Today, in the modern market of heat-preserving materials, cellulose fiber or, as it is also called, cellulose wadding, confidently holds a leading position. Is it as good as many people think it is? Does ecowool have disadvantages or are there none at all? Let's try to understand this issue together and highlight the main disadvantages of this type of insulation.

Features of cellulose insulation

Cellulose insulation first became known in our country about 8 years ago. Then the loose, lightweight material (consisting of 4/5 recycled waste paper fiber and the rest from antiseptics and fire retardants) created a sensation.

Important! Thanks to the cellulose texture, it turned out to be light and warm, retaining heated air and not succumbing to the processes of rotting and the spread of mold (insects, rodents, etc.).

Insulation properties

There are several competitive advantages that distinguish this material and allow you to make a choice in its favor:

- Ecological cleanliness and hypoallergenic properties of the insulation - the composition, in addition to wood fibers and antiseptic additives, does not include anything;

- Excellent thermal conductivity efficiency - the coefficient reaches 0.3-0.4 W/mK;

- Full resistance to aggressive environments and microbiofactors;

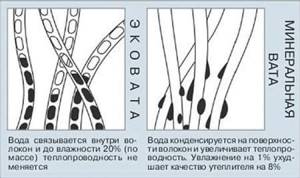

Thermal conductivity indicators of ecowool and mineral wool when moistened

- Fireproof properties - thanks to the addition of borax as a fire retardant, ecowool or other cellulose insulation practically does not ignite even at temperatures up to 1300 degrees Celsius;

- Resistance to low temperatures down to -50 degrees;

- Does not shrink or deform;

- The minimum load on the foundation leads to savings due to the unnecessary construction of additional support.

In the photo: cellulose insulation in flooring

Thanks to the natural structure of cellulose fibers, this substance reliably protects walls not only from cold, but also from heat, and is “breathable,” i.e. vapor permeable, but does not retain moisture inside. Other advantages include ease of application and the complete absence of seams in the insulation.

It is quite easy to apply: with two people in a day, as practice shows, it can cover 60-80 cubic meters of walls.

Important! The pH level of cellulose is from 7.8 to 8.3, which means it does not cause corrosive processes when in contact with insulation and metal profiles.

And here is another interesting fact in favor of the material: cellulose insulation has the highest sound insulation properties among all analogues. As for durability, the service life of recycled cellulose is 60-70 years on average under our climatic conditions.

Technical properties of the material

It remains to add a few words about the performance characteristics that will determine the choice in favor of this insulation. Let's start with simple arithmetic: let's say you use roll or slab insulation, which, when laid, can create up to 4% of joint voids.

And this is already considered ineffective work, since the thermal conductivity drops by 2 times. On the other hand, cellulose evenly fills the space under the siding, insulating voids and sealing joints. The application method often involves spraying, as shown in the picture. Although styling is also possible.

Photos of work on preparation for spraying insulation

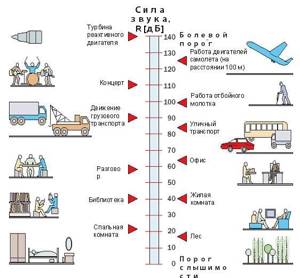

It is also necessary to take into account the sound insulation properties, which are enhanced due to the fact that thin wood fiber penetrates into all voids. So, for example, if you add 12.5 mm of 50 mm thick thermal insulation to plasterboard, we get a noise reduction of 63 dB.

And a further increase in thickness for every 10 mm will increase sound insulation by 4 dB on average.

And here are some other technical characteristics that cellulose insulation can boast of:

Noise indicators of various objects

- The density of the material ranges from 35 to 65 kg per cubic meter and depends on the area of application of the thermal insulation, as well as the manufacturer;

- The thermal conductivity coefficient, we recall, is 0.036-0.040 W/mK and varies depending on the application method;

- According to the flammability class, most insulation materials are classified as G2 - moderately flammable substances and B1 - highly flammable substances. There are also D2, which according to GOST stands for substances with low smoke-forming ability;

- The vapor permeability of the material is 0.3 mg/(m•h•Pa);

- The frost resistance class allows you to last 80 years on average.

How to make ecowool with your own hands, equipment and blowing of ecowool

Ecowool is one of the types of thermal insulation materials. This is a cellulose insulation that consists of an antiseptic and recycled cellulose. Cellulose fibers make up almost 80% of the material itself. It creates an excellent homogeneous seamless layer of insulation. What is ecowool insulation, reviews about it - we will talk about this in our article.

Definition of ecowool. Its advantages

Ecowool consists of fibers that contain lignin, a substance that, when moistened, imparts stickiness. This material is completely harmless and absolutely non-toxic.

In addition, all its components are non-volatile, which means that they cannot harm the environment and people.

There are other advantages:

- good thermal insulation and sound insulation material;

- not susceptible to rotting and fungus;

- in the event of a fire, it is not susceptible to fire for a long time;

- trouble-free installation;

It should be noted that in ecowool, as in all thermal insulation materials, rodents appear that consider it as their food.

This material contains substances such as boric acid and borax. They reduce the fire hazard and provide good protection against fungi and rot. The low cost of wool is associated with simple installation and inexpensive raw materials from which it is made.

Do-it-yourself ecowool. Laying methods

Ecowool can be installed by both professionals and amateurs. There are the following installation methods:

Blowing ecowool with your own hands confronts a person with certain problems. This method is used to insulate floors and flows. Ecowool is easy to install with your own hands; no special equipment or special skills are required.

Manual installation includes several stages.

First you need to prepare the insulation by pouring it into a container such as a bucket or basin. The next stage, “fluffing,” is carried out using a drill.

Blowing ecowool with your own hands requires direct manual installation, which consists of filling it into the ceilings. But there are situations in which additional blow molding equipment is required. After filling the insulation, it must be closed. To do this, you can use sheet materials, for example, plywood.

With the mechanized laying method, equipment specially designed for this is used. And wet-glue processing is usually carried out by professionals.

