Icer

13513 0 0

Icer September 6, 2016Specialization: master in the construction of plasterboard structures, finishing work and laying floor coverings. Installation of door and window units, finishing of facades, installation of electrical, plumbing and heating - I can give detailed advice on all types of work.

In this article I will tell you how to insulate a shed from boards with minimal cost. This technique has been used for hundreds of years and has proven its effectiveness even in harsh regions. I am sure that this option is available to anyone, and to implement it, you need a minimum set of materials and devices, which is important, because no one wants to spend significant money on a shed.

In the photo: a barn for animals and poultry must be insulated

Insulation inside

It is advisable to carry out internal work on insulating the shed in advance, in the summer.

Otherwise, you will have to come up with a place to temporarily house the animals while repair work is being carried out in the barn. Like external insulation, internal insulation is carried out in several stages. Each of them has its own characteristics, so it is worth considering them in more detail.

Walls and floor

It is better to start interior work from the floor. It is through it that a lot of cold air penetrates inside (Figure 2).

A budget option for floor insulation is as follows:

- The surface is leveled and compacted. Next, pour and compact a layer of soil. It should be 10 cm above the surface of the soil outside.

- Wet clay is mixed with straw and left for 2 days. The result is an organic insulation material – adobe.

- It is laid out on the floor in a layer of up to 10 cm and allowed to dry. This usually takes several weeks, but the result is a warm floor that does not absorb moisture and feces.

Figure 2. Floor insulation options

The disadvantage of such an adobe floor is that debris and dirt accumulate on it, so you will have to clean up after the animals more often.

But there is another insulation option:

- The floor in the barn is deepened by 15-20 cm and leveled. If the surface is uneven, add a small layer of expanded clay.

- 25-30 cm of expanded clay is poured onto the leveled surface. This material perfectly resists cold, so the barn will be warm even in severe frost.

- Next, the beacons are placed, boards or metal profiles are laid and a screed is made. Its layer should be at least 5 cm.

After completing the floor work, they move on to insulating the walls. This process is simple, but requires care and attention, since even small cracks can cause drafts (Figure 3).

Step-by-step instructions for insulating walls:

- The cracks are sealed with polyurethane foam, tow or dry moss.

- Next, make a frame from timber or boards. The distance from the inner edge of the frame to the wall should be 30 cm.

- Insulation is poured into the resulting space. The most budget option is to use sawdust. They are mixed with lime in a ratio of 1:15 to protect the wood material from moisture and pests.

Figure 3. Stages of wall insulation

If desired, the surface of the frame is further processed. To make it easier to maintain the barn in the future, the walls are plastered and then whitewashed with lime.

Ceiling

Most barns have a gable roof. The attic is usually used to store hay or other feed. Dry grass is an excellent heat insulator, but to additionally retain heat, you will have to insulate the ceiling inside the room (Figure 4).

In sheds with a pitched roof, insulation is carried out inside. To do this, a metal or wooden frame is stuffed over the entire surface of the ceiling, insulation (mineral wool or polystyrene foam) is placed inside, and then the frame is sewn up with sheets of plasterboard or wooden boards.

Figure 4. Thermal insulation of the ceiling is carried out from the attic side

Finishing is carried out in the same way as for walls.

Thermal insulation of doors

Even in a well-insulated building there will be drafts if you do not take care of insulating the doors (Figure 5).

To prevent drafts from coming through the door, do the following:

- The structure is hung on reliable hinges. After insulation, the door will become much heavier, and the hinges must support its weight.

- A strip is nailed from the outside around the entire perimeter. Several jumpers are installed inside. Insulation is placed in the resulting cells. You can use mineral wool, but it will make the door very heavy, so many people prefer polystyrene foam.

- To prevent the structure from becoming saturated with moisture, the outside is covered with film or a sheet of corrugated sheeting.

Figure 5. The door also needs insulation, since cold air penetrates through it

From the inside, the cracks in the door are closed by nailing boards or sheets of thin plywood onto them.

Construction of a barn

Usually, the first living creature that new gardeners and owners of private houses get, not counting cats and dogs, are chickens. This is understandable, because they are not at all difficult to care for at any time of the year. In spring and summer, it’s generally a pleasure to set up a canopy where they can hide from the sun or bad weather, and provide them with the necessary nutrition. And in winter it’s a little more difficult. Of course, no one would even think of taking them into the house, and in a flock with tools, the chickens will die from the cold. But don’t despair. Even a barn that looks like a sieve and is blown through by all the winds can be insulated for chickens.

First, we nail two boards to the bars, leaving room for the third. We insert it between them so that from above it lies under the first board, and from below it goes over the second. The wind cannot leak through the resulting “Christmas tree”.

Further, the frame of our shed can be insulated with your own hands in different ways. It is best to buy mineral wool if funds allow.

Or, as an option, you can blow out the empty space with polyurethane foam. But the cheapest and most reliable method will be my grandfather’s method - insulation with sawdust.

Insulating a barn with sawdust

This material can be obtained in abundance at any sawmill and for a devilishly reasonable price. The sawdust should be fine and dry.

