Areas of use

The manufacturer has developed special modifications of insulation for any construction needs, differing in density, shape and size. KNAUF mineral wool will find application anywhere:

- Can be used for thermal insulation of roofs. (Ventilated or non-ventilated)

- Insulation and soundproofing of floors.

- Thermal insulation of the foundation and plinth of buildings, in order to maintain soil stability in winter.

- External and internal insulation of walls of various buildings.

- Thermal insulation of balconies, basements and loggias

- Preventing freezing of non-residential premises, production areas and warehouses.

- Insulation of air conditioning and ventilation systems.

Thanks to the wide range of products, you can find the optimal Knauf insulation option for any purpose. The main types of Knauf mineral wool and their properties are described below.

Application

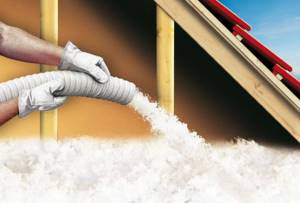

KNAUF INSULATION mineral wool is produced in the form of mats and is created on the basis of glass fiber material using ECOSE Technology. The mats are packaged in a roll format, which makes transporting the product easier.

Fiberglass mats

KNAUF Insulation insulation material is made in compliance with all accepted safety standards. It is soft and not prickly. Does not have a pungent odor. It is easier to work with during the cutting process than with other analogues.

Research work on the new material from KNAUF has proven its high heat-protective properties, and a sanitary and epidemiological analysis has stated the absence of phenol-formaldehyde resins in it.

The manufacturer's instructions recommend using mineral wool in structures with a horizontal position if there is no pressure on the material:

- for attic floors;

- for floors on joists;

- for interfloor or attic floors.

Sometimes insulation is used in pitched roofs, as well as in structures with a vertical position. Namely, when load-bearing external walls or partitions are created to separate rooms with excellent internal temperatures.

Insulation of pitched roofs

"TeploKnauf" is used in the construction of private houses.

The manufacturer has released several versions of this material:

- "Cottage" and "Cottage +". It is used both for internal insulation of houses and for pitched insulation.

- "Country house". Material intended for insulation work in outbuildings, summer kitchens, and cottages.

- "Home" and "Home +". It is used as a heat insulator for walls, roofs and ceilings.

Natural safe insulation

For facade

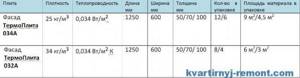

Knauf also has in its arsenal a group of facade materials, which are often used in cases where they insulate building facades and insulate loggias. This group is divided into two brands (034 A and 032 A), each of which has its own parameters. The choice of the best option is up to the buyer.

These façade materials meet the following properties:

- elasticity of structure;

- increased degree of moisture protection;

- long service life;

- ease of work.

Thermal plates of the named brands have the following technical characteristics:

- degree of thermal conductivity – 0.034 (034 A) and 0.032 W/mK (032 A);

- vapor permeability level – 0.5 mg/mchPa;

- degree of moisture absorption – 0.8 kg/sq.m. m (034 A) and 0.6 kg/sq. m (032 A);

- don't burn.

For roofing

Knauf materials are also often used for roof insulation. They are produced in the form of slabs and mats.

Thermo Roll pitched roofs grades 037 A and 034 A have the following technical characteristics:

- degree of thermal conductivity – 0.037 W/mK (034 A) and 0.034 W/mK (032 A);

- the degree of vapor permeability is equal to the value characteristic of facade materials;

- degree of moisture absorption – 0.8 kg/sq.m. m;

- do not burn;

- sound absorption coefficient of the product (thickness 50 and 100 mm) – 0.85 and 1.00, respectively;

For acoustic partition

Mineral wool-based material with a high level of sound absorption is produced in the form of mats and slabs and is used in the construction of buildings for various purposes. Its cost is quite expensive, but the costs are completely worth it.

The manufacturer offers several parameters:

- 50x610x7500 mm (roll);

- 50x610x1250 (in the form of slabs).

Advantages of mineral slabs

For thermal insulation of a house or cottage, Knauf mineral slabs are chosen more often than other insulation materials, and there are good reasons for this. The material really has obvious advantages, which include:

- Minimum thermal conductivity coefficient, which allows you to maintain an optimal microclimate in the room after insulation with a reduction in heat consumption costs.

- Excellent sound absorption performance.

- Fire resistance - Knauf mineral wool slabs belong to the group of non-combustible materials, which is especially important for insulating residential buildings, cottages and other structures.

- Light weight - the load on structures using Knauf mineral wool is minimal.

- No shrinkage - even after the expiration of the period of use (50 years), the material retains its original shape and functionality.

- Simple and quick installation - Knauf mineral wool insulation technology will be clear even to a beginner.

- Completely environmentally friendly due to the absence of toxins and dyes in mineral wool.

Among the disadvantages, one can note the higher cost of mineral slabs compared to competitive products, which, however, is justified by their high technical characteristics and long service life.

Useful properties of insulation

The produced heat insulators fully comply with consumer requirements, providing high-quality heat conservation and sound insulation.

The product line used for thermal protection of buildings and structures includes products based on inorganic fibers and expanded polystyrene.

Knauf insulation materials have technical characteristics that allow them to be used for thermal insulation work in any part of the house.

Properties and characteristics of Knauf heat insulator

- The heat conductivity index of Knauf Expert insulation and its other varieties is 0.030-0.052 W/m•K, that is, in strong winds and frosts, the thermal insulation layer reliably protects the insulated surface from cooling and heat loss. Any building can be insulated: it can be a low-rise cottage, a one-story private house or a multi-story high-rise;

- The noise absorption of Knauf mineral wool insulation has indicators of 41-60 dB, according to sound absorption classes, the insulation is divided into categories I, II and III, in each category there is a division into subcategories - suppression of low frequencies (H), absorption of medium frequencies (C), and absorption of high frequencies frequencies (V). Class I insulation has a parameter a (sound absorption coefficient) ≥ 0.8, classes II and III (categories) - ≥ 0.2-0.8;

- Fire safety according to flammability class NG (non-combustible material);

- The chemical and biological passivity and anti-allergenic properties of Knauf insulation materials allow them to be installed in any premises – from children’s rooms to production areas. Thermal insulation does not interact with acids and alkalis, and is not damaged by rodents and insects;

- Mineral Knauf thermal insulation is made only from natural materials, therefore it does not have unpleasant or synthetic odors;

- High mechanical resistance to compression or bending forces makes it possible not only to conveniently store and transport Knauf roll insulation, but also to install it on geometrically complex surfaces. After compression, the cotton wool quickly straightens, taking its original shape;

- The small specific gravity (density) of mineral wool is 35-40 kg/m3, therefore, when laying even thick layers, the insulation does not shrink or compress over time;

- Installation of insulation is simple - fastening it to a frame or tightly laying it in a confined space, while the minimum service life without replacement is more than 50 years;

- Savings on heating energy consumption when insulating a house with Teploknauf mineral wool – up to 200%;

Of the negative aspects, only one deserves attention - the comparative high cost of the material in comparison with other thermal insulation materials of domestic and foreign production. Another easily eliminated drawback is the release of microparticles of fiberglass into the air during the installation of the insulation layer, so it is necessary to work with Teploknauf using PPE (personal protective equipment).

The production of insulation is carried out in two main areas: the Knauf Insulation brand and TeploKnauf. The latter is more often used in individual construction, the Knauf Insulation brand is used in the industrial sector.

Knauf Insulation

About the advantages of Knauf insulation

1. The thermal conductivity coefficient is very small. Thanks to this quality, in winter, when frosts are especially severe, it is possible to maintain a favorable temperature in the apartment.

2. Sound absorption level is high. Therefore, KNAUF mineral wool is good to use for sound insulation. This will be especially appreciated by those whose houses are located next to a tram depot, railway or busy highway. Finally, the long-awaited silence will reign in their apartments.

