Linoleum for heated floors

The thickness of the coating significantly affects the quality of thermal conductivity, but at the same time, a thin coating does not hide the imperfections of the floor on which it lies. Every existing unevenness will sooner or later make itself felt, so before laying thin linoleum it is recommended to keep it at room temperature for 24 hours. If you are using a heated floor under linoleum, then the exposure time should be increased. The linoleum is placed on the floor (without fastening), after which the heating system is turned on.

Fixing linoleum with mastic

We should also talk about fixing linoleum to the floor. In such cases, it is recommended to use double-sided tape or adhesive mastic. When using heated floors, you should use mastic, as it can provide a more uniform thermal field.

When choosing linoleum for a heated floor, you need to pay attention to some points that are a mandatory feature of any good quality floor covering.

First of all, high thermal conductivity must be present. In addition, there must be high resistance to discoloration and fading, as well as resistance to deformation resulting from exposure to high temperatures.

As such a coating, you can use multilayer polyvinyl chloride linoleum, which goes well with almost all types of heated floors. It has a huge number of colors and can decorate the interior of any room. Of course, in addition to the advantages, this material also has disadvantages, the most important of which is the inability to use it at too high temperatures.

Thick multilayer polyvinyl chloride linoleum

The most popular heating method is electric underfloor heating under linoleum, which is divided into cable and infrared types.

Cable and infrared heated floors for linoleum, reviews of which will allow you to more accurately determine the desired type of heating, cope with the task at the highest level. However, it is worth noting here that when combining them with linoleum, the materials should be selected extremely carefully, since they must transfer heat well and be resistant to high temperatures.

Warm film floor

Thick linoleum (with an additional thermal insulation layer) can slightly reduce the level of heat output from the heated floor. For this reason, the use of such linoleum is not always effective. The ideal option would be to use a heated floor under linoleum, which has a small thickness and high resistance to mechanical and chemical influences.

The ideal solution that is suitable for almost any type of flooring is an infrared floor heating system.

Infrared heated floors under linoleum completely transfer heat through the floor covering and also provide high-quality ionization of the air in the room.

Read about how to choose a warm floor by following the link.

How to lay linoleum on a warm floor?

After installing the heating floor system and fully checking its functionality, you can lay linoleum. Absolutely anyone can do this. Before laying, do not forget to spread the roll in the room and warm it up for 24 hours.

This will allow the material to fully expand and fill the space evenly. Now the sheet can be cut into strips of the desired size and laid over the entire area of the room. We secure the edges with a plinth, and make a cutout in the places for the wire if the plinth does not have a built-in cell.

Certain types must be glued to the surface. To do this, mastic is used, which is evenly applied to the plywood, then the elements are connected.

Pros and cons of electric heated floors under linoleum

The advantages of linoleum are a large selection, low price, simple and quick installation.

But linoleum also has disadvantages when laid on a warm floor. It does not have very good thermal conductivity, which reduces the heat transfer of the heating element, and there are also restrictions on the heating temperature. Therefore, if linoleum is not selected correctly, then the following may happen:

- Color changes

- Material surface deformation

- Phenol vapor

But in general it is combined with TP, especially if it has underfloor heating signs.

Marking linoleum for use under heated floors

Natural linoleum or otherwise marmoleum is also well suited for laying on TP. Of the other types of “unnatural” linoleum, you need to choose by type, thickness, class. So that the flooring gives pleasure and lasts for many years.

Please note there is an article on the topic “Which linoleum is better to choose for a heated floor?” Read more at the link.

What are the benefits of heated floors?

This heating system allows for optimal heat distribution in the room. According to the laws of physics, heated air rises and gradually cools down there. Because of this, most of the heat given off by various heaters is wasted for other purposes. As a result, the temperature under the ceiling and in the floor area can differ by 5–8 degrees, which is quite significant for a person. A warm floor gives warmth to the area of our feet, which is very useful from a physiological point of view.