We fill the material in layers, constantly compacting it. Then you need to wait a couple of weeks until the insulation settles. After which you will need to add sawdust.

The insulation of the ceiling in the barn follows approximately the same scheme. But here you need to lay another layer of waterproofing on top of the insulation layer. We don’t just cover it with slate, but between it and the insulation layer there should be roofing felt or plastic film.

When insulating the floor of the shed, pour soil at least 10 centimeters in height above the main level. Then pour in and compact the clay. But with this method of floor insulation, you should immediately warn that the barn will always be dirty. If you want a clean floor, then replace the soil with expanded clay and fill it on top with a cement-sand screed. But this will have to be done in advance during the warm season.

Insulating a shed with shingles

By mixing clay with straw, you can make bricks - adobe, from which you can make an excellent warm shed. If the barn has already been built, it can be insulated from the inside with shingles.

Then stir for some time until the solution becomes thick enough not to fall off the base. Before use, the mixture should sit a little longer. Next, apply the mixture to the walls from bottom to top.

Insulating a shed with mineral wool

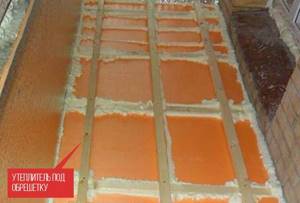

But then you will have to make a plank sheathing, with a distance between the boards corresponding to the width of the slabs or even 1-2 mm less, so that the slabs fit as tightly as possible.

After installation, we run a vapor barrier layer over the insulation to prevent it from getting wet from the condensation that forms.

Insulating a shed with foam plastic

Source

The first method is cladding with boards.

The outside of the barn can be covered with boards according to the principle of brickwork, closing the gap between two boards with a third. The walls are covered with slate in the same way as when covering the roof. In addition, the shed can be sheathed with boards from below. Sheets of slate are placed higher, and then timber is stuffed.

During the work process, insulation is poured between the walls, which needs to be compacted with something. Pine needles, fallen leaves, and sawdust can be used as insulation. These materials are mixed with lime in a combination of one to twenty-five. This avoids problems such as rodents between the walls. The ceiling also needs to be hemmed, and the same composition must be poured on top. Boards are placed above the rafters and covered with roofing felt in several layers, which must be nailed down with wooden slats at a distance of half a meter. The lower part of the barn can be lined with slate on both sides, which will protect the room from rodents and predatory animals.

The bottom of the barn is insulated by filling the floor with soil, 10 cm below the main floor, and then laying and compacting the clay mortar.

The door is made of boards knocked down diagonally, with a layer of roofing felt placed between them so as not to let out heat.

How and with what to insulate walls

A warm barn for chickens is unthinkable without good thermal insulation of the walls. Plank walls are insulated in several layers - inside and outside. A vapor-proof layer is needed inside, and a more “breathable” material outside. If there is no additional layer of thermal insulation on the inside of the walls, you can use straw.

Outside, vertical beams are installed every 60 cm; the thickness of the beam should be 12 cm.

These beams act as lathing, which is then filled with natural insulation mixed with cement. The top layer is a facing layer and serves for decorative purposes. You should definitely think about the waterproofness of the walls, so it would be good to treat the facade with a water-repellent solution.

If you use polystyrene foam to insulate the walls, you must seal the gaps between the slabs well.

If you use polystyrene foam to insulate the walls, you must seal the gaps between the slabs well.

Foam boards are attached to the walls with glue, and then additionally covered with plywood sheets. If desired, the walls can be painted in any color or varnished. It is best to use polystyrene foam no thinner than 10 cm.

Insulating the roof of a chicken coop

When planning a construction, it is recommended to think about the attic and make a structure with a reliable black ceiling. Subsequently, bedding and feed material can be stored there.

In relation to the finished structure, almost the same materials are used (to insulate the roof, additional waterproofing and vapor barrier are used), only the fastening methods change:

- Vapor barrier (vapor barrier films, membranes) is the protection of insulation from moisture that is produced inside the building.

- Waterproofing (roofing felt) serves the same purposes, but is laid outside to protect the insulation from precipitation and condensation formed due to temperature changes.

Step-by-step instructions for insulating a chicken coop

Based on cost, the most convenient type of insulation is polystyrene foam and mineral wool. Before starting insulation, the following tools are required:

- electric drill;

- roulette;

- screwdriver;

- level;

- assembly knife for cutting foam plastic;

- construction stapler;

- hacksaw.

Next, the material is calculated for the entire room. List of materials:

- timber for making a frame (4/4cm);

- sheets of polystyrene foam or polystyrene foam;

- self-tapping screws (for installation in wooden walls), dowels (for hard surfaces);

- mineral or basalt wool;

- vapor barrier film;

- any available panel material (plasterboard, plywood, reinforcing mesh).

The walls are insulated first. The procedure is as follows:

- Along the entire surface of the walls, timber is vertically reinforced at a distance of 60 cm (the width of the insulation). To do this, a beam of the required length is mounted with fasteners (screws, dowels) to the wall, thereby creating a frame for laying insulating material.

- The vapor barrier is fixed with the rough side to the wall. The film is secured with double-sided tape or a construction stapler.

