following brands:

- Foil insulation PPE 500, 500-L - based on polyethylene cross-linked in a vertical oven with a bonded transversely directed structure;

- PPE 500 NR – based on polyethylene cross-linked in a horizontal oven with a bonded transverse structure;

- PPE 500-300 – polyethylene chemically cross-linked in a horizontal oven;

- 100, 100-L – non-cross-linked polyethylene with a molecular structure based on EPPE (extruded polyethylene foam).

Types of reinforced thermal insulation materials based on polyethylene foam:

- PPE with increased wettability characteristics, intended for painting and gluing;

- Izolon with increased rigidity properties;

- Insulation in a wide range of colors;

- Izolon with additives of fire retardants, as a result of which the degree of flammability of PPE is reduced.

Basic techniques for creating flowers from isolon

In order to make a flower from isolon, you need to clearly imagine the original and know thoroughly what each vein in the petal and sepal looks like

In addition, it is important to choose the right shade combination and sizes. After this you can start making templates

Photo zone with flowers from isolon PHOTO: pinterest.nz

What you need for work

A big plus for those who are just starting to master working with isolon: the material does not require the purchase of complex, expensive tools. It is very similar to foamiran, and every home has all the equipment to work with it:

- tailor's scissors, they can be replaced with a mounting knife;

- hair dryer, suitable not only for construction, but also for household use, but with two heating modes;

- glue gun, which must have a temperature switching mode;

- stapler, staples and threads;

- paints: in a spray can or acrylic.

Using a hairdryer, you can give the blanks any shape PHOTO: ytube.tv

How to make a flower

Isolon is often used to make flowers of various sizes: from a tiny bud to a full-blown inflorescence or a composition the size of a person. They can be located on stems, formed into bouquets, and flowers are often used to create three-dimensional panels.

When creating flowers from isolon, it is necessary to take into account some nuances:

- Each flower or bud is assembled from several elements. Small parts are made in sizes 10x10, 12x12 cm², larger ones - from 20x20 to 50x50 cm². When assembled, the diameter of the flower can exceed 1 m;

- The thickness of the isolon is selected depending on the parameters of the flower. For small products you can use material with a thickness of 2 mm, for larger ones - over 3 mm.

Assembling a flower PHOTO: pinterest.ru

Stem

For large growth flowers, the stem must first of all be strong and solid. A pipe made of metal, plastic or metal-plastic is best suited. Plastic elements can be given any bend by heating.

For buds or small flowers you can use the following material:

- wire, it is better to choose it with ready-made green insulation;

- thin metal rod;

- plastic cocktail straw.

For a small stem, ordinary wire is suitable PHOTO: livemaster.ru

Petals

The technique for forming the petals of different flowers is different; when making your own, use the following recommendations.

| Illustration | Flower | Flower formation technique |

| PHOTO: youtube.com | Rose | First, a bud is formed, half-opened and opened petals are placed around it |

| PHOTO: youtube.com | Peony | For a peony, a half-open bud is used; the petals have a carved edge at the top. |

| PHOTO: skillofking.com | Tulip | The flower consists of four petals, connected in pairs around a stem |

| PHOTO: pinterest.ca | Chrysanthemum | For a chrysanthemum you need to prepare a large number of thin petals that are connected around the stem |

Stand

Most often, the following options are used as a stand:

- welded structure made of steel base;

- a concrete stand, this option is similar to a welded structure, with the exception of the base, which is filled with mortar;

- a stand from different containers, into which cement mortar is poured, and before it hardens, part of the rods from the flowers is inserted.

Metal stands PHOTO: salvabrani.com

Pros and cons of the material

Izolon has many advantages, for example, this material:

- characterized by high density and tensile strength, making it difficult to tear;

- convenient to cut not only with scissors, but also with a cutter, which allows you to create smooth and clear cut lines;

- is considered an environmentally friendly raw material for the manufacture of anything, and is also anti-allergenic and does not provoke allergic reactions;

- inert to combustion, it melts and is lightweight, and therefore does not weigh down large flower arrangements;

- does not mold, is resistant to water and moisture, and the formation of pathogenic microbes;

- adheres well to each other and other ornamental materials;

- may involve tinting with pastels, due to which life-size flowers can be made more similar to real ones;

- characterized by low vapor permeability, high levels of flexibility and elasticity;

- has no persistent chemical odor, does not emit toxic substances into the air, and therefore does not harm either humans or the environment;

- Can be painted with various dyes (including those based on rubber, as well as acrylic enamel).

