Choosing a material for insulating a metal entrance door

You cannot begin work without it, which is why you first need to decide on the best option, having previously examined each of them in more detail and purchase it. There are a large number of different insulation materials on the market, making it quite easy to choose the one that suits the cost and technical parameters. For thermal insulation, you can use not only hard but also soft materials.

Mineral and stone wool

Mineral wool is in quite significant demand on the market among consumers, which has an affordable price, perfectly absorbs noise, has the ability to restore its original dimensions after compression and, due to its soft structure, is easy to use. This insulation withstands temperature fluctuations, providing complete protection of the building from the penetration of cold into it, and it is also environmentally friendly, non-flammable and allows you to vary the installation height without the need for additional cutting.

Mineral wool is supplied for sale in rolls and sheets, which makes it possible to cut blanks of the required size, which are placed in cells created by the stiffening ribs of the door structure itself. To obtain the required thickness of the insulation, you only need to press it down (pressure), which in the end will in no way negatively affect the technical performance.

The disadvantages of mineral wool include softness, which leads to shrinkage over time, but this disadvantage can be easily eliminated by creating stiffening ribs in the door structure, which prevent the material from slipping over a long period. Its significant disadvantage is its poor resistance to the influence of moisture, often acting as condensation, which occurs due to a shift in the dew point inside the door leaf. To perform high-quality insulation and avoid this drawback, it is better to give preference to stone wool.

Unlike mineral wool, it withstands its impact and allows for effective thermal insulation even of the entrance doors of private houses. In another situation, mineral wool may be a suitable option only when insulating structures that are installed in heated vestibules or corridors of apartment buildings, as well as when additionally installing a waterproofing film inside it.

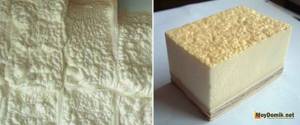

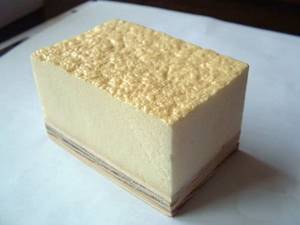

Foam plastic and penoplex

Preference is given to it quite often, since the insulation has insignificant weight, which does not lead to significant weighting of the door. The material has an optimal level of strength and excellent wear resistance, and due to its hygroscopicity, it does not require additional waterproofing. In addition, polystyrene foam has high soundproofing and thermal insulation properties, thanks to which it is possible to reduce noise levels and increase heat retention inside the house, as well as prevent the penetration of cold from the street. When choosing it, you should give preference to penoplex, which, unlike ordinary material, has a higher density, which is why such insulation, even of a finer thickness, has similar qualities as ordinary sheets of standard polystyrene foam. When using it as thermal insulation, it is advisable to additionally seal all seams with polyurethane foam to prevent the formation of cold bridges.

Note! It is not recommended to use ordinary polystyrene foam for insulation, since when heated it can release substances hazardous to health.

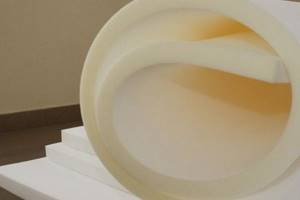

Polyurethane foam (polyurethane foam)

Not quite a traditional option for insulating doors, but which also has a number of positive qualities and even surpasses other materials in some respects. Initially, in order to obtain an effective result, you need to be able to correctly use a spray foam gun or the tube supplied with the container, thanks to which you will not only be able to complete the work fully, but also avoid spraying an excessive amount of excess.

The material itself, due to its airy structure, does not significantly increase the weight of the door leaf, withstands temperature changes and exposure to moisture, and if you know certain nuances, it is quite simply applied and evenly fills all voids, including hard-to-reach areas.

Methods for insulating the door leaf

Approximately 20 to 25% of the heat escapes through an apartment or house door. In order for the entrance system to perform its functions 100%, it requires thermal insulation. To insulate a metal door, use:

- Mineral wool.

- Mounting foam.

- Sawdust, expanded clay, and other bulk materials.

- Polystyrene boards.

- Styrofoam.

Polyurethane foam is the best option for insulating an iron door, but it requires a lot of it to process the sash. For this reason, cheaper materials are most often used, for example, mineral wool or polystyrene foam. Mineral wool is good because it is not flammable, absorbs noise, and also has high thermal insulation parameters. But it absorbs moisture; once it gets wet, it will no longer be possible to dry such insulation. When using mineral wool, it is necessary to lay a layer of polymer waterproofing film. It is best used to insulate metal doors that open into the vestibule or entrance, where there is no huge temperature difference and there is no risk of condensation.

