Heating equipment for use in private homes or relatively small spaces is becoming increasingly popular.

The prices of resource suppliers and the constant increase in housing and communal services tariffs force owners to use their own, autonomous heating and hot water supply systems.

The choice of heating installations is extremely wide; choosing the most suitable type or model is a difficult task that requires certain knowledge and experience.

One of the most respected European manufacturers of heating equipment is the Italian company Baxi, whose equipment has been highly praised in our country.

Let's consider a popular type of units from this company, capable of simultaneously heating and supplying hot water.

Double-circuit boilers from Baxi

Baxi produces a large number of double-circuit installations, since they are the most convenient and efficient in private home systems. The operating principle and design of these installations are not fundamentally different from general design directions.

A feature of Baxi equipment is the complete authenticity of parts and components that do not allow replacement with other elements . The manufacturer pays great attention to ensuring the protection of installations from external influences, creating a system of self-diagnosis and monitoring of all boiler components.

An additional bonus is adaptation to the technological conditions of our country, to low or unstable gas pressure, and voltage fluctuations in the power supply network.

There are wall-mounted and floor-mounted samples that differ from each other only in the location of the connecting pipes and the heat exchanger material (some models).

Possible errors and their elimination

The manufacturer's instructions will tell you how to start the equipment correctly. It will function properly only if there is protection from voltage fluctuations and a ground line. Special mechanical filters are also required, because... remove solid impurities from water. If installation technologies are violated and there are breakdowns on the line, boilers may produce errors.

Using the self-diagnosis system

All Baxi devices have a self-diagnosis function. Failure data is displayed, the user deciphers the error code according to the instructions and takes action. The following may appear on the monitor:

- Index E and numbers 01 – no ignition. The sensor connection and gas supply are checked. Press R and hold for 2-3 seconds.

- E02 - the thermostat has tripped.

- E03 – normal traction has disappeared.

- E05 – temperature sensor is broken.

- E10 – decrease in pressure, loss of board contacts, breakdown of the relay or pump sensor. The malfunction can only be diagnosed and repaired by a specialist.

- Errors E96, 97 and 98 – failure of the electronic board. It needs to be replaced.

Blocking information may also appear on the display. It occurs when overheating or loss of traction. The user will need to reset the boiler.

Other breakdowns

In addition to errors, equipment failures are observed:

- The burner does not operate at maximum power. The pressure is set incorrectly or the gas valve modulator is broken. To fix the problem, the owner must configure the settings according to the instructions.

- The device turns on, but immediately turns off. The reason is low gas pipeline pressure. It is necessary to make adjustments to 5 mbar.

- The coolant practically does not heat up. The problem can be resolved by testing the gas valve pressure.

- Popping sounds when igniting. There is not enough pressure, the distance from the igniter to the gas supply has changed. To eliminate damage, the gap is adjusted to 4-5 mm.

- Modulation doesn't work. The valve is being replaced.

- Failures in temperature sensor readings. New elements are being installed.

Work on replacing parts and disassembling the boiler should only be carried out by specialists.

The operation of gas boilers from the manufacturer Baksi is possible in apartments, private houses, and industrial areas. Due to the presence of several series and types of equipment, users will not have any difficulties selecting a model.

How they work

Heating equipment for private houses can be intended only for heating (single-circuit), or for heating and supplying hot water (double-circuit).

The design of double-circuit boilers is a complicated model of a single-circuit unit and can be implemented in two versions:

- With installation of a secondary heat exchanger.

- Using a bithermal heat exchanger.

The first design option is to transfer thermal energy by a heated coolant leaving the primary heat exchanger. The hot heating agent enters a secondary plate heat exchanger, in which it transfers part of the heat to cold water, after which it flows to the analysis points.

A bithermic heat exchanger does not differ in appearance from a conventional unit. It's all about the design of the tube, inside of which another one is installed, of a complex cross-section, shaped like a rhombus . The coolant moves along the upper part of the formed cavity, and hot water moves along the inner, diamond-shaped cavity.

The efficiency of such a unit is much higher than that of a conventional plate device, but maintenance and cleaning are significantly more difficult. For boilers with a bithermal heat exchanger, a water filter or softener is required.

Designs with two heat exchangers are considered more reliable because they are easier to maintain and clean.

Considering the unstable quality of water in water supply systems, as well as the common method of drawing water from one’s own wells, the preference for installations with a simpler and faster method of maintenance is quite reasonable.

Manufacturer information

The Italian brand BAXI SpA has been producing systems for heating and hot water supply for more than 50 years. The manufacturer's line is represented by wall-mounted (standard and condensing), floor-mounted models with cast iron heat exchangers, and storage-type electric boilers.

The company was founded by the Westen family in Austria, but initially it was engaged in the production of tableware. From 1978 to 1984, the brand was part of the Zanussi concern and produced boilers, water heaters, radiators and steel bathtubs. Export of products to countries around the world began in the mid-1980s under the Ocean Idroclima brand.

The manufacturer received its current name in 1999. Currently it is part of two holdings - Baxi Group and BDR Thermea. The international quality certificate ISO 9001 was received in 1993, and environmental friendliness ISO 14001 - in 2001.

The Russian representative office in Moscow was opened in February 2002. The branch is engaged in advertising, marketing, certification of new equipment, consultation and technical support.

Advantages and disadvantages

The advantages of Baxi double-circuit boilers include:

- Organization of heating and hot water supply using one installation without the need to connect additional devices.

- High-quality assembly, compliance with all European standards.

- Environmentally friendly equipment.

- Adaptation to Russian technological conditions and climate characteristics.

- The ability to independently determine and signal the occurrence of failures or failures of installation components.

- Economical, relatively low gas consumption with efficient and active operation.

Disadvantages are considered:

- Dependence on the availability of electricity and water quality.

- High cost of boilers and spare parts.

- Inability to replace parts with analogues from other manufacturers.