- The next thing to install is insulation. This can be a sheet of foam plastic, mineral wool, or both, depending on the thickness of the walls and climatic conditions. The material is installed on top of the film and tightly joined to the beam. The foam is fastened using umbrella dowels (large diameter cap).

- The final stage is to cover the foam sheet with panels or attach a reinforced mesh. Next, the walls are plastered with cement mortar.

To insulate the roof from the inside, use the same sequence of actions as for the walls. Before the cold weather begins, it is necessary to check the condition of the roof to prevent it from leaking. After the work has been done to insulate the room, the outside walls can be insulated in the same way, but plastered fairly well.

Insulation quality control

It is impossible to visually assess the quality of insulation, because possible imperfections are located inside. Usually for these purposes they resort to a thermal imager, but in the case of a chicken coop this is not advisable. Therefore, quality control is carried out at the stages of material selection and proper installation. Possible errors may lead to the following:

- if the material is chosen incorrectly, cracks appear due to shrinkage;

- If the installation rules are not followed, the vapor barrier seal is damaged, and the lack of ventilation leads to the walls getting wet and freezing.

To be sure of the quality of the purchased material, you need to pay attention to the following points:

- proven, well-known brand of the manufacturer;

- selection of material with suitable characteristics;

- product integrity.

High-quality installation of insulation will guarantee their long-lasting service and preservation of heat in the room throughout the winter.

What symptoms indicate that a chicken cannot lay an egg? More details about this, as well as what to do in this case, are written here.

How to properly raise Linda geese at home? We talked about this in our article.

Cost of insulation

Depending on the size and manufacturer, the price of packaging varies:

- Foam plastic - from 2000-2500 rub.

- Mineral wool from 400-1000 rub.

- Basalt wool from 400-1200 rub.

- Foil penofol - from 300-1700 rub.

- Waterproofing – from 250–400 rub.

- Penoplex - from 100-400 rub.

- Vapor barrier - from 200-2000 rub.

Insulating a chicken coop is a necessary measure for wintering chickens, which guarantees the preservation of livestock and egg production for the entire period. Properly organized insulation allows you to create optimal conditions for birds at different times of the year.

Useful tips

It is necessary to insulate the barn for chickens before the first frost, because otherwise, due to the cold, the bird may at least stop laying eggs, and in the worst case, hypothermia will lead to illness and death of the chickens.

To insulate their chicken coop, many people use peat moss.

It is necessary to insulate the barn for chickens before the first frost.

Not only is it an environmentally friendly material, it also absorbs moisture and chicken droppings, preventing odor from spreading. Peat moss is excellent as floor insulation in a winter chicken coop. Birds moving on such a moss floor will not get their paws wet, which means that the risk of disease in winter will be significantly reduced. Such peat can be reused as fertilizer for plants on the site.

In addition to peat moss, you can use a mixture of wood shavings and sawdust in a ratio of 3 to 1. It is best to use coniferous trees, since they best retain heat inside the barn, and are also a good preventative against a number of bird diseases.

A well-made and insulated chicken coop will not take much effort and financial investment. You can insulate a chicken barn yourself, without resorting to outside help. Despite the fact that the materials are quite cheap, it will take a lot of time and effort. However, the more carefully the work is carried out, the higher the quality will be.

Video on insulating a chicken coop

The egg production of laying hens declines sharply in winter. This is due to a decrease in air temperature and a decrease in daylight hours.

Insulating and heating the chicken coop will help keep egg production at the same level and protect birds from colds.

Since you can insulate a chicken coop for the winter with your own hands in different ways, each poultry farmer chooses the most optimal one.

Heating system installation

Most modern poultry farmers prefer electric heaters as the safest and most affordable. You can install them yourself without any special skills. They can heat a room of any size.

Infrared lamp

Infrared lamps (IR lamps) are highly efficient, converting energy into heat. They do not pollute the air in the chicken coop; after switching on, they quickly warm up the area they are aimed at.

The disadvantages of lamps include their high cost and short operating period.

For additional heating of a thoroughly insulated chicken coop with an area of 30 square meters. m and a ceiling height of 200–240 cm, it is enough to install 2 IR lamps, each with a power of 250 W. Lamps are suspended from the ceiling, placing them in those areas of the house where maximum heat is required (for example, above nests, perches or a cage with chickens).

IR lamps should be equipped with a thermostat or dimmer (power regulator) in order to avoid overheating of the room.

Important! When installing an IR lamp, you must remember that it itself gets very hot. It is hung from the wooden ceiling not close, but at a distance of 30–50 cm

Or they protect the attachment point with asbestos plate. It is better to take ceramic lamp sockets.

Heater

An IR heater is mounted like an IR lamp (Cozy Warmth, Good Warmth). Its heating area is larger than that of a lamp. It is more reliably protected from overheating. Only ceiling models should be installed in the poultry house so that chickens do not have the opportunity to come into contact with the unit. The cost of an IR heater starts from 2700 rubles.

A popular way to heat a chicken coop is to install a household fan heater or heat gun inside. Not the most economical option, spending up to 1 kW of electricity per hour, but suitable for quickly warming up a room. The fan built into the heater quickly moves air around the room, mixing cold and warm layers. The fan heater has the ability to dry the air.