Temperature distribution

Temperature distribution

In addition, this system has many advantages over traditional heating systems:

- The air with this type of heating does not dry out, which is useful for everyone, and especially for small children and people with respiratory diseases.

- There is no need to clutter the room with radiators or other heating devices, which gives more space for interior design.

Along with comfort, heated floors bring health to the residents and savings on the home heating budget.

Which floor will work well with linoleum

The following heating system can be installed under this floor covering:

- water;

- electrical;

- infrared.

The systems differ in design and installation complexity. Let's look at each in detail.

Water

It is a set of pipes with coolant circulation. Most often, the structure is connected to the heating system. A water floor is more suitable for private homes.

If the house has a gas boiler, the floor is combined with space heating. The main advantage of the design is its independence from electricity.

A special feature of the system is the mandatory installation of screed between the pipes and linoleum. If the pipe is damaged, the structure may flood. To minimize risks, it is important to perform insulation correctly.

Water TP

Electric

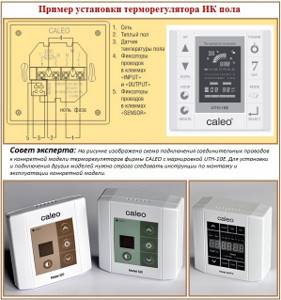

A warm electric floor is a heating cable placed between a solid base and a screed. You can select the heating temperature using the thermostat.

The undeniable advantage of the design is its autonomy. It is suitable for apartments and is often used as the only source of heat on cool autumn days. Installing such a system is only allowed in extreme cases, since it is very unique and difficult to install.

If you decide to combine electric flooring and linoleum, the latter must be of good quality. Otherwise, after some time the material will begin to smell unpleasant and become deformed.

Electric TP

Infrared

IR is considered the most successful option for linoleum, since it is very easy to install. Being a thin film with good elasticity, a warm floor takes up little space and warms the room well.

Compared to an electric floor, infrared flooring uses electricity more economically. You can set the heating level on the thermostat.

Infrared TP

Is it possible to lay the flooring product on a heated floor?

There is a lot of debate about whether this type of covering can be laid on a heated floor. Some argue that this should not be allowed under any circumstances due to the fact that the coating material releases toxic elements when heated. Others talk about the fragility of linoleum, that due to heating the coating material will be deformed, and this will inevitably lead to cracks and unevenness.

However, progress does not stand still. And fortunately, it also affected the production of linoleum. New technologies make it possible to create a material that is not afraid of temperature fluctuations, and the composition of such coatings will not have toxic properties. Therefore, the answer to this question is clear - modern linoleum can be used to cover heated floors along with other materials. The main thing is the correct choice of this material and heating technology.

Let’s say right away about heating: you need to install infrared film fields under the linoleum. This type of heating will be softer and more comfortable. This technology will ensure the compatibility of the selected coating with the use of heating.

When choosing a coating, you need to understand that linoleum must be made of a material that provides thermal insulation. Otherwise, the efficiency of floor heating will be minimal.

It is also extremely important that the material from which linoleum is made is safe for humans, toxic and climatically inert. Typically, the safety class is indicated in the product quality certificate, which it would be a good idea to request from the seller before purchasing. In addition, the documents for linoleum must indicate that this material can be intended for covering floors that have thermal heating.

If you do not pay attention to these facts, you can buy inappropriate linoleum, and during operation the floor will emit an unpleasant odor associated with the toxic compounds that make up the material. You may also notice that this type of flooring will blister and crack.

Warm floor and linoleum

Is it possible to use linoleum for a heated floor as a finishing coating? Why do users have doubts? It's all about the linoleum itself. In its appearance and characteristics, it is somewhat reminiscent of rubber, which, as is known, cannot withstand high temperatures.

When heating linoleum, problems may arise that you need to be aware of when planning floor repairs:

- Linoleum is a heat insulator. This especially applies to material with an insulated base. There is no point in heating such linoleum.