New - condensing boilers

The BAXI company is constantly striving to produce more technologically advanced products that allow maximum benefits to be obtained with minimal energy consumption - be it heat in the radiators or hot water in the taps. And devices such as condensing units fully meet these requirements.

If we look at history, the first analogs of such devices were developed in the middle of the last century, including in the Soviet Union. However, our developments were safely buried, while European consumers began to use these devices and received significant savings in blue fuel.

With the development of technology, boilers of this type have undergone significant improvements and are now presented under the Baksi brand in wall-mounted and floor-standing versions.

Operating principle of the condensate unit

When gas burns, it invariably produces hot steam and other substances. The end products are carbon dioxide and water. Engineers managed to turn hot steam into a source of additional heat in the gas boiler system, while increasing the efficiency of the device to 100%.

Theoretically, the savings of natural gas when burned in condensing devices reaches 11%, liquefied gas - up to 9%, diesel fuel - about 6%. Sometimes you can find efficiency values exceeding 110%, but this simply cannot happen. Most likely, this figure is given in comparison with other traditional models, where the efficiency is below 90%.

Advantages of condensate devices

gas wall-mounted boiler has the following advantages:

- high efficiency

- modest dimensions of boiler equipment and their light weight

- gas savings during the heating season are about 35%

- low noise level compared to traditional devices that use forced-air burners

- no vibration during operation

- does not require the construction of a chimney due to the presence of coaxial exhaust of combustion products through the wall

- the ability, if necessary, to create entire cascades of boilers

- ensuring environmental requirements by reducing harmful emissions into the atmosphere

- the presence of deep modulation allows you to use gas more economically, which extends the life of the equipment

What series and models are dual-circuit

Baxi presents several series of dual-circuit units.

These include:

- Slim . A series of floor-standing boilers with a cast iron primary heat exchanger, the power of which ranges from 15 to 62 kW. They have the ability to switch to conventional heating mode and to a heated floor system. Full set of functions, possibility of remote control using a remote control (purchased separately).

- Nuvola . Wall-mounted boilers with a capacity of 24, 28 and 32 kW with an open or closed combustion chamber. They are equipped with a removable control panel that can be installed in a convenient place. A special feature of the series is a heating tank with a magnetic anode, which allows you to work with hard water without harmful effects on the internal surfaces of pipelines and containers.

- Luna . The series is represented by models with a power of 24,25,28 and 31 kW. Boilers in this line are the most expensive, but the user ratings are not the most flattering. With a large set of functionality, the design is flawed and frequent failures of various components are noted.

- Eco . There are two series, 4 and 5 generations with a closed turbocharged burner. The power of the units is 10, 18 and 24 kW, the presence of a fully functional primary heat exchanger and a stainless steel secondary plate heat exchanger. It is noteworthy that all boilers are the same design, only in different models the power is limited by software.

- Main. High-quality boilers with compact body sizes, digital display, and a wide range of capabilities. The power of the models is 15, 18 and 25 kW. All units are equipped with a built-in water filter. The main feature of the models is a bithermal heat exchanger, which has high heating efficiency and allows for significant fuel savings.

All models and series of Baxi boilers have a similar design and equipment, differing from each other only in individual elements.

Prevention

To prevent breakdowns of the Baksi boiler and thereby extend its service life, this unit should be connected to the electrical network through a stabilizer. Imported electronics are designed for high-quality power supply, and if its parameters deviate significantly from the norm, which we still see quite often, they easily fail.

At certain intervals (after several years of operation), the outside of the heat exchanger must be cleaned of soot. If it is made of stainless steel, you can use a special brush with metal bristles. This tool is not suitable for cleaning a copper heat exchanger, as it can damage it. It is better to use a metal sponge designed for washing dishes.

Gas boiler heat exchanger

The heat exchanger of the DHW circuit needs to be washed from time to time with some descaling agent. The same must be done with the main heat exchanger if ordinary water that has not undergone the desalting procedure is used as a coolant.

The fan must be periodically lubricated, otherwise over time the engine will not be able to rotate it at a sufficient speed. Unscrew the back of the assembly and remove the stator, after which you will need to pour a few drops of machine oil inside.

The chimney, both conventional (for boilers with an open combustion chamber) and coaxial (closed chamber), must be periodically cleaned of soot. The air intake of a coaxial chimney must be kept clean.

Specifications

Let's look at the table of technical characteristics of boilers:

| Characteristic | Slim | Nuvola | Luna | Eco | Main |

| Efficiency | 90 % | 92,9 % | 92,9 % | 91,3-92,9 % | 93,1 % |

| Exhaust temperature | 85° | 85° | 80° | 85° | 80° |

| DHW temperature | 65° | ||||

| Gas consumption | 2.59-3.49 m 3 / h | 2.78 m 3 /h | 2.78-3.52 m 3 / h | ||

| Primary heat exchanger material | Cast iron | Stainless steel | Copper | Stainless steel | Copper |

| Chimney type | Separate/Coaxial | ||||

| Power supply | Single phase, 230 V 50 Hz | ||||

Only the most general characteristics characteristic of all models of a particular series are given.

The best choice

The selection of a thermostat for a heating boiler is based on the personal preferences of the room owners. When choosing, you should consider what characteristics are required when using a particular boiler.

Wired or Wireless

The communication between the control unit and the sensors and the boiler for different models is carried out wired or wirelessly. In the first case, you will need to lay a wire. The cable length reaches 20 m. This allows the control unit to be mounted at a great distance from the room in which the boiler room is installed.

Wireless thermostats for heating boilers are designed as a receiver and transmitter. A distinctive feature of products of this type is that there is no need for wiring. The transmitter signal can be received at a distance of 20-30 m. This allows you to install the control panel in any room.

Temperature setting accuracy

Depending on the design of the room thermostat, the room temperature setting differs. Inexpensive models have mechanical control. The disadvantage of cheap thermostats is the error reaches 4 degrees. In this case, the temperature adjustment step is one degree. Products with electronic control have an error of 0.5 - 0.8 degrees and an adjustment step of 0.5o. This design allows you to accurately set the required power of the boiler equipment and maintain the temperature in the room in a certain range.