The unit is installed on the floor or attached to the wall so as to prevent birds from accessing the heater. It is necessary to regularly clean it from dust and feathers, which often accumulate inside the unit.

Insulation of chicken coop walls

Wall insulation is carried out both outside and inside. This depends on the materials that make up the house. If you plan to keep chickens all year round, then you take the construction of a chicken coop seriously. The walls are erected from solid building materials (brick, foam block). The surface of the walls must be plastered and whitened with slaked lime.

In regions with harsh climatic conditions, walls are additionally insulated with sheets of foam plastic or penoplex. Let's consider the characteristics of these materials.

Styrofoam

Polystyrene foam is polystyrene granules, foamed and compressed to the required thickness. The bulk of the material is occupied by air, which gives high thermal insulation and lightness to the product. Foam from different manufacturers has different strengths and densities.

It is worth giving preference to polystyrene foam, which contains anti-peren - an important component that protects the insulation from fire.

Used as a thermal insulation material, widely used in construction:

- for the foundation (protection from soil pressure, the influence of cold);

- for the floor (laying on the floor before the screed);

- for walls (fastening from the outside and inside);

- for the roof (installed in two ways - warm roof 70 mm sheet of foam in combination with bitumen and cold);

- for the facade (a sheet 50-60mm thick is used, glued to smooth walls with special glue, fixed, plastered).

When purchasing polystyrene foam, you should know certain nuances in advance - the higher the density (stability), the lower the thermal insulation of the material. A low degree of strength and density implies protection from mechanical damage. The latest characteristics are used for insulation of frame and other premises.

A big advantage when choosing polystyrene foam as insulation is:

- excellent thermal insulation;

- its availability;

- relatively low price;

- durability;

- does not require additional waterproofing, is resistant to moisture;

- light weight;

- ease of installation.

The disadvantages include:

- low strength of the material;

- does not allow air to pass through;

- release of gases during fire that are hazardous to health.

Penoplex

Penoplex is a new generation of thermal insulation boards. It is a dense slab with a fine-cell structure, measuring 120 by 60 cm. The basis of penoplex is also polystyrene. A special feature of penoplex is the presence of a solid L-shaped edge, which allows joining of slabs without gaps.

In addition to the same purposes as the use of polystyrene foam, it is suitable for pipe insulation . It also has some properties:

- high thermal protection;

- does not emit fumes or harmful odors;

- an extended temperature range (from -50 to +75 degrees Celsius) makes penoplex suitable for different climatic zones;

- does not absorb moisture;

- long service life (about 50 years);

- withstands sharp freezing.

The disadvantages include:

- not used without lining (plaster);

- toxic when burned;

- poor rodent barrier.

Foiled penofol

A relatively new type of insulation. It is a material characterized by high thermal protection qualities; it consists of a layer of polyethylene foam and reflective foil. The thickness of the base varies from 2 to 40 mm. Foamed polyethylene blocks direct heat transfer. It can be installed in combination with other thermal insulation materials.

If the walls of the chicken coop are thin (barn type of construction), the work on insulation will be much more. Insulation is achieved by combining different types of materials. Additional materials are mineral and basalt wool - used for thermal insulation of walls and ceilings. These insulation materials withstand temperature changes well, are hygroscopic, have fire-fighting properties and are easy to use.

Nests

In the process of arranging a bird’s home, it is extremely important to make nests and fix them on the wall. During this work, it is necessary to adhere to certain recommendations:

the number of nests directly depends on how many laying hens will be housed in the house

There should be at least one such structure for every five laying hens; The nest should be about 30 cm wide, 40 cm deep, and 35 cm high; it is allowed to combine nests along one line, but they must be fixed exclusively in the dark part of the room at a height of only 0.5 m; It is extremely important that the entrance to the nest is wide (at least 25 cm in width and height). It should be raised from the bottom of the nest by at least 5 cm

Thanks to such a small threshold, the eggs will not roll out onto the floor; You need to fix a shelf next to the nest, from which it will be convenient for the birds to take off; The slope of the roof on the nest should be about 45 degrees. Thanks to this special design, laying hens will not be able to sit on it, and accordingly the nest will not be contaminated with bird excrement; Be sure to put hay or straw in the nest.

In order to attract laying hens to the nest, it is recommended to place a dummy egg in it. Experienced poultry farmers have noted that in the presence of this simple element, birds begin to lay eggs much more willingly.

It often happens that chickens begin to shit in the nests and stay overnight in them. To avoid this, they should not be placed on the floor, but rather placed on the farthest wall. Closer to nightfall, the nests can also be covered, since chickens do not lay eggs at night.

You also need to make sure that the birds have containers in the barn for drinking, eating and taking ash and sand baths. There are many variations of such designs that can be made with your own hands without much effort. For those poultry farmers who were able to build a barn on their own, manufacturing these necessary elements will clearly no longer be a problem. Having equipped the bird's home with everything necessary, it will be possible to immediately move birds into it.

