general description

It is worth noting that the underlay under the laminate must be laid on the floor during installation. There are many varieties of this material on sale. It differs in a lot of parameters. Therefore, the choice must be made depending on the characteristics of the base, as well as the laminate itself.

The floor covering can vary significantly in the way the lamellas are connected, thickness, and other important characteristics. If the substrate is chosen incorrectly, loosening in the lock joints is possible. The laminate will creak and eventually become deformed. Therefore, you need to consider what qualities the optimal type of substrate should have.

There are materials on sale that differ in material, cost and performance characteristics. One of the best options would be a backing with a layer of foil. This option will become especially relevant if the owners install a heated floor system. However, even if there are other heaters in the room, the foil will reflect the rays of the infrared spectrum back into the room.

Considering the types and prices of foil backing for laminate, one can note a significant difference. The fact is that the base under the foil layer can be very different. It is made from several types of materials. In this case, the thickness of such a layer can be different. However, almost all types of substrates have their positive and negative sides.

The best natural substrates for laminate flooring

A high-quality laminate underlay guarantees a warm, comfortable floor without unnecessary noise effects. Types, prices, advantages and disadvantages of the most popular manufacturers, the best substrates for laminate according to users - all this is collected in this TOP:

Steico Underfloor

This 4 mm thick pine wood fiber laminate underlay provides excellent sound insulation for the floor, which eliminates the squeaking noise caused by walking on the flooring. The substrate has a slight smell of pine needles, which disappears after the first airing of the room. The manufacturer recommends laying the material with the rough side up and placing the sheets so that the joints of the substrate do not coincide with the joints of the laminate boards. It is very easy to lay on the base of the floor and, if necessary, can be trimmed with a regular stationery knife.

| Characteristics | Meaning |

| Size | 790x590 mm |

| Thickness | 4 mm |

| Material | Pine fiber |

| Manufacturer country | Poland |

Pros:

- easy to install;

- low price;

- natural material;

- good sound insulation;

- no odors.

Minuses:

- fragile material;

- Possible dust formation due to improper installation.

Review: “The underlay retains the properties of a warm floor for a long time and also helps to level out remaining unevenness in the base, an excellent and inexpensive option.”

Corksribas SIlent Cork

This is an amazing and all-natural cork underlay for laminate flooring, made from the bark of the cork tree in Portugal. It is made up of millions of cells that function as small insulators and shock absorbers. After compression of any duration, it always restores its shape. Thanks to it, the detrimental effect of base unevenness on the finishing floor covering is compensated, and it is also impervious to moisture and steam. The cork backing does not collect dust, so it is safe for allergy sufferers.

| Characteristics | Meaning |

| Size | 1000x10000 mm |

| Thickness | 3 mm |

| Material | Cork tree |

| Manufacturer country | Portugal |

Pros:

- environmental material;

- excellent heat and sound insulation characteristics;

- antibacterial protection;

- elasticity;

- hypoallergenic;

- quick and easy installation.

Minuses:

- drying out on a “warm floor” is possible;

- high price.

Review: “We made the bed in the bedroom and are very pleased that we chose it, the steps are inaudible at all, the floor is warm and seems as if it is soft. Great choice".

Cezar Basic Wood Nature

The natural sheet underlay for the floating floor is made from pressed pine fiber. It perfectly levels the base of the surface, protects the locks of laminate slabs from breakage, prevents joints from coming apart and eliminates the floor from squeaks and knocks when walking. The material is completely natural, therefore it does not emit any chemical compounds and is absolutely safe for the human body and pets. Also, this type of underlay is well compatible with film-type heated floors and helps retain heat much longer.

| Characteristics | Meaning |

| Size | 590x790 mm |

| Thickness | 4 mm |

| Material | Pine fiber |

| Manufacturer country | Poland |

Pros:

- smooths out minor unevenness;

- convenient quantity per package;

- easy to install;

- low price;

- organic material.

Minuses:

- cutting creates a lot of dust;

- When working without gloves, it is easy to damage the skin.