The uniqueness of finished products made from isolon is the fact that they can be wiped with a damp cloth (with the exception of tinted fragments). At the same time, the service life of the flowers will be long, because isolon can keep its shape for more than one year in a row. This material has a certificate of quality and compliance with the required standards. However, in addition to the advantages, ornamental raw materials for life-size flowers have several disadvantages, for example:

- despite the assurances of manufacturers, sometimes suffers from transportation;

- not every type of material is suitable for creating large flowers, and therefore the choice must take into account the thickness of the raw material;

- Isolon attracts dust and becomes electrified, which is why it needs to be stored in plastic bags, and the crafts themselves should be treated with a special compound;

- is not a universal raw material for flowers of different sizes (the larger the flowers, the greater the thickness of the isolon should be).

Use for insulation

Correct use of isolon - what is it for insulation? When constructing various structures, it is necessary to consider the issues of insulation and sound insulation.

You can insulate your home not only during construction, but also as a renovation to create comfort.

A subtlety that increases the efficiency of such work is the air cushion between the surface and the insulating coating:

- Wooden planks are fixed to a wall or other surface with a distance between them of no more than 90 cm.

- Install isolon. Fastening must be done sequentially, starting from the top bar. Having stretched the insulation, attach it to the next plank.

- Glue or fasten the joints using any of the technologies used.

If you plan to stick wallpaper over isolon insulation for aesthetic reasons, then you should select thin wallpaper that does not have much weight. Otherwise, the integrity of the isolon may be compromised. Primer is not acceptable.

One common application is insulating a balcony. Will create the opportunity to use this space in colder times.

Construction professionals recommend that when insulating balconies, install according to the “sandwich” principle:

- the first layer is isolon with the foil facing out;

- the second layer is ordinary isolon or polystyrene foam. There are many myths about polystyrene foam;

- the third layer is again one-sided isolon with foil inside the balcony space.

After this, the sheathing is done and finishing work is carried out.

When insulating a living room, you should not forget to place the insulating material behind the central heating radiator. By the way, do you know which batteries are best to use in an apartment?

This is somewhat more difficult than laying on a free surface, but has an even more significant effect, increasing heat transfer from the heat source. The foil should be directed towards the room.

Areas of operation

The versatility of the characteristics determines the use of the material in many areas:

- underlay – after insulating the subfloor with Izolon, you can lay carpet or laminate in a wooden house;

- protection of communication systems - climate and refrigeration units, gas and water supply lines, as well as ventilation;

- thermal insulation of any surfaces - subfloor, walls, roof, ceilings or basement;

- insulation of outbuildings (bathhouse, sauna) and utility rooms.

The insulator is also used in commercial construction.

Features of loggia insulation

To insulate a balcony or loggia you will need rolled Izolon, as well as a drill, a screwdriver, 2x4 cm and 5x4 cm bars, a stationery knife, and a furniture stapler. Using the material it is easy to create a kind of cocoon that retains heat:

- Attach the slats vertically to the walls in 90 cm increments.

- Form layer-by-layer thermal insulation - put foil Isolon 5 mm thick at the bottom, then foam plastic, then again foil Izolon 3 mm thick.

- Secure the insulation with a stapler. One edge is fixed with staples, the rest is stretched to the rail and nailed with staples.

- Seal the joints with metal tape or masking tape.

- Treat wide gaps with polyurethane foam to eliminate “cold bridges.”

The loggia is insulated with Izolon with a foil layer on the inside.

Creation of wall thermal insulation

Foil insulation is best suited for walls - the shiny surface of Izolon will direct thermal energy back into the room. When sticking to a polyethylene base, good sound, moisture and vapor insulation can be achieved. The work is performed as follows:

- Installation of wooden slats 2x4 cm with a gap of up to 1 m.

- Laying mineral wool into the frame by surprise.

- Attaching foil-isolon to the beams using a stapler - the shiny layer is directed into the room.

- Lay out the rolls so that all the joints match.

- Sealing the cracks with metal tape.

- Padding over the thermal insulation of the counter-lattice.

- Installation of decorative finishing.

The distance from the foil to the finishing material is from 15 mm.