Heating

There are times when thermal insulation alone is not enough to maintain a comfortable temperature, especially when there is bitter frost outside. As a rule, in such situations, suitable materials are purchased for the purpose of additional insulation of the building. They can be installed on walls, floors and ceilings

In addition, it is very important to remember to insulate the window structures and the entrance to the chicken coop. Otherwise, cold air will penetrate into the building through the remaining cracks.

For windows, it is best to use special masking tape. As for door cracks, you can get by using polyurethane foam, as well as insulating the door leaf itself.

In addition, for the purpose of additional heating, fairly powerful incandescent lamps are often installed in chicken coops. It is permissible to install special heat fans. Such products can be programmable, and they are what experts recommend for purchase because they are very easy to use. They may have time and temperature adjustments.

A good solution for heating a chicken coop is infrared lamps. Such products do not affect the surrounding air, but rather objects that fall within the range of their rays. Infrared lamps must be installed correctly, for example, above perches, as well as above the floor. But you need to take into account that if you turn them on and off frequently, these bulbs burn out quite quickly and require replacement.

Materials for insulating a chicken coop

The preparatory stage before insulating the entire chicken coop is the selection of material and its calculation. The choice of material directly depends on the condition of the original building for keeping chickens. The poultry house is insulated with:

- walls (foam plastic, mineral wool, basalt wool, penoplex, penofol);

- floor (various bedding);

- roof (felt, polystyrene foam, waterproofing materials).

For winter keeping of chickens, it is recommended to attach a room in front of the entrance to the chicken coop that will prevent the direct penetration of cold air. Doors should close as tightly as possible.

Generalization

Building a barn for keeping poultry is the most important point. The dimensions of the building will depend on the number and breed of birds. For example, to keep broilers even in the countryside, it is necessary to allocate a fairly large area for them, because the birds have a large build and already weigh about 3 kg at 2-3 months. For such representatives, the recommended stocking density is no more than one bird per 1 square meter. m. In a summer cottage, you can use an old barn that was left over from other animals, properly converting it to meet the needs of poultry. To set up a winter poultry house, you need to take care of insulation. The shed needs to be insulated on all sides:

- the walls are covered with metal sheets with foam panels laid in them;

- the floor can be insulated using corrugated sheeting;

- the ceiling is insulated with felt.

The inside of poultry houses should be equipped with a simple ventilation system, access to the walking area, perches where the birds have sweet dreams, as well as feeders and drinkers. For feeding, it is better to prefer automatic designs

They allow you to save maximum time and ensure constant access to feed, which is very important when keeping broilers that must eat to their heart's content

After birth, chickens are kept in separate warm rooms or a brooder is built - a special warm container with an infrared lamp for heating and round-the-clock illumination; details can be found in many photos on the Internet. Some novice poultry farmers try to replace the structure with a cardboard box, but it is better when the chickens and chicks are in the barn. This method is only suitable as a temporary brooder; if you plan to raise poultry in the future, you will have to build a real house for chickens.

We insulate the ceiling and roof

If a farmer breeds chickens all year round, then the building is built with an attic. This allows you to store bedding, food and much more there.

But drafts moving through the attic remove heat from the house. To retain heat, the roof must be insulated. Insulation and implementation techniques are chosen depending on the structure of the roof. As a rule, the upper part of the building is insulated with mineral wool or penoplex.

Step-by-step description of the process of insulating the roof and attic

Before you begin insulating the poultry house, it is necessary to remove the bad parts of the wooden coverings.

If the boards have areas damaged by rot or mold, these areas are replaced with new parts. Before installation, new boards are treated with an antiseptic.

Step by step description:

- It is customary to insulate the ceiling with mineral wool. It is laid on boards, covered with a vapor barrier film on top and secured on the underside of the frame boards with a construction stapler. For additional protection, a second layer of mineral wool is laid on top using the same principle.

- The entire structure is lined with clapboard. The material is fixed with metal clamps.

- To protect against parasites and rodents, the material is treated with special agents and then painted.

Floor insulation

Thermal insulation work on arranging a chicken coop begins from the floor. Any material can be chosen from insulation materials. This could be peat moss, straw or sawdust shavings.

To create a temperature of +26… +28 °C, deep bedding is required. If you lay a thin layer of insulation, the thermal insulation properties will be low.

Due to its low thermal conductivity, peat moss is often used as a thermal insulation material.

Moss peat for insulating the floor of a chicken coop

Peat moss is a universal material with absorbent properties. It efficiently absorbs moisture and chicken droppings.

Thanks to this, there are no unpleasant odors in the room, which makes the material an ideal insulation material. Birds do not suffer from dermatitis and various skin diseases, since their paws always remain dry.

In spring, the litter is removed and the beds are fertilized with it.

Straw as insulation for a chicken coop

The use of straw is the most popular option for floor insulation, since it has the ability to accumulate heat and retain it for a long time.

The material is laid more than 20 cm thick. During operation, the straw cakes and its layer becomes smaller. Because of this, the temperature in the room decreases.

To prevent this, 10 cm of straw is regularly added on top. To make the bedding soft, dry grass is laid on top of the straw. The material to be laid must be of high quality, free from mold. Otherwise, the mold will spread throughout the deck and expose the birds to serious illness.

