Having decided to create a heated floor system in an apartment or house, owners are faced with another choice problem - which heating technology for the lower part of the premises to choose. There are different types of systems on the market today (some run on water, others run on electricity). However, not everyone knows that there is also an electric-water heated floor - one of the newest technologies, which has already gained good authority among many craftsmen and those who have tried this floor heating system. What are the features of this system? This article will help you understand this issue.

Electric water heated floor

Water or electric floor: which is better?

Why do people still argue about which floor is better - water-powered or electric-powered? The thing is that these heating technologies differ from each other in installation features and have certain advantages and disadvantages. And the choice is not always easy to make.

Warm floor - which is better?

Features of water floors

This is a rather complex system to install, which operates on a coolant such as hot water. The advantage of water heating is that this type is quite economical during operation.

The main disadvantage is the complexity and some installation features. For example, it is not in all cases allowed to connect a water heated floor to a central heating system - for this you must obtain permission from the management company. In a private house, you will need to install a boiler to heat water, which is also related to the operating features of this type of heating system. The boiler itself can, depending on its type, take up quite a lot of space in the house; this also needs to be taken into account when choosing this heating system.

Water heated floor

Also, to install a water heating system for underfloor heating, a lot of preparatory work will have to be done. It is worth remembering that before putting such a floor into operation, the cement screed must dry thoroughly.

Connection diagram for a water heated floor to a boiler

Features of electric floors

This heating system operates, as you might guess, on the basis of electricity. The heat generated by special cables or mats is transferred directly to the finishing floor covering, due to which the floor becomes tactilely pleasant, cozy and warm.

Electric heating floor connection diagram

The main difference from a water floor is that in this case the heating of the surface always occurs equally, while the water runs through the pipes constantly and has time to cool down before the next heating. This is both an advantage and a disadvantage of this type of heating.

Electric heated floor

On a note! Because of this feature, electric floors cannot always be used. Everything will depend on what kind of flooring is being installed, as well as on the location of the furniture in the apartment. However, the places where wardrobes and sofas are located can simply be bypassed when laying electric floors.

Electric floors are divided into film and cable. The first is laid on the surface of the screed directly under the finishing coating, the second, similar to a water floor, is filled with a cement screed.

Installing infrared film heated floors under the laminate

With the help of both types of underfloor heating, you can easily install heating in any home. However, choosing between them is always difficult. But technology does not stand still, and now there is an electric water floor on sale that combines the advantages of both types.

Instructions for using antifreeze and features of the system with them

Let us once again draw your attention to the fact that it is necessary to read the system parameters and select equipment taking into account the type of coolant used. If you calculate and assemble the system under water, and then simply fill it with anti-freeze, you will inevitably encounter problems:

- In some cases, if the system is designed for water without a reserve, there will not be enough thermal power. If the reserve was about 20%, then everything will work at its maximum capacity. And all because antifreeze has a lower heat capacity. An option to solve the problem in the case of heated floors is to install a more powerful pump. The speed of movement of the coolant will increase, and with it the amount of transferred heat will increase. But at the same time, when turning on a cold system, do not immediately set the heating temperature to a high temperature: there will be overheating (read about the consequences of this below). Raise the temperature gradually, bringing it to 40-50°C in a few days (depending on the thermal insulation of your floor, but not higher than 55-60°C).

- The volume of the expansion tank will be insufficient (it should only be membrane). This problem occurs due to greater thermal expansion. You will have to buy another tank, a larger one, or install a second one.

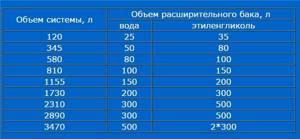

The size of the expansion tank depending on the volume of the system - Threaded connections may leak. Often, linen winding and paint are used to seal joints. Such sealing will be of no use when using non-freezing liquids: it will corrode the paint. The solution to the problem is as follows: the winding can be used in conjunction with ethylene glycol-resistant sealant.