3. Fire resistance is good. According to the fire resistance class, this insulation belongs to non-combustible materials (designated NG). This is great - after all, no one is immune from accidents, no matter how careful you are.

4. Biostability – at a high level. Mineral fibers are too tough for rodents. For people living in their own home, this is simply a salvation. After all, rats and mice nestling comfortably in a layer of insulation are by no means a homeowner’s dream.

5. Knauf insulation materials do not emit any unpleasant odors. In fact, they don't smell like anything at all. They are also soft and non-prickly. Working with such material is a pleasure.

6. Transporting this mineral wool is convenient and easy. It can be compressed well, taking up very little space. And when you arrive at your destination, you can quickly straighten it out. Moreover, the shape and size will not change at all.

7. This heat insulator weighs very little, and even after a long time it does not shrink at all.

8. The insulation is installed extremely simply, and lasts for at least half a century. This guarantee is given by the manufacturer - and you can trust him.

9. Proper thermal insulation using this mineral wool makes it possible to reduce costs during the heating season by half.

10. The manufacturer does not use any dyes or bleaches in the production of this material. The pleasant brownish color makes KNAUF mineral wool easy to recognize.

Well, does Knauf insulation have any disadvantages? There is one drawback - it is expensive, unfortunately, and not everyone can afford such a pleasure.

Functionality of mineral insulation - characteristics

Like any basalt insulation, Knauf mineral wool slabs are one of the most successful solutions for installing insulation in a private home or country house. Both in roll form and in the more familiar slab form, the insulation copes with the functions assigned to it, regardless of the external factors affecting it.

Mineral thermal insulation is resistant to fire, mechanical damage, and moisture. In other words, the material does not burn, does not sink or deform, while the thermal conductivity coefficient remains unchanged within the range of 0.035-0.4 W/m.

You can work with Knauf mineral slabs without additional protective equipment, without wasting time on installing a vapor barrier layer. The water absorption rates of the material are so impressive that additional protection from moisture is not required.

Regarding other technical characteristics, Knauf slabs and rolls differ depending on the type. The manufacturer offers several options for solving various problems, ranging from insulating internal walls and ceilings in a private house to insulating facades in country houses. Each brand has its own density, thickness, and weight.

A little about the history of the brand

traces its history back to 1932 - it was founded by the Knauf brothers in Germany and at first bore the very long name “Reinische Gipsindustri und Bergwerksunternemen”. Even from the name it is clear that the original direction of the duration was associated with the production of plaster mixtures from gypsum. As this private enterprise developed, its product range gradually expanded, and in 1949 a new plant for the production of building gypsum mixtures was opened in Bavaria. In 1958, another “technological breakthrough” followed - the first production of sheets of the now so well-known plasterboard opened.

Since the 70s of the last century, the range has gone beyond just gypsum products - mixtures using cement and lime are widely represented, the construction chemicals it produces and ready-made structural parts are gaining popularity. Well, the next stages in development are the development and implementation of the production of high-quality thermal insulation from fiberglass, basalt fiber, and foamed polystyrene.

It came to Russia with its investments in production development in 1993. This was followed by other countries of the post-Union territory - representative offices and production lines were opened in Kazakhstan, Moldova, Uzbekistan, Azerbaijan and Ukraine.

Knauf production facilities are located in many countries, and the products are constantly in demand. The photo shows a plant in the city of Krasnogorsk

As a result, the company has grown from one small family-owned enterprise into the world's largest manufacturer of building materials. The transnational group today includes more than 200 factories located in 37 countries in Europe, Asia, North and South America. On the territory of the Russian Federation, the products of this brand are produced at enterprises in Chelyabinsk, St. Petersburg, Novomoskovsk, Krasnogorsk, Kungur and other cities.

Well-recognized logo of the Knauf brand.

The obvious conclusion is that the company values its reputation very much and tries to fully support the popularity of its products. Therefore, products with the Knauf brand have occupied one of the leading positions in the construction markets of the world for many decades, deserve every possible trust and never “stay on the shelves.”

It is also interesting that Knauf invests considerable funds in charity and social projects. Thus, the company invested in the reconstruction of the historical church of Tyutchev’s estate “Ovstug”, sponsored the Prize named after. V.A. Zhukovsky for the best translation of a literary or humanitarian work from German into Russian, actively promotes other projects in the field of culture, architecture, and social policy.

So, as mentioned above, one of the areas of modern production activity is the production of various types of high-quality thermal insulation. Let's turn to this issue.

Briefly about the main thing

Knauf is a well-known brand of a German manufacturer of building materials.

Knauf mineral wool insulation is available in two series with various modifications.

TeploKnauf is a line of thermal insulation materials with different thermal conductivity, which is intended for work in the private sector: cottage, house, dacha.

The professional Knauf Insulation series is designed for insulation of multi-storey buildings and industrial facilities.

Modifications of mineral wool from the Knauf Insulation line differ in specialization: for facades, roofing, acoustic or moisture resistant, general purpose.

All options are characterized by resistance to changes in moisture, the absence of formaldehyde and other harmful components, and the ability to restore a given shape after compression during installation.

Ratings 0

About the types and technical characteristics of Knauf mineral wool

There are two main lines of Knauf insulation. The first of them is called KNAUF Insulation. It is intended for use by professionals. And heat insulators called “TeploKnauf” are intended for insulation of private houses. Next, we’ll talk about each of the insulation materials in detail.

TeploKnauf materials for private housing construction

1. Heat insulation materials TeploKNAUF Cottage and TeploKNAUF Cottage+.

These materials are made using three-in-one technology. Thanks to this, they perfectly retain heat, protect from extraneous sounds and do not let a drop of moisture into the room. The thermal insulator TeploKNAUF Cottage can be used to insulate the roof, and soundproof the walls and internal partitions. It is sold in rolls or slabs 5 centimeters thick. The size of the slabs is 123x61 centimeters. The size of the rolls is 614.8x122 centimeters. “Cottage+” insulation comes only in tile form. Its thickness is already 10 centimeters, and all characteristics are identical to the previous material.

ParametersCottage in slabsCottage in rollsCottage+ in slabs

| Thermal conductivity, at 10 0С W/m*0С | 0,037 | ||

| Airborne noise insulation index, C111*, RW (W) | 45 | ||

| Flammability group | NG | ||

| Length, mm | 1230 | 6148 | 1230 |

| Width, mm | 610 | 1220 | 610 |

| Thickness, mm | 50 | 50 | 100 |

| Volume of material in packaging, m3 | 0,75 | 0,75 | 0,6 |

| Area of material in packaging, m2 | 15 | 15 | 6 |

| Quantity per package, pcs | 20 | 2 | 8 |

Don't miss: Coolant

2. Heat insulation materials HeatKNAUF Home and HeatKNAUF Home+.

The first type of heat insulators (TeploKNAUF Dom) is made using a very promising modern technology called “3D elasticity”. Thanks to its use, the characteristics of Knauf Dom insulation are very impressive. These materials are able to adhere so tightly to the base that cold bridges have no chance. And it is more economical to use TeploKNAUF Dom+ insulation with a thickness of 10 centimeters than two layers of heat insulators of 5 centimeters each.

ParametersHeatKNAUF HouseHeatKNAUF House +

| Thermal conductivity, at 10 0С W/m*0С | 0,040 | |

| Airborne noise insulation index, C111*, RW (W) | 45 | |

| Flammability group | NG | |

| Length, mm | 1230 | 6148 |

| Width, mm | 610 | 1220 |

| Thickness, mm | 50 | 100 |

| Volume of material in packaging, m3 | 0,6 | 0,6 |

| Area of material in packaging, m2 | 12 | 6 |

| Quantity per package, pcs | 16 | 8 |

3. Heat insulation KNAUF Dacha.

This material is available in roll form. As the name implies, they are convenient for insulating a dacha (attics and ceilings between floors). In addition, it is convenient to use for thermal insulation of a summer kitchen, barn or other building on the site.