- Linoleum without a gasket will deform and warp when heated, which will quickly render it unusable.

- When heated, linoleum will emit toxic fumes, which is unacceptable in the residential sector.

These are the main reasons why many people hesitate to install heated floors under linoleum. However, the situation can be corrected; however, this will require spending additional money and purchasing the “right” materials.

Only natural linoleum, which has slightly different characteristics than synthetic ones, is suitable for heated floors. You can take, for example, marmoleum. To eliminate contact of linoleum with heating elements, you can make a layer, for example, from fiberboard. You should also be careful when choosing a heated floor system. Not every heated floor will be effective under linoleum. Let's figure out how to choose the right linoleum and heated floor system.

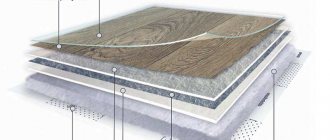

Installation of film floor pie

Let's assume that after design and calculations we have purchased a set of infrared floors with the most suitable width and the missing components of the cake in the required quantities. It remains to figure out in what sequence and how to correctly lay the infrared film floor under the finishing linoleum.

Laying the substrate and heating system

The first step is to lay a heat-reflecting substrate, the strips of which are glued together into a single sheet with tape. In large rooms with an area of more than 20 m3, it is recommended to connect the substrate with double-sided adhesive tape in order to prevent its movement relative to the subfloor. Instead of double-sided tape, fixing with a construction stapler is suitable.

Next, we proceed to the stage of constructing the film floor:

- We cut out the thermal film according to the instructions of our own project.

- We try on the “pattern” for the future installation site. If necessary, we trim, slightly change the width of the side indentation and the gap between the walls and the heating system.

- Having decided on the position of the individual panels, we proceed to assembling the heated floor.

- We lay the underfloor heating panels strictly with the copper busbar facing down.

- We isolate the exposed contacts of the panels from the edge opposite to the connection side. We simply seal the cutting areas of the silver and copper busbar with bitumen tape so that contact with the external environment of both metal strips is completely excluded.

- We install the contact clamps on the current-supplying strip of thermal film. To do this, we slightly peel off the polymer shell in order to insert one side of the clamp under it, and place its second side on top of the copper busbar.

- After checking the correct installation, firmly fix the clamp with pliers.

- In accordance with the described diagram, we equip all contacts of the film floor with clamps on the side connected to the thermostat.

- We connect the strips with wires so that phases are connected to phases and zeros to zeros. For this purpose, the package includes wires of two different colors. We remove the insulation from the connected ends of the wire and insert them two or one at a time according to the design diagram into the clamp.

- We isolate the connection points secured with pliers with two pieces of bitumen tape on both sides.

- We connect the circuit to the thermostat.

- In a convenient place, install the temperature sensor with its convex side down and connect it to the thermostat. We cover it from below with bitumen tape. The system sensor under the linoleum must be positioned so that movement on it is eliminated or is the least intense.

The infrared floor heating system has been assembled; the final work remains on arranging the circuit and laying the finishing material.

The final stages of installing an infrared floor

To ensure that individual parts of the system do not stand out under the coating and are not subject to unwanted mechanical stress, they should be “sunk” in the insulating substrate. To do this, we cut out “windows” and “trenches” in the heat-reflecting layer under all convex parts: temperature sensor, contact clamps and wire routes.

Next, we test the operation of the film floor by connecting power to it. For a control check, set the thermostat to + 30º C. We check the operation of each contact and the safety of the insulated points with an indicator screwdriver or similar device. After making sure that the infrared system is functioning normally, we cover it with polyethylene and lay down a hard protective layer.

If necessary, a hard layer assembled from plywood, gypsum fiber board, hardboard, etc. We fasten it to the rough base with self-tapping screws so that the fixation points pass through the transparent edge of the film floor. It is more convenient to work with material that has a joining chamfer along the edge.