It is the last method that is of the highest quality.

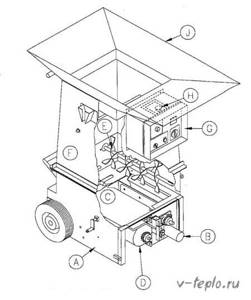

Having considered what ecowool is with your own hands, the equipment that is used in this process is also worth considering:

- blowing installation - necessary for uniform supply of insulation;

- corrugated hoses - supply ecowool to the place of insulation;

- pump set;

- special nozzles for blowing.

This equipment is necessary when it comes to mechanized insulation of a building.

Recommendations for do-it-yourself insulation

Using ecowool, you can insulate your walls yourself. floors, ceilings, attics and roofs. On construction sites you can find out more specifically what ecowool insulation is, reviews about this process and recommendations.

But we will give some basic recommendations in our article:

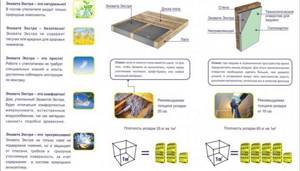

To determine the density, it is necessary to take into account the material consumption

It is important to know that when insulating with your own hands, the material consumption is much higher than with mechanized insulation. Density control can be calculated using a formula and thereby reduce material consumption. To insulate different floors, there are standards for the thickness of the floor. The thickness of the ceiling for the floor is 15-20 cm, for attic floors - up to 30 cm, the thickness of the ceilings between floors is 15-20 cm. If the ecowool insulation process is carried out manually, then it must be taken into account that the material consumption may be slightly higher than originally envisaged. When insulating materials such as concrete, brick or iron with ecowool, it is necessary to prevent the possibility of the ecowool absorbing condensed moisture. Likewise, when insulating a roof, it is imperative to protect the insulation from penetration of sub-roof condensate. This can affect not only the quality of the building's thermal insulation, but can lead to gradual destruction. This thermal insulation material is excellent for insulating residential buildings and utility rooms, as well as for insulating individual building elements.

This can affect not only the quality of the building's thermal insulation, but can lead to gradual destruction. This thermal insulation material is excellent for insulating residential buildings and utility rooms, as well as for insulating individual building elements.

Applying insulation yourself

So, we came to the conclusion that the material in question may be the best option for thermal insulation of a house in many respects. If you know how to calculate the consumption and calculate the area for insulation, taking into account the reserve, all that remains is to choose the application technology - laying or spraying.

Based on the chosen method, you should purchase cellulose for wet application, or dry for installation.

The advantages of the first option - spraying, eliminate the appearance of seams in the structure and provide an even, uniform layer that is easy to apply with your own hands. The material adheres very quickly and firmly to the surface and encloses, as if in a cocoon, electrical wiring and communications .

As for dry installation, it is advisable when installing horizontal floors. In any case, the undeniable advantage is the waste-free work and the versatility of thermal insulation in adhesion to any type of surface - from wood and metal, to glass, stone, brick and concrete.

Laying cellulose material

Let's take a closer look at some application technologies.

Dry styling by hand

This technique involves an easy technological process that allows you to do without renting special blow molding equipment and perform repairs with the help of one or two pairs of working hands.

It is necessary to prepare a container into which the insulation is laid out and fluffed using a drill or a construction mixer. Then the resulting composition is poured onto the cleaned and prepared surface. This approach is ideal for installing floor thermal insulation.

As for the walls, here you will have to prepare a frame or use a ready-made frame structure, within which ecowool insulation will be poured and compacted in layers of 0.5 m.

Dry installation of insulation by hand

Dry styling using technology

A blowing gun or equipment is used in professional construction to work with cellulose wool. This approach, although it involves extra costs, pays for itself when working with large structures and surfaces.

This is especially important in residential multi-storey construction for filling floors between floors and in the basement, sloping roofs and cavities in walls.

During operation, ecowool or another type of insulation is pumped into a gun and sprayed under pressure into the space that needs to be filled with it. Due to the physical properties of fiber expansion, they penetrate into all crevices, even those that are physically impossible to reach when laying by hand.

Dry installation of insulation using a “gun”

Wet application method

It involves working with vertical surfaces where it is simply impossible to do without adhesive adhesion. To do this, use cellulose in slabs or rolls, which can be applied in several layers and overlapping, in order to avoid the appearance of cold-permeable seams.

Lignin released in wood fiber during wetting with moisture is itself a good adhesive substance and provides adhesion to the surface. As a result, ecowool holds up well and forms a layer of sufficient density. Usually, the instructions for the batch tell the builder which installation method to choose in his case.

Methods of applying ecowool

Ecowool can be applied in just a few ways: manual and mechanical.

The manual method is quite labor-intensive, as it requires a lot of physical effort and time. Also, when filling voids with insulating wool, there will be no guarantee that “cold bridges,” so to speak, will not form in the wall. However, this method also has positive aspects: it does not require special equipment.

The ecowool roll is fluffed before starting work and manually compacted into pre-prepared voids in the floor, roof or walls. It is best to fluff ecowool in a special barrel using a construction mixer.

How to choose the right ecowool?

The purchased thermal insulation will be beneficial only when the buyer is careful when choosing and takes into account the recommendations listed below:

- The lack of markings on the label and documents for the product is the first alarm bell for the consumer.

- Request the seller to provide certificates - fire and sanitary-hygienic. They contain information about the composition of cellulose. If ammonium sulfates are used instead of the required boric acid, the biostability will be minimal and the insulation will quickly deteriorate.

- An unexpectedly low price compared to similar products should make the buyer wary. There is a possibility that ordinary shredded paper without additives is sold under the guise of ecowool.

- Get as much information as possible about the manufacturer, read user reviews.

- If possible, study the material externally. It resembles fluff, has no large fractions, but does not look like dust.

- Ecowool that is wet to the touch is not an option, even at a reduced cost.

- Deviations of the material towards gray or yellow color are unacceptable. These are the first signs of the use of second-rate components.

