Ecoover insulation has become a popular thermal insulation material. This is a reliable product created based on basalt raw materials. It is manufactured using modern technologies in the form of special plates, which allows it to be used in many construction industries.

Insulation production lines are characterized by a high degree of localization, and basalt raw material processing plants are located in close proximity to mining sites. In combination with the use of the most modern equipment in the manufacture of insulation, the reduction in costs of transporting raw materials makes thermal insulation economically accessible to a wide range of consumers.

Insulation manufacturers, due to an increased level of automation, are able to process raw materials - solid basalt - into the final product, a lightweight fibrous insulating material. At the exit, the goods are packaged for subsequent transportation.

The insulation manufacturing process is a procedure of melting mineral raw materials with the parallel addition of synthetic additives. At the same time, stretching the raw material mass using advanced technologies and specialized equipment gives the composition a fibrous structure. Production lines are equipped with filtration units that process production waste, protecting the environment from harmful emissions.

The technology has been awarded international quality assessment. Finished products have all the necessary certificates of quality and compliance.

Advantages and disadvantages

Basalt-based thermal insulation is a modern and sought-after product, although it has pros and cons.

- Compared to other mineral thermal insulation, ecoover basalt insulation is highly durable.

- The plates cope with the task of protecting premises from energy loss.

- High sound insulation rates make it possible to use the product as a soundproof barrier.

- Thanks to the introduction of modern technologies into the production line, the Ecover plant has achieved the ability to produce insulation that does not absorb moisture, which is unusual for many mineral insulation materials. This is achieved by treating the basalt mineral raw material with a water repellent. When saturated with moisture, the insulation loses its properties, negating the effect of all the work done.

- Having zero flammability, the material is able to protect the coatings insulated by it from the destructive effects of fire during emergencies.

- The environmental safety of the product is also considered an important quality.

- Among the products of various manufacturers, this basalt insulation is distinguished by its ability to maintain the original geometric and physical parameters. During production at the enterprise, the Ecoover plant uses technologies that ensure the safe operation of products in the long term. Resistance to shrinkage allows the product to be used for insulating sloped or vertical surfaces.

- The products of the factories are adapted to the standards of building structures. The product line is provided on the markets in such a way that it is possible to select insulation boards for the specific geometric dimensions of the elements of the insulated surface. This will avoid unnecessary waste during work. Different widths will allow, if necessary, to achieve maximum thermal insulation effect.

The thermal insulator is resistant to the spread of fungi and mold. Rodents and insects do not harm it. It has no unpleasant odors and does not emit harmful substances during operation. The insulation has vapor barrier characteristics that provide the necessary air circulation.

It is widely used when working on:

- insulation of floors and walls;

- thermal insulation of attics, foundations and roofs;

- finishing of slab joints and window openings;

- soundproofing rooms;

- waterproofing floors, foundations and walls;

- vapor barrier of masonry walls.

Mineral thermal insulation is used in rooms with aggressive environments at high temperatures. It is applicable in industrial buildings for insulation of ventilation or heating equipment, tanks and sewers for water and air.

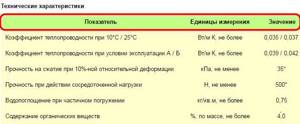

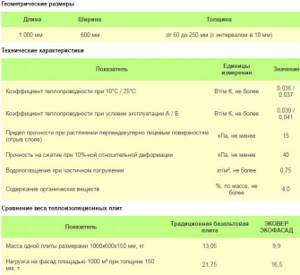

Specifications

Mineral insulation is made from basalt raw materials, mined by a manufacturer of thermal insulation materials at the Bazhenov deposit in gabbro rocks. Ecoover is endowed with its characteristics and features by adding water repellents and modified additives to the main raw materials. Its thermal conductivity is not inferior to other popular products on the market among insulating products for construction purposes. 50 mm of insulation has properties equal to almost 200 mm of wood or 300 mm of masonry made of gas or foam concrete.

The characteristics of Ecover basalt fibers give the material a special feature: it is highly resistant to heavy loads.

One square meter of surface can withstand pressure of 8 tons.

Ecoover mineral wool melts at temperatures above 1000 degrees Celsius, which makes it a practically fire-resistant product. The density of insulation in the product line of this brand reaches 150 kilograms per cubic meter. The ecoover light station wagon has a reduced density, in which it is less than 30 kg per square meter. meter. The compressibility of insulation varies from 5 to 25 percent depending on the type of material. When partially immersed in liquid, thermal insulation is characterized by an absorption rate of no more than one kilogram per square meter. At the same time, it allows water to pass through itself without absorbing it. Depending on the operating conditions, the thermal conductivity coefficient of the insulation changes. On average it is 0.035-0.040 W/m*K. The characteristics allow the insulation to be used as a soundproofing product; among the entire line of products, Ecoover Acoustics is the most suitable for these purposes. It is suitable for use in non-load-bearing structures such as frame house partitions, timber floor frames, etc. Has high vapor permeability. The composition contains no more than 3% organic additives.

