In modern life, insulation materials of various types have become widespread. The use of XPS insulator has become particularly relevant. This is extruded polystyrene foam, which is actively used in such areas as:

- construction of roads, including railway embankments and aircraft landing strips;

- internal and external thermal insulation of private houses and industrial buildings;

- multilayer thermal insulation systems (used as a component of sandwich panels);

- insulation of socles, basements;

- arrangement of heated sidewalks;

- insulation of oil and gas production equipment, refrigeration units;

- construction of inversion and inclined roofs;

- arrangement of floors on the ground, etc.

Features of the material

Extruded polystyrene foam was created in the USA in the early 40s of the 20th century. It is a synthetic thermal insulation with unique properties, which were achieved through the use of special technologies during the production process.

Modern manufacturers have mastered the production of material of various colors and shapes: in the form of cylinders, rolls, slabs, segments. The cost of insulation depends on its dimensions, density and manufacturer.

Production

XPS is produced by extrusion. Polystyrene granules under the influence of high temperatures and pressure are mixed with a foaming agent in a special apparatus - an extruder. Then, using pulling rollers and pressure, the material is squeezed through a die, which helps give the material the desired shape.

Foaming of the mixture ends when it comes into contact with air. The next stages of manufacturing are cooling of the insulation and its stabilization. The production process is completed by cutting the thermal insulator into pieces of the established size and packaging it using thermal machines.

For comparison: in the production of conventional polystyrene (foam), granules of the material are steamed with water vapor until they significantly increase in size, until the mold intended for the insulator is completely filled.

Carbon dioxide, mixtures of light freons or freon-free systems based on CO2 can be used as foaming agents. It was the use of substances purified from freons that made it possible to bring the production of the material to a qualitatively new level, making it environmentally friendly and clean. The heat insulator coming out of the extruder has a uniform structure with closed pores and microcells ranging in size from 0.1 to 0.2 mm.

Technical specifications

XPS insulator has the following unique properties:

- vapor permeability coefficient – 0.004 mg/(m•h•Pa);

- thermal conductivity level – from 0.026 to 0.032 W/(m•K);

- moisture absorption in 24 hours – 0.3%;

- specific gravity – 25-45 kg/m3.

Characteristics of expanded polystyrene

The positive qualities of XPS insulation make it perhaps the best option among the entire range of thermal insulation materials on the market:

- Extruded polystyrene foam is characterized by minimal hygroscopicity;

- Has low conductivity of heat and steam;

- Does not absorb moisture;

- Resistant to fire;

- Thanks to its structure, XPS has unusually high compressive strength and biological stability (that is, it does not harbor insects and rodents);

- This is an environmentally friendly and safe material;

- It is impossible not to note the simplicity and ease of installation - all work on thermal insulation can be done with your own hands, without assistants;

- Expanded polystyrene is not the cheapest insulation material, but its price is quite reasonable. Of course, it is a little higher than, for example, mineral wool or ordinary polystyrene foam, but the costs will be doubled. We'll talk about this a little later.

Expanded polystyrene in the form of mats of various thicknesses

Reliable thermal insulation of residential, municipal and industrial buildings plays a major role in reducing heating costs. And, as you have already noticed, extruded polystyrene foam is quite capable of providing effective insulation - with its help you can get rid of heat loss for a long time and save a lot of money on your budget.

Note! XPS expanded polystyrene can be used to insulate loggias, walls, floors, foundations, roofs, communications, garages, and many other structures.

Balcony insulation with XPS slabs

XPS insulation: review of thermal insulation

The market for thermal insulation materials is replete with offers for every taste. Mineral wool, polystyrene foam and polyurethane foam have long established themselves as reliable and safe thermal insulators. However, science does not stand still, and manufacturers are always striving to expand their market share with new products.

A relatively “young” thermal insulation material is XPS (eXtruded PoliStyrene) insulation. This is the name given to extruded polystyrene foam. Thanks to its unique combination of characteristics, the material has gained recognition among a large number of buyers.