- If you shake the ecowool, small fractions like sand should not appear. If they exist, the user is faced with ordinary shredded paper, on which the manufacturer was greedy with boric acid.

Which ecowool is better

One of the main conditions for proper thermal insulation of a house with ecowool is the choice of the right insulation. To do this, it is enough to know the key features of quality material.

When purchasing, make sure that the cellulose insulation is stored correctly. In conditions of high humidity, ecowool becomes covered with a thin crust. It causes difficulties during installation.

- Color. Good ecowool has a uniform gray color. The insulation should not contain inclusions of white and yellow shades. Their presence indicates a violation of production technology, the use of low-quality antiseptics and fire retardants, and uneven mixing of the components of the insulating material. If you use such ecowool, soon after installation it will begin to transmit heat due to moistening and settling of the cellulose.

- Smell. High-quality ecowool has no odor. It should not appear even after the material is moistened. Ask the seller to add water to the ecowool. If no odors appear, it means you have good material. If there is an ammonia smell, do not purchase. This ecowool uses ammonium sulfate as a fire retardant. It evaporates over time, depriving the thermal insulation layer of its fire-resistant properties. The substance is released into living spaces and causes discomfort to those living in them.

- Consistency of insulation. Ecowool must be uniform. If the mass contains paper dust and large inclusions, then the insulation will not work. It should consist exclusively of cellulose fibers that form air chambers between themselves when loosened and installed. Only manufacturers using professional production lines can achieve such quality.

- Appearance. Good material looks like cotton wool. If you put a lump of insulation on your palm, it will not crumble and pieces will not separate from it. Cellulose fibers adhere to each other, forming a homogeneous mass.

- Compound. The best ecowool has only three components: shredded newspaper waste paper. We buy waste newspaper paper in bulk (80%), borax (12%) and boric acid (8%) as a fire retardant and antiseptic. These substances are odorless and resemble rock salt crystals.

To ensure the presence of preservative additives in cellulose insulation, press it in the palm of your hand. Crystals of these minerals should remain on the surface of the hand. They are not volatile, so they do not pose any danger to the health of the residents of the house.

These components are very important. Thanks to them, ecowool will not harbor fungi, mice, insects and mold. Borax gives the material resistance to high temperatures and fire. It’s easy to check for the presence of a mineral. Take a handful of insulation and try to set it on fire. High-quality ecowool only smolders, but does not catch fire.

Lignin may also be included in the composition of cellulose insulation. This substance is a natural component of cellulose and is released when ecowool is moistened.

The insulation has the property of self-extinguishing, due to the release of crystallized liquid when exposed to fire.

6. Quality confirmation. Responsible companies producing cellulose insulation must have certificates of compliance with fire safety requirements, sanitary and hygienic standards, and a quality management system. These documents confirm the organization of product quality control in production.

Physico-chemical and mechanical characteristics of the material

The main indicators of ecowool include:

- thermal conductivity coefficient - from 0.032 to 0.042 W/m*K;

- compressibility - up to 25%;

- vapor permeability - not less than 0.3 mg/m*h*Pa;

- humidity by weight - up to 1%;

- flammability group - G1, G2;

- water absorption by volume - up to 1%;

- density - from 25 to 80 kg/cubic. m;

- operation is possible at temperatures from −60 to +230 degrees;

- the ability to absorb sound up to 60 dB (versus 48 for mineral wool).

There are no uniform parameters regarding cost. Cellulose insulation is available at low prices (25-50 rubles per cubic meter), but extra-class materials can cost the consumer 20 times more. Domestic analogs are much cheaper than foreign ones, but the characteristics are almost the same.

Ecowool insulation, its composition and main features

The structure of ecowool resembles a capillary-porous, rather loose surface.

- — cellulose fiber up to 81%.

- — flame retardants up to 12%.

- — antiseptics up to 7%.

Waste paper is the main material in the production of ecowool. Usually presented in light gray tones.

The following materials are very similar in structure:

When using them, the following problems are possible:

- condensate;

- fungi and mold;

- "cold seams"

Ecowool components and its characteristics

The composition of ecowool is quite simple and understandable to every user. Let's figure out what it is. The majority, or more precisely, eighty-one percent of the total mass is occupied by recycled cellulose or simply recycled waste paper. The antiseptic component in the form of boric acid is only twelve percent. This is a very important component in the production of ecowool. It is this that protects the material from rodents and insects. The remaining seven percent is fire retardant. The so-called borax is used as a means that is intended to reduce the flammability of the material.

Cellulose wool is produced in the form of loose, fibrous flakes, which, for ease of storage, as well as comfortable and easy transportation, are pre-pressed, decreasing in volume by approximately two to five times. Insulation fibers contain lignin, a substance that, when wet or exposed to moisture, “glues” them to the construction material.

Ecowool has the following technical characteristics:

- heat transfer is 0.037-0.042 W/m K;

- the density of ecowool, depending on the surface to be insulated, varies between 28-65 kg/m3;

- with a laying density of 40 kg/m3, the air permeability will be (80...120)10-6 m3/msPa;

As can be seen from the characteristics given and described above, the thermal conductivity of ecowool is practically no different from similar parameters of other mineral wools. However, it should be noted that due to the nature of its structure, cellulose is largely capable of absorbing water.

But even if you get wet by a quarter or twenty-five percent, the heat transfer coefficient will deteriorate slightly, by about 2-5%. It is worth noting the relatively low price when compared with other insulation materials on the market of goods and services.

Ecowool calculation and price per m3

The cost of 1 kg of ecowool on the construction market ranges from 28 to 60 rubles. Insulation is often sold in packages of 5-15 kg, which is convenient when ordering a large batch. The price of cellulose insulation depends on where it was produced. Imported cotton wool is more expensive, although it is no different from domestic wool. Ecowool consumption ranges from 35 to 65 kg per m3. It is not at all necessary to order “overseas” insulation. will help calculate the consumption of ecowool and the price of the material. The durability of the thermal insulation we sell can be checked over time. Otherwise, the quality of Ecowool Extra insulation can be determined with the onset of cold weather. So-called “cold bridges” do not form; ecowool insulation is carried out evenly.