Review: “We bought it to insulate the floor of a small room because of the convenient quantity in the package. It fit perfectly and leveled the floor almost to perfection. Good value for money.”

Amorim cork sheets

This substrate provides easy installation and high resistance to deformation, including point loads. The use of crushed bark agglomerate and natural glue in production is a guarantee of safety and environmental friendliness. Such material can be laid in rooms where people suffering from various types of allergies live, in children's rooms, kitchens and bedrooms. During operation, the release of harmful substances is completely eliminated. This substrate also has a huge service life - more than 30 years.

| Characteristics | Meaning |

| Size | 940x640 mm |

| Thickness | 4 mm |

| Material | Cork tree |

| Manufacturer country | Portugal |

Pros:

- antiseptic properties;

- sound and heat insulation;

- resistance to deformation;

- high service life;

- easy styling;

- non-flammable material.

Minuses:

- high price;

- incompatible with “film heated floors”.

Feedback: “We laid the underlay ourselves without any problems, it is easy to trim and levels the floor well. It absorbs sound perfectly and, I think, will definitely last until the next repair without any complaints. The product is worth the money."

Isoplaat UNDERLAY

This coniferous underlay for laminate, in addition to being environmentally friendly, has excellent soundproofing properties and well levels the rough base for the laminate. The slabs will provide acoustic comfort in the living space. Without any problems they are laid on the base of the floor using glue, a construction stapler or nails and then serve as an excellent insulation for an apartment or house. Thanks to natural ingredients and production without the use of any chemicals, it does not cause allergic reactions and does not emit odors.

| Characteristics | Meaning |

| Size | 850x590 mm |

| Thickness | 7 mm |

| Material | Pine fiber |

| Manufacturer country | Estonia |

Pros:

- low price;

- convenient packaging;

- excellent sound insulation;

- no odors;

- easy installation.

Minuses:

- large thickness;

- fragile.

Review: “The neighbors below are happy that we have such excellent sound insulation. Yes, the substrate is thicker than usual, but this minus is covered by almost zero sound conductivity, now I recommend it to everyone I know.”

Features of the material

The foil backing for laminate has a number of distinctive features. It is made primarily from polyethylene foam. There are varieties on sale that are based on foam rubber or other materials. Each manufacturer develops special formulas to create their products.

The top layer is foil or metal film. It may or may not have markings. This type of material reflects heat well, returning it back into the room. As a result, owners can save about 30% of indoor heating resources in winter. This is due to its high thermal insulation qualities.

Thickness

At the same time, the material has a very small thickness. Thus, professional builders recommend purchasing a foil backing from 2 mm to 5 mm thick for the laminate. Although materials up to 10 mm thick are available for sale. They are not suitable for laying under laminate. Their scope of application is completely different.

Also, a 1 mm thick substrate is not suitable for installation under laminate. This will not be enough to retain heat in the room and not release it through the ceilings. It is worth considering that the thicker the substrate, the more expensive it is. However, in this case, its thermal insulation and other performance characteristics also increase.

When choosing a foil backing, it is worth considering that this material has certain advantages and disadvantages.

Positive and negative sides

The presented material has many positive qualities. The disadvantage of the foil backing is the price. She's quite tall. However, it is worth noting that some types of such substrates can replace, for example, a sheet of polystyrene foam 3 cm thick in terms of thermal conductivity. Therefore, the high price is explained by the high performance qualities of foil insulation.

Even the simplest polyethylene varieties can prevent heat loss through the floor by 30 to 97%. If an electric heated floor system is installed under the laminate, the substrate will additionally protect the infrared film from moisture from below reaching it and its contacts.

In addition, the foil backing, like other types of materials for laying under laminate, levels the floor. If the differences in height and unevenness on the surface are relatively small, they may not need to be sealed with mortar. Simply lay sheets of foil backing of sufficient thickness on a clean base.

