Foamed polyethylene production technology

Polyethylene foam is made from high-density polyethylene (less commonly, low-density polyethylene). During the production process, fire extinguishing additives are added to the desired raw material, making the material resistant to fire. The production technology involves performing two main stages: melting polyethylene granules and combining the raw materials with liquefied gas, which is a good reagent. The gas forms the foamed structure of the future product. The production of polyethylene foam can take place using different foaming technologies:

- Non-crosslinked – extrusion + physical blowing agent (propane-butane, isobutane);

- Chemically cross-linked – mixing + azodicarbonamide, extrusion, forming and cross-linking with foaming under heat;

- Physically cross-linked – cross-linking by firing a stream of fast electrons and foaming.

Properties and characteristics

First of all, you need to understand what the material is. Thus, foamed polyethylene (polyethylene foam, PE) is a material based on traditional and well-known polyethylene. However, unlike the standard variety, the foam type has a special closed-porous structure

In addition, it is important to note the fact that the foam material is classified as gas-filled thermoplastic polymers

If we talk about the time the material appeared on the market, it happened about fifty years ago. Since then, polyethylene foam has been gaining popularity among users. Today, the production of goods complies with all international standards that are prescribed in the relevant GOST.

Before you decide to purchase and use the material, you must evaluate and analyze all the available distinctive characteristics of polyethylene. It should be borne in mind that these properties are not only positive, but also negative. Nevertheless, they all constitute a set of distinctive features of the material.

So, the most important characteristics of foamed polyethylene include certain qualities.

First of all, it is necessary to say about the high flammability of the material. So, if the air temperature reaches +103 degrees Celsius, polyethylene will begin to melt (this indicator is the so-called “melting point”). Accordingly, during operation you must remember this quality of the material.

The material is resistant to low temperatures. Thus, experts report that even when the ambient temperature drops below -60 degrees Celsius, polyethylene still retains such important characteristics as strength and elasticity.

The level of thermal conductivity of polyethylene is very low and is at the level of 0.038-0.039 W/m*K. Accordingly, we can talk about a high level of thermal insulation.

During the operation of foamed polyethylene, one should take into account the fact that the material itself is capable of absorbing sound. In this regard, it is often used to equip recording studios, clubs and other premises that require mandatory sound insulation.

PE does not contain any components that can harm the human body. Accordingly, the material can be used without fear for health and life (both your own and your loved ones). In addition, even during combustion the material does not emit toxic components.

The most important characteristic of polyethylene, thanks to which it is popular and in demand among a large number of users, is the fact that the material can be very easily transported. Also important is the fact that polyethylene foam can be easily installed.

PE is a material that has a high level of wear resistance. Accordingly, we can conclude that it will serve you for a long period of time. If you try to roughly estimate the service life of the material, it is approximately 80-100 years.

During the operation of the material, it is imperative to take into account the fact that it is destroyed by exposure to ultraviolet radiation. Accordingly, direct use of the material must be carried out under protected conditions.

Great variety in terms of color, shape and type of design. The most popular and in demand are rectangular sheets in black and white.

The thickness of polyethylene may vary. This indicator plays a decisive role when choosing a material. So, depending on your needs and preferences, you can choose PE with a thickness of 10 mm, 50 mm, 1 mm or 20 mm.

In addition to the functional characteristics of PE, it is important to study in detail the chemical and physical qualities of PE (for example, properties such as density, ability to absorb moisture, etc. play an important role)

Among the distinctive chemical and physical properties of the material are:

- the recommended temperature range for use of the material is from -80 degrees Celsius to +100 degrees Celsius (at other temperatures the material loses its characteristics and qualities);

- strength can range from 0.015 MPa to 0.5 MPa;

- the density of the material is 25-200 kg/m3;

- Thermal conductivity index is 0.037 W/m per degree Celsius.

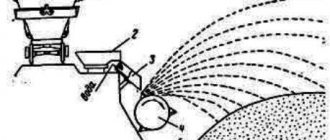

What equipment to choose for production

Some difficulties may arise with the selection of equipment. In our country there are almost no manufacturers of ready-made lines for the production of VP sheets. The only known one. Therefore, most likely, you will have to purchase either used. u. equipment (which suffers from frequent breakdowns), or purchase it in a new form from Chinese manufacturers. The approximate composition of the line includes: a raw material loader, an operator platform, a talc injection system, an extruder, a high-pressure pump, an anti-shrinkage unit, an extrusion head, an air ring with a blowing fan, a cooling element, a pulling device, a two-station winder, and a line control system. Estimated price of the line: from $150,000. The choice of equipment and technology for production also depends on what density of polyethylene is needed. Thus, the gas method is considered more expensive, while the chemical method is cheaper.

