No. 2. Mineral wool for attic insulation

Mineral wool can easily be called one of the most popular thermal insulation materials, and if we talk about attic insulation, then it can easily be given the palm. It is worth remembering that mineral wool can be different, and its properties differ depending on the raw materials used: slag wool is made from blast furnace waste, stone wool is made from rocks, most often from basalt (which is why the name basalt wool is also assigned to it), glass wool is made from glass waste or siliceous rocks. Slag wool is practically not used in private construction, glass wool is used, but not often, and stone wool is most widespread, so it is usually understood as mineral wool.

Stone (basalt) wool for the attic

Stone wool, due to its fibrous structure, has a number of undeniable advantages:

- excellent thermal insulation qualities, the thermal conductivity coefficient of the material is approximately 0.035-0.045 W/m•K;

- excellent soundproofing qualities, so if you plan to arrange a nursery or bedroom on the attic floor, this is an excellent option;

- fire resistance. The material easily tolerates heating up to 550-600C or more, because it is based on stone;

- ease of use. It is not difficult to install slab or roll mineral wool, and there is no need to use special protective equipment - the material does not contain thorny fibers, which are so dangerous when working with glass wool;

- mildew resistance;

- good vapor permeability;

- low price.

Among the disadvantages:

- the ability to absorb moisture, so the installation of reliable waterproofing is strictly necessary, which somewhat complicates the work;

- Rodents can live in mineral wool, which, naturally, will not have a very good effect on thermal insulation. Mice do not live only in a layer of expanded clay insulation, foam glass and polyurethane foam, so in other cases it is necessary to carefully seal the technological holes and take measures to eliminate rodents.

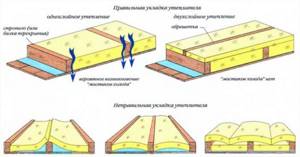

Stone wool is available in slab and roll formats. To insulate the inclined walls of the attic, slab material is better suited: it will need to be cut and inserted into the holes between the floor beams. Rolled material is not as durable and is better suited for insulating horizontal surfaces. It is recommended to use two-layer insulation with mineral wool: slabs are laid between the rafters, and roll material is attached on top of them. In this way, it is possible to minimize the risk of cold bridges. Separately, it is worth noting loose basalt insulation: it is suitable for the most inaccessible places, but it is applied using special equipment.

Glass wool

Glass wool is cheaper than stone wool, but is used infrequently due to inconvenience in work. Since the material is produced from glass waste, it contains small sharp particles that can easily injure the skin and respiratory tract. However, if you work with glass wool in compliance with all the rules of personal protection, you can insulate the attic inexpensively and efficiently. The main advantages of the material include:

- excellent heat and sound insulation properties. Thermal conductivity coefficient 0.030-0.052 W/m K;

- high strength and elasticity;

- fire resistance. Glass wool can withstand heating up to 450C without changing its properties;

- low price.

How to calculate the required insulation thickness yourself

The optimal thickness of the layer of insulation material depends on the climate zone, the area of the attic, and the thermal conductivity of the insulation. You can calculate it yourself using the formula.

δut=(R-0.16-δ1/λ1 -δ2/λ2 -δi/λi )×λut

Wherein:

- R-0 – coefficient of thermal resistance depending on the climatic zone;

- δth – insulation thickness;

- δ1,2..i – thickness of the attic structure in meters;

- λ1,2…i – thermal conductivity coefficient of construction materials;

- λth is the thermal conductivity coefficient of the insulating material.

If mathematical calculations are not your thing, you can determine the required thickness of the insulation layer based on its thermal conductivity coefficient.

| Insulation | Thermal conductivity coefficient W/(m °C) | Insulation layer thickness in mm |

| Styrofoam | 0,05 | 195 |

| Extruded polystyrene foam | 0,03 | 115 |

| Mineral wool | 0,04 | 155 |

| Glass wool | 0,047 | 185 |

| Stone wool | 0,044 | 170 |

| Ecowool | 0,04 | 155 |

| Polyurethane foam | 0,03 | 115 |

| Penofol | 0,045 | 175 |

[Table of recommended insulation layer thickness]

I had a sad experience when, in order to save money, I decided to insulate the top floor with a gable roof with 5 mm polystyrene foam in 2 layers. I realized my mistake when the temperature outside dropped to -15 °C. It was cool in the attic, and condensation appeared on the surface of the walls and ceiling. Soon dark spots appeared on the surfaces and fungus appeared.

Since the finish was plasterboard, I just had to remove it and throw it away. And in the spring, dismantle the entire insulation structure and bring the thickness of the insulation cake to the required thickness. Don't repeat my mistake, don't skimp on the thickness of the insulation.

Attic insulation

If the attic floor has been equipped correctly, it remains warm in winter and cool in summer. There are no problems with high humidity here. Icicles do not form on the roof. As with insulation, vapor and waterproofing are a necessity. This is a complex solution in which one without the other either does not work at all or does not function well enough.

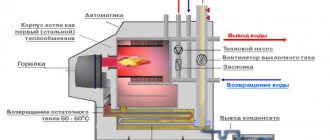

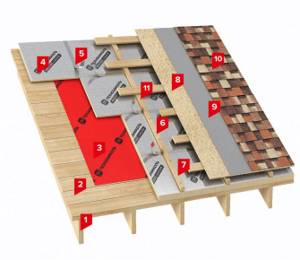

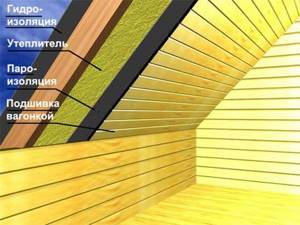

When the sloping roof acts as the walls of the attic floor, the following layer is formed in the direction from the inside to the outside:

- lining or drywall used as internal lining;

- sheathing;

- vapor barrier;

- insulating material selected in accordance with the climatic conditions of a particular region;

- superdiffusion membrane;

- ventilation gap;

- sheathing;

- roof covering.

What is the purpose of placing a superdiffusion membrane above the insulation? It is necessary to prevent condensation or precipitation that has leaked through the roofing from entering the insulation. At the same time, it removes steam that for some reason got into the mineral wool. Thus, he ensures its drying. The optimal material is with a vapor permeability of 1500 g/m2. This layer is often designated as waterproofing, but it allows steam to pass through.

How to properly insulate an attic

The insulating structure is a kind of pie of several tiers, where each layer performs its own function. Let's figure out why insulation consists of several layers and what they are needed for.

Waterproofing

The first layer is a waterproofing membrane. It is this that will protect the insulation from moisture penetration. It cannot be laid without waterproofing protection. Moisture from the roof will get onto the insulation, and wet insulation loses its protective properties, freezes and collapses.

Thermal insulation

High-quality thermal insulation will retain heat inside the room in cold weather and prevent overheating of the air in the attic in the summer. In addition, the insulation performs the function of noise protection. The optimal insulation thickness for most regions of Russia is 20 cm.

Vapor barrier

The purpose of a vapor barrier is to prevent steam generated as a result of vital activity from penetrating into the inner layer of the insulating cake. And also prevent insulation components from getting inside the room.

Insulation of attic floors and walls

Mineral wool must be protected from moisture.

This process is very similar to roof insulation:

- We lay a vapor barrier or a layer of bitumen-impregnated paper on the boards between the rafters, which will keep mineral wool particles from slipping through the support and getting into the air of the lower floors;

- then we line the heat insulator itself in two layers with a total thickness of 15-20 cm;

- If necessary, we nail additional blocks on top to increase the height of the rafters. We place a waterproofing layer on them and cover everything with boards (subfloor).

It is important to note that floor insulation also needs to “breathe”. Therefore, a vent of 3-5 cm is maintained between the top film and the floor, and a gap of 10-20 mm is left between the floor and the wall at two opposite edges of the room.

Thus, insulating a country attic from the inside with mineral wool with your own hands will be as effective and durable as possible. Interesting article: “Insulating a bathhouse with mineral wool.”