- When the coolant temperature exceeds 70°C, active precipitation will begin, which can completely clog the narrow passages of the pipes. Even if circulation is maintained, the heat output of the heating circuit becomes much lower, which again leads to overheating and even more deposits. Overheating leads to another problem: corrosion processes begin to actively take place (additives lose their properties) and the system collapses. Therefore, for systems filled with antifreeze, it is important to have heating equipment with reliable automation and install backup devices that will block the system when the temperature threshold is exceeded. That is why traditional solid fuel boilers in such systems can only be installed together with heat accumulators, which will smooth out temperature surges.

- Regular gaskets will break down and new leaks will appear. Therefore, before pouring “anti-freeze” on all detachable connections, standard gaskets are replaced with chemically resistant ones (paronite or Teflon).

To avoid these troubles, when planning, you need to take into account the fact of using antifreeze, choose compatible equipment and chemically resistant auxiliary materials.

Fluid for heated floors must be safe

Liquid electric floor

An electric water floor is a combined type of heating system that combines the advantages of both water and electric heating.

The design and principle of operation of a liquid electric floor

On a note! Calling such a floor water is not entirely correct. Some models do not use water as a coolant - antifreeze is pumped into the tubes. Thus, the correct name for this floor heating system would be “liquid floor”.

Autonomous heating system AS-22

electric water heated floor

The design and principle of operation of a liquid electric floor

This type of underfloor heating is a system of tubes or one long, thick-walled tube. When the liquid heating system is turned on, the coolant is heated, due to which a certain pressure is created and antifreeze or distilled water begins to boil (different coolants are used in different systems). This is how thermal energy is generated.

Electric-water heated floor

Advantages of electric-water heated floors

In order to fully appreciate all the benefits of liquid heated floors, it is important to know its advantages, which distinguish this system from other analogues. And electric water systems have many advantages over conventional water systems:

- they do not need to be connected to a heating boiler or heating system;

- the system does not require a pump to operate;

- when installing the floor, you will not have to install a manifold and distribution cabinet;

- the volume of liquid contained inside the system is small, and therefore the likelihood of flooding of the apartment or even severe leakage of equipment is completely excluded;

- heating of the system is as uniform as possible, the liquid inside the tube does not have time to cool;

- ease of installation compared to water systems.

Electro-water heated floor ASOT AS-07

The liquid system also has considerable advantages over the electric ones:

- since the cable is constantly inside the liquid, its overheating and burnout are excluded, unlike an electric cable simply laid in a screed;

- Repairing a liquid floor is easy. For example, adding antifreeze or replacing a heating element can be easily done through a special installation box. And the damaged area can be identified by small spots on the screed;

- thermal energy is stored not only inside the screed, but also in the pipe itself, due to which the heating effect lasts longer.

Liquid electric floor has its advantages

Expert opinion

Afanasyev E.V.

Chief editor of the pol-exp.com project Engineer.

If we compare liquid floors with film floors (which are also, in fact, electric), then the former can be used in a room with any humidity level, which distinguishes them favorably from the latter. Also, liquid-based floors can be installed under absolutely any floor covering.

Liquid electric floor can be used at any humidity level

How to choose a liquid for heated floors in the house?

Creating a project for heated floors in a house requires not only choosing the right circuit layout and the devices themselves, but also the liquid that will be the coolant. The same liquids are poured into the system as into radiators, but not every composition is optimal for heating.

It is necessary to select a liquid when installing a heated floor at the project stage, since its technical parameters are included in hydraulic calculations. As a rule, thermal calculations are carried out based on warm water data, but the use of antifreeze makes adjustments.

Different brands of this composition have individual properties due to additives, so you should analyze all possible options and choose the best one for yourself.

The floor is heated by liquid circulation through the heating circuit. The heat transfer is uniform and the room warms up to a comfortable or set temperature very smoothly and quickly.