Ability to set the hysteresis value

The room thermostat for a gas boiler has a difference between the switch-on and switch-off temperatures. It is necessary to maintain optimal heat levels in the room.

Hystersis principle

For mechanical products, the hysteresis value does not change and is one degree. This means that after switching off, the boiler will start working after the air temperature in the room drops by one degree. Electromechanical and electronic models have the ability to set hysteresis. The adjustment allows you to change the value up to 0.1 degrees. Thanks to this design, it is possible to constantly maintain the room temperature in the desired range.

Programmable

The function is only available for electronic or electromechanical thermostats. It is possible to program the control unit to set the temperature according to the clock. Depending on the model, thermostats are programmed for up to 7 days. This makes it possible to make the heating system with the gas boiler turned on autonomous. At a certain time, the thermostat turns on or off the boiler unit or changes the intensity of its operation. With weekly programming, gas consumption can be reduced by up to 30 percent.

Wi-fi or GSM

Thermostats with built-in wi-fi and gsm module connect to the internet. Gadgets with installed applications are used to control heating. This is how remote shutdown, connection of the boiler and adjustment of temperature indicators in the heated room are carried out. Using the GSM standard, the room thermostat transmits information about the occurrence of malfunctions in the heating system to the owner’s phone. It is possible to remotely turn on or off the gas boiler.

Safety

When choosing a thermostat for gas boiler equipment, you should pay attention to the presence of safety systems. Functions are available to prevent the circulation pump from stopping, protect against freezing or exceeding the maximum temperature in the heating system, etc. The presence of such options allows you to safely use boiler equipment in autonomous mode

The presence of such options allows you to safely use boiler equipment in autonomous mode.

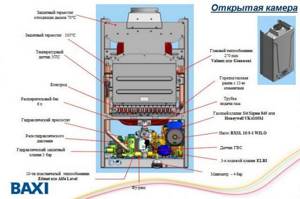

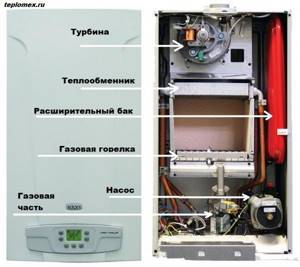

What's included

The boiler package includes:

- Primary and secondary heat exchangers.

- Circulation pump.

- Gas burner of closed or open type.

- Fan to supply fresh air to the combustion chamber.

- Expansion tank.

- Three-way valve.

- Gas valve.

- Sensor system.

- Control board.

- Connecting wires and pipes.

Some boiler models have additional elements that provide protection or performance monitoring functions.

Equipment disadvantages

If the equipment is configured and operated incorrectly, certain problems may arise:

- with a very sharp decrease in the pressure of the incoming gas, the automation system may fail;

- It is better to entrust the initial setup of the functioning of the heating unit to a specialist. Otherwise, the likelihood of gas valve or bridge failure increases;

- Sometimes pressure sensors fail.

The demand for Italian heating equipment Baxi is beyond doubt. The boilers have fairly high technical characteristics and an inexpensive price. They fit perfectly into the interior of an apartment or individual building.

Installation of a wall-mounted double-circuit gas boiler Baxi

Baxi double-circuit boilers operate on the principle common to all similar designs. The coolant moves through the system via a circulation pump.

At the outlet, it enters a three-way valve, which mixes in a certain amount of cold return to obtain the specified parameters of the heating circuit . Hot water is heated in a secondary heat exchanger, which receives thermal energy from the heated heating agent.

The combustion of gas in the combustion chamber is ensured by a fan that supplies air flow and creates the desired mode. All processes and components are constantly monitored by sensors that send signals to the control board.

If emergency situations occur, the sensors display an error code on the display, allowing the owner to take appropriate measures.

Boiler installation and piping of a double-circuit boiler

These units are installed and adjusted only by service specialists; not only the operability of the boiler, but also its warranty service will depend on this.

In addition, the boiler user will need to invite a gas specialist to draw up a contract for the maintenance of gas equipment and obtain a specialized permit to operate the boiler.

Manufacturer's requirements for installation work:

- For boilers with natural exhaust of flue gases, a separate non-residential premises with an area of at least 4 m2, a ceiling height above 2.5 m and a supply ventilation system with three-hour air exchanges are required.

- The installation of a unit with a closed firebox and a coaxial chimney can be carried out in a kitchen area, subject to the minimum installation area.

- A Navien double-circuit boiler must have an independent power supply line from the subscriber's input panel with an installed protection system and reliable grounding.

- The wall on which the Ecoclassic unit will be placed must be solid and have a heat-resistant coating.

- The gas pipeline must be laid out according to the design and specifications issued by the regional structure of the gas supplying enterprise.

To connect the boiler with in-house utility networks, there are 5 five fittings located at the bottom of the housing: heating supply/return, DHW supply/return and gas.

The connection order is as follows: first, gas is connected, then water for domestic hot water is connected, and then the heating circuit. A ball shut-off valve is connected to each outlet.

How to set it up correctly

The purchased boiler is delivered to the premises and installed in a designated area. All relevant pipelines are connected to the pipes - water, gas, coolant.

Initial boiler setup:

- Electricity is connected.

- The gas supply valve opens.

- The desired operating mode is set - “summer” or “winter”.

- By pressing the corresponding buttons on the sides of the display, the temperature of the extract air and domestic hot water is set.

After this, the burner will start and the boiler will start working. An error may appear and the boiler may block, which occurs due to the presence of air in the system.

In such situations, the error is reset by pressing the “R” button and everything is repeated until a positive result is obtained.

Design features of various models

Baxi heating devices are characterized by a wide range of products. The models differ in their characteristics and design features. The predecessors of the Main series heaters did not have a liquid crystal display. Many of the functionality inherent in modern units were missing. In general, this model range is basic for wall-mounted gas structures.