Don't forget that the infrared system needs to “breathe”. Therefore, along the perimeter of the hard flooring there should be a gap of 1-2 cm, which, after installing the finishing coating, is covered with a plinth.

To the constructed and secured rigid base we glue double-sided construction tape, used in laying linoleum, and lay the finishing coating itself.

Properties

Let's consider the distinctive features of linoleum in comparison with other types of floor coverings.

Performance characteristics:

- ease of installation and dismantling;

- practicality in care and operation;

- wear resistance;

- water-repellent properties;

- resistance to dirt and stains;

- the presence of species that do not deform when exposed to high temperatures;

- good compatibility with other building materials;

- wide selection of products according to price indicators;

- linoleum made from natural materials has antistatic properties, low flammability, and resistance to acids and alkalis.

The list of positive properties is supplemented by disadvantages.

Among the shortcomings, experts note:

- instability to low temperatures;

- color change;

- erasure;

- exposure to mold and microorganisms;

- unpleasant smell of PVC linoleum.

A wide selection of products allows you to determine the ratio of price and quality of finishing materials.

If the linoleum is of poor quality, over time it may fade and wear out.

Types and features of linoleum

First, let's look at the positive aspects of linoleum. Why do many people prefer to put it in?

We recommend: What are the advantages of Thermo heated floors?

Positive sides:

- It is convenient to clean rooms with linoleum;

- easy installation and dismantling;

- resistant to stains;

- long wear under correct operating conditions;

- repels water;

- certain types are resistant to high temperatures;

- affordable prices and wide selection on the market;

- combines with other building materials;

Some people choose other coatings for the following reasons:

- color changes over time;

- the drawing is erased;

- does not withstand low temperatures well;

- linoleum made from polyvinyl chloride has an unpleasant odor;

In order for the flooring to be of high quality and last for many years, it is necessary to understand its types and characteristics. Don't be put off by price alone.

Expensive material, in turn, can be bad if installed in inappropriate conditions, just as cheap material can be good if used correctly.

Although in some cases it is better to overpay a little for quality than to ignore important characteristics by choosing a cheaper and more accessible material.

Linoleum is divided into 3 classes according to the place of use:

- domestic. Withstands light load, suitable for installation in residential premises;

- semi-commercial. Used in commercial buildings with medium load;

- commercial. The most durable and thick type of linoleum, it is used in public institutions with a large flow of people;

We sorted out the classes. Now let's move on to the 5 main subtypes of linoleum:

- natural. It has increased fire resistance and resistance to electricity due to the organic components in the composition. Eco-friendly and safe for both people and pets. Durable and wear-resistant type of linoleum. Among the disadvantages are fragility during transportation, a flat surface is required for flooring, unstable to moisture, expensive price;

- linoleum-PVC. It does not tolerate high temperatures well, deforms over time, is easily flammable, is unstable to substances with caustic chemical composition, and has an unpleasant odor. The material is definitely not suitable for heated floors;

- alkyd (glyphthalic) linoleum. Fabric-based coating with the addition of natural ingredients, which increased the cost in the market. The products are endowed with increased thermal insulation and various designs. Disadvantages - does not withstand temperature changes, deforms over time, transportation in the cold season is not recommended;

- nitrolinoleum (colloxylin). Single-layer material based on nitrocellulose. Small thickness has both pros and cons. The first include light weight, flexibility, and plasticity. For the second, it insulates noise and heat poorly, requires a completely flat floor for installation, supports combustion, and ignites without problems;

- rubber. Two-layer coating based on rubber. Plasticity and moisture retention are guaranteed, and the rubber coating also adds anti-slip properties. Antistatic, resistant to temperature changes. Found application in public buildings, medical institutions, sports institutions.

We recommend: How to install heated floors in the kitchen?

The above types and their characteristics will help you make the right choice, based not only on price, but also on the most important qualities of the material. It would also be a crime not to touch on the types of heated floors, because in order to choose the ideal combination, you need to know the characteristics of both.