Which is better - water or antifreeze?

It is impossible to answer this question unambiguously. The owner of the house, creating a project with his own hands, takes into account his own wishes and the comfort temperature when living in the house.

There are some aspects that draw attention to the benefit of this or that liquid for pipes, so you will have to consider in detail all the pros and cons of each type of coolant.

Popular models of liquid electric floor

There are two main models of electric-water heated floors. These are XL Pipe (Korea, Daewoo Enertec) and Unimat Aqua (Korea, Caleo). They have design differences.

On a note! Unimat Aqua systems are also produced in Russia. And this is worth remembering when choosing products.

These are two completely different designs that have only a common operating principle - the coolant is heated by electricity. But the heaters and heating mechanism are somewhat different.

Types of heat sources

Boilers for heating coolant can be of several types. They differ in the features of operation, installation and the type of fuel they operate on.

There are single-circuit and double-circuit heaters. The first ones are designed to serve only one heating line or heat water. The latter act as a heat source for the heating system and provide hot water supply (DHW). The unit cannot operate in both modes: when heating water for domestic hot water, the heating is turned off.

Depending on the installation site, boilers are divided into two types: wall-mounted and floor-mounted. The former allow you to save space, the latter are distinguished by great power.

Depending on the type of fuel, boilers are:

- Diesel. The fuel for them is diesel fuel. They are autonomous, have high performance with low fuel consumption, and are easy to install.

- Solid fuel. Anything that burns is used as fuel: coal, firewood, pallets, briquettes, etc. The process is reminiscent of burning wood in a conventional stove, only it takes place at elevated temperatures without air access. The medium is heated by hot smoke generated during combustion. They are used for autonomous heating in the house. They require constant loading of the firebox.

- Gas. The most economical and effective. At a low energy cost they have the highest efficiency. To connect to the water floor system, you will have to additionally turn on the distribution manifold and circulation pump.

- Electrical. They can work using electrodes, induction or heating elements. They are easy to operate, but they are the most expensive heat source.

When choosing a boiler for connecting a heated floor system, they are guided by the following criteria:

- compatibility;

- ease of installation;

- equipment power;

- the ability to regulate the heating temperature;

- efficiency;

- ease of use;

- safety;

- manufacturer.

The quality of heating and operating costs depend on the correct selection and connection of devices and equipment.

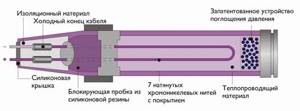

Liquid Electric Floor XL Pipe

This type of underfloor heating consists of one long, thick-walled tube with a diameter of 2 cm, which is made of a special type of polyethylene. This element is a “container” for the coolant, which is a certain brand of antifreeze. A seven-core Teflon-lined cable made of chromium-nickel metal is laid inside the pipe. The pipe is sealed at both ends, due to which there is no circulation of coolant, which, in turn, eliminates the need to purchase any other equipment.

Liquid Electric Floor XL Pipe

On a note! The approximate electricity consumption of this system is 14.5 watts/m².

Heating due to the liquid system occurs quickly and evenly, allowing for heating of the entire surface of the finishing coating. At the same time, such a floor cools down for a very long time. The advantages of a liquid floor include the fact that it is not afraid of pressure from outside, that is, you can safely place furniture on the finishing coating where such a system is located - it will not cause any harm to the heating.

Water heated floor XL PIPE

Installation of XL Pipe is carried out inside the screed, or rather, the laid system is filled with cement mortar about 4-5 cm thick. The pipes are laid according to a specific pattern. For installation you will also need a thermostat and a temperature sensor. At the same time, there are no special installation features for these elements - they are mounted in exactly the same way as when installing other types of heating. Unless you have to purchase a specific thermostat designed specifically for liquid electric floors. A mounting box 12x12x14 cm is also useful.