Also, if possible, it is recommended to lay the vapor barrier overlapping the walls downwards (that is, the ends are lowered along the walls of the lower floor and plastered). This will prevent any steam from penetrating into the mineral wool and damaging it. The walls, if necessary, are insulated in the same way. Only in this case, depending on their density and thickness, the thermal insulation layer is reduced and the external waterproofing film is removed.

How to insulate the inside of an attic roof with foam plastic

If there is a non-residential space under the roof, only the floors need to be insulated. But when it comes to residential space, it will require serious work. For attic insulation, polystyrene foam is best suited. Installation of foam plastic is carried out in several stages:

- Wooden floors are treated with antiseptics. All cracks are hermetically foamed or sealed with silicone glue;

- The entire area is covered with a waterproofing layer;

- They make a sheathing from wooden beams, in steps the width of the slab;

- Lay polystyrene foam over the entire area, while carefully monitoring the appearance of cracks or gaps that may allow cold air to pass through. Lay out the slabs in a checkerboard pattern in two layers so that the joints of the bottom are covered by the top;

- A vapor barrier is laid on top of the insulation;

- At the end, the entire structure is covered with finishing material.

Before starting work, be sure to calculate the required amount of material, taking into account the double layer coating.

Foam plastic for roof insulation

Insulating the roof is an important step in building a house. The warmth of the residents depends on it. Therefore, you need to choose exactly the material that is suitable for a specific type of roof, providing it with reliable protection. To avoid unnecessary expenses, you need to calculate the costs of materials in advance.

How to choose insulation?

The first step should be the proper selection of materials. Choosing roof insulation is not as simple a task as it might seem. The choice of thermal insulation on the market is huge, but you need to choose one for the attic that will ensure a stable level of humidity in the room and no sudden temperature changes.

The best insulation should have the following qualities:

- low thermal conductivity, that is, high heat retention;

- low hygroscopicity, that is, resistance to moisture absorption - wet insulation significantly loses quality;

- the absence of toxic components and environmental friendliness - after all, we are talking about a residential area;

- Fire safety.

In this case, the thermal insulation material for the roof must be vapor-permeable, that is, it must not interfere with the free escape of water vapor from the room. If this requirement is neglected, the result will be an accumulation of condensation and a “bathroom” atmosphere in the room. This in itself is not very pleasant, not to mention the dangers of dampness for the attic walls and ceiling.

Another important condition is that the material for insulating the attic roof must adhere well to inclined surfaces and not deform over time. Finally, it must also meet the requirements of sound insulation - if this point is left unattended, then during heavy rain or, especially, hail, the top floor will be unusable

Considering that metal tiles or metal corrugated sheets, which are now most often used as roofing, not only perfectly conduct sound, but even amplify it, you will not be able to sleep, talk or watch TV when something is knocking on the roof.

What do the professionals recommend?

To choose insulation for an attic roof, you will have to study the many materials that the modern market offers. Almost all insulation materials have their advantages and disadvantages - for example, ordinary polystyrene foam, valued by many for its low cost and ease of processing, is bad because it is not “transparent” enough for moisture rising from the room along with the air. In other words, it is better not to use it for rooms where you plan to stay for a long time, for example, bedrooms.

Glass wool is traditionally used as insulation, but at the same time it cakes quite quickly and loses its shape, and with it its thermal insulation qualities. The main disadvantage of polyurethane foam, which is becoming increasingly popular, is its inability to withstand fire, as well as its rather low vapor permeability. In addition, this material requires scrupulous preliminary calculations - the fact is that when hardening, its structure expands, which is why the entire structure can “crawl”. It is necessary to take into account the strength of load-bearing elements with utmost precision.

The best way to insulate an attic roof is something everyone decides for themselves, based on their capabilities and the intended purpose of the room. From the point of view of many experts, one of the best roofing thermal insulation can be called basalt slabs - this material is durable and elastic, retains heat well, does not lose its qualities during operation and is not prone to moisture accumulation. Another undoubted advantage is ease of installation. This is due to the fact that basalt slabs have an optimal width for fastening between the rafters and do not have to be cut to the required size.

Which insulation is best for an attic?

The attic superstructure requires a special approach to its insulation and careful selection of material. If the main walls themselves are to some extent insulated, then any roof does not have sufficient thickness to become a reliable barrier to the cold.

Which insulation is best for the attic?

Therefore, it is necessary to know exactly which insulation is best to choose for the attic, and how to use it to make the room suitable for living in at any time of the year.

Insulation for the attic

Due to the design features of the attic room, heat loss in it is always increased compared to rooms located behind the main walls. In addition, the attic does not have a thermal “cushion” on top, the role of which is played by the attic of each house. So, we can conclude that the walls and roof of the attic are most susceptible to freezing in winter, which is why it is necessary to choose the right insulation and calculate its thickness.

The attic always needs particularly high-quality insulation

The most popular insulation materials that are fixed directly under the roof are: polystyrene foam (regular foamed or extruded), polyurethane foam, ecowool made from cellulose, as well as all types of mineral wool.

It is these insulating materials that are well fixed between the sheathing or adhere to the inner surface of the roofing material, and turn a cold attic into a warm room suitable for use.

In houses located in cold regions, this material must be laid in two or even three layers. Sometimes, in combination with one of the insulation materials, infrared film is used, which is fixed to the walls of the attic and this additional heating is turned on as needed.

Criteria for choosing insulation

When choosing a material, you need to take into account many characteristics that determine both the efficiency and safety of the thermal insulator:

- The insulation must have minimal flammability and low thermal conductivity.

- The density of the material should not be too high, otherwise its thermal conductivity increases and the attic structure becomes heavier, which is extremely undesirable, since the load on the load-bearing walls of the building increases.

- Installation of insulation should be simple, and the service life should be comparable to the durability of the entire roofing structure.

- The environmental friendliness of the material is one of the main criteria when choosing it - it should not emit unpleasant odors and not decompose into any substances hazardous to human health.

For ease of comparison, some physical properties of common insulation materials are summarized in the following table:

| Properties of insulation material | Thickness in mm. | ||||||||

| 50 | 60 | 80 | 100 | 120 | 150 | 200 | 250 | ||

| Density kg/m3 | Mineral wool | 100 — 120 | |||||||

| Expanded polystyrene (foam) | 25 — 35 | ||||||||

| Polyurethane foam (sprayed) | 54 — 55 | ||||||||

| Ecowool (cellulose) | 40 — 45 | ||||||||

| Thermal resistance m²×°C/W | Mineral wool | 1.19 | 1.43 | 1.90 | 2.38 | 2.86 | 3.57 | 4.76 | 5.95 |

| Expanded polystyrene (foam) | 1.35 | 1.62 | 2.16 | 2.70 | 3.24 | 4.05 | 5.41 | 6.76 | |

| Polyurethane foam (sprayed) | 1.85 | 2.22 | 2.96 | 3.70 | 4.44 | 5.56 | 7.41 | 9.26 | |

| Ecowool (cellulose) | 1.75 | 2.08 | 2.74 | 3.50 | 4.20 | 5.26 | 7.20 | 9.01 | |

| Thermal conductivity coefficient W/m²×°С | Mineral wool | 0.042 | |||||||

| Expanded polystyrene (foam) | 0.037 | ||||||||

| Polyurethane foam (sprayed) | 0.028 | ||||||||

| Ecowool (cellulose) | 0.038 | ||||||||

| Weight kg/m2 | Mineral wool | 15.2 | 15.8 | 17.6 | 20.9 | 23.2 | 26.7 | 32.4 | 38.2 |

| Expanded polystyrene (foam) | 9.8 | 10.0 | 10.5 | 11.0 | 11.5 | 12.3 | 13.5 | 14.8 | |

| Polyurethane foam (sprayed) | 11.2 | 11.7 | 12.8 | 13.9 | 15.0 | 16.6 | 19.3 | 22.0 | |

| Ecowool (cellulose) | 12.1 | 12.5 | 13.7 | 14.4 | 16.4 | 17.9 | 20.5 | 24.5 | |

Features of insulation materials for the attic

To understand in more detail the properties of each of the insulation materials, you need to look more closely.

