Polyurethane foam (rigid polyurethane foam)

The material is a type of gas-filled plastic . 85-90% consists of an inert gas phase . Polyurethane foam is a synthetic insulation material with a cellular structure.

Technical properties:

- Thermal conductivity - 0.019 - 0.035 W/m*K.

- Density - 45-60 kg/m3.

- Water absorption - 1.2-2.1%.

- Destructive - 0.15-1 MPa (compression) and 0.35-1.9 MPa (bending).

- Number of closed pores (85-95 or more).

- Flammability is a category of low-flammability substances.

Polyurethane foam is used for thermal insulation of residential and industrial buildings . The product fits tightly to horizontal and vertical flat surfaces. Replacement of material is not required throughout the entire life of the building. Polyurethane foam is suitable for thermal insulation of floors, walls, and ceilings.

The minimum service life is 25-30 years . Chemical reagents (solvents, softeners, mineral oil, fuel, acids, alkalis) cannot destroy the structure, since the cells in it are closed. The product is resistant to rodents and insects, the development of fungus, mold and microbes. No foreign elements penetrate into the structure.

Tips and tricks from professionals

All about artificial leather (leatherette): differences, disadvantages and advantages, care

Despite the fact that polyurethane foam appeared on the Russian market relatively recently, professionals have managed to thoroughly study its properties and features of use.

They give some advice to novice masters:

- If a section of insulation is damaged, it must be cut out with a sharp knife and foamed again.

- To ensure that polyurethane foam lasts at least 30 years, it is protected from ultraviolet radiation. To do this, you can use polymer mastic or polyurea.

- For self-spraying PU foam on a small surface area, you can use disposable installations. Today they can be found in large construction stores. They will be much cheaper than professional equipment.

Polyurethane foam is a modern safe material with excellent thermal insulation properties. It is universal, suitable for processing any surface. Spraying polyurethane foam is a complex process, so it is better to entrust it to specialists.

Foam rubber (elastic polyurethane foam)

In terms of properties, foam rubber is as close as possible to plastics and rubbers. Elastic polyurethane foam has the following characteristics:

- High strength.

- Resistant to chemicals and aggressive environments.

- Plasticity, flexibility.

- Environmental friendliness, safety.

- Low thermal conductivity.

- Poor moisture absorption.

- High resistance to mechanical and physical stress.

- Poor shrinkage during use.

- Rapid restoration of the original shape after removal of the load.

Technical characteristics may vary depending on the addition of additional components during production (dyes, fillers, foaming agents).

The structure is not susceptible to the proliferation of rodents, insects, and microorganisms. Recyclable.

Release of harmful substances

Even with European safety markings, the compositions emit organic volatile substances, which is associated with the constant flow of chemical processes even in finished polyurethane.

Mattresses based on orthopedic foam are equally suitable for children and adults and are not contraindicated in people with allergies, while coconut fiber and latex, that is, natural bases, do not have such parameters. And the foam is not inferior to them in elasticity, which guarantees uniform body support and effective muscle relaxation. The advantages of orthopedic foam include:

- Practicality and reliability. No dents form on the surface under severe loads. Children are unlikely to damage the structure.

- Safety. The polymer material has the advantage of good environmental safety. During operation, it does not emit toxic components and cannot smell unpleasant. No adhesives are used in production, so you can purchase an orthopedic foam mattress for a children’s bed without hesitation.

- The material does not retain odors , does not absorb moisture and is simply cleaned of dirt.

The production of any brand of orthopedic foam, including “memory” varieties and artificial latex, is carried out in approximately the same order. Polyester and water are mixed in the chamber. The reaction between them leads to the release of a significant amount of carbon dioxide. Its molecules foam the mass with the formation of bubbles. The more of them there are, the more breathable and elastic the final product will become. At some enterprises, special catalysts can be added to speed up the reaction, and emulsifiers can be added to create a more uniform structure of the material. In addition, two or three polyesters can be used simultaneously.

General properties

Polyurethane foam and foam rubber belong to the large chemical group of polyurethane foams . They are produced on the basis of polyesters . When properly manufactured and used, the materials are completely environmentally friendly and safe for living organisms.

Polyurethane foams are widely used in various fields of activity, depending on the composition, technical characteristics and shape. The material is most in demand in everyday life, construction and industry.

General technical characteristics:

- Density - 30-300 kg/m3.

- Temperature range - from -60 to +80 °C.

- Non-conductivity of electric current.

- Light weight.

- Ozone resistance.

- Resistance to chemical reagents (acids, alkalis, solvents, etc.).