Installation of heated floor XL Pipe

The XL Pipe system is reliability, safety and environmental friendliness in one type of equipment. The warranty period is 10 years, but in general the system can be used for about 50 years if installed correctly.

Main stages of installation

Daewoo Enerpia XLPIPE-060

pros

This floor heating system has certain advantages:

- it is not a source of electromagnetic radiation;

- practically does not require installation of additional equipment;

- does not overheat and does not have a negative effect on the finishing coating;

- allows you to place furniture on top of you;

- repairable;

- economical (electricity costs are on average 20-30% lower than when using electric floor heating);

- relatively simple installation.

Minuses

- high price.

Liquid-electric heated floor. Combined heating system XL PIPE

DIY XL Pipe installation

Step 1. The base of the subfloor is prepared - cleared of debris, all cracks and irregularities are corrected. Next, 5 cm thick extruded polystyrene foam boards are laid on the surface for thermal insulation.

Laying extruded polystyrene foam boards

Step 2. The plates are secured with special “umbrellas”. First, holes are made in the slabs for fastening material, then umbrella dowels are inserted into them.

Fixing the slabs

Step 3. A reinforcing mesh with a cell size of 10-20 cm is laid on top of the polystyrene foam boards.

Laying reinforcing mesh

Step 4. The individual parts of the mesh are connected to each other with knitting wire.

Wire connection example

Step 5. The heating cable is unpacked and checked for resistance.

Checking the heating cable for resistance compliance

Step 6. The XL Pipe is laid out on the floor surface from the mounting box according to the selected pattern in increments of 20-30 cm. The pipe is fixed using plastic clamps on the reinforcing mesh.

Floor heating pipe layout

Another photo of the process

Step 7. A power cable is connected from the thermostat to the distribution box.

Power cable connection

Cable is connected

Step 8. The wires coming from the pipe are connected to the power cable. The wires can be connected with special terminals.

Connecting wires to the power cable

Connection point

Step 9. The ground wire is connected to the reinforcing mesh.

Grounding the reinforcing mesh

Step 10. A temperature sensor is attached at a distance of 5 cm from the system tube.

Fixing the temperature sensor

Step 11. The installation box is closed with a lid, the seams of which are sealed with sealant. That's it, laying and installation are complete, all that remains is to fill the system with a cement screed and wait for it to dry.

The installation box is closed with a lid

Video - Installation of XL Pipe without screed on a wooden floor

What is the basis for choosing a liquid for a heating system?

When planning the installation of a home heating system according to the “warm floor” scheme, you should not only pay attention to the type of heating devices and the method of laying the heating circuit, but also to the type of liquid that will play the role of coolant. The piping system for heated floors is usually filled with the same compounds that can be used to ensure the operation of radiators. The only caveat is that at the time of purchase you need to determine which composition is suitable for a particular heating method.

Different brands of antifreeze may have different properties, which are determined by the amount and types of additives included in the liquid. For this purpose, it is better to understand in advance the types of non-freezing liquids and find out how this or that liquid behaves in different operating modes.

*

Main article: how to choose pipes for heated floors?

For reference: By distributing the coolant through the heating circuit, the desired heating effect is achieved - uniform heat transfer occurs across the entire floor surface, due to which the entire interior space of the living space is heated to the required temperature.

It is best to decide on the type of coolant at the design stage. The physical properties of the fluid are included in thermal and hydraulic calculations. Typically, for standard projects, all thermal calculations are based on the use of ordinary water. In the case of antifreeze, it is necessary to make some adjustments to the calculations. It's all about the technological parameters of the equipment.

For example: for normal operation of a heated floor with a heating circuit length of no more than 50 m, you can do without installing a circulation pump. If it is necessary to heat large spaces and areas in this way, the installation of a circulation pump is required.

Attention! When working with ordinary water, the performance and pressure parameters of pumping equipment declared by the manufacturer are quite suitable. But in order for antifreeze to circulate normally through the heating system, you will need to purchase a pump with a performance reserve.

