- Calculation of heating mats and infrared film

- Heating cable calculation

- Calculation of UNIMAT core mat

Electric underfloor heating is represented by various types of systems: thin heating mat, heating cable, rod carbon mat, infrared film, each of which has its own range of characteristics and areas of application.

Price for heating mats under tiles from RUB 1,869.

The price for a heating cable in a screed starts from RUB 1,557.

Price for film IR heated floor from 430 rubles.

Price for rod-based infrared floor heating starts from RUB 3,158.

Proper selection and calculation of underfloor heating will ensure the most efficient functioning of the heating system with the lowest energy costs.

To make an accurate selection and calculation of a heated floor yourself, use the formulas described below or contact the specialists of the Warm Floor chain of stores in your city.

The choice of heated floors is based on the following data:

- The required degree of heating in a room or building. Electric underfloor heating can be used as a comfortable heating of the floor surface, as well as as the only source of heat in the apartment.

- The type of flooring used in the room. Each coating has different thermal conductivity and thermal sensitivity, which must be compatible with the heating system.

- Type of installation – cement screed (at the stage of major repairs); warm floor under tiles or dry installation under laminate (for cosmetic repairs).

- The total area of the room in which the heated floor will be installed, and the area not occupied by furniture.

Heating mat IQWATT from RUB 3,319.

IQWATT heating cable from RUB 3,076.

Film flooring CALEO from RUB 1,339.

UNIMAT rod floor from RUB 2,398.

Heating mat DEVI from RUB 4,261.

DEVI heating cable from RUB 4,307.

The first step to creating the optimal temperature using a “warm floor” system is to determine the required degree of heating: will comfortable heating of the floor surface be enough for you (the so-called “additional heating”) or is it necessary to compensate for the lack of central heating using a warm floor (main heating) . The answer to this question will determine the level of power that the “warm floor” system should have. For comfortable heating it is 100-150 W/m2; for main heating – 160-200 W/m2; for cold unheated rooms (balconies and loggias) – 200-250 W/m2.

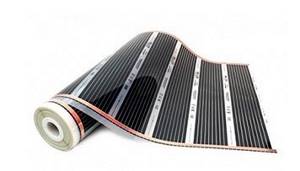

It is important that the required power is compatible with the selected floor covering, the manufacturers of which, as a rule, indicate permissible temperature thresholds. Thus, for laminate and linoleum, the optimal power is 100-130 W/m2, the floor surface temperature should be in the range of 26-28 ° C. Therefore, these coatings are recommended to be used with heated floors only for additional heating. In most cases, KEEPLY infrared film is used for such coatings. Alternative options are Devidry thermomat (manufactured by DEVI) and TVK-130 LP (THERMO).

For our customers, the service of selecting and calculating underfloor heating is free!

The cost of analogues of Keeply BASIC film heated floors is about 325-350 rubles. per linear meter. This is 650-700 rubles. per square meter.

At the same time, the thermal film itself is only heating elements, and not a “warm floor” system ready for installation.

In addition to the heating film, it is necessary to purchase components for installation - terminals or grommets, bitumen insulation, electrical wires. Read more…

Tiles and porcelain tiles are suitable for both main and additional heating, i.e. compatible with high powers – 150-220 W/m2. Manufacturers DEVI, THERMO, WARMSTAD and IQWATT offer heating mats that are widely used as heated floors under tiles and porcelain stoneware.