In addition, the substrate also has sound insulation properties. Steps on the laminate surface will be much quieter. This is especially good for apartments and houses with small children. The child constantly runs around the house. To prevent his sonorous steps from disturbing parents’ rest, you can simply put a sufficient layer of underlay under the laminate. In this case, the surface of the floor covering will be warmer. Even a barefoot baby will feel comfortable walking on the laminate.

Type and property

Adding foil to an existing variety of substrates changes their functional properties and provides a guarantee for a longer period of use. The most important difference is that foil has the ability to preserve heat rays in an apartment or house up to 40%, and with a foil stopper - up to almost 100%.

The backing for linoleum can be made from the following materials:

- polyethylene;

- polystyrene;

- traffic jams.

Polyethylene, the material from which the backing is made, seems to be one of the most common in the entire public market. In order to improve its functional characteristics, production began to make a model in which one side is sealed with foil. In stores and markets, foil polyethylene is produced in the following brands: Penofol, Isolon and, in rare cases, Ecofol. Foaming of this material is carried out in two ways: chemical and physical. It all depends on the quality of production and pricing policy. In order to obtain foamed polyethylene using a chemical method, flame retardants must be added to it. As a result of chemical exposure, pores appear in polyethylene, in which there is gas isolated far from each other. This type of polyethylene copes well with the noise of neighboring apartments; it has the property of vapor permeability and thermal insulation. There is a very big disadvantage - very poor strength, so the foil quickly falls under the linoleum. The function of polyethylene together with foil adds to the service life of the material, plus it adds waterproofing properties, qualitatively increases the efficiency and strength of thermal protection with the help of its reflection characteristic of foil. Can withstand temperatures from 30 degrees cold to 80 degrees hot.

The foaming function is carried out physically in ovens designed specifically for this purpose. This type of molecular bond is of higher quality, which is reflected in the performance properties of the material - at the same time, it does not shrink so quickly. But its price is also much higher. It is produced in a roll of 50 sq.m., has a thickness from 2 to 10 mm, there is also 4 mm, but it is intended for insulating walls or ceilings.

Polystyrene - this material is glued together with foil and foam - foamed using high temperature. It is produced in the form of a plate and has: sound insulation, impact strength, compressive strength, low thermal conductivity. If you add foil, the functionality and waterproofing will improve, which is very important for apartments or houses where there is very high moisture, or there is a risk of floors flooding with water. The pricing policy for such material is high.

Cork – a substrate made of this material has a very large number of advantages:

- durability;

- strength;

- eco-logical;

- acts as an excellent insulation material.

There are also several disadvantages:

- when laying, the room should be dry, without the slightest moisture;

- requires mandatory waterproofing.

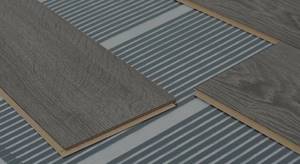

Electric heating

It is worth noting that one of the main areas of application of the foil substrate is the installation of an electric heating system under the laminate. It is a film in which a conductive substance is laminated. This paste heats up by emitting infrared rays. It is the foil that is able to reflect such heat as efficiently as possible, directing it back into the room. Therefore, for electrical systems, the presented type of substrate is preferable.

A foil backing up to 5 mm thick allows the electrical system to operate as efficiently as possible. The fact is that this material evenly distributes heat over the floor surface. The energy expended on the operation of the system in this case is spent much more efficiently.

It is thanks to the foil backing layer that heat can spread not only directly above the heating element, but also to the sides. As a result, a large floor area will release accumulated heat into the room. It will warm up faster.

Studies have shown that thanks to this substrate the room warms up 2 times faster. Therefore, installing a more expensive material under a laminate is completely justified. This purchase pays for itself in just a few months of operation of the heated floor. It is also worth considering that the foil material removes heat from the heating elements. This additionally protects them from overheating. The heating film will work much longer. When choosing a foil material, you should not purchase varieties with a metal coating. It conducts current. The shiny coating can be made from different polymer materials. This option will be preferable when using an electric floor system.