Ecover Standard 50: characteristics

One of the most popular types of this insulation is Ecover Standard 50 due to its technical characteristics:

- overall dimensions 100x60 cm;

- density ranging from 28 to 60 kg per cubic meter;

- thickness from 5 to 20 cm;

- percentage of moisture absorption – no more than 1.5% of the volume;

- compressibility is not higher than 15%.

The material belongs to the group of non-flammable (NG). Packaged in branded shrink polyethylene film with the logo of the material manufacturer and the full name of the heat insulator.

Excellent thermal insulation qualities, maximum environmental friendliness, low cost, durability, hydrophobicity, lightness and simplicity of installation, no special requirements for storage conditions, resistance to changes in temperature and air humidity, frost resistance, long service life have made Ecover a popular thermal insulator for new construction and renovation of existing buildings. Does not contain components that irritate human skin.

Storage of the material and its transportation does not require specific conditions. When storing, the material is not subject to creasing. According to compressibility, the material belongs to the semi-rigid type of slabs.

The Ecover series of modern products offers a wide range of materials that serve as an ideal natural material for insulating all load-bearing structures of a building, from foundation laying to roofing of any shape.

Geometric dimensions

The dimensions of ecover insulation are selected specifically for ease of use. The slabs are sold in standard sizes of 1 meter by 60 centimeters. The company creates products with a thickness of 30 to 250 mm, which will make it possible to produce thermal insulation where large insulation costs are not required, or in places where there is practically no thermal insulation layer. In this case, it does not matter which brand is used: standard or ecoover acoustic, since the consumer selects the required insulation thickness. In the product line, the thickness change step in the assortment is 10 mm.

How much does Ecover insulation cost?

Thanks to the favorable location of the plant in Asbest near the Bazhenov deposit and the well-established Izotech technological line, the cost of Ecover in Moscow is 25-30% lower than imported stone wool insulation. In addition, the price depends on the size and volume of the Ecover packaging, as well as the density and thickness of the material. Don’t know where to buy high-quality Ecover insulation without intermediary markups? Call the number to get a personal discount and free consultation with a specialist!

Facade insulation

The development of technology and the experience of builders when working on insulating walls of building facades raised the question before developers about the need to create a material suitable for thermal insulation of walls. This is how the basalt insulation of the ecover façade became. Traditionally possessing high resistance to external factors, the new product began to be used for insulating external walls and in ventilated facade systems.

Ecover vent facade 80 is also applicable for single-layer insulation of wall surfaces as the main thermal insulation material. It is also used as a surface layer with an air gap in ventilated systems on top of other heat insulators.

For thermal and sound insulation of wall surfaces in façade systems, eco-facade eco-cover is suitable for plastering with a thin layer. It has greater strength compared to other products. Due to its technical characteristics, eco-facade eco-facade is suitable for use in finishing works on buildings of any number of floors. Ecover vent facade has less water absorption than insulation for interior work.

There are several types of insulation for facade use, among which are the following brands:

- Facade decor;

- Façade decor optima;

- Sandwich;

- Sandwich K.

Advantages

Looking at the breadth of the Ecover company’s product range, it becomes obvious how wide the scope of application of the manufacturer’s products is. This in turn is due to the positive properties of the thermal insulation material:

- Use in production of exclusively natural, environmentally friendly mineral raw materials.

- Preservation of the shape and technical properties of the material under significant temperature changes.

- Chemical resistance, heat resistance, non-flammability, water-repellent qualities of the thermal insulator.

- Excellent soundproofing properties.

- Resistance to ultraviolet radiation, microorganisms and rodents.

- Long service life.

- Easy installation using simple improvised means.

- Availability and reasonable price.

Internal insulation

For interior work, the following brands of insulation are distinguished:

- light;

- standard;

- roof;

- acoustic.

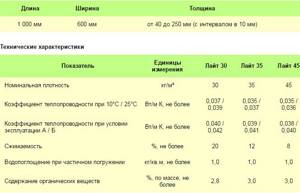

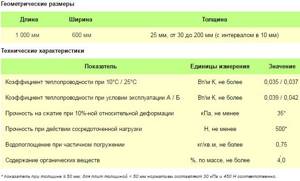

Brand Light

Ecover mineral wool belongs to the class of light basalt slabs. The main purpose is thermal and sound insulation of non-load-bearing building structures in buildings of any type and class. In addition to being used in partitions of frame walls, attic roofs, attic floors and floors, it can be used in the construction of three-layer, layered (well) masonry. Ecover light universal is used for insulation of various tanks, pipelines, air ducts and other industrial utilities that require thermal insulation. The Light and Ecover light universal brands are suitable for installation as the first layer in ventilated facades.