- Breathability.

- Low resistance to torsion.

In production, 3 main casting technologies are used:

- Rotary - coating of large objects and cylindrical elements.

- Free - creating complex heavy forms.

- Under pressure - used for large-scale production of parts.

The chemical composition prevents the proliferation of insects, rodents and the development of microorganisms.

d_kalinin

There is an opinion that if foam rubber is used as a filler for upholstered furniture, then the service life of such furniture is much shorter than if the filler is polyurethane foam! Is this really so?

Does the person who asks the question: “What’s inside your sofa – foam rubber or polyurethane foam?” know what this foam rubber and polyurethane foam are? Probably no. You will ask why?

Because foam rubber and polyurethane foam are one and the same.

The word foam rubber originates from the times of the USSR. In the Soviet Union, polyurethane foam, used for the manufacture of upholstered furniture, and not only, was mainly from a Scandinavian company called “ Porolon” , which is where the common noun foam rubber came from.

Distinctive characteristics

- Manufacturing basis . Elastic polyurethane foam is produced using polyesters of a linear or slightly branched type of structure. As a rule, the finished material has an open-pore structure. To produce rigid material, highly branched polyesters are used, forming polymers with a high degree of cross-linking. The structure of the product has closed pores. For additional properties, glass fiber, glass mats and other additional components are added to the composition.

- Elasticity . Elastic polyurethane foam retains its shape much better after twisting and stretching. The material quickly returns to its original state after exposure to external forces. Elastic polyurethane foam is the most flexible building product in use.

- Density _ The average rate of rigid polyurethane foam is 45-60 kg/m3, elastic - 8-20 kg/m3. With equal thickness, the density of the foam is higher. When creating general characteristics, you will have to spend three times more elastic material than rigid material, which is uneconomical.

- Characteristic technical characteristics . Elastic polyurethane foam has high thermal insulation and sound insulation. The material is characterized by dielectric and shock-absorbing properties. The product adheres well to wood, metal, fabric and paper surfaces. Rigid polyurethane foam has high electrical insulation and low moisture absorption ability.

- Price . Elastic material is cheaper than rigid polyurethane foam. When choosing a product, you need to pay attention to the technical characteristics and properties, and not to the cost. Each material has its own scope of application. Only in some cases can they be replaced with each other.

How to choose a quality polyurethane foam mattress

Choosing a polyurethane foam mattress is not at all as difficult as it might seem at first glance. First, you need to make it a rule not to buy such products in dubious stores and spontaneous markets. Here you will not be shown product certificates, and the quality of the goods will be too far from perfect. Even foam mattresses that are quite normal at first glance can soon reveal their shortcomings.

Let's get acquainted with the characteristics

When buying a foam mattress, you need to carefully read the characteristics of the selected sample. Here we are interested in elasticity and resistance to deformation. Good elastic mattresses will be able to demonstrate their excellent orthopedic properties - you will be able to feel the elastic rigidity of the surface. It would be nice if the store showed you the padding of the selected mattress and let you test the mattress in practice (in some stores you can evaluate the product by simply lying on it).

Hardness level

It is better to avoid super-soft mattresses, as they do not promote comfortable sleep. It is best to give your preference to mattresses of medium and high hardness . It’s much more comfortable to sleep on them, although at first glance you wouldn’t be able to tell – after a soft base, such foam mattresses seem quite hard. But in the morning you feel sleepy and collected, which indicates the excellent orthopedic properties of the selected sample.

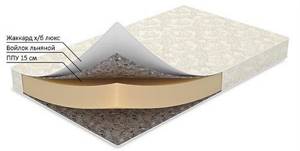

Foam mattresses with combined padding have good properties. For example, two materials may be found inside at once - coconut coir and foam rubber. There are also more complex combinations; such mattresses are quite expensive, but can boast of good characteristics.

Scope of application

You need to choose a material based on the required properties . Polyurethane foams have been used in various fields of activity for a long time. Specialists know in which case the material is needed.

Float-type objects, mechanical supports, and heat-insulating elements with a wide temperature range are made from elastic polyurethane foam. Foam rubber does not change its properties upon contact with liquid nitrogen and heated elements at temperatures up to 120 ° C. Thanks to the open pores, various household items are made from the material (sponges, pillows, seats, soundproofing systems, etc.).

Rigid polyurethane foam in aircraft, automobile and ship construction. Poor water absorption is used to produce unsinkable boats, pontoons and other elements. The material produces heat- and vibration-resistant systems with permeability to electromagnetic waves.

Repair and constructionComment