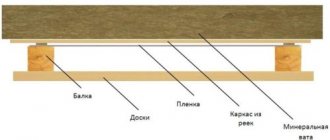

How to properly lay polystyrene foam with foil

Expanded polystyrene mats for floor insulation and subsequent installation of a low-temperature “warm floor” system.

It is necessary to consider which side to lay the insulation with foam foil in the narrow direction of installation of low-temperature heating systems, that is, heated floors. Now you can find on sale special foam mats (sheets), which are covered with foil on one side. In addition, markings are applied to the foil for laying polymer pipes or electrical cables. As you know, heat sources when installing heated floors must be at a certain distance from each other for the system to work correctly.

In this case, the most important role is played by insulation with foil; how to fix it correctly is a key point. The essence of reflective insulation is to reflect infrared rays, that is, heat. Like a mirror, it reflects up to 97% of all IR radiation. Naturally, the reflected rays must return back into the room, so the logical conclusion on how to lay foil insulation suggests itself. Of course, with the reflective surface inward.

Methodology for laying insulation with foil for heated floors:

- the subfloor is leveled;

- foam boards with foil are glued with construction adhesive;

- Cable or pipes are laid according to the markings;

- everything is filled with screed with reinforcing mesh.

Another important point is how to correctly lay insulation with foil: the slabs must fit snugly to the floor. It happens that due to the unevenness of the mats themselves, they lie unevenly on the floor, even if it is perfectly flat. To correct the situation in places where the thermal insulation does not fit tightly, it is simply cut. That is, several smaller ones are made from one sheet, and the operation is carried out locally, after the mats are laid.

Considering the principle by which foil insulation works, figuring out which side to put is as easy as shelling pears. Reflective insulation should reflect IR radiation into the room; accordingly, it is placed with the shiny side in the middle.

Such slabs are used only for floor insulation; they are not used for walls and ceilings, since there are thermal insulation options specifically designed for this. These include:

- mineral wool in mats and rolls with one-sided or double-sided foil;

- foamed polyethylene with foil.

By the way, ordinary foam plastic or its extruded analogue in tandem with penofol perfectly replaces mats for insulating floors and further laying a low-temperature heated floor system. The only inconvenience is the lack of markings.

If you are going to build a private house, then water heating will be the best option for heating it. There are, of course, air, steam and electric heating, but they cannot compete with a liquid coolant circuit.

The two-pipe water heating scheme for a two-story house can be vertical and horizontal. Drawings with explanations here.

Base material

It is worth noting that there are various types of foil substrates on sale. They differ in the manufacturing method. So, you can see in a specialized store a foil backing for 3 mm laminate LMP, PPE, NPE, etc. It is made by different manufacturers.

The presented abbreviations indicate the method of foaming polyethylene. The performance characteristics of the material directly depend on this. The listed popular types of materials indicate the type of substrate base. These are all types of polyethylene.

The cheapest type is NPE substrate. This is a gas-filled type of material. Its low cost is explained by its relatively short service life. Over time, such material sags. It loses its heat and sound insulation qualities.

Much more often today, more expensive types of polyethylene foil materials labeled PPE and LMP are purchased for laminate flooring. These are more modern types of substrates. Their performance qualities and durability exceed NPE. PPE and LMP materials are distinguished by the presence of closed pores. The material is environmentally friendly and does not emit toxic substances.

When choosing between NPE 4mm and PPE 2mm laminate backing, it is better to purchase the second option. In this case, the thermal insulation qualities will be almost the same. But the durability of PPE will be many times greater than that of NPE.

The best artificial underlays for laminate flooring

Artificial underlays for laminate differ from natural ones in cost, in the presence of hydro- and vapor barriers, they are more suitable for rooms with low floor loads and low traffic. The following article presents the best options, selected based on user reviews.

Ultraflex

A special backing for the laminate made of physically cross-linked polyethylene foam has unsurpassed sound insulation properties, provides high-quality vapor and noise insulation, forms an additional water barrier, and the structure of the polyethylene foam creates excellent shock absorption for the floor. The material is biologically resistant to the development of mold and mildew, does not harbor insects, is very easy to install and cut to the desired size, has low thermal conductivity and does not react with building materials.

| Characteristics | Meaning |

| Size | 1050x52500 mm |

| Thickness | 5 mm |

| Material | polyethylene foam |

| Manufacturer country | Russia |

Pros:

- convenient styling;

- excellent water barrier;

- protection against fungus formation;

- low price;

- large volume.