Application of non-crosslinked polyethylene foam

- Non-crosslinked polyethylene foam is convenient for packaging and, if necessary, softens pressure during loading. Has an unlimited shelf life. It cannot spoil and is beneficial when packing valuable goods and cargo. In the packaging market, NPE has no equal competitors, and occupies 90% of applications.

- Used as packaging material for electrical equipment, dishes, furniture, glass products. Perfectly protects the surface from dust and technical debris.

- NPE is excellent for insulating from moisture, water, steam, condensation and mechanical noise.

- Subject to minimum quality requirements, it is used in construction as thermal insulation and mechanical engineering. Not suitable for use when there are powerful loads or the air temperature is too hot.

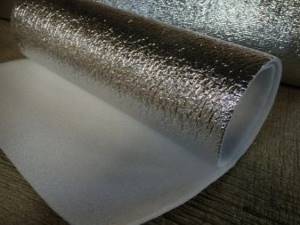

- It is well used to reduce energy costs while saving heat in the house - thanks to reflective insulation. Widely used to level the surface, put under parquet, laminate, linoleum.

- It has a variety of release forms - in polyethylene mesh, in rolls, in sheets of different thicknesses. With a laminated or foil base, non-crosslinked polyethylene foam will perform protective functions depending on the requirements and the task at hand.

- In the European Union, there is a restriction on the use of NPE; it is used only for packaging.

Step-by-step plan for opening a business for the production of foamed polyethylene

- Analysis of the polyethylene market.

- Renting premises.

- Purchase of equipment.

- Conducting an advertising campaign.

- Organization of sales and waste disposal.

After organizational issues are completed, it is necessary to obtain permits issued by the local administration, SES, and environmental service. Also, at the initial stage of launching production, it is worth solving the problem of waste disposal: start the production of garbage bags or enter into an agreement with a company that uses such waste in its production.

Do I need permission to open a production facility?

The production of foamed polyethylene is a harmful process. Therefore, when starting a business, you will need to obtain a certificate for the production of polyethylene and obtain permits. To successfully sell products, you will need to undergo certification for compliance with GOST 10354-82. There are also requirements for the room in which the film will be produced.

(

3 ratings, average: 2.00 out of 5)

Loading…

Similar business ideas:

- Sawdust recycling as a business idea

- TOP 30 business ideas with minimal investment

- Production of plastic products

- TOP 30 business ideas without investment

Properties of thermal insulation raw materials

Pipe thermal insulation performs a protective function for pipelines. Foamed polyethylene is used for various engineering communications:

- heating lines;

- cold and hot water supply pipelines;

- sewerage;

- air conditioning systems;

- air vents in ventilation.

For heating and hot water supply pipes, insulation is needed to reduce heat losses in the coolant and level out the thermal expansion of the material. For cold water pipes, the heat insulator serves as protection against freezing and condensation on the surface. Polyethylene foam protects sewer channels from freezing and reduces noise levels. Ventilation and air conditioning pipes are protected from ice and condensation.

Polyethylene foam performs thermal insulation functions due to its technical characteristics:

- thermal conductivity coefficient is 0.03-0.04 W/m*K;

- the density of products varies among different manufacturers from 25 to 40 kg/m3;

- water absorption – no higher than 2%;

- fire resistance class G2 in accordance with GOST 30244 (refers to moderately flammable material);

- application temperature – from -60 to +90 degrees;

- a vapor permeability of 0.001 mg/m*h*Pa allows the material to be classified as completely vapor-proof;

- minimum service life - 20 years, maximum - 80 years;

- strength is expressed in tensile strength at break up to 0.3 MPa and elastic modulus in dynamics up to 0.7 MPa;

- depending on the insulation layer, the sound absorption coefficient is from 25 to 55%;

- resistance to aggressive chemical influences.

High insulation properties demonstrate the features of insulation for pipelines for various purposes. Low thermal conductivity allows you to reduce the thickness of the heat insulator without changing the efficiency. Polyethylene foam exhibits waterproofing properties and protects metal pipes from corrosion. The material does not rot, has high hygienic indicators, fungi and bacteria do not multiply on the surface.

The disadvantages of the heat insulator are flammability at temperatures above 300 degrees, spontaneous combustion at 400 degrees. In addition, the material is not resistant to ultraviolet radiation.

Due to its elasticity, the material is resistant to deformation, but it can be damaged by sharp objects. Low cost and ease of installation allows the use of polyethylene foam at industrial facilities and in private engineering systems.