Order ecowool on our website or call us at the number provided. Production facilities are located in many cities of Russia.

Installation technology

Cellulose ecowool insulation can be applied to insulated surfaces in several ways. These include the following:

- manual application;

- industrial dry method;

- industrial wet method.

When applying manually, the material is poured into a prepared container of sufficiently large volume and whipped or fluffed using a mixer attachment with an electric drill or hammer drill. The material, ready for use, is placed by hand into prepared niches or cavities.

For significant volumes of work, this method is too expensive in terms of labor investment and is ineffective. When industrially applying dry insulation, this disadvantage is compensated by the presence of a compressor, with the help of which the pre-fluffed cotton wool will be blown in.

For mechanized wet spraying of material on the surface, specialized blowing installations are used. The fiber is fluffed up in the hopper of the unit, if necessary, additional adhesive is added and, under pressure, wetted with water through nozzles, it is sprayed onto the surfaces.

The consumption of the composition per 1 m2 will be directly proportional to the thickness of the insulation layer and its required density. The density of wool when insulating horizontal surfaces should be about 45 kg/m3. For vertical planes this value will be 65 kg/m3. Knowing all the necessary parameters and what characteristics ecowool has, you can always calculate the volume, calculate the amount of m3 of product for thermal insulation of a structure of certain sizes.

Due to its properties, the insulation is applied as a monolithic coating, without seams or joints, which avoids the occurrence of cold penetration points. But, unlike working with other materials, you always need to carefully control the packing density of ecowool. Violation of the permissible values can lead to a deterioration in the quality of thermal insulation over time.

Ecowool installation methods

There are three methods of insulating surfaces using cellulose:

- dry (includes two subspecies - manually and using a cannon);

- wet (spraying);

- wet adhesive spraying.

The advantage of the first method is all-season use. A vapor barrier is laid on the previously cleaned base of the insulated surface, then an aluminum or wooden frame is attached. Ecowool is laid with a reserve, since it will definitely shrink. The gun is used in the construction of multi-storey buildings or other large areas. The method is expensive, so it is not suitable for insulating a country house.

Wet spraying is appropriate on open surfaces. The cellulose is first moistened with water and then applied to the base.

When applying ecowool with wet adhesive, a composition is used to increase the level of adhesion of the mixture. Suitable for insulation of pitched roofs, arches, vaults and other inclined surfaces. Subsequent shrinkage must also be taken into account here.

Negative aspects of cellulose

In order to get a complete picture of this insulation, let’s consider the disadvantages of ecowool.

- The use of specialized equipment, since manual installation is quite labor-intensive.

- The personnel performing the work require fairly high qualifications.

- The presence of a large amount of dust during installation of insulation.

- When the composition is wet sprayed, its drying time can reach 72 hours, which is not always convenient and sometimes even unacceptable.

- Shrinkage of cellulose wadding. Over time, the installed thermal insulation can lose up to a quarter of its volume, which will lead to the formation of uninsulated niches.

- Significant absorption. In order for the fiber to dry, it is necessary to create conditions for good ventilation.

- When vertical blowing, it is necessary to create a frame from reinforcement or wooden beams.

In fairness, it is worth noting what disadvantages there are of ecowool, among those pointed out by experts and people who have already encountered it in their homes. There are cases of an allergic reaction “to library dust”, expressed in the form of urticaria.

However, these are isolated cases and only individual intolerance to any component of this material can lead to negative consequences.

Also, some Internet users are concerned about the presence of boric acid in the insulation, which under certain conditions may end up in direct contact with a person. Let us remind you that its content in the material is 12% . This concentration generally does not pose a danger to the human body. The objectivity of this information remains entirely with those who distribute such data on online forums.

Rid your home of rodents and insects

To permanently protect your home from the invasion of rats and mice, as well as insects, you do not need to use toxic chemicals - just insulate the house with ecowool, and these uninvited guests will lose interest in your home.

The fact is that both insects and rodents cannot live next to ecowool - they cannot tolerate the borates that it contains. Boric acid and its salts are non-volatile, resist fire, and are safe for humans. Consequently, the use of cellulose insulation allows you to solve a number of important problems:

- increased thermal insulation;

- increased sound insulation;

- protecting your home from rats and insects;

- protection from drafts;

- natural regulation of home humidity;

- absence of mold and mildew.

Advantages and disadvantages of blown ecowool

Blown-in cellulose insulation can be composed of basalt, fiberglass and cellulose. Basalt mineral wool is made from basalt stone, and no formaldehyde is added to it. Glass wool is the result of crushing thermal insulation boards; cellulose insulation is made from waste paper. Fire retardants and antiseptics are added to all types of thermal insulation.

Advantages:

- Low thermal conductivity and light weight;

- High moisture resistance and vapor permeability;

- Fire safety and non-flammability;

- Long service life;

- Easy installation.

Flaws:

- To operate, you will need compressor equipment;

- On plasterboard surfaces, ecowool should be applied in two layers to avoid swelling of the surface;

- The need for surface waterproofing;

- High cost of use for small volumes of insulation.

Performance properties of blown ecowool

Ecowool layer calculation

Starting information you will need:

- Construction material of building walls;

- Average annual thermal resistance in the region (reference information);

- How many external doors and windows are there in the house?

- Additional heat leaks;

- Thermal insulation material and heat transfer coefficient.

What kind of material is this?

Ecowool is a loose thermal insulating material, gray in color and made on the basis of cellulose. The material includes:

- recycled paper (about 81 percent);

- fire inhibitors (about 7 percent), which form a self-extinguishing effect and increase the fire resistance of ecowool to 232 degrees;

- fungicides and antiseptic substances (about 12 percent), protecting the material from the effects of fungi, mold, mice, etc.