In addition, it is necessary to install the circulation pump correctly. The impeller or wet rotor of the pump must be positioned horizontally. Otherwise, a pump for underfloor heating installed in a vertical position will lose up to 30-40% of its power. In order for antifreeze to circulate normally through the water circuit, the pump pressure must be 50-60% greater than in the case of ordinary water. This is the first one.

*

Main article: what to choose, radiator or heated floor?

The second thing that needs to be taken into account is the increased length of the heating circuit and the diameter of the pipes used when working with other liquids. Antifreeze has low heat transfer compared to water, so for the normal functioning of the underfloor heating system, more intensive circulation of the coolant will be required. Not all types of pipes used for the heating circuit can interact with antifreeze. For these purposes, special pipes are produced that have the appropriate diameter and have low reactivity to interaction with chemical compounds.

Capillary heated floor Unimat Aqua

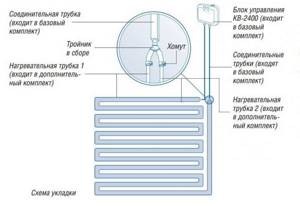

The Unimat Aqua system is slightly different from the XL Pipe. Instead of one thick tube, it has a large number of small diameter tubes in its structure. That is why the system is called capillary. It is connected to a special device with a power of about 2.4 kW, due to which the coolant is heated and thermal energy is released. The system is closed, the pressure in it is created using the same device. The system also does not require the installation of additional heating equipment.

Capillary heated floor Unimat Aqua (basic set)

On a note! The volume of liquid inside the Unimat Aqua system is no more than 6 liters. The coolant is distilled water.

The heating area of one system is about 20 m². That is why it is not used for spacious rooms, although several Unimat Aqua can be installed in one room. Service life is about 5 years.

Installation diagram of capillary floors

Unimat Aqua is available in two types – basic and additional. The first consists of a control unit, an installation kit and two sections of connecting pipe. From all this a small pipeline is formed. The additional set consists of coils of small-diameter tubes, the quantity of which is enough to heat an area of 10-20 m2. Also used for installation are damper tape, fasteners for tubes and material that reflects thermal energy. A standard cement mixture is used to fill the screed.

Unimat heating systems

pros

The main advantage of this system is the multifunctional control unit, which can:

- determine and control the room temperature or heating of the coolant;

- set the time for turning on and off the heating system.

Minuses

The system is completely safe and can be installed even in a bathhouse. But Unimat Aqua has a certain drawback - it is similar to a water floor system. The coolant comes from the heating unit at a higher temperature, gradually cools down, and therefore the heating of the floors will be uneven.

When installing a heated floor, it is necessary not only to carry out the installation correctly in compliance with technology and all standards, you also need to become familiar with the temperature gradation. Often, users set their own parameters for the heating system, which negatively affects its operation. But what temperature of a warm floor is considered borderline high, low or optimal? Read more about this in a special article.

Table. Characteristics of Unimat Aqua.

| Characteristic | Meaning |

| Largest heating area | 20 sq. m. |

| Nutrition | 220-230/50 V/Hz |

| Water temperature heating control | 30-70 degrees |

| Air temperature heating control | 0-40 degrees |

| Maximum length of tubes | 140 m |

| Timer adjustment | 1-12 hours |

| Electric cable length | 1.4 m |

Installation of underfloor heating Unimat Aqua Caleo

Step 1. The surface of the subfloor is thoroughly cleaned of debris, all irregularities are removed.

Surface preparation

Step 2. Select a location for installing the thermostat on the wall.

Choosing a location for installing the thermostat

Step 3. A groove is made in the rough base or screed for laying the temperature sensor.

Strobe for laying the temperature sensor

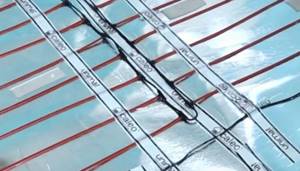

Step 4. Heat-reflecting material is laid. The sheets are connected to each other with tape or secured to the base with a stapler.