Foam plastic (expanded polystyrene)

- Expanded polystyrene has a fairly rigid structure, consisting of individual foam fragments tightly connected to each other. But if you look at the volumetric content, this material contains only 2.5% polystyrene and 97.5% air. Therefore, when it is used, it is the air layer created by this insulation that prevents the cold from penetrating into the room.

Inexpensive, but still not the best insulation - polystyrene foam

- Expanded polystyrene is produced in slabs of different sizes, thicknesses and densities. The slabs can have dimensions of 1000 × 2000, 1000 × 1000, 1000 × 500 mm, and thickness from 20 to 1000 mm.

- The material has not only high thermal insulation qualities, but also good noise absorption, and it will be enough to cover the wall with slabs having a thickness of 30 ÷ 50 mm to ensure a high sound insulation effect.

- When insulating an attic, given the small thickness of the walls, foam plastic will be required of the greatest thickness; only in this case can the necessary heat and sound insulation be created. In this case, it is necessary to take into account compliance with installation technology.

- Expanded polystyrene has a low hygroscopicity rate, that is, it practically does not absorb moisture.

The material is very easy to install

- Properly installed polystyrene foam does not deform for a long time, withstanding quite large loads.

- Expanded polystyrene shows good resistance to aggressive environments and will last a long time if covered with finishing materials.

- However, this insulation is destroyed when exposed to ultraviolet rays, various solvents and other aggressive chemical compounds.

- No harmful microorganisms appear inside this insulation, since the material is not a favorable environment for their development. However, if its surface is significantly contaminated, fungal colonies may form on it.

- Lightweight foam plastic is easy to install. It will not cause problems in cleaning after its installation is completed. The material can be cut without problems with a sharp knife, and sometimes the cutting tool is heated to make the cut more even.

- Polystyrene foam is safe under normal conditions, but over time and with frequent heating, it begins to release substances harmful to humans.

Calling expanded polystyrene fireproof is not possible

- Expanded polystyrene ignites when exposed to an open flame, and when burned it melts and emits a large amount of smoke containing very toxic substances that can be dangerous not only to health, but also to human life.

The attic is precisely such a place, which first of all falls under the rays of the sun, which heat up the roof quite strongly. And this can lead to a rapid loss of the foam’s thermal insulating properties. Therefore, it is better to use it to insulate stone walls, reliably closing it from external influences, and to find a more acceptable option for the attic.

Mineral wool

Mineral wool is a material familiar to everyone, which has been used for many decades and has proven itself as a reliable and convenient insulation material. It is produced from different raw materials, so its characteristics also vary. Mineral wool is divided according to the material of manufacture into slag, stone, basalt and glass. Each of them has its own parameters: thickness and length of fibers, load resistance, heat resistance, thermal conductivity, and hygroscopicity.

Mineral wool is one of the most popular insulation materials

To learn more about the properties of all types of material, you need to consider each of them, since the table presents only average indicators.

Stone wool

Stone wool is the best of all others in terms of environmental friendliness and safety

- This type of mineral wool has fibers up to 16 mm long and 3 to 12 microns thick. The characteristics of this type of insulation are the best for insulating residential premises, therefore it is most often used for installation in the attic.

- The thermal conductivity of stone wool varies from 0.076 to 0.12 W/m×°C.

- The maximum heating temperature is 550-600 degrees.

- Stone wool is the most comfortable for work, compared to slag or glass wool - its fibers are not sharp and do not injure the skin and mucous membranes.

A type of stone wool can be loose basalt insulation. It has no binders and is therefore not produced in slabs or rolls. Mats are stuffed with loose wool, or it is poured onto horizontal planes and compacted to the required thickness. Due to the fact that the material does not contain melting substances, such cotton wool can withstand temperatures up to + 900-950 degrees. The main parameters - the thickness and length of the fibers, insulation abilities - are the same as those of ordinary stone wool. Basalt insulation can be called the safest of all mineral insulation materials.

All types of such mineral insulation tend to soundproof a room well. This quality is especially characteristic of basalt material. In addition, this material is the only one of all that does not contain phenol-formaldehyde resins, so it is absolutely safe for human health.

Glass wool

- Glass wool fibers have a length from 13 to 45 mm and a thickness from 4 to 16 microns. They have good elasticity and strength.

- Glass wool has a fairly low thermal conductivity, which is 0.029-0.050 W/m×°C.

- This insulation can withstand high temperatures of no more than +450, and low temperatures - up to -55-60 degrees.

. Glass wool is the most affordable, but to work with this material, it is necessary to take safety measures, since its microscopic fibers can get into the mucous membranes of the respiratory organs or eyes and cause serious damage. Therefore, having chosen glass wool for insulation, you must definitely purchase a respirator, safety glasses, gloves and a suit that will not leave areas of the skin exposed.

Slag

Slag - inferior in efficiency and, in addition, may be undesirable for metal parts of the structure

- The length and thickness of slag wool fibers is identical to the fibers of stone insulation, but the maximum temperature for it is no more than 300 degrees. At temperatures exceeding this limit, the substance that binds the fibers begins to melt, which leads to loss of heat and sound insulation functions of the premises.

- The material is hygroscopic, therefore it is suitable only for internal insulation work and requires very reliable waterproofing.

- The disadvantage of this insulation is the blast furnace slag included in its composition, which, when the material is moistened, reacts with metal elements and can lead to their gradual decomposition. Therefore, if slag wool is chosen for insulation, then it is recommended to abandon the metal profile for sheathing the attic.

- With good waterproofing, the thermal conductivity of slag wool varies between 0.046-0.048 W/m×°C, and in principle the material can be called quite suitable for insulation work in an attic superstructure.

- Do not forget that to work with slag it is necessary to have protective devices, since its fibers can harm the skin and mucous membranes, just like the components of glass wool.

Mineral wool is considered a non-flammable material, but this is not entirely true. The material can sometimes ignite at critical temperatures, although with a tendency to extinguish on its own. This factor largely depends on the quality of the material produced - in particular, on the amount of possible organic impurities and binders.

High-quality mineral wool is almost impossible to light

Despite this, mineral wool is considered the best option for attic insulation due to its pronounced positive qualities and relative cheapness.

Ecowool

- Ecowool is made from cellulose and does not contain adhesive components, therefore it is a 100% environmentally friendly material.

Ecowool - a product of cellulose processing

- Cellulose is produced from wood, so ecowool has the natural insulating properties inherent in natural wood. As you know, such materials retain heat many times better than synthetic types of insulation. Therefore, in a room with walls on which this insulation is installed, heat is better retained in extreme cold and cool in the summer heat.

- The insulation consists of 80% cellulose, 12% fire retardants, and 8% antiseptic non-volatile agents such as boric acid.

- Since the material has a loose capillary-porous structure, and also due to its components, rodents, insects, and various microorganisms do not take root in ecowool.

- The presence of fire retardants in the material allows it to have a degree of moderate flammability, that is, it is very difficult to ignite in an open, directed flame and, at the same time, has the property of self-extinguishing.

Ecowool is very difficult to ignite and self-extinguishes very quickly

- When insulating ecowool walls, you can refuse to use a vapor barrier membrane, since there is no risk of condensation due to the fact that the insulation is a “breathable” material. Even with slight moisture, it does not increase in size and does not lose its heat-insulating properties, and besides this, it dries quickly.

- Another advantage of ecowool is its affordable price, but the only difficulty in working with such insulation is its installation, which requires special equipment.

If you find the opportunity to use ecowool for insulating the attic, this will be the most ideal - reliable and completely safe option.