It is also worth noting that the manufacturing procedure for this insulating material takes only five minutes. First, waste paper is delivered to the production site. It is poured onto a special conveyor, through which the paper enters the so-called primary mixer. There, the material is divided and cleared of metal elements (such as paper clips) using a built-in magnet. Next, the raw material is crushed using the same mixer into small shreds (width - about 50 millimeters), fire retardants and antiseptics are added.

Then the raw material is fed into another device - a fiber manufacturer, which crushes it into thinner pieces (dimensions are about 0.4 centimeters). A small amount of borax is added at the end. That's it, the cellulose insulation material is ready for use!

Scope of application of cellulose thermal insulation

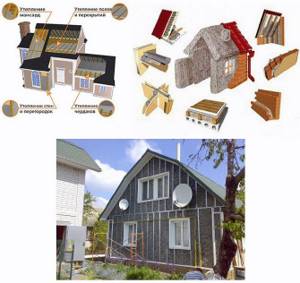

Since the material in question is in many ways similar to mineral wool, its scope of use is very wide. Cellulose insulation is recommended for insulation:

- external walls using the “ventilated facade” technology, if finishing is expected (siding, etc.);

- interior partitions;

- floors (except for “warm” ones);

- attic floors;

- attic;

- roofs for sheet or rough covering (gypsum fiber board, gypsum plasterboard, chipboard, fibreboard and others);

- external walls of wooden and brick houses (the recommended thickness of the cellulose layer varies from 75 to 100 mm).

Modern developments in the construction industry open up wide opportunities for consumers. The market for insulation materials, which is developing at a rapid pace, is no exception. One of its worthy representatives is ecowool based on recycled paper - thermal insulation that allows you to save money at the construction stage, avoid overuse of cellulose, optimize the interior space of the house and preserve the health of the inhabitants of the sheathed building.

Features of insulation of different parts of the building

Insulation of house walls

Cellulose material can be used for insulation of buildings, both for interior decoration (under cladding made of sheet materials) and for external insulation of buildings (under ventilated facades). In both cases, first the profiles for the wall panels are attached to the wall and only after that the insulation is applied. Note that when finishing facades, the thermal insulation properties of the wall (brick, concrete, wood, glass) should be taken into account. This will reduce the cost of building foundations and there will be no need to think about vapor barriers. Since the material is breathable. In some cases, savings reach 30% of the construction cost.

Insulating the roof of a house

Ecowool is excellent for thermal insulation of attics or heated attics, since it is environmentally friendly and does not release heat from the house. For such purposes, it is necessary that the insulation thickness reach at least 75 mm, the optimal option is 100 mm.

Boric acid

Boric acid (orthoboric acid or lat. acidum Boricum) is a weak, monobasic Lewis acid, often used as an insecticide, antiseptic, and fire retardant.

In the photo "Boric acid"

Application

- Boron fertilizer

- Used in laboratories to prepare buffer solutions

- In medicine - as an independent disinfectant for adults, and also in the form of a 2% solution - for washing the skin after contact with alkalis

- Also, various combination preparations are produced based on boric acid (ATX group D08AD), for example Teymurov’s paste

- Registered in the food industry as food additive E284

- In jewelry - as the basis of fluxes for soldering gold-containing alloys

- In everyday life - extermination of cockroaches, ants, bedbugs

- In the production of ceramics, fiber optics, fiberglass, glass

- As a fire retardant to protect wood

- As part of electrolytes for copper and nickel plating

The use of cellulose (ecowool) for insulation of building envelopes

Currently, with high energy prices, there is an increasing need for the use of energy-saving technologies and materials designed for more rational use of all types of energy.

In particular, measures to insulate residential and industrial buildings are one of these ways to reduce operational costs. In the construction market, among the many thermal insulation materials, insulation such as cellulose , photo 1a. In this article we will look at what cellulose is as a thermal insulation material.

The use of cellulose (ecowool) for insulation of houses

Cellulose insulation (photo 1b) consists of:

- crushed wood fibers (cellulose) of gray or light gray color (81%);

- flame retardants (up to 12%);

- antiseptics (up to 7%).

Cellulose as insulation is also called ecowool or in pressed form - ecoboards .

Photo 1. Cellulose insulation and its composition

Treatment of cellulose with antiseptics and fire retardants prevents the processes of rotting, burning and eating by insects. Substances intended for processing cellulose are also called impregnants . Most often it is boric acid or borax. Boric salt (sodium tetraborate) is a hygroscopic substance that can absorb moisture without reducing its thermal insulation properties.

Manufacturers claim that fire retardants and antiseptics are toxic and dangerous for fungi, rodents, bacteria, but at the same time non-toxic and harmless to human life and health. A solution of boric acid is even used in medicine as a disinfectant.

For the production of crushed cellulose, paper raw materials or secondary raw materials (waste paper) are used.

Properties of ecowool (crushed cellulose)

In table 1 presents a comparative description of the properties of ecowool and other thermal insulation materials.

Comparison of ecowool and other thermal insulation materials

Specifications

Glued basalt wool (with binder)

Unglued basalt wool (without binder)

Ecowool

Manufacturers guarantee frost resistance of ecowool - more than 80 years. Due to the pH value = 7.8...8.3, ecowool does not cause corrosion of metals. The average density of crushed cellulose is 30...35 kg/m3.

The purpose of ecowool and methods of its use (laying)

Cellulose is used for insulation, photo 2:

- external and internal walls;

- interfloor ceilings;

- roofs;

- insulation of floors along joists.

Photo 2. Application of ecowool

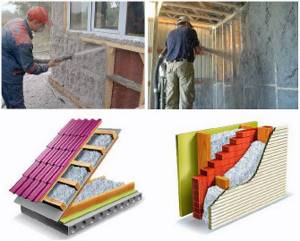

Shredded cellulose is applied in two ways:

- manual installation (less economical);

- installation using a blow molding unit (for example, Cellophant M95-230/4.7 kW-SE).

Cellulose can be applied wet or dry by hand or machine.