It is characterized by the following features:

- The heater includes a bithermic heat exchanger;

- with its help, the air in the room and the water in the DHW circuit are heated;

- heating circuits have different structures. The coolant does not mix in them;

- the latest modifications of heating devices have small dimensions;

- the combustion chamber is made in the form of a closed structure;

- heating devices are used to create a heating system in individual buildings and premises whose area does not exceed 240 m2.

Baxi Eco models have a plate device for heat exchange. Stainless steel is used for its manufacture. Using this heat exchanger, the hot water supply circuit is heated. The first element is used only for heating the heating circuit. This design allows you to significantly increase the life of the heater.

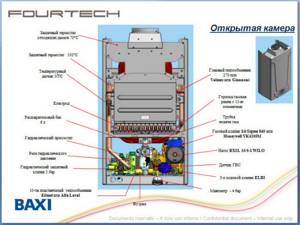

The Baxi Four Tech series is a cheaper modification of Baxi Eco heating devices. They also have different heat exchangers. Plastic, not copper, is used to make hydraulic supply pipes. Due to this, the cost of the product is significantly reduced.

User manual

The operation of boilers has no specific requirements or conditions. The user only needs attention, periodic maintenance, and timely response to errors . They are displayed on the display and indicate that a fault has occurred.

Often the occurrence of an error is a consequence of a random signal or a power surge, so the boiler is usually rebooted and started again. All repair work must be carried out by service center employees.

It is not recommended to carry out such activities on your own, since the result may be opposite to the owner’s expectations.

Setup and adjustment

So, let's look at the Baksi gas boiler - operating instructions, setup and adjustment. To set up the boiler, just set the desired temperature on the room thermostat - the unit will do the rest itself. All data is shown on the display. The most convenient are thermostats with a programming function, through which you can plan the boiler operating schedule for a day or a week in advance (depending on the model).

In Luna-3 Comfort series boilers, the controller is removable and can control the operation of the boiler remotely. It looks like a panel with a display and keys, which also contains a room temperature sensor.

Wall-mounted boiler BAXI Luna 3

The controller is placed in one of the rooms at any convenient place and with its help the operation of the heater is adjusted. On it you can view the results of self-diagnosis and, if necessary, view a list of recent errors - it is stored in memory.

Technical faults and error codes

All failures or breakdowns of boilers are immediately diagnosed by a system of sensors that display an alert in the form of a digital code with the letter “E” (error).

The most common mistakes and owner actions:

- E01 . Keep the burner off. Possible reasons are lack of gas (check the valve), burner nozzles are clogged with soot, problems with the sensor itself.

- E02 . Thermostat overheating. The problem occurs either when the water moves too slowly, or when the heat exchanger is contaminated from the inside with lime deposits.

- E03 . Fan stop. Check it for functionality and replace it if necessary.

- E05 . Failure or short circuit of the air temperature sensor.

- E06 . Failure or short circuit of the DHW temperature sensor.

- E10 . Reduced coolant pressure. The most likely cause is a leak in the heating circuit. This most often occurs when using heated floors, since external radiators signal themselves by the appearance of puddles or streams of hot water.

- E25-26 . Blockage or failure of the circulation pump, failure of the corresponding sensor.

- E35 . False signal about the presence of flame. There may be water on the board, breakdown of the sensor on the case, etc.

- E96 . The power supply voltage is too low.

The full list of errors is much more extensive, so it is recommended to have the user manual included with the boilers at hand. There is no point in learning these codes by heart; it’s easier to look at the list at the right time.

Errors that occur during operation

TM Baxi boilers have a self-diagnosis function, thanks to which these units independently detect their own faults. The test results are displayed on the display in the form of an alphanumeric code. Each code indicates several possible faults. Below are the most common ones.

Error E01 (flame control sensor activated)

- When connecting the boiler to the electrical network, the phase and neutral wires were reversed, as a result of which the boiler cannot turn on (this is true for phase-dependent models, for example, Main 24 Fi and Main For). The power cable must be connected correctly.

- The burner cannot develop sufficient power. Reasons: breakdown of the gas valve or diode bridge, lack of air (smoke can leak into the air intake tract), as well as incorrect pressure settings in the heating circuit.

- The gas pressure has dropped or its lower threshold has been set incorrectly. If a decrease in pressure is observed frequently, the lower limit in the settings should be set at 5 mbar. In the event of such a malfunction, the boiler turns off immediately after starting, and popping noises may also be heard when it is turned on.

- The combustion control sensor or ignition unit is faulty.

E02 (coolant overheating sensor)

The cause of overheating may be clogging of the heat exchanger with scale, a breakdown of the circulation pump, a clogged filter, or the appearance of an air lock in the heating circuit.

False alarms of the system are possible due to a breakdown of the temperature sensor or its insufficient contact with the coolant (should be installed with thermal paste).

E03 (traction sensor)

The chimney is clogged with soot or condensation, is too long or has an incorrect design (for example, there is no mandatory vertical section at the beginning, with a length of at least 2 diameters). Be sure to check the fan for functionality.

E04 (flame tracking electrode)

Triggers when the burner goes out repeatedly (more than 6 times). It is necessary to check whether flue gases are leaking into the duct. The reason may also be voltage fluctuations.

E05 (coolant temperature sensor)

The error appears when this sensor fails or when its contact with the board is broken.

E06 - appears when the temperature sensor of the water heating circuit is faulty (in double-circuit boilers)

If this sensor signals a gradual or sudden decrease in temperature in the DHW circuit, the 3-way valve may have failed.

It is checked as follows:

- after turning off the boiler, wait until the coolant in the pipes and radiators cools completely;

- cut off the heating circuit using valves;

- start the boiler in water heater mode;

- check the temperature of the hot water in the DHW circuit and the coolant: if the medium in both circuits is heated, the 3-way valve needs to be changed.

E10 (minimum coolant pressure switch)

This message is displayed mainly due to a breakdown of the circulation pump or a clogged heating circuit. The filter and heat exchanger are more susceptible to this (they become overgrown with scale).