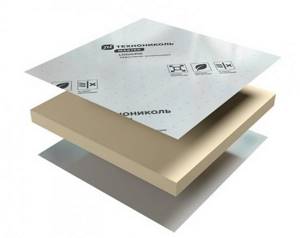

PIR boards

PIR boards are a modern, energy-efficient insulating material, actively used in Europe and Russia. This type of thermal insulation is hard, it is a slab with a porous structure, inside which all the microcells are closed and filled with air. The chemical structure of the material has strong and rigid chemical bonds. Thanks to this, the insulation is resistant to both physical and chemical influences. By the way, PIR is similar in chemical composition to polyurethane, but it is a completely different polymer - polyisocyanurate.

TECHNONICOL PIR board with foil lining

There are not so many manufacturers of PIR boards in Russia. One of them is TECHNONICOL, well known to builders. The company produces a wide range of PIR insulation materials, aimed at use in a particular area of construction. There is even a special type of material for arranging roofs and attics - LOGICPIR Pitched roofing.

What's good about this material?

- Minimal water absorption. The material does not absorb moisture and does not rot even at high air humidity.

- Long service life - up to 50 years. Moreover, during this period the insulation will not lose its properties.

- Environmentally friendly. It is not hazardous to health and does not emit any harmful substances into the atmosphere.

- Easy to install. Markings on the surface of the slab, ease of cutting, low weight, and L-edge at the ends of each slab ensure quick independent installation and the creation of a continuous thermal insulation contour that does not have cold bridges.

- Aluminum coating on both sides. When insulating the roof with PIR boards, there is no need to install an additional hydro- and windproof membrane. If you carefully glue all the joints between the insulation elements, you will get a continuous waterproof layer that reliably protects the entire roof structure from moisture.

LOGICPIR Pitched roofing - the insulation is thin and will allow you to insulate the attic without reducing the amount of free space inside it. There is no need to be afraid of freezing - the energy efficiency of the material is high, since the thermal conductivity coefficient is only 0.022 W/m*K. Also, due to its light weight, this insulation does not create additional load on building structures.

On a note! TECHNONICOL has a whole roofing system - TN-SHINGLAS Attic PIR, which has been repeatedly tested in practice. By implementing this system, you can get not only excellent insulation of the attic, but also high waterproofing of the roof as a whole.

Prices for PIR boards

TECHNONICOL PIR boards Pitched roofing

Video: Installation of LOGICPIR attic insulation from TECHNONICOL

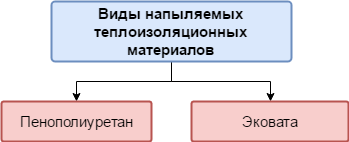

Polyurethane foam

This insulation is also often used to insulate attic rooms. Its installation is carried out using spraying, and this is one of its main advantages, since it creates a seamless, sealed surface. It is able to protect the attic superstructure from the penetration of wind and cold. From an operational point of view, sprayed polyurethane foam can be called the most effective material for heat and sound insulation:

Structure of hardened polyurethane foam

- Polyurethane foam covers absolutely all cold bridges that can be created by wooden sheathing elements.

- The material is lightweight, so it does not weigh down the structure of load-bearing walls, which means a thick layer of it can be applied to the surfaces of walls and floors.

- The endurance of polyurethane foam to temperatures varies between -155 and +210 degrees.

- A very important point in installation is that the surface to be sprayed on does not require any preparatory work.

- The service life of the insulation, if properly installed and covered with decorative material, will be fifty years or more.

- Spraying can be carried out on structures of various shapes, including very bizarre ones, which is convenient if, for example, a shaped roof is made in the attic in the form of a tent or arch. This is helped by good adhesion of polyurethane foam to any surface.

- The insulation provides good sound insulation to the room.

- There is absolutely no risk of condensation with proper ventilation.

However, polyurethane foam also has disadvantages. one of them

The first is the impossibility of installing insulation without certain, quite complex and expensive equipment.

Secondly, polyurethane foam cannot be called a completely non-flammable material. When it ignites, smoke is formed, which contains very dangerous toxic substances, which include poisonous gas such as hydrogen cyanide. In principle, in terms of the degree of danger in this regard, it is comparable to expanded polystyrene.

At high temperatures and an open flame, polyurethane foam can catch fire

Therefore, when preparing polyurethane foam, fire retardants are sometimes added to its composition. They will reduce the risk of fire, but if the material does catch fire, then these additives will only increase the amount of components released that are toxic to humans.

Prices for popular types of insulation

Insulation

Briefly about carrying out insulation work

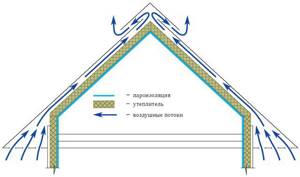

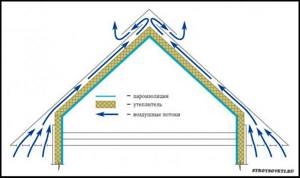

The need for air exchange for attic insulation

When insulating an attic room, it is necessary to take into account the provision of reliable ventilation. If material made in mats is laid, then an air gap is provided between the insulation and the finishing material. The size of this gap will depend on the roof covering. For example, if the roof is covered with one of the metal coatings, then the ventilation layer can be from 20 ÷ 25 mm. If you choose natural tiles or soft roofing for covering, the gap increases by one and a half to two times. When using sprayed insulation, ventilation holes are located in the eaves.

Insulation should not interfere with the free circulation of air under the attic roof

In the absence of good ventilation, there is a high probability of condensation settling on the insulation. Condensation occurs when there is a sharp difference in temperature indoors and outdoors, so it is very important to correctly calculate the thickness of the thermal insulation layer, which will not allow cold air from outside to come into contact with heated air indoors.

Installation of insulation material in mats (plates) or rolls

If material produced in mats or rolls, for example, polystyrene foam or mineral wool, is used for insulation, then it is necessary to use additional vapor barrier and windproof elements of the insulation system.

Windproof film is necessary to protect against drafts, which contribute to heat loss in the room. Such a membrane is attached to the outside of the rafter system, and the familiar roofing material or ordinary dense polyethylene film is often used as this layer. Individual sheets of material are laid with an overlap of 200 - 250 mm and glued together with waterproof tape. The film is attached to the rafters using brackets, and then a lath is placed on top of the rafters for attaching the roofing material or the base under it.

Windproof film

The spaces between the rafters will serve as niches for laying the first layer of insulation.

Laying a layer of mineral wool

Next comes the horizontal sheathing - its bars are attached at a distance from each other that will be equal to the width of the insulation mats.

In this case, exactly two layers of material are necessary, since the rafters can become bridges that conduct the cold.

If necessary, two layers of insulation are made, and then a mandatory vapor barrier layer is applied.

On the horizontal sheathing, after laying the second layer of insulation between its guides, a vapor barrier film is fixed, which will completely cover the insulation and become another barrier to the cold, but at the same time allow the insulation to “breathe.” It is also overlapped and glued with tape.

The joints of the film membrane are glued with special tape

Slats with a thickness of 20 ÷ 25 mm are fixed on top of the vapor barrier. They are mounted horizontally or vertically, depending on how the lining will be positioned, if the decorative finishing will be made with such material.

Video: insulating an attic space with mineral wool

Ecowool insulation

Installation of auxiliary materials when using ecowool for attic insulation requires a separate detailed study, since in this case there are some nuances. These issues are covered in more detail in a separate article on our portal dedicated to attic insulation technology .

It should be immediately noted that the windproof film in this case is fixed in exactly the same way as when insulating with materials in mats.

Next, ecowool is laid between the rafters. Its installation can be done wet or dry.

- Wet application of the material is carried out using special equipment that sprays material mixed with water and a special glue.

Ecowool is sprayed under pressure, so the material fills all the gaps and cracks, thus creating good heat and sound insulation.

Ecowool spraying under pressure

After spraying, excess material is removed using a special roller and at the same time leveled.