Wood shavings and sawdust for heating the chicken coop

Tree shavings make good bedding for a chicken coop. It is poured in a thin layer onto the main flooring to add softness.

Coniferous sawdust is considered the best because it contains essential oils. The floor surface is covered with pine sawdust and small shavings in a ratio of 1:3. The litter tends to cake, so it is regularly loosened.

Ceiling insulation

A well-insulated chicken coop also means insulating the ceiling. Particular attention is paid to the attic floor. For insulation, a vapor barrier is used, which can be replaced with ordinary dense polyethylene. Without such a layer, the insulation will get very wet. The material is laid over the ceiling with an obligatory overlap on the walls.

When choosing insulation for the ceiling, decide for yourself whether you are going to store anything in the attic. If not, then regular hay will suffice; the optimal layer thickness is 25 cm. If you need to go into the attic often, it is better to put a sheathing over the insulation.

Foam plastic slabs can be laid without using sheathing, and boards or chipboard sheets can be laid on top of it to make it comfortable to walk on.

How to insulate a chicken coop for the winter with your own hands

For the proper development of birds, it is very important to observe not only feeding conditions. But also the temperature! For example, it is necessary to maintain certain thermometer readings at each stage of chicken growth

When the chicks are just born, they need a stable ambient temperature of 29 - 30°C Celsius. Such indicators can be achieved with the help of brooders - special devices for raising young animals.

As the birds grow, the temperature is lowered to +18 - 20 degrees Celsius. And the birds are transplanted into a chicken coop.

If you want to raise chickens in the cold season or in northern regions, you need to take care not only about the presence of brooders. An important aspect of farming is the insulation of poultry housing.

Every farm owner should know how to insulate a chicken coop for the winter with his own hands. To achieve the required temperature in the room, you need to study the work procedure in detail. It is necessary to insulate the floors, walls, ceilings and roofs. Don't forget window and door openings too.

Note! Chicken coops must be equipped with a ventilation system. Because ammonia accumulates in the air

Therefore, the ventilation system will provide access to fresh air.

DIY barn insulation technology

How to insulate a shed? The technological process is not complicated. It does not require highly qualified workers or the use of expensive equipment. To carry out the work, general construction skills are quite enough; the owner of the barn can do it with his own hands. He will be required to be careful and strictly follow technological recommendations and safety regulations.

Materials and accessories

To insulate a shed using mineral wool or penoplex you will need:

You should also equip a workplace for cutting material indoors or under a canopy. It should be spacious and level and well lit.

Wall insulation

The method of insulating walls depends on the selected material. If you decide to work with bulk insulation, such as sawdust or expanded clay, you will need to build a second wall connected to the main one with wooden vertical logs at a distance of 10-15 cm from the main wall of the barn. The boards of the second wall are laid horizontally, nailing them starting from the bottom. Every half meter of height you need to stop, fill in the insulation flush with the top board and tamp it down.

If sheet material, mineral wool or penoplex is selected, proceed as follows:

Now you can attach the internal cladding from thin boards, plywood, OSB or moisture-resistant gypsum board.

Floor insulation

A budget method for floor insulation is as follows:

The top of this floor is sprinkled with sawdust or straw, which is changed periodically. For goats and sheep, it is recommended to make beds 20-30 cm high from the floor level; the animals willingly spend the night on them and do not freeze.

Straw with clay - a way to insulate the floor in a barn

A serious method of floor insulation involves removing soil to a depth of 30-40 cm, filling it with expanded clay, and making a clay or cement screed. Wooden floors are used less frequently in animal housing buildings. They are insulated using polystyrene foam or penoplex. Mineral wool is not used because it will inevitably get wet from urine and water spilled from drinking bowls.

Ceiling insulation

Up to half of all heat loss passes through the ceiling.

To properly insulate the ceiling, you need to proceed as follows:

If there is no rough ceiling in the barn, sheets of foam insulation are attached directly to the roof sheathing using disc dowels and adhesive.

Spraying polyurethane foam onto the roof from the inside is very effective.

We insulate the doors

If the door is an uneven opening in the wall, somehow closed with a cracked shield made of slabs on rope loops, there is no point in insulating such a “door”.

You will need to install a normal door frame, seal the gap between it and the doorway with foam, and hang a solid wood door.

Windows are also insulated in the same way. To preserve heat, old windows are covered with polyethylene, pressing it against the wall with a glazing bead.

How to insulate doors and windows

Most heat leaves the room through doors and windows

Based on this, door and window openings need to be given the greatest attention. How to properly insulate a chicken coop? Thermal insulation is very important

If there are windows, it is necessary to install a second glass. Another effective way to insulate window openings is to use plastic film, which is attached to the strips at a distance of 1.5 cm from the glass.

Window insulation film

It is imperative to use a sealant; it is necessary to seal all existing cracks in the frames and windows. Additional insulation will be required on the side of the window hinges. For this purpose, you can use either self-adhesive store-bought insulation or a felt strip that is nailed to the frame.