Minuses:

- creasing of the material;

- may release toxic substances.

Review: “On the advice of friends, I chose this inexpensive underlay and was pleased with the result; it did its job, absorbs noise well and keeps the floor warm.”

Tepofol

If installed correctly, this underlay will last a long time, while it has excellent heat, sound and waterproofing properties, makes it easy to level the subfloor, and also really saves on building materials. Foamed polyethylene, covered with a metallized film, copes with its task perfectly and does not cause any complaints. The material is completely safe for all inhabitants of the living space.

| Characteristics | Meaning |

| Size | 1200x25000 mm |

| Thickness | 3 mm |

| Material | Foiled polyethylene foam |

| Manufacturer country | Russia |

Pros:

- high insulating properties;

- strength;

- rot resistance;

- flexibility and ease of installation;

- high thermal reflection.

Minuses:

- rapid loss of original shape;

- cannot be mounted on wooden surfaces.

Review: “An excellent inexpensive underlay, I bought it for additional waterproofing and because it is easy to install. I was pleased with the result and am ready to recommend it to everyone.”

Penoterm

This substrate is made of foamed ribbed polyethylene covered with a polymer film. It forms a system of air channels through which water vapor is removed, and the polymer film provides additional waterproofing. The material compensates for minor unevenness in the base of the floor, prevents damage to the laminate locks and eliminates squeaks when walking. During installation, this substrate does not emit dust or harmful substances. It is protected from the formation of fungus and mold, and reduces heat transfer to the floor, so it will always be warm.

| Characteristics | Meaning |

| Size | 1000x12000 mm |

| Thickness | 3.5 mm |

| Material | Polyethylene foam |

| Manufacturer country | Russia |

Pros:

- protection from dampness and moisture;

- increasing the service life of the floor covering;

- does not corrode or rot;

- does not crumble or generate dust during installation;

- reduces heat loss.

Minuses:

- low strength;

- short service life.

Review: “I bought it to inexpensively insulate and insulate the floor in my dacha. Surprisingly, for the money I was very pleased. The laminate doesn’t creak, the floor is warmer.”

Quick Step Basic

The three-layer backing consists of foil, foamed polyethylene and waterproofing film. It has all the necessary qualities of a laminate substrate, and also meets all European quality standards and is tested for the absence of emissions of harmful chemical elements. It has good leveling quality and high waterproofing properties, protects against excess noise when walking, and is perfectly compatible with heated floors of any type, even when using a thin laminate. This material will save money on repairs.

| Characteristics | Meaning |

| Size | 1000x15000 mm |

| Thickness | 2 mm |

| Material | Polyethylene foam |

| Manufacturer country | Belgium |

Pros:

- good insulation;

- the presence of an adhesive strip for installation;

- levels up to 1.4 mm of the coating base;

- high strength;

- compatibility with any heated floors.

Minuses:

- short service life;

- tendency to lose shock absorption.

Review: “Thanks to the three layers in the backing, it does not allow any moisture to pass through and creates the effect of a warm floor; the laminate does not creak or knock when walking. Excellent material at a reasonable price.”

Tuplex Professional

This warm underlay is perhaps the best option for a subfloor such as a concrete floor. Despite being only 3 mm thick, it has three layers of insulation. First, a microperforated membrane film is installed, which removes moisture. The middle layer is granulated polystyrene foam, which increases the elasticity of the substrate, smoothes out any defects up to 2 mm, absorbs noise and creates the effect of quiet walking. The last layer is high-density polyethylene, which prevents moisture from entering the laminate. This material is perfect for any room.

| Characteristics | Meaning |

| Size | 1100x10000 mm |

| Thickness | 3 mm |

| Material | Polyethylene/expanded polystyrene |

| Manufacturer country | Russia |

Pros:

- excellent water-repellent properties;

- very elastic material;

- noise suppression;

- ease of installation;

- suitable for heated floors.