Leveling the surface of an insulated wall

Another installation option could be to fill closed wall or floor cavities with wet ecowool.

Filling the attic floor with ecowool

First, a vapor barrier film is attached and stretched to the walls from the inside, a hole is made in it, through which the space is filled with heat-insulating material - ecowool.

Filling an ecowool cavity in a wall

- The dry insulation method is excellent for laying ecowool on the attic floor. This method can be done manually or using the same equipment.

If insulation is done manually, the insulation is simply removed from the packaging and loosened. Then it is distributed between the floor beams and compacted. The thickness of the layer should be equal to the height of the floor beams.

However, it is better to install the insulation under pressure using special equipment.

Dry application of ecowool on the floor

Ecowool is covered with a vapor barrier film on top, and slats 20 ÷ 25 mm thick are placed on top of it on the beams - this lathing will create the necessary ventilation gap. After this, the floor covering is laid.

Video: “dry” method of applying ecowool

Spraying polyurethane foam

Polyurethane foam is increasingly used for thermal insulation of buildings both inside and outside. It is especially popular for frame buildings and attics.

The only hitch in carrying out the work yourself may be complex equipment for spraying polyurethane foam, without which it will simply be impossible to do. There is an option to rent a device from a specialized company, but this will also be expensive, not to mention buying it. In addition, you need to learn how to configure it correctly and have at least basic skills in working with it.

Spraying polyurethane foam on attic walls

Perhaps it will be easier and cheaper to invite a specialist who will do this work quickly and accurately. For small volumes, the process can be started and completed in one day.

Spraying can be carried out on any surface - smooth and rough, plywood, metal or even a dense vapor barrier film reinforced with rope weaving.

Sprayed polyurethane foam forms a seamless surface, while penetrating into all small and large gaps and sealing them hermetically.

PPU can be sprayed directly onto the inner surface of the roof and sewn on top with decorative material - this insulating layer will be sufficient if the building is located in a climate zone with mild or moderate winters.

Video: insulating the attic with sprayed polyurethane foam

So, each material has its own advantages and disadvantages. Of course, the price of insulation, the complexity or availability of its installation play a big role, but still the issues of thermal insulation efficiency and safety should come to the fore, so you need to focus on the material that will create the most comfortable atmosphere in the attic room and, at the same time, bring minimum damage to the health of the residents of the house.

Find out detailed information about which insulation is not chewed by mice from our new article.

What is more convenient: rolls or mats

In fact, the form in which this or that insulation is sold plays a big role for many ordinary people. Some people prefer to work only with slabs as they are more convenient, but for the majority, rolls seem rational: rolled out and secured, what could be simpler?

Roll insulation is also convenient because, with a standard distance between rafters of 61 cm, the roll can be easily cut in half with a regular knife, and its halves will fit perfectly into their niches - just roll them out:

But in practice, for many, packing rectangular slabs turns out to be less convenient, which leaves the most waste. But it is easier to transport, and the insulation in it does not bend, like in a roll, which is a critical issue for many materials:

Now imagine what happens to insulation in poor-quality packaging: moisture and water vapor penetrate the material through holes and slits (and this stuff is everywhere), the insulation gets wet in places and changes its geometry. On site, you unpack the roll or slabs and begin installation, and then it turns out that the insulation, swollen and heavy in places, does not fit together in any way, the cracks are visible even to the naked eye. Having somehow suffered, you cover all this stuff with clapboard or drywall - and that’s it! We don’t leave finished insulated walls unfinished, even for several hours - why? And as a result, not dried insulation ends up in a closed and dark space - an ideal place for the development of mold. The consequences are usually not at all pleasing to the eye, and you will recognize their presence by the unpleasant smell coming from underneath within a few weeks.

Sprayed materials

With sprayed materials, as I said above, you won’t be able to insulate an attic with your own hands. But they have one advantage over slabs - they are applied to the surface in a continuous layer. As a result, cold bridges are excluded, so their use also makes a certain sense.

Sprayed materials include the following insulation materials:

Types of sprayed materials

Option 5: polyurethane foam

Polyurethane foam is a polymer material that is sprayed in the form of foam. Like other polymer heat insulators, it has a cellular structure. Moreover, its cells are filled with gas.

The presence of gas inside the cells provides polyurethane foam with the lowest thermal conductivity

Advantages:

- Moisture resistance. This insulation for an attic roof does not require a vapor barrier;

- Strength. After hardening, it forms a “shell” on the surface that is resistant to mechanical stress;

Polyurethane foam adheres well to any surface

- Good adhesion. This allows you to spray polyurethane foam on any surface;

- Durability. Serves for at least 30 years;

- Fire safety. Fire retardants are added to polyurethane foam.

Flaws:

- Difficult to apply. Insulation must be carried out by qualified specialists. For such services, it is better to contact large companies without trying to save money;

- High price. This method of insulation is one of the most expensive;

- Toxicity. The foam has a strong toxic odor. True, after hardening the material is absolutely safe for health;

Liquid insulation is toxic

- Increased thermal conductivity. The gas eventually leaves the cells and they fill with air. This leads to a slight decrease in the efficiency of the insulation.

Characteristics:

| Properties | Basic values |

| Thermal conductivity, W/(m*K) | 0.020-0.041 |

| Density, kg/m3 | 30-80 |

| Strength, MPa | 0,3 |

Price. On average, insulating a square meter of surface with polyurethane foam costs 500 rubles.

Ecowool - environmentally friendly insulation based on cellulose

Option 6: ecowool

For those who want to make their home environmentally friendly, ecowool is a good alternative to eco-insulation. This cotton wool is made on the basis of cellulose. As a rule, the raw material for it is newsprint.

Ecowool adheres well to any surface

It must be said that insulating an attic room can be done in several ways:

- By wet spraying method. In this case, the cotton wool mixed with the adhesive composition is supplied under pressure;

The dry method is applicable to frame structures

- Dry method. This technology is applicable only to frame structures; in particular, roof insulation can be done in this way. Its essence boils down to covering the frame with film and pouring dry cotton wool into the space of the frame through a hose;

The manual method allows you to insulate wooden floors

- Manual. This technology allows you to insulate only wooden floors. The instructions for insulation are extremely simple - simply pour cotton wool between the beams and level it out.

Advantages. The main advantage of ecowool is its environmental friendliness. Also, the material has other advantages:

- Vapor permeability. In this parameter, ecowool is not inferior to eco-warm wool;

- Fire safety. Non-flammable;

Ecowool is fireproof

- Biostability. Ecowool does not rot, rodents and insects do not grow in it;

- Durability. This attic roof insulation can last more than 60 years.

Flaws:

- It takes a long time to dry. The cotton wool can dry out for several days;

- Shrinkage. May exceed 20 percent. Therefore, ecowool should be applied in excess;

- Moisture absorption. Cellulose wool needs high-quality waterproofing.

Characteristics:

| Options | Values |

| Vapor permeability | 0.30-0.67 mg/(m*h*Pa) |

| Density | 25-70 kg/m3 |

| Thermal conductivity | Up to 0.041 W/(m*K) |

Price. A cube of cotton wool when insulated using the spraying method costs an average of 2,000 rubles, 15 kg of dry wool costs about 500 rubles.

That's all I wanted to tell you about insulation. Moreover, I have explained which one is better.

Mineral insulation

When installing insulation, it is necessary to strictly follow the requirements of the technological map.

If there is a gap between the elements, then it must have a certain amount, no more and no less.

In the case where the roof structure does not imply the presence of a gap, there should not be one.

Mineral insulation has high technological qualities.

According to experts, this is the best heat insulator that is used to insulate an attic roof.

Based on the source material, mineral insulation is divided into the following types:

- slag;

- glass wool;

- stone wool.

Each type of insulation is produced using a specific technology.

Slag wool is produced from by-products of metallurgical production. Due to its technical and operational characteristics, it is not used in the construction of residential buildings.