Heating with pellets is considered environmentally friendly and economical. How to make a pellet boiler with your own hands and whether it is possible to convert a solid fuel boiler to use pellets - this is the subject of the next topic.

Why we need a boiler safety group and what elements it consists of, we will consider in the following material.

Boiler connection

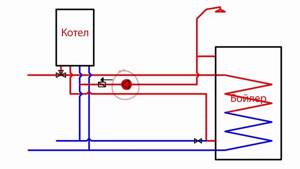

The boiler allows you to stabilize the temperature of the hot water supply and eliminate surges when using the bath or shower. The simplest and cheapest design option is a storage tank into which hot water flows from the boiler.

When it is dispensed from the boiler, the missing volume is immediately refilled from the boiler. The connection is made to the hot water pipe.

It is not advisable to use more complex and expensive options, since their price will be excessive expenses that are not justified by the results obtained.

Connecting the boiler to communications

The Baksi boiler unit is placed in a non-residential area, for example, in the kitchen, subject to reliable supply ventilation providing 3-hour air exchange.

The heating circuit is connected to the supply/return pipes located on the rear panel of the device according to the accepted wiring diagram.

Next, the boiler chimney system is connected:

- Install the chimney pipe through the adapter to the boiler smoke pipe.

- The chimney and the smoke pipe of the unit must have the same dimensions; it is indicated by the manufacturer in the technical documentation.

- The smoke channel is selected in such a way that the chimney section is as short as possible.

- The vertical section of the pipe from the connection point to the tip must be at least 6 m and provide draft in the combustion chamber in the range of 0.8 mm - 3.0 mm water column.

- The thrust is measured while the device is operating.

- The chimney must be firmly attached and must not rest on the boiler unit.

- The places where the pipe passes through the structural elements of the wall, ceiling and roof must be well insulated.

Next, connect the internal elements to the Baxi boiler control module:

- connect a transformer for piezo ignition and a gas pressure switch to the 6-terminal connector;

- connect the main 2-stage valve to the 9-terminal connector;

- connect an additional 2-stage valve to the 3-terminal connector;

- connect the left electrode of the ignition cable and the right electrode of the ionization cable to the piezo igniter;

- install primary temperature and pressure sensors in the technical holes indicated on the piping diagram provided by the manufacturer.

Owner reviews

Let's consider the opinions of Baxi boiler owners who are not interested in deliberate distortion or biased presentation of information:

Despite the fact that gas is considered the most economical type of fuel, the cost of heating periodically increases. In order to slightly reduce your costs, you can set your gas boiler to an economical mode. Baxi gas boilers consume a small amount of fuel, and when configured in this mode, consumption will be significantly reduced. In this article, we will consider the temperature of the coolant, connecting the room thermostat, maintenance and setting the Baxi gas boiler to economical mode.

Reviews

According to users and experts, equipment under the BAXI brand has proven itself to be reliable and durable, easy to maintain, of decent quality and easy to use, with flexible settings, and characterized by almost silent operation. Consumables for repair work are always available in large service centers.

However, despite the intuitiveness and simplicity of the interface, there are a number of parameters that must be set by specialists when putting the equipment into operation. Among other things, the unstable temperature of the hot water supply and the loud bang that accompanies the ignition of the device receive negative feedback.

What is clocking of a gas boiler?

The clocking of a gas boiler is the frequency of switching on to heat the coolant. If external control devices are not connected to the equipment, then the interval between turning on the gas boiler can be no more than 10 minutes. The default interval is 3 minutes.

It is not recommended to turn on the equipment frequently. The most economical consumption will be with continuous operation of the gas boiler. If the equipment operates continuously for a long time, it means that a mode has been set in which heat losses in the house are compensated while maintaining a suitable temperature of the coolant.

Residents of small apartments often face the problem of high gas consumption. This is due to the fact that the equipment was designed for heating and water heating, and therefore has high power.

Different models of Baxi gas boilers differ in configuration parameter numbers, so you need to study the instructions before setting up the equipment.

ECO FOUR and ECO 4S

Probably the most popular BAXI boiler in Russia is the Baxi Eco Four 24. It is easy to maintain and operate, and is well assembled. Hydraulic group made of brass and secondary plate heat exchanger made of stainless steel, continuous smooth modulation of the flame, operates quite quietly. The actual gas consumption for heating the apartment is no more than 250 m3 per month even in the most severe frosts, which undoubtedly confirms the cost-effectiveness. The turbine DHW flow sensor allows you to accurately regulate the water temperature - you just need to set a comfortable value once (for example, for me it’s 39 degrees) and never return to the settings. The ECO 4S model replaces the BAXI FOURTECH and features a hydraulic group made of composite material.

Coolant temperature

Gas saving is also associated with proper adjustment of the coolant. The standard configuration of a gas boiler does not include an outdoor temperature sensor, so you must independently adjust the temperature depending on the weather. For example, decrease or add. This method is not suitable for everyone, since it is necessary to constantly monitor the temperature. Baxi gas boilers have the ability to connect additional functions. Therefore, you can purchase a separate outdoor temperature sensor and connect it. This way the temperature will be adjusted automatically according to weather changes. In addition, you can use weather-sensitive automation. In the equipment settings, you must select a climate curve. In accordance with the parameters, the gas boiler will consume less gas.

Baxi heating system wiring diagrams

Despite the fact that the manufacturer has taken care to provide the user with all the necessary documentation for connecting the boiler to the heating system, in order to maintain warranty obligations, it is not recommended to do this yourself; you need to invite a service department, which will be recommended in the store when purchasing the unit.

This will allow not only to maintain the warranty on the equipment, but also to resolve future issues with the city gas inspection, which will have to give permission to operate gas equipment.