Extruded, or extruded polystyrene foam, is expanded polystyrene foam that is produced by extrusion. Essentially it is plastic with a uniform fine-mesh (0.1-0.2 mm) closed structure. The fundamental difference lies in the more advanced technology of foaming polystyrene granules, as a result of which the resulting material is fundamentally different from the usual ball foam. Despite the fact that these two insulation materials are made from the same raw materials, the set of properties of the finished products has significant differences.

Characteristics and properties of XPS insulation

XPS looks like a smooth slab and is available in colored or transparent versions. The finely porous structure can be seen with the naked eye in the cut. The slabs are produced with smooth edges and with a so-called “L” edge, which ensures reliable adhesion of the insulation elements during installation. The combination of other characteristics created a real sensation when the material was introduced to the market:

Water absorption (0.2% at full immersion) is so low that this parameter is often neglected in design calculations. It's all about the XPS structure, the cells of which are closed and water does not penetrate into them under any circumstances. Moisture can only be absorbed by cells whose integrity is damaged when the slab is cut, but in this case the amount of absorbed moisture is negligible.

The lowest thermal conductivity coefficient among all known insulation materials is λ = 0.029 W/m*K. This material, like polystyrene foam, consists of 97% air, but undoubtedly benefits from almost zero hygroscopicity.

The density (specific gravity) value ranges from 25-45 kg/m³, as a result of which even a child can easily lift the XPS slab. This property makes for ease of installation, as well as ease of storage, reducing the cost of material handling.

High frost resistance is also ensured by a low water absorption rate. Thanks to this property, XPS insulation can be used in the Far North.

Resistance to chemical compounds: acids, water, oils, saline solutions, caustic alkalis, bleach, alcohol and alcohol-based dyes, fluorinated hydrocarbons, cement, ammonia, CO2, propane, acetylene, butane, paraffin, as well as any solvents inorganic origin.

High compressive strength allows the material to be used not only in insulating loaded roofing structures, but also in the construction of heated sidewalks, roads, railways, and runways. Easy to process - use a regular knife when cutting

High fire resistance is achieved by introducing special substances into the composition - antiperen. Thanks to this technological procedure, XPS insulation is considered a self-extinguishing material, which means it burns only when in contact with an open flame source.

When burned, it releases harmful and toxic substances, so it, like other polystyrenes, is not recommended for use for internal thermal insulation of premises. According to SNiP 21-01-97 “Fire Safety of Buildings and Structures”, as well as Federal Law No. 123, extruded slabs of increased flammability can still be used in building structures, and with increased fire safety requirements, extruded polystyrene foam with flammability group G3 should be used.

Application area of XPS boards

Manufacturers and sellers talk about the versatility of XPS, but based on the main results of certification tests, the following possible applications can be identified.

Insulation of foundations, basement and semi-basement premises. The material does not rot under the aggressive influence of the soil, ideally protects the structure from the forces of underground heaving of soils of any complexity. It is both an insulator and a waterproofing agent. The main habitat in the Russian Federation is located on wet and swampy soils, so XPS insulation is especially popular for this type of work. The only “competitor” of the material in foundation insulation is polyurethane foam, but it seriously loses in cost, and due to its manufacturability, it cannot be installed by hand. Here extruded polystyrene foam is the undisputed market leader.

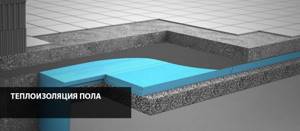

Thermal insulation of floors of the first floors in private and industrial construction. Insulating the floor of the first floor has two main goals - insulation of the floor and its hydro-vapor barrier from moisture flows rising from the ground or basement. With the use of XPS, the insulated floor will achieve maximum strength.

Insulation of the facade. External thermal insulation of walls can be performed using the “wet” method, as well as using the method of ventilated frame construction for siding cladding.

Insulation of roofs, mainly inversion ones. Since the material does not absorb moisture, it is an acceptable solution for flat roof load-bearing structures.

Insulation of walls from the inside is usually carried out in high-rise apartments when it is impossible to carry out external insulation. In this case, it is necessary to take care of installing a reliable supply and exhaust ventilation system, since the vapor permeability of the material is close to zero.

The durability of XPS insulation is estimated at 50 years when used at temperatures from −50°C to +75°C. Its reasonable cost makes it an affordable insulation material for most Russians.