Thermal insulation parameters:

- Density from 25 to 45 kilograms per cubic meter.

- Compression resistance ranges from 8 to 20%.

- Water absorption 0.75 kg per m2.

- At temperatures from -10 to + 25 degrees, thermal conductivity changes from 0.035 to 0.039 W/m*K.

- Included in the class of non-combustible materials.

Scope of application

The versatility of Ecover mineral wool allows it to be used in almost any construction industry. In the field of construction and repair, such products are considered simply irreplaceable, as they harmoniously combine all the qualities that are needed to create comfortable conditions in a home or other type of premises.

The main areas of application of this material are:

- walls and internal partitions;

- loggias and balconies;

- attic floors;

- floors;

- ventilated facades;

- roof;

- pipelines, heating and ventilation systems.

Due to its light weight, ease of installation and affordable cost, Ecover thermal insulation is actively used in domestic conditions, as well as in industrial and public places.

High-quality sound insulation created using this material provides the most comfortable conditions at almost any construction site, as it has low thermal conductivity, moisture absorption and compressibility.

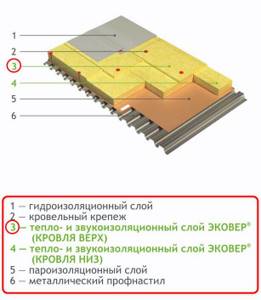

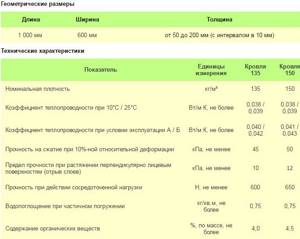

Brand Roofing

Ecover roofing is a thermal insulation product used as a single-layer roof insulation. Ecover has the necessary characteristics for installing roof insulation both without cement and with cement screed. Ecover roofing is suitable for insulating attic and interfloor ceilings, as a thermal insulation layer between the first floor and an unheated basement.

Thermal insulation parameters:

- Density 135 or 150 kg per m3 (indicated in the name).

- Compression resistance 45 kPa.

- Water absorption 0.75 kg per square meter. meter.

- At temperatures from -10 to + 25 degrees, thermal conductivity changes from 0.036 to 0.038 W/m*K.

- Incombustible.

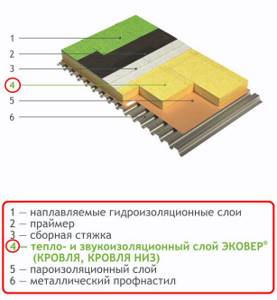

Roof top

Ecover roofing top is a type of rigid mineral insulation for installing two-layer thermal insulation of a flat roof. It is used as a top layer on top of roofing bottom insulation.

Roof insulation parameters:

- Density from 160 to 190 kg per m3.

- Compression resistance from 65 to 120 kPa.

- Water absorption 0.75 kg per square meter. meter.

- At temperatures from -10 to + 25 degrees, thermal conductivity changes from 0.037 to 0.04 W/m*K.

- Included in the non-flammable class.

Roof bottom

Ecover roofing bottom belongs to the class of rigid insulation materials used for roofing thermal insulation work. It is suitable for installing single-layer thermal insulation of a roof, as the first layer in combination with the Roof Top subtype or extruded polystyrene foam, as a fire insulation layer.

Roof insulation parameters:

- Density from 100 to 120 kilograms per m3.

- Compression resistance from 25 to 40 kPa.

- Water absorption 0.75 kg per square meter. meter.

- At temperatures from -10 to + 25 degrees, thermal conductivity changes from 0.035 to 0.038 W/m*K.

- Non-flammable

Product lines

The Ecover company has divided its mineral insulation into separate series - in accordance with their purpose and main characteristics.

1. Universal plates.

For private low-rise buildings, as well as interior work, a light series of general building thermal insulation is produced:

- Ecover Light is available in three density options (30, 35 and 45 kg/m3) and has the usual thermal conductivity for mineral wool of 0.035-0.042 W/m·K. Reduced water absorption at the level of 1% is provided by water-repellent additives. However, according to reviews from builders, lightweight slabs cannot boast of a stable structure, which often leads to ruptures and the appearance of gaps in the thermal insulation layer.

- Ecover Light Universal - allowed for use on surfaces where the temperature does not exceed +400°C. It has only one version (28 kg/m3), but it has improved compressibility - 25% versus the maximum 20% for the previous series.

- Acoustic - as the name implies, this is not so much insulation as a soundproofing material that can absorb noise up to 46-58 dB. The manufacturer promises a complete absence of shrinkage, which, with a density of 35 kg/m3, seems doubtful for vertical structures. Judging by the reviews, even slabs weighing 45 kg/m3 slip in the wall sheathing. But the thermal conductivity of acoustic mats is low - only 0.035-0.037 W/m K.