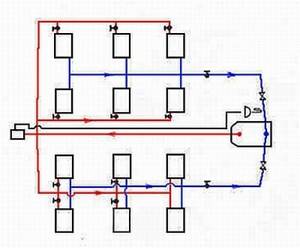

Thus, the user’s task will be to select the desired strapping pattern. It will depend on the installed heating circuit. According to existing heat supply schemes, it can be:

- two-pipe for houses with a large heating area;

- single-pipe with natural circulation for houses with small heated area;

- combined, for multi-circuit heating systems.

Two-pipe scheme

The two-pipe Baksi circuit is made from a heating source, a circulation pump, an expansion tank, a safety group, a mud trap and a coolant purification filter.

The principle of operation of a two-pipe network:

- Cold water enters the heating circuit through the filter to the suction of the network pump.

- Water enters the boiler and is heated to the temperature set by the user on the operating panel.

- The heated coolant is supplied to the heating system.

- From the supply pipeline there are branches to each heating device.

- Cooled water from the radiator flows through the return branch into the common return line and is pumped into the unit for the next heating cycle

Air vents and a heat sensor are installed on the heating device, which regulates the coolant depending on the set temperature.

Thanks to this scheme, the radiators heat up evenly and, if necessary, can be completely individually switched off.

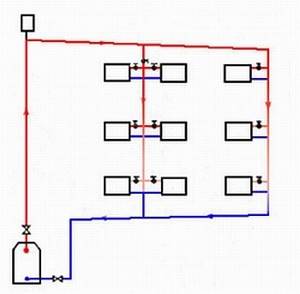

Single-pipe scheme

A single-pipe scheme with natural circulation is an affordable and economical piping scheme designed for small-sized one-story houses.

The scheme is as follows:

- The gas boiler is installed on the wall in the kitchen.

- The supply from the device comes through one pipeline, to which all radiators are connected in series.

- The heated coolant from the device enters the supply line, which has an upper distribution, and then sequentially passes through all the heating radiators.

- From the last radiator it flows into the return line and then into the boiler for a new heating cycle.

- The movement of the medium occurs under the influence of natural circulation that occurs due to the temperature difference in the supply and return. For efficient movement, the supply and return pipelines are installed with a slope. The vent is installed at the highest point, usually in the attic.

- An expansion tank is installed in the system to compensate for the thermal expansion of the coolant.

The disadvantage of this scheme is that the first batteries along the coolant flow are overheated, and the last ones are underheated. The efficiency of the circuit can be increased by integrating a circulation pump into the circuit, which will increase the heating area from 40 m2 to 150 m2.

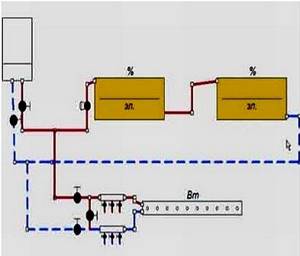

Combined diagram of the Baxi gas heating system

This is the most progressive boiler piping scheme; it has several independent heating circuits - a radiator and a “warm floor” system.

Typically, radiators are installed in bedrooms and the living room, and in other rooms in the kitchen, bathroom and other utility rooms, “warm floors” are installed, which operate at lower temperature conditions and can work with reverse coolant.

In this option, the system will more fully remove heat from the heating network water. At the same time, the lower the temperature in the return pipeline, the higher the efficiency of the heating network installation is ensured.

The return coolant temperature limitation is set by the manufacturer for a specific unit model in order to counteract the formation of condensation in the flue gases. To distribute the coolant across different circuits, you will need to install a Baxi boiler with a hydraulic manifold and separate circulation pumps for each circuit.

Setting the Baxi gas boiler to economical mode

The gas boiler can be set to economical mode. If the equipment is installed in a small apartment, then you must select the minimum parameters F08 and F10. The first indicates the maximum net power of the heating system, and the second indicates the minimum net power of the heating system.

The modulation range of a 24 kW gas boiler starts at 40% of the maximum power. Therefore, the minimum operating mode can be 9 kW. This power is enough to heat a house with an area of up to 80 square meters, and the intervals between switching on will increase.

In addition to saving gas, the service life of the gas boiler elements is also extended. For example, a fan, a relay on the control board and a gas valve.

Model overview

LUNA 3 Comfort1.240.

Wall-mounted single-circuit. Approximate price 48,000 rubles. Weight 31 kg. 91% efficiency. Heating capacity 9.3-24 kW. Open firebox. There is automatic ignition. “Comfort” models provide a connection to “warm floors”. Copper heat exchanger.

ECO Four 24 F

Dual-circuit. The Ecofor device is a representative of a new generation. Compact. Hangs on the wall. Closed firebox and separate heat exchangers. Heats rooms up to 240 sq.m. There is an LCD display that displays the current parameters. Power 9.3-24 kW. 91.2% efficiency. Almost silent operation. Power consumption – 80 W.

Luna Duo-Tec1.28

Double-circuit turbocharged. Efficiency – 106%. Connection to heated floors. Outside temperature sensor. There is a remote control unit. 28,000 W – heating capacity. Heats up to 210 sq.m.

Nuvola Duo - Tec+

Wall-mounted version. Condensing type. Closed firebox. Can run on liquefied gas. Electronic control. There is an LCD display. Weighs 62 kg. Warm floors mode.

POWER HT 45

Floor-standing condensing type unit. The cost is more than 138,000 rubles. Open firebox. Without DHW. Powerful boilers can be connected in cascades. Width – 45 cm. Power 48.7 kW. Weight 60 kg.

SLIM 2.230i

Floor installation. Open firebox. Weight – 155 kg. Two circuits. 22.1 kW. Heats an area of up to 166 m2. Capacity 13 l/min. The capacity of the expansion tank is 10 l. The price is about 100,000 rubles.

SLIM 2.300 Fi

Powerful floor-standing boiler. Efficiency 90%. Nominal heating output 30 kW. Closed firebox. Heat exchanger – cast iron. Turbocharged gas exhaust. Weighs 184 kg. The cost is about 140,000 rubles. Expansion tank – 10 l. Dimensions (HxWxD) – 85x65x60 cm. There is a circulation pump.