Main characteristics and properties

Houses or apartments insulated with xps polystyrene can reduce costs during the heating season and improve the thermal insulation of the room, preventing the appearance of dampness and mold on the walls.

Color

Silver polystyrene foam with carbon has higher thermal insulation properties.

In technical documentation, the standard color for polystyrene foam boards is white.

But if for insulating a house it is necessary to choose a material with higher thermal conductivity properties, preference should be given to silver insulation boards, which contain nanographite, which is responsible for improving the qualities of the material.

TECHNONICOL fasteners

TECHNONICOL fasteners No. 01 and No. 02They are polymer toothed spikes with a self-adhesive upper part (protected with a special film for convenience). Designed for fastening TECHNONICOL XPS insulation boards and membranes to various bases. |

Telescopic fastenerIt consists of a tubular rod with a diameter of 1 cm with a narrowing at the end and a flange with a diameter of 5 cm. High-quality polymers are used in production, thanks to which the fastener is particularly strong and durable. |

TECHNONICOL self-tapping screwsMade from high-carbon steel C1022, they have a unique ELECTROPOLYSEAL coating (patented development of the American company PPG IndustrialCoatings), which prevents corrosion. Diameter – 0.48 cm. Used with disc fasteners. |

Areas of application of extruded polystyrene foam

Thermal insulation has a wide range of applications. The high strength characteristics of insulation are its main advantage and allow it to be used not only as a material for thermal insulation, but also as a building material.

Insulation of the apartment

- Balcony insulation

- Creating a “warm floor”

- Thermal insulation of walls

- Insulation of floors

Insulation of a private house/cottage

- Foundation insulation

- Insulation of the base and blind area

- Insulation of indoor walls (including balconies)

- Insulation of pitched roofs

- Insulation of floors of interfloor ceilings and the first floor

- Creating a “warm floor”

- Insulation of flat roofs of low-rise buildings, cottages

Insulation in industrial and civil construction

- Thermal insulation of the foundations of multi-storey buildings and other civil and industrial facilities

- Thermal insulation of flat roofs of multi-storey buildings and other civil or industrial facilities

- Thermal insulation of facades and plinths

- Thermal insulation of loaded floors with increased requirements for the strength of the thermal insulation layer

- Stylobate structures

Insulation of roads and bridges

- Thermal insulation of the bases of transport structures

- Thermal insulation of the foundations of railway structures

- As expansion joints in concrete or to protect waterproofing (on railway bridges)

- Thermal insulation device to prevent thawing of permafrost soils

Minuses

Despite all the advantages of the unique insulation, it is necessary to pay attention to its disadvantages. Caution should be exercised when XPS comes into contact with certain types of varnish, acetone or drying oil. These substances can not only damage the surface of the insulator, but also completely dissolve it.

Also, the insulation is easily susceptible to the influence of products obtained through the distillation of petroleum and the influence of some alcohols. That is why you should pay special attention to the composition of the adhesive mixtures with which you plan to attach the insulator. It is important that they do not contain ethyl acetate, petroleum toluene, coal tar or its derivatives.

During prolonged use in air, extruded polystyrene foam undergoes oxidation, although modern industry is gradually reducing all negative aspects to a minimum.

Thermal conductivity

The main characteristic of the material is thermal conductivity. To verify this indicator, it is recommended to request the corresponding document from the seller. By comparing product certificates, you can choose the highest quality and most reliable insulation. It is almost impossible to evaluate this characteristic visually.

Experts identify the optimal value of thermal conductivity, which is about 0.030 W/m-K. This indicator may vary up or down depending on the type of finish, quality, composition and other aspects. Each manufacturer adheres to certain criteria.

Range

On the building materials market you can find polystyrene thermal insulator XPS from different manufacturers. The most popular products are Ursa, an American brand Dow.

TechnoNIKOL offers a fairly wide range of extruded polystyrene foam. This includes Technoplex slabs used to insulate balconies, loggias, partitions, as well as a large number of different insulation products from the Carbon line. The Carbon series includes materials intended for professional builders (Prof), for insulating private houses and cottages (Eco), for thermal insulation of roads, floors with high loads (Solid), and also used as the main layer in various thermal insulation panels (Sand) .