Polystyrene foam has a low cost. When purchasing it, you need to choose materials with a high degree of density. Polystyrene foam and polystyrene, similar in parameters, are not afraid of moisture, and therefore are useful for insulating the front door. Their sheets can be of different thicknesses, and therefore the material can be easily selected for any type of door leaf design. The canvas can be insulated from the outside or from the inside. And if necessary, on both sides. We must not forget that installing insulation increases the thickness of the sash. This must be taken into account during installation work and the selection of fittings - locks, handles and peepholes.

Insulation of the door frame

Insulation of a metal entrance door should begin with the elements of the frame. If the box is made from a corner, then insulation is possible only in the places where the box adjoins the doorway. In this case, the gaps are filled with foam, and the excess insulation is cut off with a construction knife. If the box is made of a rectangular or square pipe, the insulation is placed inside the profile.

The better to insulate

To insulate the door frame, use foam or bulk insulation (sawdust, expanded clay).

Polyurethane foam is used to eliminate gaps between the frame and the doorway, as well as to fill the cavities of frame elements made from profiles.

Bulk insulation is used only for profiled frames. The profile is filled through a technological hole drilled in the upper part of the box. The diameter of the hole should allow the largest fractions of filler to pass through.

This method has a significant drawback: it is impossible to ensure that the entire internal space of the box is filled with bulk materials. As a result of uneven filling, voids are formed that freeze. Therefore, the use of bulk insulation is possible only in production conditions, when assembling the box in the workshop.

Materials and tools

To insulate the box you will need the following tools and materials:

- electric drill;

- metal drills with a diameter equal to the diameter of the nozzle of a cylinder with polyurethane foam;

- polyurethane foam;

- construction knife.

Insulation instructions

To fill the door frame with foam, you will need to prepare technological holes with a pitch of 500 mm. Through these holes, the internal space of the profile is filled with polyurethane foam. Excess foam coming out through the holes must be removed with a construction knife.

The gaps between the door frame and the doorway are cleaned of old insulation, moistened and filled with polyurethane foam. Excess foam is removed using a construction knife, after which the contact point between the box and the wall is masked with putty.

Insulation of metal door leaf

In order not to leave the entrance open for a long time, you should prepare everything you need in advance.

Required tools and materials

- Drill and set of drills.

- Screwdrivers or screwdriver.

- Carpenter's knife.

- Building level.

- Hacksaw for wood and metal.

- Thermal insulation boards or unshaped products.

- Penofol or regular polyethylene film for protection against moisture.

- Steel profile to strengthen the frame.

- Wooden blocks - their thickness is selected according to the thickness of the frame.

- Self-tapping screws.

- Glue liquid nails.

Step-by-step instruction

Before insulating a door in a private house or apartment, you need to establish why the heat is being lost. It is possible that the channels are the rigid frame and through fasteners. In this case, the layer does not need to be changed. If it is possible to replace it with a more efficient one, it is better to do so.

- The sash is removed from its hinges and placed on a workbench. The place can be equipped on the floor. Work begins on the side facing the room. The fittings and cladding are dismantled. The casing consists of a metal sheet and a base, which is a sheet of fiberboard. Porous pads are removed. Then measure the free area between the steel frame elements. It will be needed to create a wooden sheathing consisting of beams. It should not be made of steel and aluminum profiles - these materials conduct temperature better.

- The bars are treated with an antiseptic and varnished. Processing takes several days, but without it the parts will quickly become unusable. Atmospheric moisture condenses inside the canvas in winter. It permeates the array, creating an environment for the proliferation of microorganisms. The varnish covers the fibers, and the antiseptic destroys mold and bacteria.

- The bottom is covered with plastic film with an overlap of 10 cm. It is attached with glue. The joints are taped. A frame is installed on top. The bars are cut and connected with metal corners. Instead, you can place short bars in the corners, adding rigidity to the sheathing. The spacing between prefabricated elements corresponds to the width and length of the panels used as infill. The slabs should fit tightly into the cells, but without significant deformation. The cracks are filled with polyurethane foam.

- If an unshaped mass is used, the cell sizes are set arbitrarily. The smaller they are, the stronger the joint between the outer and inner sides of the fabric, and the higher the conductivity.

- When spraying polyurethane foam or polyurethane foam, you can run parallel slats from top to bottom, installing a stiffener between them in the middle. It is better to place mineral fiber in cells up to 50 cm high, otherwise the mass will settle down.

- A polyethylene film is glued to the wooden frame and covered with a fiberboard sheet removed during dismantling. It is attached using self-tapping screws. Then the metal sheet is returned to its place.