The production of this cotton wool is carried out using special technology.

The material has the following characteristics:

- biostability;

- high sound insulation ability;

- non-flammability;

- vapor permeability;

- stability of geometric dimensions.

Experienced builders prefer to choose stone wool.

This choice is explained by the fact that stone wool has a rigid structure and can withstand significant mechanical loads.

When designing the insulation of an attic roof, it is necessary to ensure optimal vapor permeability of the protective layer. Basalt wool is best suited for these purposes.

Another important point is that the insulation should not attract rodents and insects. The appearance of mice or cockroaches can cause great damage to the comfort of a living space.

According to the conclusion of supervisory authorities in the construction industry, mineral insulation materials are recognized as safe for human health and are not carcinogenic.

Installation types

How to make a roof warm? They insulate it in two ways:

- insulation is done before the final installation of the roof (slate, tiles, corrugated sheets) - the insulation is placed on top , from the street side;

- the insulation is laid from below , when the roof is finished, the work takes place inside the attic.

As a rule, the first method is most often used during initial construction. Then, when it is planned in advance to use the attic space. This method is also used in the case of re-roofing or reconstruction of a building.

The second type of insulation installation is used more often. After all, with this method it is possible to carry out work at any convenient time. For example, there is a new addition to the family, and at the family council they decided to allocate a separate room to one of the family members. But there is no money to build a good extension to the house. There is only one way out - to equip a room in the attic, make a residential attic . You can gradually insulate it during the cold season (of course, not in severe frosts).

Methods for insulating the attic

In order to figure out how to insulate an attic roof for winter living, you need to know that there are several insulation options: internal and external.

Insulating the roof from the outside is an ideal option, since such a structure will not let in heat from the inside due to the warm circuit and will be reliably protected from freezing. This prevents the formation of condensation, therefore, the risk of mold and mildew is minimized. However, if the attic roof is already covered with roofing material, then insulating it will be extremely difficult, and the roofing material will have to be removed.

Most often, the attic is heated for further living in it from the inside. For this purpose, a wooden frame is being erected in the attic, which will serve as a niche for laying insulation. There are various technologies for thermal insulation.

External insulation of the attic occurs during the construction of the building. The gable roof is insulated. Internal thermal insulation is carried out with the roofing material already covered (if there is a need to make this room comfortable for living at any time of the year).

External thermal insulation

A ventilation hole with a diameter of at least 2 centimeters should be drawn through the layers of insulation. It is necessary to remove steam and condensate from the vapor barrier membrane. These holes are made in both the upper and lower parts of the roof slope. Thus, the air flows from bottom to top along the hole, collecting excess moisture from the vapor barrier film along the way and removing it out through the top hole.

However, all work on external insulation of the attic is carried out exclusively in the warm season in dry, sunny weather. All surfaces are carefully examined for any defects before thermal insulation. All areas must be dry. The wood must be impregnated with antiseptics. To prevent corrosion, metal surfaces are treated with butyme mastic.

External insulation of the attic occurs as follows:

- Lathing from boards is stuffed from the bottom of the rafters

- Vapor barrier film covers the sheathing and rafters

- Insulation is laid between the rafters

- The thermal insulation material is covered with steam and waterproofing on top

- The sheathing of boards is stuffed over the insulation

- The roofing material is attached using self-tapping screws to the sheathing.

https://youtube.com/watch?v=wyqkTCuRs4k

Internal thermal insulation

When choosing a material for thermal insulation, you need to pay close attention to its characteristics. It should be relatively light and easy to install without overloading the attic floor

It is also advisable to use environmentally friendly and fire-resistant material.

It is best to use basalt insulation; it is laid without the formation of cracks or voids. If insulation is used in the form of slabs, then the gaps must be filled with foam. When covering a vapor barrier membrane, you need to remember that the insulation sheets must have an overlap of no less than 20-30 mm.

When insulating a room internally, the procedure for carrying out work is as follows:

- The lathing is placed on the rafters or a specially prepared frame.

- To prevent wind penetration, the structure is covered with a protective film.

- A layer of thermal insulation is laid between the rafters and the frame.

- A vapor barrier membrane is placed on top of the insulation.

- The sheathing for the ventilation hole is stuffed over this structure.

- The sheathing is sheathed on top with plasterboard sheets or OSB boards.

When deciding to insulate a room with your own hands, you need to look at how to insulate an attic for winter living. The video will help with this. It covers in detail all stages of the work.

Today, many people are in a hurry to leave the noisy metropolis and find themselves in the lap of nature, which energizes and gives cheerfulness and new strength. It’s a rare person who doesn’t dream of living outside the city and enjoying the fresh air every day. However, in doing so, he faces some difficulties, because climatic conditions do not allow carefree living alone with nature all year round.

Creating favorable conditions for living in a country house is not an easy task, and this article aims to help overcome difficulties. Create coziness in your home, and let a warm and comfortable atmosphere always reign in it!

How to properly insulate an attic roof yourself: work order

Correctness and consistency of actions in insulation are the key to successfully completed roof insulation work. The main rule is close contact between the rafter elements and the insulation itself. To make the attic roof suitable for winter living, you need to take the following steps:

- First, protect with waterproof film;

- attach the slats taking into account the free placement of the insulation;

- the last layer should cover the wooden beams so that cold air does not pass through them;

- if there are empty spaces left, they must be blown out with foam;

- You also need to install another layer of vapor barrier material.

If through holes occur during work, they will need to be closed.

We insulate the roof from the outside with our own hands

To insulate the outside of the roof, you need to use special dense materials such as slabs. Choose specimens that are moisture resistant. It is advisable to carry out thermal insulation work along with the facade of the entire house. It is necessary to nail boards from below that will prevent the pits from sliding down. The board must be equal in width and thickness to the material used.

Roof insulation work from the inside

Please note that all wood must be treated with antiseptics, fire retardants, and special solutions for outdoor use.

Before starting thermal insulation work, check whether there is a ventilation system in the space under the roof.

To make the attic warm without having problems with excessive humidity, you must strictly follow all the instructions for the work. If the roof is also the walls of the attic floor, and has a broken structure, then the algorithm for carrying out the work is as follows:

- The lower part is the inner lining. This could be drywall or lining.

- Next, the sheathing is installed.

- The vapor barrier is laid first, then the heat-saving material. The thickness of the insulation depends on the place of residence. For the middle zone, 200 mm is enough; for colder regions this figure should be higher.

- A superdiffuse membrane is placed on top. This leaves a gap for ventilation.

- The last step is to lay the roofing material.

The slabs themselves for insulation need to be laid out in a checkerboard pattern. Work must be carried out starting from the bottom. The film for waterproofing is also spread from below, moving upward, taking into account an overlap of 10-15 cm. The resulting borders must be taped with tape. This is necessary to protect against leaks and condensation.

This layer cake will allow you to retain heat, creating additional living space.

Insulation from the inside

The process of thermal insulation of the attic inside can be divided into two parts:

- Basic. When insulation is carried out during construction. Light insulation is used here if it will not be used as an attic in the future.

- Additional. When additional installation of insulation is carried out taking into account the creation of a full-fledged living space.

When it becomes necessary to insulate the structure of an attic roof from the inside, the most common problem in this case is the small thickness of the rafters.

Insulating the attic from the inside

*

Main article about working with walls.

To fix the problem, you will need to create additional sheathing or frame. Next, the work is carried out in several steps:

- Creation of sheathing and counter-lattens from wooden slats.

- Twine or a thick thread is stretched to the rafters over the entire area of the sheathing, which will hold the material during operation.

- We build a metal frame, which is mounted to the rafters with brackets.

- We insert insulation over all areas of the roof.

- The metal staples are unclenched; they will additionally hold the material during finishing.

Insulating the attic roof is the most popular method for attic spaces. It is advisable to select the material based on mineral wool. Sometimes ecowool or polyurethane foam is used, in which case a vapor barrier is not required.