Dry manual application method: This method is used for insulating horizontal surfaces (floors, ceilings) or for insulating roof slopes with a slight slope (attics), etc. The essence of this method is that the cellulose is first fluffed using a drill and a whisk, and then spread evenly with slight compaction, photo 3. The manual method is ineffective, since the material consumption in this case increases to 50%, and the length of installation time increases by 20 times or more.

Photo 3. Dry method of applying ecowool

Installation using a blow-blow installation. This method of application is characterized by high productivity (3...9 m 3 /hour) and the ability to supply material to a height of up to 25...30 m. Using an installation under high pressure, cellulose is injected into any voids and crevices, photos 4, 5.

Photo 4. Installation using a blowing machine

Photo 5. Installations for blowing ecowool (cellulose)

The wet method is used for application to open vertical surfaces and with a large slope, photo 4. Cellulose moistened with water or glue has good adhesion to concrete and wooden surfaces and, after drying, forms a fairly dense thermal insulation layer. Application is also carried out using an installation that supplies cellulose mixed with glue (usually PVA, 2...10%) under pressure. The wet method of applying ecowool is the most effective method of insulation.

Cost of insulation - Ecowool

For correct calculation, let's take the insulation thickness of 100 mm. The price will include all work and the material itself.

Horizontal surface - 190 R/m2

Sloping and vertical surfaces from 240 R to 350 R/m2

The approximate cost of insulating a house with a total area of 120-150 m2 on a turnkey basis (thermal circuit) ranges from 100 to 200 thousand rubles. The price is comparable to all types of insulation with basalt or mineral slabs.

Insulation calculator

Ecowool calculation calculator

Do-it-yourself ecowool production

Ecowool is a cellulose insulation made from recycled waste paper. Its composition contains 81% cellulose fibers, which allows it to perform its functions perfectly. In modern construction it is used to create a seamless thermal insulation mass, but for full operation it contains boric acid and borax. Borax is intended to make the material fireproof, and boric acid is intended to resist fungi, mold and rodents.

Ecowool goes on sale in the form of an unmolded mass of cellulose fibers. For transportation and storage, bulk material is compressed and placed into special high-density briquettes. Before use, it is unpacked and dried, and during drying it increases in volume by about 3-4 times. The technology for making ecowool is so primitive that it can be made at home.

How to make ecowool yourself

To produce cellulose insulation, you will need waste paper and a powerful shredder that will process recyclable materials. By its principle, the chopper should work like a regular coffee grinder. Often an old activator washing machine is used that has undergone a slight modernization.

Recycled raw materials are loaded into a shredding machine, where they are preliminary and completely crushed using different knives. Next, the finished cellulose material must be fluffed and dried. Any fan unit is suitable for these purposes. Here cellulose is mixed with boric acid 12% and borax 7%.

Ecowool - waste paper after the shredder

Ecowool installation methods

Installation of cellulose insulation can be done manually or by machine. The manual method is less expensive and is recommended only for backfilling floors during the construction of upper floors and dry backfilling into walls. It is actively used by developers due to its low cost.

The mechanized method is a more productive solution and has a number of advantages:

- installation speed;

- economical insulation consumption;

- no risk of errors.

The main feature of mechanized laying is the use of blow molding equipment. Based on this, there are several types of installation, namely dry, wet and wet-adhesive.

- Dry method - designed for insulating horizontal and inclined walls. The main task is to fill closed planes located in walls, fill ceilings between floors and non-demountable structures.

- Wet method - designed for insulating house walls and various vertical surfaces. Wet ecowool is perfectly strengthened on any walls, creating a single mass.

- The wet-glue method differs from the wet method in that glue is added here to enhance the adhesion of the insulation. The advantage is slight deformation during drying and the absence of dangerous chemical compounds. The technique is perfect for thermal insulation of ceilings and other horizontal surfaces to which there is no direct access.

Advantages and disadvantages of ecowool

It is worth highlighting the advantages of cellulose insulation:

- Excellent thermal insulation. Compared to mineral wool, the advantage is 11-12%.

- Low breathability and elasticity. Unlike mineral wool and polystyrene foam, it better blocks sound waves, protecting the house from unnecessary noise.

- Fast drying. This way, the insulation helps maintain the natural level of humidity, creating comfortable living conditions.

- No toxic substances or phenolic binders.

- Homogeneity of mass. Thanks to its composition, after installation, ecowool creates a seamless layer that fills the entire volume, without forming cold bridges and voids, which cannot be said about mineral wool and polystyrene foam.

- Thanks to the processing, ecowool does not burn and is not susceptible to mold and mildew.

- No smell.

Disadvantages of ecowool:

- The need to use special equipment.

- A large amount of dust during dry installation.

- Difficulties in thermal insulation of walls in the house.

- The need to strictly follow the installation technology.

- Impossibility of use in floors with a constantly high level of humidity.

https://kak-sdelatsvoimirukami.ru

Eco-friendliness of ecowool

There is a lot of controversy about the environmental friendliness of ecowool. There are extreme supporters that it is very environmentally friendly. Others say that it is not at all environmentally friendly, let's try to figure it out.

Ecowool consists of three components:

- Newspaper waste paper

- Borax

- Boric acid

“Ecowool is full of lead because it’s made from newsprint.”

As for newspaper waste paper, it means there is no lead in the newspaper since it has long been produced in a way that eliminates the presence of lead in the equipment.

“Printing ink is harmful to health”

The harm caused by printing ink is greatly exaggerated; it has its own hygienic certificate, on the basis of which newspapers are produced. Millions of people read, touch, enclose every day and no one has yet gotten sick, much less died, from contact with printing ink. So we can say with confidence - “This is a myth”

What is ecowool

Remembering that suburban construction in Russia began to actively develop in recent times, ecowool appeared relatively recently in St. Petersburg and the Leningrad region.