Heat-reflecting material is being laid

Step 5. The floor heating system is laid out on the surface on the side where the thermostat is planned to be installed.

The heated floor system unfolds

Step 6. Where the mat needs to be rotated, one connecting wire is cut. The strip rotates 180 degrees. The tubes must not intersect with each other.

The connecting wire is cut

Attention! The cut should only be made in the middle of the power wire. The maximum strip length should not exceed 25 m.

Step 7. The system is glued to the surface of the heat reflector using tape.

The system is glued to the surface of the heat reflector

Step 8. Installation wires are used to connect the mats to each other. To do this, the ends are stripped of insulation at the cut site. A sleeve is installed in this place, it is clamped with crimping pliers.

Connecting mats

Step 9. Place a heat-shrinkable tube over the wire. The power wire is connected to the connecting wire. The sleeve is crimped and heated with a special hair dryer. The sleeve is closed with a tube, which is then heated and shrinks.

The junction of the power wire with the connecting wire

Step 10. Next, the system is connected to the thermostat. The Unimat Aqua strip is attached to it using a connecting wire and special regulator clamps. The connection is made according to the diagram included with the thermostat.

Connecting the system to the thermostat

Step 11. Holes are cut in the heat reflector to connect the future screed with the base of the floor.

Holes are cut in the heat reflector

Holes in the heat reflector

Step 12. The temperature sensor is installed inside the corrugated tube. It is located along the rods of the system.

sensor for heated floor

Installing a Temperature Sensor

Step 13. System functionality is checked for 15 minutes.

Checking the functionality of the underfloor heating system

Step 14. The system is filled with cement mixture and a screed is formed.

Filling the system

Video – Installation of Unimat Aqua floor

Liquid or water electric floors are an excellent alternative to other types of heating. It is easy to use, practical and performs its functions well. The use of such systems will add coziness to your apartment or house, making the flooring warm and pleasant.

Residents of private houses often do not know what type of heating to choose in order to ensure the most comfortable living conditions. So, heated floors or radiators - which is better in a private home? Read in the special article.

Installation technology

Let's consider what stages of work have to be performed when installing a heated self-leveling floor.

Preparatory work

The entire working surface is cleaned of dirt, uneven areas are eliminated, and defective areas are repaired. After this, you can proceed to the masses, where the installation of the heating system will be carried out. Here you will have to take into account certain nuances:

- you should not use places for laying infrared film where you plan to install large items,

- When installing the system, the distance from the walls determined by building codes is maintained,

- make sure that your system is located at a sufficient distance from other heating devices (at least twenty centimeters),

- It is mandatory to lay a thermal insulation layer, which minimizes heat losses. It is best to use materials with a foil surface, laying them out with the metallized side up and securing the edges with tape.

Installation of heated floors

- Film heated floors can be laid independently or using grommets. The laid sections are connected by wires and connected to the thermoregulatory unit. After this, the thermostat and temperature sensor are synchronized. It is recommended to mount the sensor in a corrugated pipe. The system is easy to check. It is turned on for a few minutes so that all the elements warm up. If this does not happen, you should check all installation steps and find the error,

- Cable floors are laid in almost the same way as film floors, but there are certain differences. Cables must not be stacked on top of each other. In addition, you can start the heated floor system only after the self-leveling surface has completely dried. It is prohibited to fill the temperature sensor with the mortar mixture. The formation of void areas containing air bubbles is unacceptable,

- water system. To create such a warm floor, pipes are laid out on the surface, connected and filled with mortar. It is recommended to use metal-plastic or copper as the material for the device. The second option is more durable, but will also be more expensive. If you want to increase thermal conductivity, then use pipes made of plastic material. It is not recommended to lay cheap polypropylene - it will quickly fail.

Film heated floor