ParametersHeatKNAUF Dacha

| Thermal conductivity, at 10 0С W/m*0С | 0,044 |

| Airborne noise insulation index, C111*, RW (W) | 45 |

| Flammability group | NG |

| Length, mm | 7380 |

| Width, mm | 1220 |

| Thickness, mm | 50 |

| Volume of material in packaging, m3 | 0,9 |

| Area of material in packaging, m2 | 18 |

| Quantity per package, pcs | 2 |

There was no video dedicated to the technical characteristics of this line of insulation, but there was a cool promotional video:

Insulation of the house

Today, more and more owners of private houses are thinking about the need to insulate their country house. This allows you to significantly reduce energy costs, make a private home as comfortable as possible, protecting it from dampness and mold.

Insulating a house with Knauf mineral wool

Mineral wool produced by Knauf is now increasingly preferred as insulation for house walls. Insulation with mineral wool is truly universal. This innovative product has a number of undoubted advantages.

These include the following characteristics that these insulation materials have:

- Excellent level of elasticity, which is 20% higher than previous indicators. Thanks to this, mineral wool from Knauf is not prone to cracking and cracking, which will make your home as warm and comfortable as possible.

- At the same time, Knauf mineral wool is a very rigid material that perfectly holds plaster on the walls of the house.

- The product is perfectly installed on a private house and holds the structure.

- The dust percentage of Knauf insulation is reduced by 15%, which makes working with this type of insulation in a private home much more comfortable.

- The moisture resistance of new generation mineral wool from Knauf is 25% higher than that of previous analogues. Thanks to this, this insulation perfectly resists dampness, protecting the country house from the appearance of mold and mildew.

- To create home insulation, the company uses exclusively plant-based components that do not contain phenol-formaldehyde resins. This guarantees the safety of using mineral wool for the environment and humans.

In view of these features, the use of Knauf mineral wool for insulating buildings is now increasingly preferable. This is an excellent material that allows you to efficiently insulate a building.

Insulation of the house outside and inside

There are several ways to insulate a country house with mineral wool. The insulation can be installed outside and inside the room. Insulating walls using any of the methods has its advantages and technological features.

When insulating a country house from the outside with mineral wool, you must follow the following insulation technology:

- the thickness of the house’s insulation must correspond to the type of material from which it is built;

- using several layers of mineral wool, it must be installed in such a way that the second layer completely covers the seams of the first, ensuring continuity of the coating;

- first of all, it is necessary to attach a base profile to the house, the width of which will be equal to the thickness of the installed Knauf mineral wool at a height of 40-50 mm from the ground;

- the mineral wool must be secured at the corners with a serrated bandage;

- reinforced mesh installed on the house can provide additional protection for mineral wool;

- It would be advisable to install plastic corners at the corners;

- The top surface of the mineral wool is protected by applying a layer of facade adhesive and attaching the facade covering, for example, by plastering.

Knauf mineral wool can also be used as internal insulation. This solution will somewhat reduce the area of the house, but installing insulation from the inside of the house is much simpler and cheaper.

Insulation of walls of different types of houses

The choice of a specific type of home insulation is largely determined by the design features of the country house, as well as the material from which it is made:

- For wooden buildings, mineral wool is the only possible way to insulate a private house, since wood is considered a very capricious material that requires a special approach. The tree is susceptible to shrinkage and seasonal expansion. Because of this, the thermal insulation layer may crack. It is also quite likely that the joints will expand. This leads to the formation of so-called cold bridges, leading to freezing of the walls. To prevent this, it is necessary to use mineral wool to insulate the walls during thermal insulation.

- Frame-type buildings also require the use of mineral wool. Laying insulation for such structures must be done between the guides, which are installed directly over the entire surface of the walls.

- To insulate structures made of brick and aerated concrete, you can use various types of thermal insulation materials, including mineral wool.

Selection rules

If you are purchasing Knauf insulation for the first time, it is recommended to seek the help of experienced consultants who will help you choose one option or another, as well as calculate its quantity.

The cost of insulation depends on the following:

- his type;

- number of slabs;

- their size;

- loads;

- equipment locations.

When choosing one or another insulation option, consider the following:

- thickness of the slabs - walls need structures that are thinner than those for the floor;

- for pitched roofs, choose products based on fiberglass or basalt;

- polystyrene foam with a water-repellent effect is best suited for the foundation.

When insulating, do not forget to provide waterproofing, vapor barrier and windproofing. To fix the insulation, be sure to use dowels or polyurethane foam.

Products of the Knauf brand are much more expensive compared to analogues, but the high price is due to the excellent quality of the products and their long service life. Accordingly, you will not have to spend additional money on unnecessary repairs during use.

Application

KNAUF INSULATION mineral wool is produced in the form of mats and is created on the basis of glass fiber material using ECOSE Technology. The mats are packaged in a roll format, which makes transporting the product easier.

Fiberglass mats

KNAUF Insulation insulation material is made in compliance with all accepted safety standards. It is soft and not prickly. Does not have a pungent odor. It is easier to work with during the cutting process than with other analogues.

Research work on the new material from KNAUF has proven its high heat-protective properties, and a sanitary and epidemiological analysis has stated the absence of phenol-formaldehyde resins in it.

The manufacturer's instructions recommend using mineral wool in structures with a horizontal position if there is no pressure on the material:

- for attic floors;

- for floors on joists;

- for interfloor or attic floors.

Sometimes insulation is used in pitched roofs, as well as in structures with a vertical position. Namely, when load-bearing external walls or partitions are created to separate rooms with excellent internal temperatures.

Insulation of pitched roofs

"TeploKnauf" is used in the construction of private houses.

The manufacturer has released several versions of this material:

- "Knauf Cottage" and "Cottage +". It is used both for internal insulation of houses and for pitched insulation.

- "Country house". Material intended for insulation work in outbuildings, summer kitchens, and cottages.

- "Home" and "Home +". It is used as a heat insulator for walls, roofs and ceilings.

Natural safe insulation

For facade

Knauf also has in its arsenal a group of facade materials, which are often used in cases where they insulate building facades and insulate loggias. This group is divided into two brands (034 A and 032 A), each of which has its own parameters. The choice of the best option is up to the buyer.

These façade materials meet the following properties:

elasticity of structure; increased degree of moisture protection; long service life; ease of use. Please note! Facade insulation does not create additional cutting chips, so the work of cutting it is less dirty.

Thermal plates of the named brands have the following technical characteristics:

- degree of thermal conductivity – 0.034 (034 A) and 0.032 W/mK (032 A);

- vapor permeability level – 0.5 mg/mchPa;

- degree of moisture absorption – 0.8 kg/sq.m. m (034 A) and 0.6 kg/sq. m (032 A);

- don't burn.

For roofing

Knauf materials are also often used for roof insulation. They are produced in the form of slabs and mats.

Thermo Roll pitched roofs grades 037 A and 034 A have the following technical characteristics:

- degree of thermal conductivity – 0.037 W/mK (034 A) and 0.034 W/mK (032 A);

- the degree of vapor permeability is equal to the value characteristic of facade materials;

- degree of moisture absorption – 0.8 kg/sq.m. m;

- do not burn;

- sound absorption coefficient of the product (thickness 50 and 100 mm) – 0.85 and 1.00, respectively;

For acoustic partition

Mineral wool-based material with a high level of sound absorption is produced in the form of mats and slabs and is used in the construction of buildings for various purposes. Its cost is quite expensive, but the costs are completely worth it.

The manufacturer offers several parameters:

- 50x610x7500 mm (roll);

- 50x610x1250 (in the form of slabs).