Thermal insulation of floor covering

To properly insulate the floor, you will need to additionally use mineral wool, polystyrene foam and expanded polystyrene. It is allowed to work on standard surfaces or to organize a substrate for heated floors. Experts provide a step-by-step algorithm of actions that must be followed:

- Preparation. The old covering is dismantled and garbage is removed from the room.

- Inspection of the lower structure. The peeled and cracked screed is removed and a new one is installed. All cracks are closed with mounting foam or cement-sand mortar.

- Making a subfloor. Boards are attached to the surface in increments of up to 1 m, and chipboard or plywood is fixed to the joists. 5x4 cm beams are attached on top of the materials.

- Installation of waterproofing. The surface is first coated with a primer and then lined with a waterproof film. Its edges protrude beyond the walls by 10-15 cm and are fixed with a stapler. The film is overlapped by 10-15 cm, all connecting lines are taped with metal tape.

- Laying Isolon. It is allowed to use material 4-10 cm thick. Before installation, the insulation is cut into the required sections. Laying is done on top of the waterproofing coating, the joints are taped with metal tape.

- Lag fastening. The extreme ones are located near the walls, the intermediate ones - in increments of 50-69 cm. They are fixed with self-tapping screws.

- Installation of the second layer of thermal insulation. The auxiliary material is adjusted to the size of the cells and laid out without gaps. The cracks are closed with polyurethane foam. A polyethylene waterproofing film is placed on top of the mineral wool or polystyrene foam, which is secured with staples.

- Laying the final coating.

For finishing flooring, you need a backing made of sheet plywood or boards 3 cm thick.

Properties and characteristics depending on the type

The properties and characteristics of isolon directly depend on its type and determine the possible scope of application. Before choosing a particular variety, it is worth getting acquainted with the available options.

Cross-linked – PPE

During production, changes occur in components at the molecular level. This group includes products with a cross-ligament and mesh molecular base. The specificity of the composition increases the resistance of the material to aggressive environments, and also increases moisture resistance.

Unstitched – NPE

This variety is distinguished by the almost complete absence of connections between the molecules of the components. Essentially, this is a gas-filled raw material with a closed cell structure. Even at the foaming stage during the heat treatment of the substance, carbon dioxide is added to it. It fills pores that are larger than other materials. In addition, NPE has less flexibility.

Based on the crosslinking method, it is possible to select materials with a chemical or physical option for performing this task.

However, depending on the type of crosslinking, there is no difference in quality characteristics and appearance between the materials.

Taking into account the structure, isolon can be foil-coated or uncoated.

PPE and NPE

PPE – cross-linked polyethylene foam. During the production of this variety, the components change their state at the molecular level. They come with a cross-ligamentous and mesh molecular base. Thanks to this, the material better resists the effects of aggressive substances and has increased moisture resistance, which significantly expands its possible scope of use.

PHOTO: elektro.guruThe cross-linked structure increases resistance to external influences

Features of the material

The basis of the material is closed-cell fine-cell polyethylene foam. The porous structure provides good thermal insulation properties with minimal weight. Unlike another popular foam insulation - expanded polystyrene - isolon is plastic (the main disadvantage of EPS is fragility).

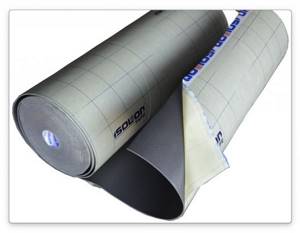

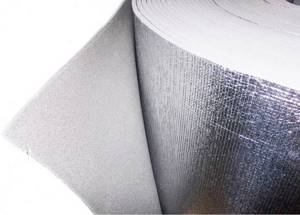

Many models are laminated with aluminum foil up to 14 microns thick, which gives the insulation reflective and heat-reflecting properties, as well as water resistance. The foil can be on one or both sides.

There are types reinforced with polypropylene mesh. The reverse side of the material is self-adhesive or without glue. Combined types are treated with foil on one side and glue on the other. To avoid gluing during transportation and storage, the adhesive surface is covered with a protective film.

Isolon sizes

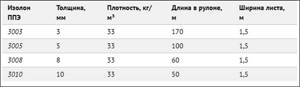

As we noted above, isolon is available in different variations: sheets, rolls, skeins. Rolled isolon most often has a thickness from 2 to 10 mm, a width from 80 to 150 cm, a length from 50 to 200 m. For convenience, the marking of the material is read as follows: the first two numbers indicate the foaming ratio, the second two indicate the thickness of the sheet. For example, Isolon 3005 has a thickness of 5 mm, a foaming ratio of 30 and a density of 33 kg/m³.