But waterproofing is mandatory, regardless of the insulation material. For this purpose, special membranes are used that can allow steam to pass through without allowing moisture to pass through. A gap for ventilation is needed between the waterproofing material and the roof, the thickness of which varies depending on the type of roof. It will release excess steam from the insulation to the top.

Features of attic insulation

Insulating an attic from the inside is not difficult to do with your own hands.

Planning to carry out this operation with your own hands is a person who does not have a specialized education in this field or the necessary work experience. Must know some subtleties. Today, experts point out the following features of attic insulation from the inside:

- There are increased demands on the insulation of the attic space, as a future living room. This is completely justified. After all, the attic has more wall area than any other rooms in the house and is in contact with the environment, so there is always more heat loss here;

- thermal loss occurs not only through the attic covering, but also through the floor, walls or gable of the attic, therefore insulation is carried out along their surface, from the inside;

- The roof slabs and rafters are designed for light loads. When choosing a thermal insulation material, you must take this fact into account. You need to choose a material with a minimum specific gravity that will not put a large load on the roof rafters;

- Attics are always a place for condensation to accumulate. The explanation is simple. Warm air always rises. It is characterized by a high level of humidity. And at the top of the house there is an attic. Warm air condenses on the cold surface of the roof and attic floor. Therefore, water droplets form there. As a result, the insulation may get wet. It must be accompanied from the inside with a vapor-tight membrane.

Warm attic - additional living space

No matter how large the room is, there is always a need for one more room - a guest bedroom, a playroom, a gym, or just a convenient storage room.

According to regulatory documentation, an attic is a room formed by a facade and roofing. According to sanitary standards, the distance from the floor to the line of intersection of the wall with the roof should be at least 1.5 m, and to the ceiling - 2.5 m. At the same time, an area with a “high” ceiling (2.5 m or more) should occupy from 50 % of the total attic area.

It is obvious that in private housing construction there are deviations from the standards. For example, the configuration of the attic space can be influenced by factors such as the shape and size of the roof: houses with a high roof have higher attic ceilings, but the floor area is narrower.

One of the successful options for using an attic space is a small living room for relaxing adult family members or children's games. Here you can retire to read or do handicrafts

To increase the size of the attic, they resort to various techniques: increasing the height of the lower tier of the sloping roof, making the facade walls higher. Interesting attic design options can be viewed on the Roofing Guide website.

However, with all the advantages of an additional comfortable room, there are nuances that increase the cost of construction and finishing work:

- window installation;

- ventilation equipment;

- hydro- and thermal insulation.

The last point is also important because literally everything will have to be insulated: the floor, gables, walls, often consisting of two parts - the facade and the roof. At the same time, the same requirements apply to thermal insulation materials as to insulation for residential premises. In addition to suitable technical characteristics, they must be absolutely safe.

An example of how the shape and height of the roof can affect the size of the attic - therefore, the features of the under-roof space must be taken into account when planning the living space

Mineral wool brands

The characteristics of the insulation can be determined by the markings:

- P-75. This is a flexible material with a density of 75 kg/m3. Mineral wool P-75 is usually used for horizontal surfaces that are not planned to be loaded, as well as for structures and communications with a very slight slope. This type of material is suitable for roofing, ceilings, attics, heating and ventilation pipes.

- P-125. The density of this composition is 125 kg/m3. Mineral wool of this type differs from the previous one in that it has improved sound insulation. Also P-125 is more flexible mineral wool. It is considered the best solution if the house is built from gas or foam blocks. P-125 is used for insulating facades, balconies, and interior partitions.

- PZh-175. This mineral wool has the highest rigidity. Thanks to this, it is excellent for loaded as well as vertical structures. The density of PZh-175 is 175 kg/m3. Mineral wool meets the minimum fire safety requirements and provides excellent noise protection. Typically, the material is laid on surfaces made of wood, concrete or steel.

- PPZh-200. This material has the highest density - 200 kg/m3. In addition, PPZh-200 is a non-flammable composition, so it can be used in the construction of retail departments, warehouses and other facilities. However, installation is only possible on flat surfaces, which will only be subject to static loads. This material is not flexible, as it contains an internal reinforcing layer.

Also, when choosing the best material, you should pay attention to its rigidity.

Selection of mineral wool

If you go by the rigidity of the composition, then you should pay attention to the following nuances:

- Soft insulation is best suited for insulating pipes, chimneys, and roofing “pies”.

- Semi-rigid mineral wool is more often used for insulating facades. Also, mineral wool of this type is often placed between sandwich panels.

- Rigid compounds are optimal for flat surfaces made of metal or wood.

The thermal conductivity indicator is selected in accordance with temperature indicators in winter. It is also worth considering the thermal conductivity of the building walls themselves. As a rule, mineral wool is purchased with a small margin of “temperature stability” in order to be prepared for any weather conditions. But you shouldn’t be too zealous either, since in this case the material will cost more.

Also, do not skimp on the manufacturer. It is better to give preference to Ursa, Rockwool, Paroc, and Isover. Germany has the most stringent requirements for insulation materials, which is why their quality is much higher.

Which roll material or mats to choose?

When choosing insulation for the attic, the question may arise: is it better to use rolled material or slabs? In this case, the answer will be individual for everyone, since everyone has different preferences.

Practical experience shows that material in rolls is more convenient to use. Simply roll out the roll to the desired length and cut off a piece. In addition, when insulating a roof that has a standard distance between the rafters, you can easily cut the material in half and fill the free space with them.

In the case of insulation boards, the advantage is convenient transportation. However, practical application is more problematic since the slabs are rectangular in shape.

In conclusion, it should be recalled that when buying insulation for the attic, it is very important to pay attention to the packaging. There should be no scratches or damage on it that indicate a leak. Only in this case is protection against moisture ingress into the insulation guaranteed before installation work begins.

Moisture that gets onto the material through poor-quality packaging leads to the insulation getting wet and changing its shape. As a result, installation becomes difficult in many ways, and gaps form between the slabs. In addition, damp material becomes a favorable environment for the growth of mold and mildew, which spoil the appearance of the surface and become a source of unpleasant odors.

Only in this case is protection against moisture getting into the insulation guaranteed before installation work begins. Moisture that gets onto the material through poor-quality packaging leads to the insulation getting wet and changing its shape. As a result, installation becomes difficult in many ways, and gaps form between the slabs. In addition, damp material becomes a favorable environment for the growth of mold and mildew, which spoil the appearance of the surface and become a source of unpleasant odors.

Do-it-yourself ceiling insulation

Proper insulation of the ceiling is unthinkable without careful preparation of the insulated surface

First of all, it is extremely important to achieve perfect smoothness and evenness. All previously used finishing materials must be eliminated, and the surface must be cleaned and, if necessary, puttied.

Large irregularities are removed radically - with a hammer and chisel. In old houses, the ceiling may be replete with cracks and depressions in the area of slab joints. They are sealed with putty. Interpanel seams must be cleared and filled with foam for installation. If the work plan includes replacing outdated electrical wiring, these measures cannot be avoided.

For the arrangement you will need the following types of tools:

- screwdriver;

- hacksaw;

- screwdriver;

- water or laser level;

- plumb line;

- paint brush or foam roller;

- hammer;

- construction stapler;

- stationery knife;

- ladder.

List of required materials:

- mineral wool;

- metal corners;

- self-tapping screws suitable for working with wood and metal;

- material for insulation from steam and moisture;

- putty;

- polyurethane foam and a special gun for applying it;

- construction tape;

- wooden or metal beam;

- paste;

- disc dowels.

Safety regulations

When it is planned to work with insulation based on mini-slabs in a private house, its structural features must be taken into account. The material contains a huge amount of ultra-small fibers. They can form a suspension in the air that is dangerous to human health.