HeatKNAUF NORD

TeploKNAUF NORD mineral wool is a universal thermal insulation material used for insulating pitched roofs, walls of any structure, joist floors, interfloor, attic, and basement floors. The insulation can be used in difficult climates. KNAUF INSULATION technology is used for its production.

Application:

- in professional construction: thermal insulation for the construction of enclosing structures of low-rise and non-residential buildings;

- in private housing construction: insulation of walls, roofs, facades, floors for maximum energy saving;

- in difficult conditions, at extremely low temperatures: TeploKNAUF NORD insulation can be used in northern regions.

The material is made from Fine Fiber with increased elasticity - the slabs hold their shape better and tightly fill the enclosing structure. The number of fibers has been increased by 33%. Mono layer production technology involves the formation of one layer - the material better maintains its integrity even under load.

Advantages:

- 15% warmer. The thickness of the insulation layer can be reduced by increasing the volume of the premises. At the same time, heating costs will remain low;

- 40% stiffer. Hard and elastic material is easier to install. It holds its shape better, does not deform, and does not shrink. The thermal insulation layer can last more than 50 years;

- 20% cleaner. It generates less dust, making it more comfortable to work with slabs - even in the heat or when insulating complex structures;

- moisture resistance is 10% higher. It is easier to insulate the facade: work can be continued almost immediately after the rain. Lasts longer: absorbs less moisture, retains its original structure.

Thermal insulation TeploKNAUF NORD is produced using ECOSE technology without synthetic resins based on acrylic or phenol-formaldehyde, using organic raw materials. The insulation is hygienic, safe, and can be used for residential premises.

Characteristics HeatKNAUF NORD

| Indicator name | Unit measurements | Index |

| Thickness | mm | 50 |

| Width | mm | 610 |

| Length | mm | 1230 |

| Slabs in a pack | PC | 12 |

| Area per pack | m2 | 9 |

| Volume per pack | m3 | 0,45 |

| Packages on a pallet | PC | 24 |

| Coefficient of thermal conductivity | W/m•K | 0,035 |

| Flammability group | Not flammable |

Insulation of facades and walls

Insulation of facades and walls

The KNAUF Insulation company offers a high-tech solution for insulating walls and facades in private housing construction - “TeploKNAUF For ROOF AND WALLS”. Thermal insulation materials "TeploKNAUF" for external insulation of house walls are created specifically for the Russian climate.

For construction projects, KNAUF Insulation offers a wide range of specially developed products for thermal insulation of infrastructure, residential and other structures, taking into account strict regulatory requirements and specified product characteristics.

Environmentally friendly wall insulation

Any wall - wooden, brick or concrete - freezes. And this is the path to cold air, drafts in the legs, condensation, dampness and mold... This can be avoided if you use additional insulation with high-quality insulating materials. Wall insulation with TeploKNAUF materials prevents freezing and maintains a healthy microclimate in the house for many years.

Why TeploKNAUF insulation is the best for walls

TeploKNAUF mineral wool insulation has the following advantages:

- Environmentally friendly The insulation is absolutely safe for the environment and human health, as well as for people with respiratory diseases and allergy sufferers;

- Low thermal conductivity The material perfectly insulates the room, creating the effect of a “breathing thermos” with an optimal temperature / humidity ratio.

- Non-flammability TeploKNAUF wall insulation does not support combustion and is able to withstand open fire.

- Moveable and reusable Flexible and soft, the insulation is not afraid of repeated bending.

- High noise insulation indices One material – two benefits! All TeploKNAUF insulation products have good heat and sound insulation, which will allow you to make your home warm and quiet.

What material to choose for wall insulation?

KNAUF Insulation Facade TS 032 Aquastatik (slab)

KNAUF Insulation Facade TS 034 Aquastatik (slab)

KNAUF Insulation Facade TS 035 Aquastatik (slab)

HeatKNAUF NORD

HeatKNAUF For ROOF AND WALLS

What to choose: internal or external wall insulation?

Depending on the wall material, wall insulation is carried out from the inside or outside. What to choose in your case?

The preferred option is external thermal insulation of walls . Insulation of walls from the outside requires good adhesion of the base. However, if the old finish doesn't hold up well, just get rid of it.

Fill cracks in the base with cement mortar, mastic or acrylic-based filler. Prime the cleaned surface. Attach thermal insulation material according to the manufacturer's instructions. External wall insulation as a finishing layer involves the installation of a ventilated facade or plastering.

Insulation of walls from the inside should be given preference in cases where there is no access to the outer surface of the wall.

By performing internal thermal insulation of walls with TeploKNAUF materials, you don’t have to worry about the environmental safety of the room. All KNAUF Insulation products are manufactured using the unique ECOSE® technology and do not contain phenol-formaldehyde and acrylic resins. This technology involves the replacement of chemical components with natural materials, which allows the use of these materials in all types of buildings, including children's institutions.

Indoors, TeploKNAUF materials are also used for floor insulation or soundproofing of internal partitions. At the same time, both sound and heat insulation of the adjacent room is ensured, which is especially convenient when a common wall of the living room separates it from the pantry, bathroom and terrace.

However, it is not recommended to insulate walls from the inside in frame and wooden houses. This can disrupt the vapor barrier of the room, which will negatively affect the material of the house. In frame houses (with wooden or metal elements) it is necessary to use thermal insulation as part of a multi-layer wall “pie”.

Knauf Insulation products can be purchased in all regions of Russia and the CIS.

For purchasing questions, please contact the official representatives of our company in your region. You can find official dealers in the “Where to Buy” section.

Source

Types of Knauf insulation

So, as we have already said, Knauf mineral wool thermal insulation materials are divided into two subgroups or lines:

- Insulation;

- Teploknauf.

Each is intended for its own tasks and was developed specifically for their implementation.

The Insulation range is known for its exceptional quality. This is rather a professional, rather expensive, almost universal type of insulation. It is very convenient to lay it on a large scale when multiple areas need to be processed.

In addition, the Insulation line offers excellent performance and extreme durability. Mineral wool Insulation insulates a house for decades. Moreover, the manufacturer himself provides a minimum 40-year warranty.

Basalt wool Teploknauf in rolls

But this does not mean that in 40 years there will be nothing left of the slab. Most likely, it will serve you for quite a long time, provided, of course, that the Insulation wool has been used under normal conditions.

But the Teploknauf line is a simpler insulation. So to speak, a household option. With its help you can decorate a small cottage, country house, etc.

Knauf Insulation

The Insulation line, in turn, is divided into 4 more subtypes. In fact, they are exactly what are used in the work.

So, as part of insulation from the Insulation group, Knauf mineral wool is distinguished:

- Heat Roll;

- Heat Stove;

- Acoustic partition;

- Pitched roof.

Heat Roll are high quality mineral wool rolls. Since it is convenient to work with rolls only in certain situations, they are used mainly for finishing floors or attics.

Heat slabs are already mineral wool slabs. Plates are more versatile. They can be mounted in any convenient place. Unless you need to be careful with the roof.

The Acoustic sample or Acoustic partition, as is already clear from the name, is intended for arranging sound insulation. In fact, any mineral wool insulation in itself does a good job of dampening noise loads, but this type of thermal insulation was specially created to absorb all sounds.

The last option is intended for insulating roofs between the rafters. It is the lightest and airiest from the Insulation line. The slabs are very elastic, they can be deformed and compressed by almost 40%, which allows them to be safely laid in frames of any size.

Teploknauf

The Teploknauf line is divided into the following samples:

- Cottage, Cottage+;

- Home, Home+;

- Country house.

Wall insulation using frame technology with Knauf mineral wool

The Cottage and Cottage+ models are the most expensive and high quality. In fact, that’s why the word “cottage” is in their name. With their help, the walls, roofs, ceilings and floors of the house are insulated. Any cottage can be finished with this insulation quickly and easily.