Characteristics of rolled isolon PHOTO: holodine.net

Advantages and disadvantages

Let's name the main advantages of the material:

- high strength, resistance to mechanical stress;

- durability – the service life of the material reaches 80-90 years;

- low vapor permeability, water absorption less than 1%;

- excellent sound insulation;

- ease of installation;

- environmental friendliness;

- low weight;

- safety for humans;

- Isolon is a fireproof material; when heated, it decomposes into carbon dioxide and water.

Among the disadvantages:

- high price;

- requires special transportation conditions;

- instability to aggressive chemical compounds;

- instability to damage from sharp objects, so a protective lining is necessary.

Important! Izolon does not emit toxic substances when burned.

How to choose isolon for insulation

The choice of material depends on the purpose. For sound insulation of interfloor ceilings and floor insulation, isolon with a thickness of 0.8 mm to 1 cm is most often used. When installing heated floors - from 2 to 4 mm, for laying laminate - from 2 to 3 mm.

Important! When installing a floor with a dry screed, one-sided foil-coated isolon is best suited. If the floor is made with a “wet” cement-sand screed, it is better to choose a double-sided one.

Depending on the purpose, different types of insulating material are used:

- Isolon “Tape” or isolon in tape is used to insulate ceilings and cracks. This is an excellent sealant for insulating window niches and loggias;

- Isolon “Block” is a sheet material used for internal thermal insulation of premises, external thermal insulation of seasonal auxiliary buildings, interfloor ceilings, flat and pitched roofs, foundations;

- For insulation of heating mains and other pipelines, foil-coated isolon is preferred, the performance characteristics of which are an order of magnitude higher due to the reflective layer.

Kinds

The following types are available:

- uncrosslinked – NPE;

- cross-linked – PPE, which is divided into subtypes: chemically cross-linked PPE NX and physically cross-linked PPE NR.

In terms of its characteristics, isolon NPE is inferior to cross-linked ones.

Izolon PPE is resistant to aggressive influences and has higher heat, sound and moisture insulation values. It is possible to combine different types in one product.

To reduce losses from radiation of heat waves absorbed by the internal surfaces of the room, a fairly simple but very effective method is used - covering the isolon with foil. The role of foil is its ability to reflect infrared rays. This significantly increases the importance of isolon in its fight against heat loss.

Please note: Mineral wool characteristics and properties

Foil-coated isolon comes in the following modifications:

- “A” – one-sided foil coating;

- “B” – coated on both sides at once, which increases resistance to external influences;

- “C” – self-adhesive;

- “ALP” – self-adhesive, with a protective film.

Insulation with foil must be laid in such a way that its metallized layer “looks” into the insulated room

When laying foil-coated isolon with a protective film, it should be carefully removed, freeing the surface with the applied adhesive composition. If a non-self-adhesive option is used, then you should use glue that is suitable for this purpose in terms of its properties.

Some varieties of isolon have a high wettability value, which facilitates the use of glue for their fastening.

Installation technology of thermal insulation material

Installation of isolon does not require a lot of knowledge, however, a certain algorithm of actions still needs to be followed.

To avoid damaging the insulating layer, the sheets are laid end-to-end during installation. Aluminum tape is used to seal the seams.

Sequence of work when insulating walls using isolon

Important point! When installing thermal insulation material, protect yourself from electric shock, as the material has high electrical conductivity.

When insulating balcony structures, it is important to prevent the occurrence of condensation. That is why it is necessary to leave ventilation gaps.

Features of using foil insulation

The use of materials with foil for insulation depends on a couple of indicators: the properties of a particular heat insulator and the place where it will be used. In general, with the help of such thermal insulation, floor structures are insulated, the heat transfer of heating radiators is increased, and air ducts and pipelines are finished. Thermal insulation of entrance doors of verandas, loggias, porches and balconies also gives excellent results

When installing foil-type insulation, you need to acquire all the necessary tools for the job:

- Construction stapler.

- Small carnations with large heads.

- Nail puller and hammer.

- Construction tape with foil coating.

- Direct insulation with foil.