- The perimeter of the sash is covered with tape insulation. It is placed on a clean, grease-free surface, 0.5 cm away from the front edge.

Eliminating Gaps

Heat loss occurs not only through a metal leaf or door frame. During the installation of the structure, a so-called technological gap is created - a gap between the wall and the box, usually its dimensions are about 2 cm. For insulation work, it is best to use polyurethane foam. Simply covering the cracks with cement is not a solution, since such a mixture is not a heat-insulating material. It does not protect the room from the cold, but shrinks over time.

Thermal insulation of the technological gap must be carried out in the following sequence:

- From the side of the room, remove the casing in the place where the box comes into contact with the wall. Secure the polyethylene film.

- Remove the casing from outside the apartment. Moisten the space in the crack with water. You can use a spray bottle. This is necessary so that the polyurethane foam hardens much faster.

- Apply the first thin layer of foam. Its path should be uniform, without breaks or omissions.

- After about 20 minutes, when the first layer of foam expands, apply a second ball of it. It is necessary to ensure that the substance does not bleed beyond the perimeter of the door frame.

- When the foam has completely hardened, remove the polyethylene film that served as protection from inside the apartment.

- At the end of the work, install the platbands in place.

If the foam appears a little outside the box, it’s not a big deal. It must be carefully cut with a construction knife.

Instructions for thermal insulation of doors using wooden mortgages

Installation of rack frame

Foaming gaps between metal and timber

Filling the seams between the insulation with foam

Insulating an iron door with your own hands using wooden mortgages is a feasible task. Mortgages are bars that are necessary to hide the internal filling of the door. They are located around the perimeter of the sash and along its central part. In the place where the lock will be mounted, it is necessary to install additional bars. The fixation method is chosen depending on the material of the structure. If the frame is made of angles, you must pre-drill the holes. Self-tapping screws for metal can be screwed into a profile pipe without drilling. The size of the screws should exceed the width of the bar by 5 mm.

The next stage of work is to fill all the gaps between the metal and the installed beam with foam, after which you can lay the insulation of your choice. The main condition for high-quality insulation is that the thickness of the material is equal to the depth of the door cavity. To prevent the insulation from moving out of place and falling out during installation of the outer skin, it should be placed on glue.

The seams between the individual layers of insulation must be filled with foam, after which the door is left for several hours. After the foam has completely dried, it is necessary to cut off its excess and cover the door on top of the insulation with a pre-prepared panel or slats.

Seal installation

Another weak point in the design in terms of heat loss is the area where the sash comes into contact with the frame. If it does not fit very tightly, a draft will appear. This problem can be eliminated by installing a seal. It is produced in the form of a self-adhesive tape, which can have a different profile (section).

If the gap is small, then an oval or round seal will be useful.

If the gap is more than 3 mm, then it is worth buying a tape with a cross-section in the shape of the letter P.

Before insulating a metal entrance door, in addition to the seal itself, for insulation work you will need to acquire scissors and some kind of solvent to degrease the door.

The scheme of work is as follows:

- If an old seal was installed on the door, it must be removed and the surface thoroughly cleaned.

- Degrease the area for the tape using a solvent.

- Glue the seal around the perimeter of the sash, retreating approximately 3 mm from the outer edge. In this case, the tape must be pressed well to ensure good adhesion (without waves).

Do not pull the tape too tightly while gluing. Otherwise, it will not adhere well to the surface of the door and may come off. It is not recommended to purchase a seal that is too thick, as this may cause the door to open and close poorly.

Insulation of gaps

If a gap of more than 5 mm is formed, it must be insulated, otherwise heat will escape through the cracks. First you need to determine how much the gap needs to be closed. You will need sealing self-adhesive tape or silicone.

The gap area is cleaned of dirt and degreased. Measure the required length of the tape, cut it, remove the paper, glue the tape onto the gap, pressing it tightly. They start working from the top.

The easiest way is to apply silicone into the recess. You can use a construction gun if the gap is large. The gun is held at an angle of 45°, wait for the composition to dry, then remove the excess silicone. The cracks can be covered with felt, thick fabric, or wooden slats.

Important!

In the place where the loops are located, insulation is glued to the inside of the canvas. The joints of the tape are trimmed in the corners.

How to insulate a door frame?

Many people think that to insulate a metal entrance door it is enough to insulate only the leaf. But in fact, the box also needs insulation. If it is made of a metal corner, then insulation can be done only along the perimeter where it adjoins the opening. To do this, just blow out all the cracks with foam. When the substance hardens, the excess can be cut off with a knife.

In the case when the box is made of a square or round pipe, then insulation can be placed inside it.