The Dom and Dom+ samples are more focused on finishing pitched roofs and protecting light structures. For example, for insulating attic walls.

Well, the Dacha model is the cheapest of the insulation materials. Designed for use in cheap country houses where it makes sense to save on materials.

Review of the Knauf Insulation line (video)

Known types and features of insulation

Thermal insulation and various insulation materials from Knauf are presented in a large assortment. The most popular product has become slabs made from mineral wool and expanded polystyrene. Knauf mineral wool can be glass or basalt, and is available in the form of slabs, mats or rolls to improve operation and practical installation. Rolled material is excellent for installing horizontal surfaces, while the slabs are more elastic and weigh much less when compared with mats. Insulation materials are divided into two types depending on the installation method: glued to the base and for fixing under frames.

Materials can be used for insulation inside and outside, depending on their type and purpose. The Knauf line includes materials for ceilings, floors and walls. There are options for insulating facade thermal insulation, installing interfloor ceilings, roofs, roofs, basements and basements. Products are produced for ventilated and non-ventilated facades, options for hanging systems or plaster.

The company produces three lines of materials:

- HeatKnauf. This line was created primarily for private buildings and contains roll-type insulators suitable for walls, interior partitions and roofs, as well as ceilings. Teploknauf insulation is divided into three types: Dacha, Teplodom and Cottage.

- Insulation. A group of these products was created for finishing large building structures, for example, shopping centers, hotels, schools, hospitals or clubs. The Insulation line includes Thermo Roll insulation, as well as Thermo Plate, Acoustic, Knauf Pitched Roof series, Ecoroll and Knauf Ecos.

- Knauf Therm. This included materials for insulating ceilings, floors, walls, and facades. Thermo-plates are divided into several varieties, each of them has its own characteristics and purpose. The line consists of three types: Knauf Therm facade, Knauf Therm Floor, and Knauf Therm Roof.

Knauf Therm for heated floors

Roll series Teploknauf

Materials for industrial insulation

All brand insulation, regardless of type, has a minimum service life of 50 years and is distinguished by impeccable technical characteristics, convenience and reliability during operation.

Various types of cotton wool

Stone or basalt wool has become one of the most popular materials of the company. In the process of its production, basalt rocks of the mineral type are used, melting lava stones and adding to them binding components with additional chemical elements that bind the fibers. Finished fibers are solid rolls or slabs. Knauf mineral wool does not contain phenol resin, formaldehyde and other harmful substances, it is not toxic and not hazardous to health, during installation of mineral wool it does not emit dust and does not require respiratory protection.

The brand's basalt wool has impeccable characteristics: it can withstand temperature changes, does not change shape and is not susceptible to fire. The level of its thermal conductivity is 0.035-0.4 W/m, water absorption readings are 1-2% of the total volume. The density of a material always depends on its type. The company offers several varieties of mineral wool intended for walls, roofing and other elements.

Selecting the appropriate type of mineral or glass wool from Knauf must take into account construction needs and specific purposes. The cost will depend on the size, quantity and type of material.

Mineral slabs

Mineral wool from Knauf, the technical characteristics of which comply with European standards, is produced only in the form of slabs. This is a good choice for thermal insulation of country houses and private houses, therefore it is mainly chosen for construction work. The slabs have a minimal level of thermal conductivity, so they are able to create an ideal microclimate in each room, as well as reduce costs for heat consumption. They absorb sound and can be used for sound insulation.

Knauf insulation in the form of mineral plates is a non-flammable material with a good level of fire resistance. The slabs weigh little and do not create unnecessary load on the floor structures. They do not shrink and are able to retain their original shape even after the full expiration date of 50 years. The density of minislabs is ideal for insulation inside and outside. Their installation is not difficult even for beginners; the technology is as simple and understandable as possible. The material contains no toxic substances or dyes, it is safe and environmentally friendly.

TeploKnauf

Insulation of this type is made mainly for private houses; they are classified as roll type and are chosen for mounting ceilings, roofs, walls and partitions inside houses. Roll insulation from Knauf is divided into three types: “Dacha”, “Cottage” and “Teplodom”. The Dacha series materials have a sheet thickness of no more than 50 mm and are suitable for installation in seasonal homes. The Knauf Cottage option has a high level of thermal insulation, maximum protection from humidity and noise. Sheets of the Teplodom series have a thickness of 50 to 100 mm and extremely high thermal savings. They are released in standard and mini format.

Knauf Insulation

The Insulation line includes materials developed for the largest construction projects: shopping centers, clubs, schools, hotels and hospitals. This is the best choice for those who require the maximum amount of material for hundreds and thousands of square meters. The group of insulation materials of this type includes the categories “Acoustic”, Eco and thermo roll, Thermo plate, Pitched roof and Knauf ecos.

KNAUF Insulation Thermo Plate 037

Universal thermal insulation material. It is made in the form of slabs, in two versions, differing in thickness - 10 or 5 cm. Used for insulating any part of the house:

- for interfloor ceilings;

- pitched roof;

- walls;

- internal partitions (allows you to isolate rooms with different temperatures;

- floors, including above the basement or ground.

The material is characterized by high sound absorption and does an excellent job of sound insulation. The slabs are installed between the load-bearing joists.

Main characteristics in the table:

In the production of these boards, innovative technology for processing raw materials “Knauf Ecose” is used, thanks to which working with Knauf mineral wool becomes very comfortable - the material is soft to the touch, does not crumble, is easy to cut, and does not smell.

Don't miss: Single-pipe heating system for a private house: diagrams, options

Brief information about the Knauf company

A small family business, Knauf, appeared in Germany in 1932 and began its activities to conquer the European market. Today the company owns more than a hundred enterprises located in various countries around the world, including Europe, North America, Iran and China.

Knauf company logo

The main types of products produced at the company's facilities:

- Various types of insulation, including Teploknauf insulation;

- Plasterboard sheets;

- Gypsum boards;

- Metal profiles;

- Knauf pro tape;

- Dry mixes;

- Polystyrene;

- Construction equipment.

German thoroughness and quality are the main features that characterize all production under the Knauf brand.

Acoustic Partition KNAUF Insulation

In the production of this type of insulation, a special technology is used to maximize sound insulation properties. The effect is achieved due to specially shaped fibers in the slabs - the basalt threads here are very thin and long.

This is the optimal choice for premises where good sound insulation is especially important - cinemas, clubs, production workshops, hotels, kindergartens or hospitals. However, this elastic elastic insulation is perfect for both residential buildings and apartments, if it is necessary not only to insulate the room, but also to protect it from intrusive noise from the outside. In any case, you can count on excellent results from such sound insulation.

Knauf Acoustic insulation is produced in two main forms - slabs and mats. The standard characteristics include the following:

This revolutionary development will especially appeal to those who value peace and quiet in their home. The release form is so well calculated that during cutting and installation there is a minimum of scraps and waste.

Advantages of Knauf Acoustic plates

The main advantage of the material is its ability to absorb various types of sounds and noise. The soft base captures and absorbs sounds as effectively as possible. Thin fibers provide good air and steam permeability, which makes it possible to use insulation in rooms with high humidity. The flexible structure helps insulate and isolate sewer sounds. The material can be tightly wrapped around the pipe, thereby reducing the noise of the sewer drain. You can use cotton wool both for apartments and private houses. Quite often, Knauf ceiling soundproofing is used as insulation for roofs, attics and attics.

Speaking about the advantages, one cannot fail to note the environmental friendliness of the material. The product is made from natural raw materials, so it does not contain any harmful elements or resins. Knauf soundproofing walls are odorless, so they are often used in soundproofing residential buildings and public spaces.