How to connect a room thermostat?

Almost all Baxi gas boilers have the ability to connect a room thermostat. If the temperature in the room drops, the device will send a signal to the heating equipment and the boiler will automatically start working.

All indicators depend on the balance and type of heating system. Thanks to the programmable thermostat, you can set the desired temperature during the day. If the temperature in the room is reduced by 1 degree, then you can save about 5% of gas in a year.

In Europe, it is mandatory to install a room thermostat for the energy efficiency of the heating system.

High boiler power

Operating a gas boiler at maximum power levels causes rapid heating, as well as pulsed operation of the unit. The heating level is determined by the modulation of the gas burner. When receiving a heated return, the boiler goes into standby mode, and as the return cools down, the boiler turns on again. Due to the high starting power of the boiler in the off-season, the problem of turning the gas boiler on and off occurs most often.

A room thermostat can solve the problem. In this case, regulation is carried out automatically. If the room temperature is reached, the thermostat will signal the boiler to turn off. The heating system cools down faster than the air temperature. Therefore, the boiler will turn on less often and work longer.

It is of no small importance to determine the optimal power of the equipment, taking into account the region of residence, the total area of the heated room and the degree of insulation of the building. Currently, condensing boilers used in low-temperature heating systems have proven themselves best.

This reliable option is characterized by heating the coolant in the return circuit within 60°C.

Maintenance of Baxi gas boiler

Almost all gas boilers have the same design, regardless of the manufacturer. Through the heat exchanger, thermal energy from fuel combustion is transferred to the coolant. A gas boiler may have 1 or 2 heat exchangers. During operation, the heat removal surface becomes contaminated with soot, and scale forms inside the gas boiler. Due to these contaminants, the characteristics of thermal transfer are reduced, therefore, energy consumption will increase.

In order for the Baxi gas boiler to operate in economical mode, it is necessary to periodically carry out maintenance of the system. Particular attention should be paid to units with bithermic heat exchangers, which are difficult to clean due to their design.

Types by number of circuits

Wall-mounted units are divided into single- and double-circuit. The former are intended only for heating rooms, while the latter additionally heat water.

Single-circuit

A single-circuit boiler has one heat exchanger in which the liquid is heated using heat from the burned gas. It is located above the burner in the combustion chamber and consists of a coil pipe on which a ribbed box is placed.

The materials for the manufacture of such devices are:

- cast iron;

- copper;

- steel.

The most resistant to corrosion are copper heat exchangers, but they are the most expensive. Cast iron stands are wear-resistant, but due to their fragility and heavy weight, they are usually used in floor-standing models. Wall-mounted boilers mainly use stainless steel heat exchangers.

Single-circuit units operate exclusively as heating units. To prepare hot water, it is necessary to connect additional equipment.

Dual-circuit

This heating unit has an additional DHW (hot water supply) circuit built into it. Heat exchange in it is realized in a different way - by heating one liquid from another.

The burner does not turn off. The three-way valve disconnects the primary circuit from the heating system. The coolant begins to circulate through the secondary heat exchanger, where water is heated for domestic needs.

In this case, the heating system does not function. However, a significant drop in temperature in the room is not observed, since this requires many hours of operation of the boiler to prepare hot water. In reality this never happens.

Baxi gas boilers: review, device, model range

wall-mounted gas boilers have literally flooded the Russian heating equipment market over the past decade. This is not surprising. When a potential buyer is faced with a choice: to buy an inexpensive boiler, but unfinished and domestic, or a reliable, but expensive one made in Germany, the choice is often made in favor of Italian manufacturers of gas boilers.

As a rule, they are distinguished by a fairly good price-quality ratio and a developed technical service network; spare parts are easy to find. Let's consider the most popular brand of gas boilers in Russia, Baxi, reviews of which we can often read on specialized forums, online blogs or on the company's official website.

We will analyze in detail the main models, types, design, technical characteristics of wall-mounted (mounted) single-circuit and double-circuit gas boilers Baksi, identify their main advantages and disadvantages, and also understand how they differ from each other according to the operating instructions.

Basic models of wall-mounted gas boilers from Baxi

The following models of wall-mounted gas boilers from Baxi are available on our market:

— Baxi Main Four and Baxi Main 5 (fourth and fifth generation of boilers); — Baxi Four Tech and Baxi Eco 4S; — Baxi Eco Four and its more compact analogue Baxi Eco Compact; — Baxi Luna-3 and Luna-3 Comfort with a remote control panel; — Baxi Nuvola-3 with built-in storage boiler.

Baksi wall-mounted gas boilers differ in the type of exhaust of combustion products and are:

1. Baxi turbocharged gas boilers with a closed combustion chamber

A special fan (turbine) is installed in the boiler, with the help of which combustion products are forcibly removed from the boiler into the atmosphere. To do this, you will have to additionally buy a coaxial chimney, or a pipe system for separate smoke removal and air supply.

The coaxial type of chimney of the “pipe-in-pipe” type is installed with one end (through the elbow) on the boiler, and the other end goes out through the wall to the street. This is very convenient, because... there is no need to specially fence the chimney through the roof.

Gas boiler Baxi Main Four 240 Fi

2. Atmospheric boilers Baxi with an open combustion chamber

If your private home already has a chimney with a diameter of at least 130 mm, then you can buy a boiler with an open chamber, the combustion products of which are released due to natural draft. Such boilers are often called “aspirated” boilers.

On the Baxi boilers themselves, the diameter of the smoke outlet pipe is 121-122 mm, so an aluminum corrugation with a diameter of 125 mm, capable of withstanding temperatures up to 400 degrees Celsius, which can be stretched up to three meters, is suitable for them. Or you can use stainless steel chimney pipes of the same diameter. True, this chimney option will cost a little more.

These models do not have a turbine, and the Baksi boiler is marked with the article “i”, or it is not indicated at all. For example, "Baxi Eco Four 24i" or "Baxi Four Tech 24".