Suitable for these purposes:

- Polyurethane foam. It is convenient to seal the gaps between the wall and the frame, as well as fill all the cavities of the door frame.

- Bulk materials. This could be expanded clay, sawdust. To do this, make a hole in the profile and fill it with filler. If you perform this procedure yourself, then not all voids can be filled with material. Thorough insulation is only possible when the box is manufactured in a factory.

But you can try to do the insulation yourself. To do this, you will need a drill and suitable metal drills, the insulation itself (spray foam), and a knife.

Completing of the work:

- Holes are made every 50 cm.

- Using them, the cavity inside the box is filled with foam.

- All of its excess that has emerged through the holes is cut off with a knife.

- The gaps between the opening and the box are also filled with foam.

- When the substance becomes hard, it is cut and puttied.

Internal and external insulation of a metal door will reliably protect the room not only from thieves, but also from frost. You can carry out insulation work on your own by placing suitable material on the outside or inside of the sash. You should also take care of insulating the box and gluing the seal. Only a set of measures will prevent heat loss.

Insulating the door from the inside

Before insulating an iron door from the inside, you will need to acquire some materials. So, for work, in addition to insulation, you will need a polyethylene film, a wooden beam for assembling the sheathing, metal corners for the frame, and self-tapping screws. You will also need a hacksaw and screwdrivers.

Insulation of the sash from the inside of the room is carried out according to the following scheme:

- Before you insulate an iron entrance door with your own hands, it must be removed from the awnings. It is better to place the door on a horizontal surface or stools.

- All fittings should be removed: remove locks, latches, handles.

- Remove the fiberboard sheet that covers the sash.

- Make a frame from the timber, inside of which the insulation will be placed. When assembling it, you need to take into account the location of the fittings so that the strips do not interfere with them. To make the frame more durable and rigid, the corners are fixed with metal corners.

- Inside the frame you need to place the selected insulation, apply a layer of glue to the sheathing and attach a polyethylene film. This will provide better insulation.

- All gaps and cracks must be filled with foam.

- Then the interior fiberboard trim needs to be put in place and the door hung on its hinges.

- After insulation, install all the fittings in place and check their functionality.

Many people are interested in how to insulate an iron door from the inside without disassembling it? This is quite easy to do. A frame is made on the inside of the canvas so that you can not only position the insulation, but also secure the decorative facing panel. It can be MDF, plywood with a decorative pattern, or artificial leather.

If the door structure is non-removable, and all the seams are welded securely, there are not the slightest holes, then it is allowed to fill the interior space in the door with perlite or expanded clay. Although it is quite difficult to do this evenly, there is a risk that part of the space remains unfilled.

Do-it-yourself insulation of a metal entrance door

The process begins with the selection of the optimal thermal insulation material, which determines the effectiveness of insulation and its duration.

How to insulate a metal door

Types of insulation:

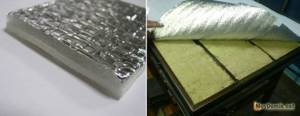

Penofol

Thanks to the reflective ability of the foil layer, it retains almost all the heat in the room. Used only as additional material.

Insulating a metal door with penofol

Rigid insulation

These include polystyrene foam and expanded polystyrene (penoplex). Their advantage is ease of installation and relatively low price. Since it is not hygroscopic, it does not require additional films. This is the only suitable option for installation in a cottage, country or rural house. Indeed, in this case, the door serves as a barrier to low temperatures and wind, which is not observed in apartment buildings where the door opens into the entrance.

Insulation of a metal door with polystyrene foam and polystyrene foam (penoplex)

Note. When choosing thermal insulation material, give preference to penoplex (expanded polystyrene). It is an order of magnitude denser than polystyrene foam and will provide the door with much more effective insulation.

Soft insulation

This category includes glass wool and mineral (basalt) wool. Their difference is only in the raw materials; in terms of their thermal insulation characteristics, they are not very different. Mineral wool is characterized by environmental friendliness, fire safety, and the ability to vary the installation height without additional trimming.

Cotton wool is sold in rolls or sheets, which makes it possible to cut blanks of the required sizes from it and place them in cells formed by the stiffening ribs of the door itself. To ensure the required height (thickness of insulation), simply press down the material (press cotton wool), the thermal insulation properties will not be affected.

But cotton wool has a drawback that prevents it from being recommended for installation in iron doors for private homes. Because There are different temperatures on different sides of the door, and sometimes the difference is up to 40 °C (-15 outside and +25 in the house). This leads to a shift of the dew point inside the insulation, and the wool gets wet. The effect can be neutralized by installing a hydrobarrier film.