Compliance with thermal conditions

To select a high-quality floor covering, no special knowledge is required, because in the instructions the manufacturer indicates the possibility of using this material in the construction of heated floors. This information can be found near the marking; the permissible heating level is also reflected there; it is 27 degrees.

For your information! If the temperature is exceeded, the floor product will be damaged.

PVC linoleum can withstand +30, but there is no guarantee that the material will not be damaged, and the release of harmful substances is also possible.

To monitor compliance with the temperature regime, you will need a high-quality thermostat, ideally digital. Then, the temperature level will be maintained automatically.

Types of substrates

To insulate the floor under linoleum, you first need to select a substrate. There are several types of such material. Here are the most popular:

- cork;

- jute;

- linen

Let's look at each separately.

Cork backing is made from compressed crushed cork oak bark. This insulation is produced in rolls. The advantages of this material include:

- environmental friendliness - made from natural cork;

- There is a pleasant feeling when walking on this surface, as it is quite soft.

It is precisely because of the last positive quality mentioned that a problem may arise: if you place a heavy object on the coating, then after some time dents may form on it. To avoid this, you should choose the hardest cork backing.

Jute backing is a material consisting of 100% natural jute fiber. It is made as follows: jute fibers are punched with a needle, then rolled on rollers under high temperature. This substrate is fire resistant, resistant to mold and rot.

Linen backing is 100% pure natural linen. It is made by double-piercing with a needle and then impregnated with anti-fire and anti-fungal agents. Linen backing is a good material for thermal insulation under linoleum.

Warm floor under linoleum - installation and installation

- First, you need to determine the configuration and area of the floor area that will be heated in the future. Measurements should be taken only in areas where household appliances or furniture will not be located. The IR film must be placed along the entire length of the room, which will avoid too many connection points for installation wires. If electrical wiring runs inside the floor, it should be at a distance of approximately 50mm from the IR film and insulated from the floor or wiring with heat-insulating material. There must be a distance of at least 200mm between heat sources (pipes, ovens, fireplace, etc.) and the IR film.

- Then you should start preparing the heating elements, for which the heating film is cut along the cutting lines along the heating strips every 250 mm. It is prohibited to cut the film along any other lines. Contact clamps are installed on the finished heating elements. In those places where current-carrying copper strips and a two-layer film pass, the tip of the wire is installed so that it is located on the contact strip inside the thermal film. Then a grommet is inserted into the hole, which must be riveted using a special stapler or hammer.

Open the films

- The cutting lines of the contact strip are insulated on both sides using a waterproofing strip. Protected copper wires with a cross section of 1.5 sq. mm. are brought to the tip and clamped using pliers. After this, the junction of the copper bus and the electrical wire with the tip on both sides must be insulated with a waterproofing strip. Parts of the heating film must be connected in parallel to each other, and the highest total power of the heating elements that are connected to the thermostat should not exceed 3500 W.

- When connecting the heating system, be sure to take into account the presence of other electrical appliances that can also be connected to this network.

- If the total power of the heating system is more than 3500 W, it is advisable to make the connection using separate electrical wiring, which is protected by a separate circuit breaker. In addition, heating devices should be connected using a magnetic starter.

Insulation of infrared heated floor wires

- Then you need to lay thermal insulation with a reflective layer and secure it with tape.

- Heating elements are laid on the thermal insulation with copper strips down. They should be laid in such a way as to avoid contact between adjacent strips. The heating elements are attached using tape, a stapler or furniture nails, which will minimize the likelihood of the strips moving during installation of the coating.

- Heating elements should only be attached through the transparent rim located on the sides of the element. The heating element should be located approximately 5mm from any supply section of the element, which also includes copper electrical bars. The wires should be positioned so that the main ones are under the baseboard. In those places where the contact strips are insulated and thickening of the system is observed, cuts are made in the thermal insulation in order to level the surface for the final coating.