The material is easy and convenient to work with. Considering the light weight of the material, it does not require special equipment for loading and transportation. One package contains 16 slabs measuring 1250*610*50 mm. This number of slabs is enough to cover an area of twelve square meters. To work with the slabs, you do not need special equipment or tools; the installation technology is similar to those used when installing basalt or mineral wool.

Knauf ceiling soundproofing is carried out using a structure made of aluminum profiles or wooden beams. Due to the parameters of the slabs, the frame base is built according to generally accepted dimensions with a step width of 60 centimeters. The slabs have the same width, which makes it possible to use sound insulation with virtually no waste.

Distinctive features

The main distinguishing feature of Knauf acoustic materials is the high quality of the products. The production of mats is based on German technology using exclusively high-quality equipment. Taken together, the result is an ideal soundproofing material that has all the necessary qualities and features.

If we compare KNAUF mats, it is important to note that the product is characterized by a relatively low cost, which is especially pleasant for major renovations. Of course, when comparing wool and gypsum-based slabs, the differences will be significant. Firstly, the composition of the material differs. Secondly, a frame is not required for its installation. In addition, the panels can be used as a leveling surface. The thickness of the sound insulation does not exceed five centimeters, and this is ideal for working with small rooms.

Pitched roofing KNAUF Insulation

For maximum convenience and efficiency in thermal insulation of roofs, Knauf has released a line of special-purpose insulation materials - Pitched Roof.

Products in this category are produced in the form of mats and slabs. They are used for thermal insulation of pitched roofs on a wooden base, but are also suitable for floors on joists in the attic. There are no restrictions on the type and purpose of insulated buildings for these materials. Special impregnation AQUASTATIK provides the insulation of this series with increased water resistance. Like all Knauf basalt fiber products, these products are not fire hazardous.

There are 4 types of insulation in the line:

Knauf roofing insulation will not only help keep your house warm in winter, but will also protect you from the summer heat, and also provide excellent sound insulation.

Advantages

The choice of building and finishing materials often becomes a serious problem. The consumer is not always aware of the subtleties of production; he has to be guided by the appearance of the insulation, reviews on the Internet and an attractive price.

However, the quality of the insulation is indicated by completely different characteristics:

- Environmentally friendly. The entire line of Teploknauf insulation is made from natural material - basalt fibers (basalt insulation). This material gives the insulation a gray tint and is absolutely safe for human health.

- High degree of sound insulation and sound insulation.

- Zero fire hazard (non-flammable insulation).

- Thanks to the increased density of the material, a high level of resistance to aggressive influences and dampness is ensured.

- Extended service life.

- Easy to install and handle.

Any insulation has a number of features that should be taken into account. When installing mineral wool, it is mandatory to use protective equipment against small particles of glass wool - gloves, goggles and a respirator.

In addition, layers of insulation are covered with protective materials. Waterproofing is necessary for any type of insulation. To protect the material from moisture, the Knauf company uses unique aquastatic technology, which prevents condensation from entering the slab.

Facade KNAUF Insulation

This modification of thermal insulation materials was developed specifically for insulating external walls that have several layers (for example, brick cladding).

Do-it-yourself water heated floor installation

Thanks to Aquastatik impregnation, Knauf Facade slabs practically do not absorb moisture. In addition, the material is characterized by excellent strength and elasticity, because it is made from special thin and long fibers (length 150 mm). It is manufactured in the form of slabs of two main types, slightly different in characteristics: Facade ThermoPlate 034A and ThermoPlate 032A. The technical parameters are shown in the table below:

This material is perfect for thermal insulation of facades of any buildings - schools and hospitals, offices and residential buildings, industrial and agricultural premises. The insulation is placed in the form of a layer between two levels of the wall. Knauf facade slabs are made of non-flammable material, which makes their use not only convenient, but also fireproof.

Criterias of choice

When selecting thermal insulation for the ceiling, the characteristics of the protective material, installation features, floor material, and the volume of material investments are taken into account.

The following criteria for thermal insulation products will help you choose insulation:

- flammability;

- weight and size;

- durability;

- thermal conductivity;

- environmental friendliness;

- vapor permeability.

The main complaint made against various types of thermal insulation is their flammability. Sawdust, straw and polystyrene are highly flammable. Vermiculite, expanded clay, foam glass, and earth are not affected by fire. Other types of insulation do not form flames, but they melt at high temperatures. Fire safety requirements must always be observed, especially when laying flammable materials.

The weight and size parameters are important when installing and transporting building materials. Weight is taken into account if one or two people are involved in laying the insulation. Thickness is important when carrying out interior work.

The durability of thermal insulation depends on the strength of the source material, operating conditions and the correct placement of layers during installation. High-quality thermal insulation should not change its properties under temperature changes and mechanical load.

Thermal conductivity is the main indicator of a material, which characterizes the rate of heat transfer to the environment. The lowest coefficient in this sense is possessed by: penoplex, polyurethane, isolon, glass wool. Expanded clay transmits heat best.

Environmentally friendly include all types of bulk insulation and reed mats.

The vapor permeability of a material is important for wooden structures, since wood is exposed to moisture and is prone to condensation. Mineral wools have the highest level of vapor permeability. Artificial insulation has water-repellent properties, is moisture resistant and does not allow steam to pass through easily.

There are two types of floors in the house - wood and concrete, based on the properties of these structures, and choose the type of insulation. For a wooden house, it is better to give preference to thermal protection made from natural raw materials. Eco-friendly materials have good vapor permeability and will allow wooden floors to be ventilated. Synthetic types are also suitable for concrete.

To insulate the attic space of the roof, you can choose any insulation - bulk, roll, foam or panel. On top of rooms, the thickness of the insulating layer should be less than for external work. Roll and tile materials are usually used under the ceiling.

Often the selection criterion is the budget that will be spent on repairs. Cheap insulation can be selected depending on the type of floors and operating conditions of the room. The availability of a certain type of thermal insulation also depends on the cost of all work. Transportation of large and heavy material, rental of professional equipment for applying penoizol are also included in the total costs.

Knauf Ecoroll

This brand of roll insulation meets all the characteristics mentioned above - high levels of heat and sound insulation, 3D elasticity technology, environmental friendliness, fire resistance and protection from rodents. The mineral fiber in the product is highly vapor permeable, which allows the house to “breathe” and maintain a comfortable indoor microclimate.

Mineral wool Knauf Ecoroll is recommended primarily for thermal insulation of horizontal structures.

Manufactured in the form of large-volume rolls, it is one of the most budget options in the KNAUF product line. The size of a regular roll is 8.2 m x 1.22 m. The mineral wool in the roll is compressed in such a way that when unpacked it increases in volume almost 6 times. Soft and easy to use, this wool is used in structures that are not subject to load - it is used to insulate and soundproof:

- frame houses;

- pitched roofs;

- attics;

- ceilings between floors;

- interior partitions;

- floors on joists.

This affordable material is almost universal when insulating a residential building. Its density is slightly lower than that of other Knauf products - 10.5 kg/m3. The large area of insulation in a roll allows it to be laid with a minimum number of joints, which significantly reduces heat loss.

The manufacturer is constantly expanding its product range, thanks to which EcoRoll is now available to customers in the form of slabs.

Knauf basalt insulation is a huge selection of heat-insulating materials of various shapes, sizes, densities and other characteristics. This variety makes it possible to purchase the right product for any type of work. What they have in common is excellent quality and durability, as well as exceptional safety of all products of this brand.

The priorities of the Knauf company are constant improvement of production technologies and strict quality control. This allows the German manufacturer to lead the global building materials market for many years.

Knauf Insulation - insulation for professionals

If the TeploKnauf line of insulation products was developed for self-insulation of a house, and working with them did not require any special professional skills, abilities, knowledge, or tools, then the professional line of Knauf Insulation insulation products are professional-quality materials for multi-story construction and are aimed at industrial and social construction.