Baxi wall-mounted gas boilers are available in two versions:

1. Single-circuit.

This type of boiler only provides for heating the coolant in the heating system. These boilers have only one main heat exchanger. This type of boiler is not very popular because its cost is slightly lower than that of double-circuit models.

In turn, a wall-mounted double-circuit gas boiler can always be used only for heating, and the second circuit for hot water cannot be connected at all.

You can simply buy a Baxi double-circuit gas boiler, even if there is no running water in the future. After all, perhaps after some time you will find the second circuit of this boiler useful, and you will not have to buy a new device.

2. Dual-circuit.

Such boilers are most popular among buyers, as evidenced by numerous reviews of Baxi gas boilers. They are able to work both as a heating unit and as a flow-through gas water heater. Moreover, when using running hot domestic water, the heating of the heating circuit does not turn on automatically, unlike many brands of floor-standing gas boilers.

Double-circuit wall-mounted gas boilers have two separate heat exchangers, or one bithermic one for heating both circuits in one monolithic block. Boilers of this type are in greatest demand among potential buyers. Having purchased such a boiler, we get both a boiler for heating and a gas water heater for hot water supply in “one bottle”.

Design features of Baxi double-circuit gas boilers: instructions

Double-circuit boiler Baxi Eco 4S 24F

2. All boilers are equipped with a circulation pump made by German manufacturers, either Grundfos or Wilo. This pump is capable of raising the water column in the heating system up to 6 meters, which is quite enough for a two-story house or cottage. The circulation pumps built into the boilers are quite economical and are equipped with an automatic air vent.

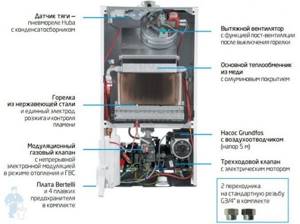

Device and main elements

In terms of their design, TM Baksi units are not much different from other gas boilers. They consist of several components.

Gas burner device

This node includes several elements:

- Gas burner: in the most affordable models, a burner with constant power is installed, in more expensive ones - with step control. To maintain a constant temperature in the room, the automation system has to periodically extinguish such burners and then re-ignite them. The most expensive Baksi boilers are equipped with modulating burners, the power of which is smoothly regulated. Such burners operate constantly and in the most optimal mode, so the set temperature is maintained with high accuracy.

- Combined gas valve: allows or blocks the gas supply to the burner depending on the signals from the automation devices.

- Ignition unit: consists of an electronic circuit and an electrode. This unit converts the mains voltage supplied to it into high-voltage high-frequency pulses, which are supplied to the electrode. As a result, a spark flashes between the electrode and the burner (in some models, between two electrodes), igniting the gas-air mixture on the burner.

The combustion chamber of TM Baksi boilers is closed, that is, air is taken into it from the street. The only exception is the Luna-3 Comfort 240i model, which has an open camera.

The pipe for connecting the gas supply line is located in the middle between the pipes for connecting the heating system.

Heat exchanger

The company installs both steel and copper heat exchangers in its units.

The latter are more efficient due to their high thermal conductivity.

The successful design of the heat exchanger allows you to absorb 90.8% of the heat generated in the combustion chamber (some models have a slightly lower efficiency - 88.7%).

In addition to the main heat exchanger, the Baksi heater may have another one designed for preparing hot water. Such boilers are called double-circuit boilers. Some models, for example, Baxi Ecofor 24, can heat water in an external boiler.

A mesh filter is installed at the inlet of the heat exchanger.

Expansion tank

For different models, the volume of this element can be 8 or 10 liters.

Russian manufacturers of heating equipment have made a lot of progress in the quality of their equipment. Among the popular companies is Conord. Gas boiler Conord - user reviews and overview of characteristics, read carefully.

The heating diagram for a house with a gas boiler is presented here.

Follow this link https://microklimat.pro/otopitelnoe-oborudovanie/kotly/elektricheskie-kak-vybrat.html you will learn how to choose the right electric heating boiler and which domestic and imported manufacturers are considered the best.

Automation system

All units of this brand use energy-dependent automation. The total power consumption of the boiler, depending on the model, is 135 or 165 W. For most models, for example, Luna-3, Eco-3, Slim, Nuvola, the automation is weather-sensitive.

This means that in addition to the timer and room thermostat, you can connect an outdoor temperature sensor to it. Taking into account weather conditions allows the system to promptly switch the boiler to the optimal mode, which makes the heating system more economical.

The wall-mounted model Luna-3 Comfort (3rd generation boiler) uses a temperature sensor instead of a room thermostat.

Internals of the Luna boiler

Analyzing the information received from it and from the street temperature sensor, this boiler itself calculates the dependence of the coolant temperature on the air temperature outside. This property is called self-adaptation.

What you need to consider before buying a Baxi boiler

If the issue of purchasing a single-circuit or double-circuit boiler from Baxi has already been finally resolved, you need to think about calculating the power for the future device. According to the standard, it is calculated based on 1 kW per 10 sq. m. living space.

For example, if the area of the house is 125-145 sq. m., the device must be no weaker than 12 kW. But here it is worth taking into account the insulation of the house and its degree, as well as possible heat losses. In order not to make mistakes with these indicators, it is better to leave this work to specialists, since here you will have to pay attention to the chimney; its choice is made based on the characteristics of the combustion chamber.

Follow the link to read a review of the best economical gas boilers for 100 square meters.

If frequent power outages are acceptable, you need to buy an additional battery. Most owners of private houses, first of all, pay attention to energy-independent wall-mounted gas boilers. But for such equipment you will have to pay a fairly large amount of money. If the family is large, you should think about installing an additional boiler, if one was not provided for.

Before purchasing, you can ask about the type of heat exchanger installed in the unit; if it is copper, this is definitely an advantage over other models, since this device will last longer. As for cast iron heat exchangers, they are also not subject to corrosion, but the downside is that they are very heavy and have undesirable fragility. If you take into account all these features, the gas boiler will last a very long time and will not require repairs.