Correct laying of wires when installing film heated floors

- Then you need to carefully inspect the system, as well as check the reliability of the insulation and fastening of the wires. After this, it is necessary to measure the resistance of the heating strips. If there are sources of possible short circuit in the system, they should be eliminated and then the performance test should be repeated.

- Using adhesive tape, a temperature sensor is attached under the cutting line (where there is no heated section of the film). Heating elements and a sensor are attached to the thermostat.

- Then you need to turn on the thermostat and leave it for a few minutes. Place your hand against the heating element - the heated film floor under the linoleum should generate heat at a pleasant temperature.

- After this, the infrared film is covered with a vapor barrier material, and the joints are secured with tape.

The installed heated floor is covered with Izospan thermal insulation

- Fiberboard or plywood sheets are laid on the vapor barrier material, which are attached to the primary screed using screws and carefully leveled. Sheets of plywood are attached only through a transparent rim located along the cut lines of the IR film and the sides of the element. The element should not be attached closer than 5mm from any supply areas of the elements.

- Next, linoleum material is laid on a warm floor under linoleum, the price of which will be lower than, for example, under a laminate covering, in accordance with the manufacturer’s instructions.

High-quality designed and installed heated floors under linoleum, a video about which you can watch below, can not only make living in your home more comfortable, but also allow you to significantly save on heating.

We recommend reading: preparing the base and installing linoleum on a wooden floor.

Preparing the base

Installing a heated floor under linoleum begins with preparing the base. The easiest way is to fill in a new screed, and then proceed with the installation of the structure according to one of the classic schemes. However, when you place heated electric floors under linoleum on a wooden floor, the additional layer of concrete can have a negative impact on the stability of the entire structure. In such cases, it is necessary to use different restoration methods.

The main requirements for the base on which the rolled heated floor under linoleum is placed: evenness, cleanliness and the absence of noticeable defects. First of all, all cracks and gaps have to be eliminated. Next, the surface is treated with antiseptics and waited until completely dry. When you install an electric heated floor under linoleum on a concrete floor that you have just made, the surface will be flat by default (subject to basic construction technology). In the case of an old base, leveling will most likely be required. When installing water equipment, the requirements for this parameter are not so strict. When installing a film heated floor under linoleum, do-it-yourself installation requires the presence of an almost ideal surface. If it is unrealistic to eliminate unevenness and differences by resorting to sanding, you can lay plywood. It is important that the edges of the boards fit very tightly to each other.

Thermal insulation

Before installing a heated floor under linoleum, the base should be well insulated. If this is not done, some of the energy will flow down. If you don’t want to waste heat so inefficiently, you’ll have to spend money on purchasing insulating material. In the role of insulation, which makes floor heating under linoleum as effective as possible, you can use:

- extruded polystyrene foam;

- polypropylene plates;

- metallized lavsan film;

- cork backing.

To properly lay a heated floor under linoleum, the insulating material must be placed with the reflective surface facing up. The strips/plates are secured with construction tape or staples from a stapler. The elements should fit together as tightly as possible. For reliability, the seams should also be taped.

Materials and tools

To assemble a “warm floor” under linoleum you will need:

- infrared “warm floor” kit, which includes:

- film with elements emitting infrared rays (sold in different widths: 50, 60, 80 and 100 cm);

- electrical wires;

- special clips for fixing the film on the insulation;

- contacts in the form of clips;

- bitumen-based tape.

- temperature sensor with wires;

- Temperature regulator;

- foil insulation (you can buy a backing with foil or lavsan on one side 3 mm thick);

- electrical tape for insulating wire twists;

- metallized tape;

- knife;

- roulette;

- pliers for crimping contacts;

- pliers for stripping insulation from wiring;

- construction pencil.

In addition, for the preparatory work you will need:

- hammer drill or wall chaser;

- electric drill with a crown.

Linoleum and heated systems: what should you be wary of?

Everyone knows that linoleum is a fairly elastic synthetic material that can change its structure under the influence of the external environment. For example, he is afraid of changes in air temperature in the room, or rather, too high or low values.