The most common mistake many builders make is incorrect installation of the material with the foil surface facing outward. Due to the fact that the foil is a reflector, it is designed to return heat to the room. But if you place the insulating material on the wrong side, you won’t be able to achieve this effect.

When laying foil insulation , it is recommended to enclose it in a wood sheathing.

Slabs, rolls or sheets of material must not be laid overlapping. They must be installed strictly on the same plane, secured with nails or construction staples.

Material with an adhesive surface does not need to be secured with additional fasteners, but to increase service life it is still better to use small nails. In the absence of an adhesive coating, rubber or acrylic adhesive can be used to fix the material on the surface.

After installing and securing all layers of heat insulation, the joints between them must be treated with foil tape. This completes the installation.

When installing a heat insulator on vertical surfaces that have mold, wallpaper or dirt on them, they must first be cleaned, otherwise the fixation will be very unreliable, and the material will simply fall off over time. In addition, it is recommended to treat the surface with antiseptic agents.

Easy to use and very high-quality foil insulation will save money and keep your home cozy and warm.

Tips and tricks

When choosing isolon, you should adhere to the following recommendations:

- The cost of thermal insulation products does not always determine its quality, so you should pay attention to the manufacturer of the product, as well as its technical characteristics, in order to choose a product that is ideal for insulating a particular surface.

- Installation and fixation of seams cannot be done with ordinary tape; there are specialized adhesive aluminum tapes for such purposes.

- During the installation process, do not forget about the ventilation layer, which must be formed near the walls.

- Products, especially products with a foil layer, require compliance with the specified storage conditions, as well as care during transportation of the goods.

- Violations made during the installation of heat-insulating material can damage the integrity and structure of the isolon, as a result - the product will lose its properties.

A very important parameter of isolon is the thickness of the products. It is this indicator that determines the scope of product operation.

Experts advise that when purchasing material, tell the consultant or distributor of the product the area in which you plan to use thermal insulation.

To help make the right choice, manufacturers classify products based on thickness and area of installation.

- To carry out work on thermal insulation of pipes located directly underground, it is necessary to use PPE with a thickness of 15 to 45 mm with a foil layer for work.

- Sound insulation in multi-storey buildings between floors will have a high level of quality if you use isolon of 8-10 mm thickness. Such material will be enough to reduce noise from the movement of people living above, as well as to eliminate the audibility of low-volume music from neighbors. But for buildings where the top floor, for example, will be used as a gym, you need to purchase products with greater thickness.

- Floor coverings, for example, laminate, can be insulated with high-quality 3-5 mm products. For a “warm floor” system, preference should be given to products with a minimum thickness. Based on the type of floor screed, it is recommended to use different types of isolon: for a dry screed - foil material, for a wet screed - you need to lay products with a metallized layer.

- Thermal insulation of wood and concrete bases is carried out with products with a product thickness of up to 10 mm.

Basic properties

Many consumers are wondering what isolon is. If you are also one of them, you should know that the material does not perceive temperature changes and does not change parameters when they fluctuate sharply. The structure is characterized by high noise insulation qualities, while the thickness is relatively small.

Izolon is quite often used by motorists for interior decoration. It is impervious to moisture and is able to protect metal from corrosion. For the hood, you should purchase a foil version that is laid on mastic. In order to avoid installation difficulties, it is better to purchase insulation with an adhesive surface; it can even be laid on a base with complex geometry.

If you are wondering what isolon is, then you should also know that this material is durable and reliable. It does not require additional maintenance during operation, is fireproof, does not support combustion, but evaporates. At the same time, it decomposes into carbon dioxide and water.

The main purpose is repair work inside buildings. When creating self-leveling floors, a thin layer of thermal insulation is laid to prevent the solution from leaking to the lower floors. The layer acts as thermal protection and a water barrier, which is important when renovating multi-story buildings.

Among the main properties, ease of installation should be highlighted. The canvas will need to be laid out and secured. In the case of walls, ventilation must be provided. When insulation is carried out from the inside, in the absence of an air layer, the materials will collapse. This is due to the fact that they are hygroscopic and should be protected from moisture or provided with drying and ventilation.

When answering your question about what isolon is, you should know that it can also be used externally. This is due to the fact that the material is resistant to ultraviolet radiation. Due to the fact that isolon has high sound insulation properties, it can be used as insulation for a balcony; it will not decompose under the influence of ultraviolet radiation and will not attract insects, rodents and birds.