Acquaintance with Ecowool in low-rise suburban construction in St. Petersburg began in unfavorable conditions for it: it was unclear about the supply of cellulose insulation, not to mention the equipment for installing Ecowool, although it was used in Europe even in pre-war times. But even in our time, we still hear from construction teams who have built more than one country house: ECO-WOOL - what is it? Ecowool is an environmentally friendly material that consists entirely of natural ingredients:

- borax – 7%;

- boric acid – 12%;

- recycled cellulose – 81%.

The loose consistency of ecowool allows for seamless installation, after which there will be no drafts, mice or insects in the house. There is no problem with residues - there is no waste during installation, every gram of ecowool will reliably protect your home.

How to apply cellulose insulation yourself

So, we found out that, based on numerous parameters, the insulation described in the article is the best option for thermal insulation. And if you know how to correctly determine the material consumption and calculate the area of the treated surface (with some margin), then the only thing left to do is to choose a specific application technology. There are two options.

- Spraying.

- Laying.

Next, based on which method was chosen, buy cellulose - for dry or wet installation.

Note! The main advantage of spraying is that there are no seams left after installation work, and the insulation layer is uniform and even. Moreover, the work is easy to do on your own. Ecowool adheres to the surface quickly and reliably, it hides (like a cocoon) all communications and electrical wiring.

If we consider dry installation, then it is recommended to use it when insulating horizontal surfaces. The advantage in this case will be the absence of waste and the fact that the adhesion of the heat insulator will be universal for all types of surfaces - wood, metal, cement, stone, brick or even glass.

Let's take a closer look at each of the technologies.

Option #1. Dry laying of ecowool

This technique is a fairly simple process to perform, for which you do not need to rent expensive blow molding equipment. Moreover, in this case, only one or two people will be required to work.

First, a special container is prepared. Ecowool is placed in it, which is then fluffed using an electric drill or a mounting mixer. The working surface is cleaned and properly prepared, after which the finished fluffy composition is poured onto it. As noted above, this technology is ideal for floor thermal insulation.

If we talk about the walls, then they will require the construction of a special frame (or, as an option, you can purchase a ready-made factory frame structure), where the cellulose insulation will be laid and carefully compacted layer by layer (the thickness of the layer should be 50 centimeters).

Option #2. Dry laying using special equipment

Blowing devices (in most cases a so-called blowing gun is used) are used when carrying out professional construction work with cellulose insulation. It is worth knowing that this technique is associated not only with additional costs. The fact is that it completely pays for itself when we are talking about large objects or surfaces of a significant area.

This is especially true in the construction of multi-storey residential buildings, when it is necessary to fill the ceiling in the basement or between floors, in an inclined roof or in wall cavities.

During the actual installation, ecowool is injected into the equipment used, after which it is sprayed under high pressure throughout the treated space. Subsequently, the fibers, due to their physical characteristics, expand and fall into all cavities and crevices, even into places that would be impossible to reach if laying was done manually.

Option #3. Wet styling

This technology is suitable for thermal insulation of vertical surfaces, where, as is known, it is impossible to do without an adhesive composition. For such purposes, ecowool is used in the form of rolls or slabs and can be laid not only in two or three layers, but also with an overlap in order to prevent the formation of seams that allow cold air to pass through.

Lignin, which is released when cellulose fibers are moistened, already has high adhesion, so the insulation reliably adheres to the working surface. As a result, the insulation adheres well and forms a dense protective layer. As a rule, the manufacturer's instructions tell you which installation option is best to choose for certain application conditions.

Subtleties of insulation

Let's consider the main nuances when thermally insulating a particular part of a building.

Walls

When insulating load-bearing structures, ecowool can be applied not only outside, but also inside the house. Be that as it may, first the profiles for further installation of the panels are fixed, then - according to the previously chosen method - the insulating material is applied. By the way, when using the dry application method, ecowool can be applied with already installed finishing panels, using previously left holes.

During the work, do not forget about the thermal insulation properties of the material from which the walls are made. Thus, the cost of construction work can be reduced by approximately 30 percent.

Roof

Heated attics and attics are perfectly insulated using cellulose insulation. Indeed, this material is environmentally friendly, and it eliminates heat loss almost completely. The thickness of the insulating layer in this case should be 75-100 millimeters.

Floor

Ecowool is an excellent option for interfloor ceilings. It not only insulates, but also increases the sound insulation of each room. If you plan to install a “warm floor”, then the cellulose should be laid on top of a rough screed laid on a crushed stone “cushion”.

Video – Ecowool “Unizol”

As a result, we note that cellulose insulation is an ideal option for residential buildings. Its advantages are obvious, and the few disadvantages are insignificant or easily eliminated. That's all, good luck and have a warm winter!

Types of ecowool

Ecowool is a product of processing waste paper, that is, newspapers, cardboard, magazines, newspapers.

Defective copies are also used during the printing of book aids and trimming during the production of corrugated products.

The use of waste makes it possible to create a capillary structure, which is in demand for insulation.

Ecowool typology:

- dry - used for dry spraying;

- sprayed - a solution mixed with water is used for wet installation in places where facing work is not expected (warehouses, exhibition halls, hangars, rooms with low requirements for the decorative appearance of the ceiling and walls);

- stabilized - ecowool with less material consumption is used for both dry and wet spraying (used in places where minimal time is required to prepare the heat-saving material for application);

- with oil - a solution with an oil additive significantly reduces the amount of dust generated during spraying (combinable with 2 installation methods). Necessary for use in residential buildings (private houses) and public places with high traffic, where there is a risk of inhalation of sprayed dry particles by adults and children.

A relatively new type of ecowool is a material designed in panels. Ready-made building layers can be installed without the use of blow molding units.

About technology

Ecowool is a cellulose insulation material for new construction and renovation.

All components of this material are non-toxic, non-volatile, natural components harmless to humans.

The service life of ecowool, according to world experience, is more than 50 years.

Doesn't rot. Repels rodents. "Breathing."

The required thickness for the floor and ceiling is 200mm; on walls – 150mm. Laying density 40-80kg/m3.