But, nevertheless, professionals do not recommend insulating an iron door with cotton wool in a private house. It can become an acceptable option only if the entrance door to the apartment is insulated, since in this case there is not such a big difference in temperatures (it is much warmer in the entrance than outside).

Insulating a metal door with mineral wool

Inflatable insulation

Presented with polyurethane foam. Spraying makes it possible to fill all the cracks, but has a high price.

Insulation of a metal door with polyurethane foam (PPU foam)

Thermal insulation of luxury metal doors is carried out using three types of materials: foam plastic (main material), penofol (additional), polyurethane foam (filling the voids of the stiffeners and frames).

Note: a set of materials that can be found in stores is of little use for insulating an external metal door, because They use dermantin, foam rubber or synthetic winterizer as insulation.

Insulation methods

Modern metal and wooden entrance structures are already on sale with thermal insulation. Another question is that the thickness or quality of the material is not enough to retain heat in the house (Chinese models mainly suffer from this). Also, preparatory work is required for custom-made items, which are initially produced only in the form of a canvas with a box.

In total there are 3 main options:

- end sealing;

- use of rollers;

- insulation for doors.

What is used for thermal insulation

The sealing of the ends and the rebate is used in any case if it does not fit tightly and air movement is felt. Even an insulated door without a seal will let in cold air and heat will begin to escape through it.

Rollers can be used both as an independent element and for upholstery with decorative or insulating materials.

Thermal insulating upholstery is applied on the inside, decorative on the outside or both. Depending on what material is used, the finishing method is chosen.

- foam;

- isolon;

- mineral wool;

- Styrofoam;

- expanded polystyrene.

- leather;

- vinyl;

- leatherette;

- leatherette, etc.

It is very easy to work with foam rubber - the finished sheets are attached to the panel and secured on top with strips. But the inexpensive material accumulates water, which creates cold bridges. In addition, mold can form under the foam rubber.

Izolon is structurally similar to foam rubber, but does not absorb water as actively and does not crumble during operation. They fasten it in the same way as foam rubber.

Step-by-step instructions for insulating a wooden door in a private house

The work is carried out taking into account the characteristics of the entrance group and the installation technology of the selected insulation.

Tools and materials

In the process of working, the following set of tools, devices and materials is required:

- nail puller, pliers;

- screwdriver, hammer;

- hacksaw, jigsaw;

- tape measure, stationery knife, scissors;

- construction stapler.

It is also necessary to prepare the estimated amount of insulation, sealant, sheathing material and fasteners.

Preparatory work

At the preliminary stage, the following work is performed:

- remove the door leaf;

- unscrew door fittings and hinges;

- remove the casing, if present;

- remove old insulation and sealant residues.

Next, the canvas and box are checked for structural defects, distortions and other defects are eliminated.

Cutting and laying insulation

Based on the measurements, blanks of the required sizes are made. When arranging a frame structure, the voids are tightly filled with layers of insulation. The material is fixed using a construction stapler.

Door trim

Dermantin is mainly used as a finishing layer. The upholstery fabric should be cut taking into account a margin of 10 cm on the sides in order to create the necessary thickening around the perimeter. The upholstery is secured with decorative nails and cord to form a distinctive raised pattern. Next, install the door hardware.

The surface of the door leaf is lined with artificial leather from the inside

Seal installation

To eliminate gaps, use self-adhesive strips or install a harpoon seal. Thanks to the special shape, the product fits as tightly as possible to the base, ultimately eliminating the risk of drafts and reducing the level of heat leakage from the room.

Additional measures and means of hydro- and thermal insulation

For maximum quality insulation of a street door in a private house, the joint around the perimeter of the frame is equipped with dermantine rollers with a foam insert inside. It is recommended to line the surface of the entrance sheet with artificial leather from the inside. From the outside, the structure is sheathed with a material that is highly resistant to aggressive atmospheric influences.

Insulation materials

There is a huge range of thermal insulation materials on the market, from cheap (foam plastic) to very expensive (polypropylene plates), and all of them are successfully used for insulating metal doors. Let's look at each of them in more detail.

Mineral wool has remarkable heat-insulating and noise-proof properties. It is absolutely harmless and is not expensive at all. And among its characteristics are excellent moisture resistance and good resistance to sudden temperature changes. However, it also has a drawback - looseness, which creates places that allow cold to pass through.

To avoid this, when insulating, you need to install protective strips that will prevent the material from sagging.

Foam plastic is used to insulate inexpensive doors. It has a very modest cost, high density, low thermal conductivity and long service life.