Minuses:

- with prolonged use it loses elasticity;

- may release toxic gases when exposed to extreme heat.

Review: “I’m very happy with the choice of this particular flooring, as I laid it myself on a concrete floor and saved money by choosing a high-quality base for the laminate. I advise you to buy this particular shelf.”

Rubber-based insulation

When choosing a substrate for flooring, it should be noted that there is an alternative to polyethylene materials. The basis for the foil can be rubber foamed in a special way. This backing has a black base color. Rubber varieties of substrates are superior to polyethylene-based materials in all respects.

Pores are formed in the rubber, which are smaller in size. At the same time, the material is quite dense. It does not deform under compression and does not sag over time. It can be laid on uneven floors by choosing a roll thickness of 5 or even 6 mm. This will not damage the floor covering.

The foil backing for laminate based on foam rubber has the highest thermal insulation rates. It has the same thermal conductivity as a 3 cm thick sheet of polystyrene foam. This is a good option for the floor. The cost of such a material will be an order of magnitude higher than that of polyethylene-based substrates. However, this pays off in the first heating season. Home owners will be able to save on energy bills. Much less thermal energy is required to heat the room.

It is also worth noting that the service life of rubber-based materials is 1.5-2 times longer than that of polyethylene substrates. Therefore, the choice of this particular type of insulation is justified and cost-effective.

Reviews about manufacturers

There is a large selection of substrates of domestic and foreign production on sale. Considering reviews of foil substrates from 2 mm thick, it should be noted that Russian-made products are more popular. It is of high quality and reasonable cost.

Among foreign companies, buyers choose products from the South Korean brand DH-Hilon and the Portuguese manufacturer Sedacor. The first of the presented brands specializes in the production of polypropylene substrates. This is a strong, durable material that is not afraid of significant pressure. The cost of one roll is 1250-1300 rubles. The manufacturer leaves markings on the surface of the foil. This makes installation of the material easier.

The substrate under the Sedacor trademark is supplied to the domestic market from Portugal. A distinctive feature of this material is the use of cork as a base. The cost of this material increases significantly compared to its competitors. However, cork has a number of advantages. This is an environmentally friendly coating. It does not burn and reflects heat well. Also, the presented material has high noise-absorbing qualities.

The cost of a roll from a Portuguese manufacturer is about 2300-2400 rubles. This is an expensive type of substrate. It is purchased much less frequently than other types of insulation for laminate flooring.

Reviews of domestic manufacturers

According to customer reviews, the 5-mm substrate for LMP Normaizol laminate is of high quality. It is produced by a domestic manufacturer. The cell structure of the material is closed. This guarantees high performance qualities of the polyethylene substrate. The cost of this material is approximately 800-850 rubles. per roll.

Another popular one. The company produces polyethylene substrates of various thicknesses. They can be mounted both under electric heating systems and simply under laminate. The cost of production of this brent is about 750-850 rubles. per roll.

Another popular manufacturer is. Innovative technologies are used in the manufacture of the substrate. As a result, the highest quality material is supplied to the market. This backing is made of cross-linked polyethylene. His cells are closed. This increases the thermal insulation qualities of the material. The cost of substrates is reasonable. It is about 700-750 rubles. per roll.

Another well-known manufacturer of universal laminate underlays is. This domestic brand produces many types of materials for arranging the presented flooring. The average price of a foil backing for a laminate of the presented brand is about 850 rubles.

Which side to lay

You can lay the foil backing yourself. The process is distinguished by its simplicity and speed. It consists of two stages - preparation and installation itself.

Preparation

Before laying laminate boards, you need to thoroughly prepare the floor surface. The durability of the floor covering will depend on the quality of the preparatory work.