Our company has all the necessary equipment and materials for high-quality insulation of house structures using ecowool

Quality control of work is carried out using thermal imaging equipment and it is free for you!

Ecowool is a unique thermal insulation material made from environmentally friendly material. It is used for insulating buildings for almost any purpose, including private houses.

Four main installation options, a wide range of density and heat and sound insulation properties, selected in each individual case, as well as a high rate of home insulation are the reasons why ecowool occupies almost 70% of the market for thermal insulation materials in Western countries.

In our country, ecowool insulation is only gaining momentum, although it is an almost ideal option, taking into account the climate and the prevalence of raw materials.

Cellulose is a abundant and cheap material. Divided into fibers and fluffed up, it acts as insulation no worse than mineral wool or vermiculite. Among the obvious advantages: cellulose weighs little and is an environmentally friendly material. However, using it in its pure form in construction is not practical and even dangerous.

The insulation consists of 80% cellulose, fibers obtained from recycling waste paper. The remaining 20% are additional components that make ecowool resistant to fire and biological factors that can damage it.

To prevent the fibers from scattering, a monolithic layer of insulation is formed using lignin, a natural biological glue that binds the fibers together, but does not contribute to creasing of the material.

The fibers are combined in a chaotic manner, forming a lush, voluminous structure with excellent thermal insulation properties. It does not wrinkle or compress under its own weight. The same lignin is used as a binder in the wet method of applying ecowool.

When adding a small amount of water, ecowool easily sticks to the insulated base and does not fall off after drying, even after a significant period of use.

Borax is used as a fire retardant to reduce the fire hazard of cellulose. A natural material that can completely eliminate the risk of cellulose fire. Even when directly exposed to flame, the material does not ignite, but only slightly smolders without maintaining combustion.

It does not emit harmful substances when burning and practically does not smoke. In full compliance with GOST 30244, the fire safety group of ecowool is G2, group D2 for smoke and B2 for ignition.

The presence of boric acid makes it impossible for any vegetation or even living creatures to gain a foothold in the insulation layer. During the entire service life, ecowool does not rot or decompose under the influence of bacteria. Even rodents avoid it, simply because boric acid affects their sense of smell, not poisoning, but repelling.

Characteristics

For clarity, you need to compare the characteristics of ecowool with other popular insulation materials.

Ecowool largely combines the good features of other insulation materials, while having a number of features that are important to consider when designing a private home:

- In production, natural material is used - cellulose;

- Affordable price in relation to the closest analogues;

- Seamless insulation that fills the entire volume allocated for it;

- If the filling density is selected correctly, it will not wrinkle over time;

- Moderate moisture absorption, the bulk of the moisture remains in the surface layer;

- With equal ease it takes away excess moisture from the air and gives it back - a “breathable” material;

- An ideal solution for an aerated concrete house or log house when using vapor-permeable building materials;

- Suitable for manual and automated installation;

- High sound absorption coefficient in the audible range. Absorbs and absorbs waves.

Ecowool is laid in pre-prepared niches and voids formed by lathing and several layers of vapor barrier material and the surface of the insulated base. The minimum effective thickness of the material is 45-50 mm. The maximum is limited by the design features of the insulated room.

The insulation layer is calculated based on the thermal resistance of the walls, ceiling or roof slope. As a result, the resistance of the building envelope must meet the requirements of the project and the established standards for the region of construction.

Ecowool is transported to the construction site in compressed form, causing it to lose up to 3-5 times in volume. Before use, it must be fluffed up and returned to its original volume and, accordingly, density.

The task of insulating a private house with ecowool comes down to uniform distribution of the material over the insulated surface, followed by lining it with a protective vapor-permeable layer.

Automation of the ecowool laying process is carried out using special equipment. The compressed cotton wool is broken up by a screw and finally fluffed up under the influence of a strong stream of air.

It is transported with the same volume of air from the preparation site to the insulation point at the construction site. Due to the lightness of cellulose and its structure, it can be moved pneumatically through a pipeline up to 200 meters horizontally and up to 40 meters upward.

Blowing is carried out gradually, starting from the bottom up for walls or from one of the corners evenly along a horizontal surface. The outlet of the transport pipeline is abutted against an already laid layer of insulation to minimize scatter and to control density.

In a private house, using ecowool, you can insulate roofs and walls, floors between the first and subsequent floors, the attic and roof slopes. The exception is the ceiling above the basement and the base of the house above the foundation, where there is no way to effectively remove moisture.

The principle of insulation is extremely simple. The frame of the insulation belt with cells of arbitrary width and length is formed from wooden logs and bars. The standard pitch for joists and sheathing is 600 mm, the length can reach 6 meters.

Floor

The logs form ideal cells for laying ecowool. For floors formed by slabs, additional sheathing will be required. The base must be waterproofed, preferably with a vapor-permeable membrane.

To insulate the ceiling with ecowool, it is necessary to prepare niches hemmed from below between the sheathing beams for filling with insulation. For floors with joists, the insulation is laid directly between the joists to which the sheathing is attached.

Ecowool

Country of Origin

: Russia

Composition

: cellulose

Method of application - machine on vertical surfaces, manual on horizontal ones Scope of application : external and internal heat and sound insulation

Along with traditional basalt insulation of enclosing structures (mineral wool), in private housing construction our company offers high-quality external insulation of facades of wooden and stone houses with cellulose insulation (ecowool). Cellulose ecowool insulation is made from wood pulp, recycled paper and cardboard. For fire resistance, fire retardants are used in cellulose ecowool. These are ammonium sulfates or phosphates, borax in combination with boric acid (antiseptic), the proportions are approximately 80%/20%. It is important to note that the layer of ecowool sprayed or laid in closed cavities is 150 mm thick. density 65 kg/m3. corresponds in thermal conductivity to a brick wall 4.5 bricks thick. Meanwhile, gaps left even in 4% of the insulation area will give a 25 percent reduction in the heat capacity of the wall.

To insulate houses, the wet-adhesive method and the dry method are used.