One of the materials often used for insulation is corrugated cardboard, which has excellent resistance and rigidity, good noise and heat insulation. The price of corrugated cardboard is very low compared to materials installed in premium doors.

Concrete mortar is often used to insulate metal door frames.

A heat-insulating material such as foamed polyurethane is used to insulate expensive doors. It is light in weight, has good rigidity, and is completely harmless. The high cost of the material is justified by its excellent insulation properties, moisture resistance and fire resistance.

For expensive doors, foam panels are mainly used. Today they have the highest thermal insulation rates, and in addition, the best moisture resistance and sound insulation.

Modern technologies, together with the fashion for everything natural, have given the world another insulation material - wood fiber, made from coniferous wood. It has good density and sound insulation, sufficient strength and rigidity. This material is completely harmless and environmentally friendly.

The only disadvantage of wood fiber is its cost. This insulation is one of the most expensive on the market.

Sometimes foam rubber is used for insulation (it replaces mineral wool). It has significant insulating functions, low cost, good elasticity and flexibility. But its service life, unfortunately, is very short, about three years.

Material such as isolon is more expensive, but it has excellent performance. For example, its thermal insulation properties are more than 100% higher than those of mineral wool. Izolon has good moisture resistance, effective sound insulation and is resistant to temperature changes.

Based on the above data, you can easily decide on the choice of material.

Stages of plating an iron model

The sequence of actions when covering an old door depends on its design. If the design is more modern and the metal panels are attached to the base with screws, the insulation is done internally. When starting internal insulation, we remove the metal structure and place it on a work surface. Unscrew the screws and remove the metal panel (to ensure that the screws unscrew well, lubricate them with machine oil). Using a tape measure, take the dimensions of the internal cells of the door.

Carefully measure the insulation material and cut it off. Be sure to cut out a place for the door lock and peephole. For old doors, polystyrene foam or foil-lined stone wool are great. We treat the inner surface of the old structure with glue (liquid nails) and glue the prepared insulation. If there are any gaps between the old door and the insulation, fill them with foam. You must work carefully, squeezing out the mounting foam in small portions. It is important to ensure that it does not get on the bolt lock mechanism. For additional sound insulation, we lay foil insulation between the insulation and the metal sheet. We cover the structure with a metal sheet and screw in the screws.

If the old door is made by fixing metal panels by welding, then we proceed to insulate the old door using the external method. We prepare wooden blocks 20 (30) x 20 mm. We measure the parameters and cut the slats to the required length. Using a drill, we make holes for future fastening in the metal sheet. We assemble the base from prepared wooden blocks and fasten it to a metal sheet with self-tapping screws.

We prepare insulation according to the specified dimensions. We line and glue the insulation into the cells between the slats. We fix the MDF panel or board with screws. Additionally, for sound insulation, the door can be treated with leatherette from the outside or inside. To do this, we bend the leatherette and fix it with staples. Lubricate the lining and hem of the leatherette with glue (liquid nails) and press firmly against the metal sheet. This work is painstaking. At the last stage, we install door locks, handles, and a peephole. We return the finished door to its place.

When covering a single-layer metal door, it is necessary to measure the cells between the stiffeners. We cut the inner material to the specified size. We quickly glue the insulation into the cavity. We eliminate cracks and small gaps using polyurethane foam. We decorate with MDF panel.

How to insulate a metal door in an apartment

The technology of door thermal insulation depends on the structure of the door leaf. First, the material is chosen - most often it is foam or mineral wool.

How to insulate a metal door from the inside for the winter with your own hands:

- Remove the door from its hinges and place it on a flat surface.

- Remove the cover from the inside.

- Old material is removed and cleared of debris.

- The metal frame is filled with foam sheets, which are cut to fit the recesses. The sheets must fit tightly into the frame. They are secured with foam or liquid nails. For mineral wool, a frame is first made.

- The remaining voids around the foam are filled with foam.

- The insulation is covered with plywood or penofol, and leatherette is used for decoration.

- The door is hung on hinges.

Before carrying out work, it is necessary to seal the installation seams and insulate the door frame. The openings are blown out with foam; a cement mixture can be used. The protruding foam is cut off with a knife. After all work is completed, the opening is sealed around the perimeter with rubber tape.

Beautiful ideas

The appearance of the front door always emphasizes the status of the owner. Therefore, in a private home the requirements are especially high. Here it is important to take care of a decent image. The market for metal doors is saturated with a variety of products. Another good thing is that doors can be ordered according to a personal project.

And yet, how nice it is to work on the design yourself! We offer several ideas for decorating metal doors with your own hands. The design of a door in an apartment is interesting because the outside can be decorated so as not to attract other people's attention. The simplest, most affordable way is to decorate a metal door with bright fittings. You can attach new numbers to the outside, add stylized handles, hinges, and locks.