Preparation includes following these steps:

- The floor surface must be smooth, hard and dry. The first step is to dismantle the old coating and assess the condition of the existing screed. If there are many cracks and chips on it, it crumbles and peels off, then it needs to be dismantled and a new one created. If the defects are minor, then remove any existing chips and cracks using putty and level the surface.

- When choosing the material used to level the surface, it is necessary to take into account the depth of the unevenness . Measure the floor using a building level and calculate the difference between the highest and lowest points. If the obtained value is more than 3 cm, then it is advisable to use a traditional cement-sand screed. If the depth of the uneven surfaces does not exceed 1 cm, then you will have to use a self-leveling mixture.

- Before installing the laminate, the screed must be completely dry . You will have to wait about 14 days. To check the readiness of the surface, you need to use a simple method: place a glass jar with the neck pointing down. Wait a day and inspect the glass. If moisture has settled on it, then you need to wait a little longer, since the screed has not dried.

- If installation is carried out on a wooden base, then the condition of the surface must be assessed to detect the presence of unevenness, cracks and instability . If the condition of the floor is unsatisfactory, the boards will need to be re-laid. Minor irregularities can be eliminated by installing fiberboard sheets.

- Preparatory activities end with thorough cleaning of debris and dust . A vacuum cleaner will help you do this job.

The video shows the preparation of a substrate for laminate with foil:

As for the shortcomings, there is only one. This is a high price, because of which not everyone can buy such a high-quality lining for laminate flooring.

Installation

The foil product must be laid in the direction in which the laminate will be installed. Lay the lining so that the reflector is located on top. Leave an allowance on the strip that is centered along the wall. It will be several centimeters.

All strips are installed end-to-end and secured using foil tape. It must be glued extremely carefully so that there are no creases in the edges of the material or cracks.

In order not to destroy the integrity of the floor covering with shoes, the process of laying the underlay should occur in stages.

The material is laid in a volume that will be sufficient to lay 2-3 rows of laminate boards. After this, install the floor covering and lay the next strip of lining. After installing the laminate boards, mask the allowances that are located near the wall under the baseboards.

Here's a video on how to lay a backing with foil:

In order for the installation process to be completed as accurately and efficiently as possible, you must adhere to the following recommendations:

- You cannot choose a thick substrate or lay it in 2 layers. To hide strong unevenness in the floor, it is better to carry out preparatory work to level the surface as evenly as possible, and then lay thin insulation on the dried layer.

- When laying the lining, it is necessary to ensure that its seams do not coincide with the joints of the floor covering.

- Installation of the roll backing should overlap the walls. Further strips are laid without overlap, secured with masking tape.

- Sheet insulating material is laid in a checkerboard pattern and then secured with tape.

You may also be interested in learning about what color of laminate to choose for your apartment.

But how to choose a high-quality laminate for an apartment and what criteria you should pay attention to is described in great detail in this article.

It will also be interesting to learn about which class of moisture-resistant laminate is the best and which one should be used

But this article will help you understand what are the pros and cons of a coniferous substrate for laminate and what you should pay attention to.

For those who want to learn more about how to lay underlay under laminate, you should watch the video in this article.

According to reviews, foil backing for laminate made in Russia has many advantages. It is manufactured using the latest technologies. The company supplies the market with products from both the cheap and expensive segments. Each buyer will be able to choose the best option for himself.

So the simplest and most inexpensive option is an NPE polyethylene backing. Its cost is from 600 rubles. per roll. However, experts say that the thermal insulation qualities and durability of this material leave much to be desired.

The top seller was the Izolon PPE substrate. This is a cross-linked polyethylene material. It has closed pores. The material is elastic, elastic, and does not lose its original qualities for a long time. Under normal conditions, this material can be used for more than 25 years. The cost of the PPE substrate is about 850 rubles. per roll.

This manufacturer also sells material made on the basis of foam rubber. This is the best option for installing laminate flooring, including using an electric heating system. The cost of this material is about 1500 rubles. per roll. However, the cost corresponds to the quality of this material.

Having considered the features and types of foil substrates for laminate, everyone will be able to choose the best option for their home or apartment.