- Ecover Standard - a small series is available in only two density options - 50 and 60 kg/m3. Efficiency indicators are acceptable (0.035-0.04 W/m K), compressibility is minimal - 5-6%. If mineral wool slabs will experience any mechanical loads, it is worth purchasing Standard-60, since it is the only one in this line that has at least some strength (4 kPa).

The entire “light” Ekover line can be used to insulate loggias, floors along joists, where there is a solid base, since these slabs become bad by surprise. The manufacturer's advice to install Universal in partitions raises doubts about the durability of such thermal insulation. No, it will serve, but without additional fastening, slipping cannot be avoided.

For external use, mineral slabs of higher density are produced, which means the thermal insulation characteristics should be better. The range of facade materials is represented by the following types:

Rigid slabs of increased hydrophobicity are designed for insulating walls under thin-layer plaster. They can withstand compression of at least 40 kPa, and tear-off of layers - from 15 kPa. During installation, you should pay attention to the markings of the slabs: the side with the applied stripe should be adjacent to the frame of the house. Thermal conductivity coefficient is 0.035-0.041 W/m K. Ecofacade-10 has the same characteristics, but in terms of strength it is noticeably inferior, withstanding only 10 kPa in tensile strength and only twice as much in compression.

These boards are also designed for thermal insulation of plastered surfaces, but have better compressive/pull strength. In the basic model it is 45/17 kPa, for the Optima line it is 50/20. Thickness options can be chosen from a size range of 30-200 mm.

As part of the same series, especially durable Lamel slabs with perpendicular fibers are produced. Thanks to this, Ecover basalt insulation is able to withstand the weight of ceramics glued to it. Of course, the manufacturer had to slightly sacrifice thermal conductivity, increasing it to 0.039-0.043 W/mK, but the peel strength of over 80 kPa is truly impressive.

Practically windproof, dense basalt wool slabs can be used not only for external insulation with a ventilated gap, but even under plaster finishing with mandatory mesh reinforcement of the surface. The manufacturer also allows the laying of insulation between reinforced concrete panels to reduce heat loss through three-layer enclosing structures. Ventilated facades are presented on the market in four density options from 70 to 120 kg/m3 and with a compressive strength of 10-25 kPa. Water absorption, as in the entire facade series, is low - 0.75%.

Any Ecover façade wall insulation for plastering or tiling has an important property: the surface of these slabs does not fluff when the solution is applied, which ensures a stable shape of the insulating layer and good adhesion.

Roof thermal insulation in the Ecover line is represented by high-rigidity slabs, which are not very popular in private construction. They are intended rather to work on flat roofs in use. And on pitched ones you should use one of the brands of general construction insulation, the description of which is given at the beginning of our review. This is confirmed by the technical characteristics of the insulation, which is more suitable for creating a two-layer protective coating with high compressive resistance: from 45 to 50 kPa.

With a density of 135-150 kg/m3, there is no point in using such materials for attic and basement floors, unless they are prepared for pouring a concrete screed. But when you need really reliable and durable insulation, you can buy certain types of mineral wool to create an effective underlying layer (100-120 kg/m3) and a more rigid top layer for a flat roof (160-190 kg/m3).

Ecover Step insulation with a density of 135 kg/m3, as well as its reinforced analogue Step Plus (150 kg/m3) are intended for the installation of acoustic floors, insulation of basements and ceilings - especially before the installation of built-in heating systems. Mineral wool can withstand a distributed load of at least 30-35 kPa and a directed load of about 450-500 N (depending on the thickness of the layer).

The Ekover company also produces highly specialized types: for fire protection of concrete objects and metal structures. The manufacturer’s assortment also includes insulating layer boards for sandwich panels (grades C and K).

Reviews about the use of thermal insulation

“I took Ecover Light with a density of 45 kg/m3 for a bath, but then I regretted it - the weaving on light sheets is uneven, some slabs simply fell apart in my hands if handled carelessly. I ticked a box in my mind, and now I’ve decided to buy insulation from “not our” production for the roof of my house. But Decor Optima was still installed on the façade. The quality cannot be compared with the previous one: dense, elastic. Working with him is a pleasure!”

Acoustic

Acoustic eco-cover has become a material that can not only retain heat, but also exhibit a good sound-absorbing effect. It is suitable for creating a sound threshold. Ecover acoustic creates the necessary acoustic effect in cultural premises.

Ecover acoustic has the following characteristics:

- The sound absorption coefficient is 0.95.

- Compression resistance does not exceed 12%.

- Water absorption 1 kg per m2.

- At temperatures from -10 to + 25 degrees, thermal conductivity changes from 0.035 to 0.037 W/m*K.

- Non-flammable composition.

In addition, ecoover acoustics are highly effective in apartments when there is a need to protect yourself from neighbors.