For those who prefer natural materials, we can recommend covering the inside of the door with MDF panels or simple wooden slats. The design and color of the metal door of a private house, as well as the shape, depend on the style in which the house or cottage is built. For fittings, you can use forged parts, stained glass windows, glass inclusions. And instead of a modern bell, you can hang a knocker or gong.

Insulation of vestibules

Before purchasing a sealant (silicone, foam rubber, polymer), measure the perimeter of the canvas. They take into account not only the size of the box, but also the thickness of the narthex, it is 3-5 cm.

The process of insulating the vestibule:

- degrease the area where the tape will be attached;

- They start gluing from the bottom, carefully removing the paper from the sticky layer in small pieces, pressing the tape tightly to the surface.

For better insulation of the house, the tape is also glued to the edge of the box. In a private house, it is better not to use rubber materials; the door goes directly to the street, and not to the entrance. Temperature changes will destroy rubber; in the cold it quickly hardens.

Improving the characteristics of Chinese products

The Chinese-made door is a non-demountable structure. To insulate it, remove the door and place it horizontally. We remove the handles, peephole, locks. Then we begin to attach the frame and stiffeners to it, both from the inside and from the outside. Therefore, we choose a wooden beam with a thickness of 20 * 20 mm, or more (we start from the thickness of the insulation material). If desired, you can weld a metal base, attach it with self-tapping screws or weld it to the door leaf, and fill the joints with polyurethane foam.

The next step is laying insulation. If fibrous materials are selected (mineral wool, stone wool), we lay out a water-repellent material larger in size than the base cavities, approximately 200 mm, secure with glue (liquid nails) and line the wool, having previously cut out a canvas slightly larger than the size of the base cells, and cover with another layer of water-repellent material. We fold the edges of the film tightly onto the top layer and secure with tape.

We cover the insulation with foil isolon or penofol with the foil side facing the room. This will improve the soundproofing qualities of the door. Polystyrene foam, expanded polystyrene, polystyrene, foil-coated isolon do not need waterproofing, since they themselves have water-repellent properties. Next, use a tape measure to measure the distance between the stiffeners, cut the insulation a little larger than necessary to avoid the formation of a cavity between the insulation and the base of the door. We glue the insulation into the cavity with glue (liquid nails).

We coat the base attached to the surface with mounting foam at the joints. The next step is to decorate the structure with an MDF sheet, panel or alternative material. It is important to remember that the decorative panel must be attached from the bottom up. We secure it, install locks, a peephole and handles, and hang the door. Now the door keeps the house warm and also protects from noise.

We insulate the door gap and line the doors

High-quality lining of a metal door on the inside is designed to protect the heat-insulating material, acts as additional sound insulation, and also fulfills its main decorative purpose.

Therefore, such a finishing coating must be: durable, moisture-resistant and, most importantly, have an attractive appearance . In most cases, sheets of laminated chipboard or MDF, plywood and leatherette are used as the final interior decoration of iron entrance doors.

- is cut from the selected facing material in accordance with the dimensions of the doors . The resulting sheet must exactly match the outer frame of the door leaf, but in no case more, as this will lead to the door closing poorly or not fitting into the frame at all. Holes for a lock, door handle and peephole are cut out in a sheet of decorative coating using an electric jigsaw.

- If the cladding is done with plywood, then before installing it, the sheet is covered with leatherette or other practical material for greater aesthetics . The material is cut to the size of the plywood with an overlap of 1 cm on all sides. The allowances are folded along the edges of the canvas and secured with furniture nails or staples. For beauty, you can make patterns from decorative nails on the front side.

- The decorative facing sheet is secured with self-tapping screws to the wooden internal frame . Additionally, the edges of the cladding are coated with glue. Fastening of self-tapping screws should occur at equal intervals of 300 mm along the door perimeter. It is better to use decorative fasteners with large caps.

- At the next stage, the previously dismantled elements are installed : lining, peephole, handle, etc.

- Finally, to prevent drafts, a rubber sealing tape on a self-adhesive base is glued around the perimeter of the iron entrance door frame. To do this, simply remove the protective layer and press the seal against the door frame.

Tips and tricks

The following recommendations should be followed:

- It is best to insulate a plastic door with glass, using an additional double-glazed window;

- it is necessary to pay equal attention to both the insulation of the canvas and the thresholds and the perimeter of the doorway;

- standard Chinese metal doors immediately need to replace the insulation.