Insulation of the loop circuit

If the chicken coop is in the design process, make sure in advance that the windows are small in size - the larger the glass area, the more intense the heat loss. One small window on the sunny side is enough - on the east or south wall. For the winter, you can install double frames, and in the summer, replace them with a regular mosquito net or one layer of glass. To insulate a barn for chickens with the onset of cold weather, the windows must be insulated with a special plastic film, which will subsequently prevent them from freezing in the winter. The film does not in any way prevent the penetration of sunlight into the chicken coop.

The window in the chicken coop should not be too large

It is also better to place the door in the south, so even in winter it can be opened slightly to ventilate the chicken coop. The doorway, like the window, should not be too large.

The door to the chicken coop should be small but convenient

However, keep in mind that it should be convenient for you to carry out all the necessary work to care for the birds and maintain the chicken coop in proper condition - changing the bedding on the floor, cleaning, removing manure, etc.

The door must be insulated. In severe frosts, the doorway is additionally covered with a rug or an old carpet. The doorway can be insulated using dense film insulation.

How to insulate a barn - working from the inside

Shingling, although a budget option, will take you a lot of time. If you value time, then instead of budget options you can use more expensive ones, but also more effective in terms of speed of work. These include the option of insulation with mineral wool and polystyrene foam. There is no point in talking about the advantages of materials - we have already talked about this more than once in articles devoted to these heat insulators. Let us remind you of the disadvantages - mineral wool is easily saturated with moisture, as a result of which it loses its thermal insulation qualities and also cakes over time.

When insulating with mineral wool, nails are hammered onto the walls in a checkerboard pattern to create a reinforcing mesh. Rolls of mineral insulation are unwound and laid on the walls, while a reinforcing mesh is created using rope to hold the wool in the desired position. There is no need for mesh if you use rigid or semi-rigid slabs instead of soft rolls. But in this case, you will need to make a sheathing of boards with your own hands.

The distance between the boards should correspond to the width of the slabs, and even be a couple of millimeters smaller so that the slabs fit tightly into the space. How to insulate a shed with mineral wool for the winter? The secret is to prevent the material from getting wet due to condensation. Therefore, a layer of vapor barrier is placed on top of the insulation - glassine or more modern versions of membranes.

Insulating foam inside a shed is even easier. If the base is strong, you can glue the insulation boards with your own hands using any available glue, even regular PVA. Both polyurethane foam and liquid nails are suitable. For greater strength, you can fasten the slabs together with the adhesive base using special dowels. In any case, after this, be sure to protect the material from mechanical damage. Any sheet materials will do. In a chicken coop this could be flat slate, and in a small horned shed it could be sheets of plywood.

General points

For a chicken or turkey to lay eggs well, it must be healthy.

That is why it is so important to pay enough attention and effort to building a high-quality, strong and warm poultry shed. Most novice farmers do not dare to have livestock due to the lack of suitable premises for their maintenance, believing that they cannot afford to build from scratch. However, if you carefully study the issue, which is what we will do in this article, it will become clear that building a good-quality chicken coop is not only not difficult, but also not so expensive

However, if you carefully study the issue, which is what we will do in this article, it will become clear that building a high-quality chicken coop is not only not difficult, but also not so expensive.

Choosing a location for a bird shed

First of all, you need to choose the right place for construction. In this case, it is necessary to start not only from considerations of the square footage of the future barn. Keep in mind that poultry waste products emit a rather strong unpleasant odor, so if the barn is located on the leeward side, the odors will constantly be directed towards the residential building. It is best to place sheds for animals and poultry at a sufficient distance from residential buildings next to a toilet or cesspool.

The dimensions of the object being built are directly affected by the free area of the site. The best place to build a shed is on a small hill, then in the cold it will not need to be heated additionally, and in the warm season it will warm up faster. In addition to the space for the barn, it is necessary to allocate an area for walking poultry - this is a prerequisite for the comfortable and healthy well-being of pets. Its area should exceed the area of the barn itself by 2-3 times.

You can build a chicken coop using existing plans developed by professional builders and experienced farmers, or you can take one of them as a basis and create your own unique poultry shed design, ideal specifically for your site. At the end of the article you will find several examples of chicken coop designs.

Bird shed dimensions

Poultry is quite unpretentious in keeping, but this does not mean that it does not need care and attention at all. Remember, the more comfortable your chickens and turkeys live, the better they will lay eggs. In this part of the article you will learn how to arrange a poultry barn according to all the rules.

The chicken coop must be durable, warm and safe. This is a kind of smaller copy of a residential building, the residents of which should feel safe and comfortable in it. It must have ventilation and lighting. It is not at all necessary to conduct electricity there - you can install several windows for natural light.

Birds are social animals, but they still require personal space. Otherwise, strong individuals will begin to dominate the weak, peck at them and fight. To avoid this, it is better to think in advance about how many chickens will permanently live in the barn and, based on this, calculate the area of the room. No more than 4 chickens or 3 turkeys can be placed per 1 m².