A feature of the line is the division of insulation according to purpose:

- For façade insulation.

- For roof insulation.

- For soundproofing.

The scope of application is determined by the specific technical characteristics and installation features. The KNAUF Insulation size range is wider: 50 mm, 70 mm and 100 mm in thickness.

Do-it-yourself insulation of the frame.

Facade KNAUF Insulation

The material was developed for insulating external walls made of any material and built using any technology. Knauf Insulation insulation is perfect for insulating buildings made of brick, blocks, concrete slabs, and houses built using frame technology.

Today, knauf insulation insulation for facade systems is produced in two slightly different variations: Thermoplate 034A and Thermoplate 032A. They differ primarily in density, and as a result, in the quantity and volume in the package.

Insulation for walls Knauf facade is mounted between two layers of the wall - internal and external; it is often used to create ventilated facades, as well as when sheathing a house with siding systems. Special impregnation with water-repellent compounds ensures that the insulation does not lose its properties upon contact with atmospheric moisture.

KNAUF Facade allows you to reduce the cost of heating buildings by 2 or more times.

On a note.

The Knauf Insulation façade is optimally suited for industrial construction, as well as for insulating the walls of social infrastructure facilities. It is often used as the main insulation for agricultural buildings where animals are planned to be kept year-round.

Knauf Ecoroll

Special mention should be made about the material for horizontal surfaces. Knauf Ecoroll insulation is designed specifically for insulation and sound insulation of floors and ceilings on joists. A special feature of the insulation is its high vapor permeability, which ensures proper steam and air exchange in the room and guarantees not only comfort for residents, but also protection from moisture and mold.

KNAUF ECOROLL is very popular when constructing houses using frame technology.

Pitched roofing KNAUF Insulation

A special development by KNAUF will allow you to easily insulate a pitched roof. Features of the material are a convenient form of release, which allows you to quickly install insulation on inclined surfaces, as well as high-quality impregnation with Aquastatic water-repellent compounds.

Insulating the roof with KNAUF Insulation pitched roofing material will not only protect the house from freezing in winter, but will also provide a comfortable indoor temperature in the summer heat, and will also soundproof the rooms on the roof side.

Knauf for roof insulation.

KNAUF Insulation pitched roofing is a solution for those buildings where the top floor is an attic and iron or metal tiles were chosen as the roofing material. The material will absorb unwanted sounds that inevitably occur during rain.

In addition to Knauf roofing systems, roofing insulation is popular for insulating floors on joists on the first floors and in attics.

KNAUF Insulation pitched roofing is available in two thicknesses of 100 and 50 mm and two types of slab and roll, which allows you to select the material so that a minimum amount of scraps remains during installation.

Installation features

Preparing the frame for external wall insulation

When installing Knauf Cottage brand mineral wool, you must follow the manufacturer’s recommendations and basic rules so that the result is as ideal as possible. The installation process consists of several stages and includes installation of the frame, the insulation itself, and the application of a vapor barrier film. You can handle this process yourself if you have skills in the field of construction and finishing work, or you can entrust the installation to professionals.

Frame

A primary wooden frame is necessary for direct installation of insulation on the walls. Without it, the material will not hold up. Before installation, the walls are cleaned of unnecessary elements and wooden blocks are prepared, which are treated with a fire-resistant compound. They are fixed horizontally and vertically to the walls from one corner to the other; in the presence of unevenness, special substrates are made from various materials.

The beams are secured using 75 mm self-tapping screws, each fastening is installed at a distance of at least 40 cm from each other. After installing the first beam, you need to measure 58 cm from it, since the width of the slab is 61 cm, then fix the second and subsequent beams while maintaining this distance. The windows are framed with bars horizontally and vertically, taking into account the plane of the wall.

If necessary, you can use additional substrates to level the surface of the walls and secure all the beams with the slabs as securely as possible.

Installation of insulation

Installation of insulation

The slabs are installed starting from the corner, they are slightly compressed and placed between the beams, then fixed to the wall using special mushrooms. For one slab you will need at least 3-5 mushrooms, taking into account the material in one package, each of them is mounted in a through hole with a diameter of at least 6 mm, made with a hammer drill or drill. The insulation can be cut to fit the spacers using a paint knife. After filling all the cells between the bars, they proceed to installing the film.

Installation of vapor barrier film

Vapor barrier of attic roof

The film is necessary to prevent the formation of condensation inside the insulation; if it is present, the steam particles simply come out to meet the cold air. It must be installed with the smooth side up, taking into account the instructions, each strip is placed from bottom to top, taking into account an overlap of 10 cm or vertically from the corner. For the most reliable fastening, the film is sewn to the wood blocks using a construction stapler. The seams must also be taped with double-sided tape to prevent them from coming apart. After the walls are covered, you can begin installing the siding.

Siding

For siding, bars measuring 25x50 or 25x100 mm, special screws with a length of 35 to 55 mm and a screwdriver are used. The frame boards are impregnated with a bioprotective solution and cut to the required length, which must correspond to the length of the boards for the first frame. Next, you will need to form the corners and screw them to the horizontal bars on the first frame vertically, the next boards are attached at a distance of at least 25 cm from each other. Following these rules helps make the structure more durable in addition to the standard insulation procedure.

It is important to always follow the manufacturer's recommendations and not combine materials that are incompatible with each other. In this case, the insulation copes well with its direct and additional functions.

Sources

- https://kvartirnyj-remont.com/uteplitel-knauf.html

- https://ProUteplenie.com/materialy/uteplitel-knauf-raznovidnosti-materiala-svoystva-i-primenenie

- https://srbu.ru/stroitelnye-materialy/94-utepliteli-knauf-tekhnicheskie-kharakteristiki.html

- https://stroyday.ru/stroitelstvo-doma/yteplenie-doma/uteplitel-knauf-texnicheskie-xarakteristiki.html

- https://planken.guru/otdelka-i-montazh-fasadov/utepliteli/uteplitel-marki-knauf-i-ego-harakteristiki.html

- https://www.vestmet.ru/teploizoljacija/knauf/

- https://uteplimvse.ru/vidy/vata/knauf.html

[collapse]

Knauf soundproofing materials: main characteristics

The material for soundproofing walls from KNAUF is fiberglass with the best technical characteristics, which is a combination of unique developments and advanced technologies. The fibrous structure of the wall material provides excellent sound insulation properties, so this material is actively used as an intermediate layer in interior structures. In addition, working with such material is so easy that you can even soundproof a room using detailed instructions yourself, without the help of a specialist.

Holes of a certain diameter, which are located over the entire surface of the partition, provide the required percentage of perforation. With the help of these holes, the sound wave is damped. Good sound insulation of walls is achieved by reducing intense sound reflection from perforated surfaces. Perforated sheets have different patterns and hole diameters. In addition, they are available in different fabric colors. On the back side the acoustic material has a non-woven fabric.

The use of materials for soundproofing walls of this brand allows you to reduce the noise level to 57 dB. By installing such material into the structure, you automatically minimize almost all household noise and create comfortable living conditions.

It is important to note that the material used to soundproof the walls is not flammable. It is produced using modern ECOSE technology, which does not involve the use of phenol-formaldehyde resins, so the finished materials are absolutely safe for residential premises and are even recommended in kindergartens, schools, playrooms, bedrooms, and other children's premises

There are two main products of this brand for soundproofing rooms:

- The new AcoustiKNAUF, which is ideal for homeowners and allows them to significantly reduce major household noise. Such wall materials have high elasticity, restoreability, as well as rigidity, and a reduced level of dust. These properties allow AcoustiKNAUF to fill the structure as much as possible and create conditions for comfortable life and work.

- Insulation Acoustic Partition, which is intended for professionals. With its help, professional sound insulation of all residential types of buildings is carried out, since this partition has high sound absorption rates, increased elasticity, and also protects the room from noise.