To minimize possible harm, residents and workers will need to carefully consider the following rules:

- Workers must use protective masks, gloves and other special clothing when working with the mineral stove. Such measures will prevent fragments of material from entering the respiratory tract and onto the skin.

- It is necessary to prevent contact of the insulating material with the air that enters the house through the ventilation system in order to protect the residents.

Mineral wool density and thickness of mineral wool

Mineral wool is perhaps the most common insulation material for attic roofs due to its low cost and good thermal insulation qualities. In addition, the advantages of this material are also fire resistance, good breathability and low hygroscopicity. On the other hand, the thermal insulation characteristics of mineral wool are significantly reduced when wet, which makes it mandatory to equip it with waterproofing and vapor barrier membranes.

Mineral wool has several varieties:

- glass wool;

- slag;

- basalt or stone wool.

Glass wool is made from the finest glass fibers 5-15 microns thick and 15-50 millimeters long.

It has an elastic and durable structure, and requires great care when working: to avoid irritation, when laying it, wear a protective suit, gloves, goggles and a respirator. Resistant to temperatures from minus 60 to plus 450-500 °C

Slag wool, made from blast furnace slag, contains fibers 4-12 microns thick and approximately 16 millimeters long. This material can withstand heating up to 300 °C, but is ineffective when arranging thermal insulation of the attic due to its high hygroscopicity. In addition, slags with residual acidity can have an aggressive effect on metal surfaces, which is also a significant disadvantage. The disadvantages of slag wool are also its fragility and “prickliness”, which creates inconvenience when working with it with bare hands.

Basalt (stone) wool is made from gabbro-basalt or diabase with composite and binder additives. Its fibers are approximately the same size as those of slag wool. In terms of technological characteristics, this material is superior to all other types of mineral wool, and therefore is especially often used for thermal insulation of attic roofs. Stable when heated up to 600 °C (some types - up to 1000 °C). When using this type, the elasticity and density of mineral wool for attic insulation are sufficient so that the material does not wrinkle or settle when installed on slopes.

As for the required thickness of mineral wool for insulating an attic, it largely depends on climatic conditions, averaging 15-30 centimeters. It is clear that in regions with colder and more humid climates, the thickness of the insulation for the attic roof should be relatively greater.

Technology for self-installation of mineral wool

First, you need to make sure that the outer elements of the roofing pie (or at least the waterproofing layer) have already been installed. This is necessary to protect the mineral wool from atmospheric moisture before installing the outer membrane.

Place mineral wool tightly between floor beams or posts

Next, the width of the openings between the rafter beams is checked. If the size ranges between 550 mm and 600 mm, then you will not have to cut the insulation (you can use the factory width of the slabs 600 - 610 mm). If the distance between the rafters is more than 600 mm, it will be necessary to cut fragments of the required width from mineral wool slabs based on the installation compression of 20 - 30 mm. For example, if the rafter niche has a width of 720 mm, then sections of 700x600 mm are cut out of 1200x600 mm slabs. Residues 500×600 are accumulated for use in insulating various contours (for attic walls, around window openings, for laying crossbars on top, etc.)

The second method involves cutting rectangular slabs diagonally and relative displacement of the halves along this diagonal. When shifted, the overall width increases, ensuring that the ends of the wool rest against the vertical edges of the rafters. However, in this case, for a tight connection, the following slabs will have to be cut curvilinearly from the outside.

Installation of mineral wool and further operations are carried out alone using the following techniques:

Fastening mineral wool with nylon thread

- If there are no significant differences in width in the openings between the rafters, you can install mineral wool slabs without preparatory work. Pressing the material by 20 - 30 mm allows you to lay out all the insulation elements from the inside of the room into the roof slope. Otherwise, to support the wool, a temporary (removable) sheathing of planks, boards, or nylon thread (non-removable) is used, stretched along the lower edges of the rafters in a zigzag using a stapler. Layers of mineral wool are laid out in a checkerboard pattern to cover the joints.

- A vapor barrier film is stapled from below to the ends of the rafters. It must be joined with an overlap, gluing the joints with special tape.

- The lathing is installed to install the final ceiling cladding.

Step-by-step photo instructions for installing thermal insulation

Execution of work

The technology for reducing the thermal conductivity of attic roofs is generally quite simple. Especially if you choose mineral wool as the material used.

Installing it from inside the room is not too difficult, although it requires compliance with certain safety measures (use of a respirator, tight closed clothing and glasses).

Preparing for work

Before starting work, the entire internal surface of the roof, made of wood, is treated with a special antiseptic impregnation, and the metal elements are treated with an anti-corrosion liquid. A film is attached to the rafters, serving as waterproofing, and a sheathing is installed on top of it.

Next, a waterproof membrane is laid, taking into account the need to create a two-centimeter gap with its help, which serves for ventilation of the room. Additional air flow can be created by doing every 10–15 square meters. m of roofing special ventilation ducts.

Laying insulation

Installation of roof insulation materials is carried out between the rafters in the direction from bottom to top. The pieces of insulation should be slightly larger than the distance between the beams. This way they will fill the space better.

Fixation is carried out using special frost-resistant glue or anchors. It is desirable that the mineral wool slabs fit tightly against each other to increase the thermal insulation properties of the structure.

To avoid the appearance of cold areas, so-called “cold bridges,” a second layer of insulation is laid on top of the first layer. In this case, the seams should not match.

The last layer of insulation material requires the installation of a vapor barrier. To do this, wooden slats are mounted on top of the heat-insulating layer, onto which a vapor barrier membrane is attached. There is no need to stretch the material; it should sag a little. This will ensure a ventilation gap between the mineral wool and the finish.

Polyurethane foam

Spraying polyurethane foam is a good way to insulate an attic. In addition, the material has the following properties:

- Excellent degree of thermal protection.

- Possibility of insulation without a frame and special fastenings.

- The absence of seams, which are always conductors of cold.

- Creating tightness in hard-to-reach places.

- No reaction with any roofing material, excellent resistance to moisture and vapor permeability.

- Good grip on any surface.

- Polyurethane foam is not afraid of rodents and insects, and is also not affected by mold and rot.

But polyurethane foam still has a drawback: it cannot be applied independently without special equipment.

What to use for work?

Despite the high hygroscopicity, mineral or cellulose wool can be considered the most optimal. This material fills all the cracks well and allows you to create a monolithic shell contour around the attic space.

It is convenient to install cotton wool both at the stage of roof construction and in the finished building. The main thing is to use types of cotton wool that have a higher density. Penoizol is also suitable, but only in the form of wet foam. This is the only way to ensure continuous coverage.

Criteria for choosing insulation for the attic

High-quality insulation makes the attic suitable for year-round use. When choosing a heat insulator, you need to pay attention to the performance characteristics of the materials, including comparing

:

- noise insulation properties;

- ease of installation;

- moisture resistance;

- resistance to biological degradation;

- lifetime;

- efficiency;

- environmental friendliness;

- fire safety.

But the main quality by which insulation material is evaluated is its thermal conductivity coefficient, on which the ability to retain heat in a room depends

.

From the point of view of ease of installation and use of insulation, preference should be given to universal materials. If the same thermal insulator can be used for walls, roof and floor, the insulation of all structures will last the same period.

Sound insulation properties are a particularly important parameter if the roofing is made of metal (seam roofing, metal tiles, corrugated sheets). Gusts of wind, rain and hail make such a roof “sound”, and staying in the attic will cause discomfort.

Slab insulation from a well-known manufacturer

Since the roof frame is usually made of wood, it is advisable to use insulation that is fire resistant and flame retardant. Otherwise, an accidental fire will cause the entire attic and roof to quickly become engulfed in fire.

To ensure that condensation does not form on the wooden structures of the rafter system and gables and that the insulation does not lose its thermal insulation properties due to moisture penetration, it is necessary to insulate the attic space with a vapor- and moisture-proof material, or to use reliable hydro- and vapor barrier. This affects the speed and complexity of installing the insulating layer and influences preferences when choosing a material.