Inside the barn you need to install nests, perches, feeders and drinkers. It is best to place the perch as far as possible from the front door, since the bird will rest there, and therefore it is better not to disturb it again. In this case, the perches should be slightly inclined, but just enough so that the chickens can move freely along them. Usually, to make a perch, wooden beams with a diameter of up to 5 cm are used, the upper part of which is rounded so that it is convenient for the bird to clasp the pole with its paws. The beams are installed parallel and in several tiers, maintaining a distance of at least 25 cm (up to 40 cm), between the floor and the lower beam there should be 40-50 cm. Experienced farmers advise making a perch in 4 tiers, attaching the beams to the walls using hinges.

As for the equipment of nests where birds will hatch eggs, you can use wooden boxes (for vegetables and fruits) or baskets to make them. Use hay or straw as soft, warm bedding, which is periodically replaced with fresh one. One nest can accommodate 3-5 laying hens.

At the bottom of the barn door you need to make a closable hole (miniature hole) approximately 30 cm high. It is necessary for the birds to freely exit to the walking area.

So, based on the above information, you can calculate the exact dimensions of the future chicken coop and walking area. A barn for 10-20 chickens will occupy an area of 2x3 m, and the walking area should be several times larger.

Options for insulating barns and households. buildings

- The best option is to build two parallel walls with space for insulation;

- The roof, like the walls, needs to be insulated. To do this, you need to lay the insulation on the joists and press it on top with boards. It is necessary to make a sloping roof so that moisture does not penetrate inside;

- To prevent the cold from creeping in from the ground, you can put wooden pallets with straw on the floor.

This method is the cheapest, since everything can be made from scrap materials and no special skills are required.

If you decide to repurpose an old shed for the winter, there are several ways to do it.

Boarding

The easiest option is to make a second wall of boards with space for insulation. In this case, the boards will need to be nailed overlapping to avoid gaps between them.

As you can see in the photo, to form a wall without gaps, first two boards are nailed with a retreat, and then a third one is closed on top.

Edges that are too crooked can be trimmed in advance with a circular saw.

During the construction of the wall, insulation must be poured into the resulting compartment. Sawdust is good for this, but sometimes dry fallen leaves and pine needles are also used. The advantage of sawdust is that they are small, dry, and the price is almost zero; they can be obtained in any carpentry workshop.

To avoid rodents between the walls, mix sawdust with slaked lime (“fluff”) in proportions of 25 to 1.

Pour the materials onto a wood or metal board and mix with a shovel.

The layer of sawdust insulation should be 20-30 centimeters thick on the walls, ceiling and floor. They need to be filled in layers and compacted constantly. After this, you need to give time for the sawdust to settle; it is advisable to add more after 1-2 weeks.

The ceiling will need to be hemmed and sawdust poured there in the same way. To obtain a box for insulation, you need to make a false ceiling by filling a second layer of boards above the rafters. They are covered with roofing felt on top and nailed every 50 centimeters.

To protect the lower part of the barn from rodents, you can fence the walls on both sides with slate. The floor is insulated by pouring a layer of soil 10 cm above the base layer, and then clay is poured on top and compacted. The main thing when insulating is not to allow moisture to penetrate inside the sawdust, otherwise they will quickly begin to rot.

To make a warm door, the boards are knocked down diagonally, and roofing material is inserted between them. With this design you will retain maximum heat inside the room.

Wall covering with shingles

If money is tight, but you want to get a warm utility room, then the walls can be sheathed with shingles:

- To do this, you need to nail the slats diagonally, first in one direction and then in the opposite direction. The slats can be replaced with goat willow branches, then the layer of clay can be made thicker;

- To apply clay to shingles, you need to prepare a solution. Soak the clay with water to the consistency of sour cream and gradually add sawdust or straw, achieving the desired consistency. Do not apply the solution immediately, but let it sit for a while;

- Start working from the bottom, applying a clay solution at least 3-5 centimeters thick. Throw it on and smooth it out with a spatula. The layer should be uniform, pay special attention to the corners - you can increase the layer on them by rounding them;

- After clay plaster, the walls should dry for several days;

- Cracks will appear that can be repaired with a solution of clay and sand, mixing them 1 to 2;

- Then you need to whitewash the walls with lime. If you work in the cold season, it is better to use slaked lime, since it will heat up when in contact with water, but then be especially careful about safety precautions.

Lime painting instructions: Dissolve quicklime granules in half a bucket of water.

In just a minute, the reaction will begin and the solution will become very hot.

After this, fill the bucket with water to the end and add a spoonful of salt;

- Use the same clay solution to seal all remaining cracks in the ceiling and floor. To insulate the ceiling, make a box of boards and bars, and fill it with clay and sawdust with a layer of about 10 cm.

This method is quite labor-intensive, but does not require any money.

Insulating a shed from the inside

The next method, insulating the shed from the inside, will suit you if the boards on the walls are more or less even and without cracks. You can call it the most expensive, since it requires the use of purchased materials, unlike the previous two options. But the appearance will be more or less beautiful, you can even convert the barn into a workshop.

Typically, mineral wool is used for internal insulation, which is tightly packed into cells made of bars. Like the insulation of the loggia and facade, in the barn you need to protect the insulation from moisture with a layer of vapor barrier with foil. You can also use spray foam for insulation from the inside.