The front door requires special attention when protecting from the cold. The entire perimeter should be insulated, and the door should be closed tightly and quietly using a seal. The insulation process for doors made of plastic and metal with wood is different.

Insulation of doors around the perimeter. Thermal insulation of iron, wooden structures, windows and loggias

Heat in a home is a combination of many factors, each of which, to one degree or another, influences the temperature in the room.

One of the main steps in this list is occupied by the doorway, which serves not only as an entrance to the room, but also as a potential niche for the penetration of cold. Even if the walls are insulated according to all the rules, an uninsulated door will noticeably freeze, thereby lowering the temperature in the room. Thermal insulation of a doorway can be done with your own hands, given its small size and simplicity of technology.

Insulated entrance door photo

However, despite the small area, the insulation of the front door is significantly different from other types of thermal insulation and, accordingly, has a number of features that must be taken into account when carrying out this process.

Detailed instructions in this article will help you insulate the door around the perimeter yourself, without the help of professionals. With its help, you will save money on hiring specialists and at the same time provide high-quality thermal insulation.

Advice from professionals

The following recommendations from experienced craftsmen will help you avoid common mistakes when insulating a wooden front door:

- It is more effective to use heat-insulating material on both sides.

- You should choose consumable components from trusted manufacturers.

- The selected material must have high performance characteristics.

- The outer cladding must be resistant to precipitation.

- Each stage must be treated with full responsibility.

In the video on how to insulate a door with leatherette with your own hands, you can get acquainted with some of the features of the work:

Common Mistakes

Anyone can stumble: both an experienced installer and a novice home craftsman. When insulating a metal entrance door, there are a number of common mistakes that are most often made.

It is better to insulate a metal door that can be easily opened with a can opener without disassembling it, on top of the inner lining

What to watch out for:

- Season. During the cold period, it is better to postpone door insulation until later, even if there is a very warm entrance or dressing room.

- Ignoring details. The gaps between the frame and the material during insulation, the door frame and slopes also need thermal protection, just like the canvas. If you only insulate the door, the room will not become much warmer.

- Saving. When using natural insulation, you should not ignore membrane films, because otherwise the cotton wool will get wet and become useless. In addition, wet insulation will significantly increase the weight of the door, which can lead to deformation of the fasteners.

A metal door insulated in accordance with all the rules, in addition to providing armor against evildoers, will also reliably protect the house from extraneous noise and pervasive cold. In addition, insulation protects the canvas itself from corrosion and, accordingly, increases its service life. Use the materials that are available to you and don’t be afraid to make mistakes, because only those who do nothing make no mistakes.

Some models of metal entrance doors are already insulated from the factory

Note! If your door has already used up its lifespan, instead of insulation, you should think about a modern solution in the form of a door with a thermal break.

Which insulation is better to choose?

To make an insulated wooden door with your own hands, you will need thermal insulation material, as well as material for the top decorative finish. The gaps are sealed with a sealant. When the question arises of how to insulate a wooden door in a private house, pay attention to the following materials:

- polystyrene foam as internal insulation for wooden entrance doors. The slabs can be sheathed on the side of the room.

- Foam rubber is considered the most common insulation material, which is covered with artificial leather on top. Porous material allows you to create a volume effect. Foam rubber loses over time and crumbles into crumbs.

- Mineral wool does not burn, has good thermal insulation properties, but quickly cakes. When exposed to dampness, it accumulates moisture. Under the weight it slides off a vertical surface.

- Foamed polyethylene - isolon has a structure similar to foam rubber. The material has better thermal insulation properties and a longer service life. Isolon does not tolerate long-term exposure to direct sunlight.

- Polyurethane foam is applied by spraying, firmly adheres to the wood, and penetrates into all cracks. The disadvantage is the impossibility of performing work without special equipment.

- Expanded polystyrene resembles polystyrene foam, but has improved characteristics. The material has self-extinguishing properties when exposed to open fire.

When choosing insulation for the doors of a wooden house, it is important to consider the thickness of the material. Thick layers will weigh down the sash and create an obstacle to normal closing. Thin is useless. You need to find a middle ground between these two parameters.

Foam and polystyrene

Polystyrene foam is a foamed polymer material whose bubbles are filled with air. Polystyrene has a similar structure, but it is filled not with air, but with nitrogen, due to which it is much less susceptible to destruction and combustion, while its price is slightly higher. Both materials are produced in the form of slabs of various thicknesses, so you can choose the thickness of the insulation layer that will allow you to insulate the iron door and achieve the desired thermal insulation properties. Polystyrene foam and polystyrene are not afraid of moisture, so they can be used in any room.

Insulating a door with polystyrene foam