The use of large perforated plasterboard sheets allows the creation of continuous ceiling surfaces that are easy to putty. Perforation can be either round or square.

Related Posts

- How to independently select and apply profile 27 60

- Isover thermal insulation overview

- TechnoNIKOL

- Choosing non-flammable insulation for walls and ceilings: tips and tricks

- Baswool insulation: characteristics and scope of application

- Foil insulation: types, properties and possibilities of use

- Insulation of a veranda in a wooden house

- Izovol

- Insulating the attic with foam plastic

- Ecover insulation: pros and cons

- Insulating the attic from the inside if the roof is already covered: step-by-step instructions

- Insulation of a flat roof

- Types of roll insulation and the distinctive features of each of them. roll insulation for walls: choosing the best thermal insulation special thermal insulation coating

- How to properly insulate a garage outside and inside with your own hands step by step

- The best stone wool insulation - a review of manufacturers and brands

- Insulation of facades. insulation for exterior walls of a house

- Types of insulation, their classification, properties and application

- We insulate the wall of the apartment from the inside with our own hands

- Properties and types of dowel mushrooms for fastening insulation

- How to cut gvl: how to cut sheets at home

- Sprayed insulation in polynor cylinders: advantages and principle of operation, thermal insulation inside and outside buildings

- "technoplex" 50 mm: characteristics, reviews

- Do-it-yourself insulation of walls with polystyrene foam - detailed instructions

- Aluminum foil for bath insulation

- Mineral wool, its characteristics and insulation composition

Read with this

- How to independently select and apply profile 27 60

- Isover thermal insulation overview

- TechnoNIKOL

- Choosing non-flammable insulation for walls and ceilings: tips and tricks

- Baswool insulation: characteristics and scope of application

- Foil insulation: types, properties and possibilities of use

- Insulation of a veranda in a wooden house

- Izovol

- Insulating the attic with foam plastic

- Ecover insulation: pros and cons

New development

Monolithic materials are used for thermal protection of houses, cottages, walls, facades, roofs, floors, foundations.

The newly developed Knauf Therm Floor is a durable material for insulating plinths, foundations, and blind areas with a load of up to 12 tons per m2. Flor foam has moisture absorption of up to 0.8% of the volume of insulation. Used in the installation of “warm floor” systems.

If you need an effective, convenient, innovative material to protect your home from heat loss and noise penetration, choose Knauf products. It meets all the stated characteristics and will help you forget about the cold and noise in the house for a long time.

What is Knauf Cottage

The insulation is produced in the form of compact slabs

Knauf Cottage insulation belongs to the category of non-flammable elastic insulation, has optimal water-repellent qualities and is recommended as insulation for walls and pitched roofs. The material is produced in the form of compact slabs with a convenient density and thickness of 50 or 100 mm, which makes it possible to select it taking into account the size of the structures in a particular room.

Installation using slabs from the Knauf Cottage series does not cause difficulties even if you have no experience. The shape of the slabs allows them to be installed over several approaches, and insulation of walls or roofs in a single layer without the formation of cracks and joints. The material is easily cut and adjusted to the required dimensions, which ultimately saves time spent on installation. In addition to thermal insulation, the slabs have ideal sound-absorbing properties and are a universal building material.

Technical characteristics: “Teploknauf Dom” and “Dom Plus”

Taking a closer look at the “Teploknauf House”, you can understand that its length, width and thickness are 1230 x 610 x 50 mm, respectively. One package contains 0.6 m3 of material. As for the thermal insulation area, it is limited to 12 m2 in one package. There are 16 canvases in one package.

This material is also non-flammable, like Dom Plus. The Teploknauf Dom Plus insulation has the following parameters: 1230 x 610 x 100 mm. The volume of material remains the same, but the area decreases and becomes equal to 6 m2. There are 8 canvases in one package.

Fibrous materials

- Basalt wool is distinguished by a fairly low coefficient of thermal conductivity of up to 0.05 W/m2 K. It shows the amount of energy that passes through a layer of insulation with an area of 1 square meter with a temperature difference of 1 Kelvin (equal to 1 degree Celsius). A reliable thermal barrier is provided by still air located between the randomly located fibers of the slab or roll.

- Knauf mineral wools are non-flammable materials, do not spread combustion over their surface, and do not emit substances harmful to breathing when heated. 3. Stone wool has high biological and chemical resistance. Does not react with active chemicals, is not used as food by rodents and insects, and does not spread fungus and mold in its volume. Does not deteriorate when exposed to sunlight.

- Knauf mineral wool is a material with a high degree of vapor permeability, which allows it to be used with so-called “breathable” materials. These include wood, foam and aerated concrete, and slag blocks. Due to their internal structure, they absorb moisture when there is an excess of it in the air and release it when there is a deficiency. On the one hand, this is a good quality that allows you to maintain indoor humidity at a constant level. On the other hand, the negative side is that there is a danger of the development of microorganisms on the surface under the insulation.

- Knauf mineral wool confirms its environmental safety with appropriate certificates. It contains no substances harmful to human health. During operation, Knauf mineral wool does not emit harmful substances and fibers into the atmosphere.

- Dense slabs are an excellent sound insulator, reducing noise levels by 45 dB.

- A distinctive characteristic of Knauf insulation is its long service life. If the manufacturer sets this period at 50 years, then the fact is much longer.

Monolithic insulation

- The thermal plate is made from polystyrene foam. Thanks to the extrusion process, it acquires the property of thermal insulation. The numerical indicator of specific thermal conductivity is one of the lowest among insulation materials and is at the level of 0.04 W/m2 K.

- Knauf Therm expanded polystyrene can operate for more than 50 years, subject to operating conditions.

- The thermal plate is destroyed when exposed to direct sunlight. It has extremely low chemical resistance to acids, solvents, and petroleum products. Therefore, the insulating outer layer on the walls must be protected with plaster or siding.

- She has complete biological passivity. Does not spread fungus, mold, bacteria on its surface. Not used as food by rodents and insects. Therefore, it is better to insulate the roof from the inside using polystyrene foam materials.

- Thermal board has a high density, which makes it an indispensable sound insulator for building envelopes.

- Its fire danger is quite high. When exposed to open fire, the hot plate ignites, maintains combustion, and releases substances harmful to breathing into the atmosphere.

- When used under the required conditions, the thermal stove is absolutely environmentally safe. It does not smell, does not emit harmful substances, and does not break down.

For professional use

The use of Knauf Insulation insulation gives excellent thermal insulation results regardless of who installs it: a professional builder or the owner of the house.

The line of manufactured products allows you to select the material needed for a specific case.

Due to its environmental friendliness, Knauf Insulation insulation is recommended for use in residential buildings, preschools, schools, medical and medical institutions.

Using mineral wool as thermal insulation

Insulation with Knauf mineral wool is carried out by home craftsmen themselves. This material can be used for thermal insulation of the facade. The work can be based on wet-type technology, which combines facade insulation and decorative plaster. This technique is actively used in places with cold climates.

The wall materials can be:

- concrete;

- wood;

- brick.

Different types of compounds are often used as plaster. Mineral wool is placed under a decorative wet layer, which makes the structure stronger and helps save money on heating. Plaster can be:

- mineral based;

- silicate;

- acrylic;

- silicone.

After drying, the layer can be painted in any color using facade paint.

Technical characteristics: "Teploknauf" for roofing

This material is a professional insulation material that comes in the form of rolls. The thickness is 150 mm. Thermal insulation is characterized by an enhanced water-repellent effect. It is specially designed for pitched roofs.

“Teploknauf” roof insulation has an elastic structure that allows it to fill the space under the roof. This material is comfortable to use and safe, as it does not contain acrylic resins or phenol-formaldehyde. Made using water-repellent impregnation.