The question arises: how does the canvas react to a nearby heat source - water, electric or infrared underfloor heating? And can they be combined, being layers of the same floor covering?

The practice of laying heated floors under linoleum has existed for a long time, and there are no special contraindications to the use of this tandem, however, when choosing both a heating system and linoleum, it is necessary to take into account their characteristics.

The packaging with a roll of flooring must have a pictogram indicating the possibility of using it in combination with heated floors

The heating system, in turn, must be a uniform, smooth coating, without protrusions, since linoleum is laid only on a flat surface. To ensure this point, another layer of plywood is often placed on the warm floor.

If one of the installation conditions is neglected, the linoleum will stretch when heated, and when cooled it will shrink and warp, and within a month it will lose its shape and color.

The option with linoleum is suitable if a water or infrared heated floor is laid on a concrete or wooden base; in other cases, difficulties may arise. To avoid them, let us consider in more detail the characteristics of all the listed materials.

Infrared floor under linoleum

The easiest way to install a heated floor under a decorative linoleum covering with power supply to the heating element is in this way. When an electric current passes through the graphite coating applied to the surface of the heating tape, infrared radiation occurs in the form of heat. It is not the air that is heated, but the surrounding objects, primarily the laid decorative material.

Mounts on any flat surface. Suitable for any room in the apartment. To protect the film coating, a polyethylene film or linoleum backing is sufficient.

The advantage of the method is quick dismantling.

Two types of infrared film: striped and solid

Laying linoleum

If linoleum was purchased in the winter or was left in a cold room for a long time, before laying it, it needs to lie in a warm room for at least a day and restore its natural elasticity. A sheet of linoleum is rolled out on the floor and the required length and width are measured, corresponding to the dimensions of the floor itself. It is necessary to add approximately 10 cm to the measured values to run under the baseboards, or, if there is a pattern on the surface of the material, you need to make a reserve for each fragment of this pattern so that the floor looks harmonious during final installation.

There are two methods for laying this material:

- On a dry floor surface.

- On glue.

If the room is small, such as a kitchen in a Khrushchev-era building or a loggia, then dry installation is allowed. This method is not suitable for large rooms. Here you need to use glue or mastic for construction work. The floor surface is coated with a roller dipped in special glue. The reverse side of linoleum is also treated with glue.

After the linoleum is spread and secured to the floor surface, the baseboards are installed, fitting the remaining part of the material under them, secured with corners and plugs.

Recommended option for heated floors under linoleum

The most effective option for heated floors, suitable for linoleum in all physical, technological and economic parameters, is infrared heated floors.

- Firstly, because with this heated floor it is not possible for the linoleum to overheat. Although, due to improper installation, a fire is possible;

- Secondly, laying plywood on this heated floor does not reduce its efficiency; rather, on the contrary, it creates a comfortable heating layer uniformly heated by infrared radiation.

Let me remind you that IR radiation does not heat the air in the room. Under the influence of infrared radiation, objects falling under it warm up. From floor film or carbon rods to furniture and people in the room. By the way, this is partly why I don’t install film heated floors under permanently standing furniture. The carbon fiber rod is laid.

What type of heated floor to lay under linoleum

- water floor The basis is the pipes through which water circulates. The system is laid inside concrete or on top of a wood frame. It is most often used in private houses, since for installation between the heating system and the coating it is necessary to make a screed, which is impossible to do in apartment buildings. Used in high rooms due to the size of the installed structure. Slow warm-up;

- electric heated floor. Consists of electrical cables that are laid in a screed. The temperature is adjusted by a special regulator, which is installed and attached to the wall. Heating occurs quickly, heat spreads evenly over the surface of the room, but if the system is not turned off in time, the surface will be damaged due to overheating;

- infrared floor One of the electric floor types. The system consists of heating graphite strips. Heating is gradual and uniform. This type is not recommended for installation in showers due to moisture intolerance.