To select a heated floor, it is important to consider the condition of the base surface on which the system will be mounted:

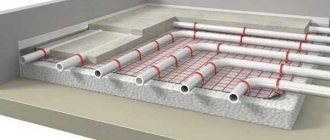

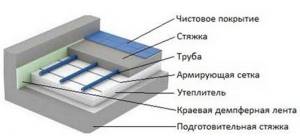

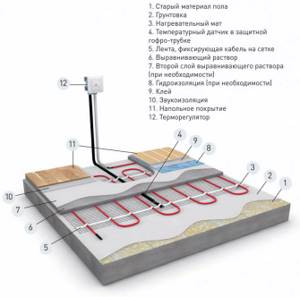

- For major repairs, it is recommended to install cable systems (model Warmstad WSS from WARMSTAD (Russia); Deviflex 18T from the manufacturer DEVI (Denmark); heating cable SVK-20 from THERMO (Sweden)), mounted under a cement screed with a height of 3-5 cm. Such heated floors are compatible with absolutely any floor covering. The system is turned on after the screed has dried, after 30 days.

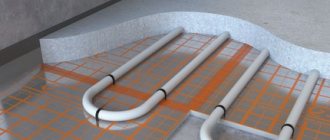

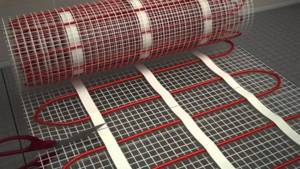

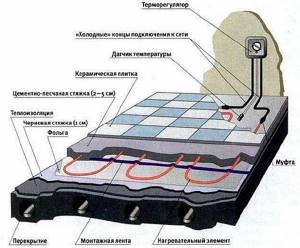

- In the case where the screed is already equipped, heating mats, such as IQ Floor mat from IQWATT or infrared rod-heated floor UNIMAT, are suitable. Thin mats are installed in a thin layer of leveling soil (1-1.5 cm thick), and UNIMAT thermomats are placed under tile adhesive (2-3 cm).

- Another option for an equipped screed is dry installation, which allows you to maintain the height of the room. Infrared films KEEPLY, CALEO or VIOLET are designed for this purpose and can be turned on immediately after installation.

Pay attention to the location of the object in which the heated floor will be installed. It is worth considering factors such as the presence of heated rooms below and above or a cold foundation (soil). In case of high heat losses, it is necessary to place heat-insulating material under the heating system.

Most “warm floor” systems are installed in that part of the room where there are no large objects or equipment (bed, closet, refrigerator), that is, in free space. This is necessary to prevent the system from “locking up” and causing further overheating. If you are not sure that the furniture will always be in one place, then you need to choose a warm floor with a self-regulating function - the UNIMAT rod mat. This property allows the system to independently adapt to its environment, reducing or increasing the power level as needed and thereby saving energy.

The calculation of a warm floor is carried out in three different ways, depending on the type of heating system.

Classic thin heating mats. Characteristics and main differences.

By specific power

Thin heating mats produced by various manufacturers are very diverse. One of the main characteristics of mats is specific power , that is, the electrical power consumed - and also the thermal power output - per 1 m² of heated area. The consumer is offered the following range of rated power density values: 100; 130; 150; 160; 180 and 200 W/m² with an industrial AC supply voltage of 230 V.

Width

The width of the base mesh - which is also the width of the heated strip of the area - can lie in the range of 0.5...1.0 m. The most commonly produced rolls are 0.5 m wide. This is the optimal width, allowing you to quickly spread out the selected mats over an area of any configuration. The complex contour of the heated area is not an obstacle to the installation of heating mats, since there are special layout methods, which we will consider in the section devoted to their installation.

By thickness

Heating mats were originally developed with the goal of installing a “warm floor” system with a minimal rise in the level of the floor covering above the existing base. Therefore, the heating cable installed on the mesh has a very small diameter, from 2.5 to 4 mm. For some users, the construction (total) thickness of the mat is of fundamental importance. For example, when renovating a floor, it is not advisable to rehang or change the height of doors in order to adjust their position to the new level of floor covering. The thickness of the electric heated floor mat can be 3; 3.5; 4; 4.5; 5 mm. This parameter is related to the design of the heating element of the cables installed on the mats (single-core and double-core mats), and to the sheath material (fluorine-containing polymers, silicone, polyvinyl chloride, etc.).

Based on screen availability

The next parameter characterizing the electrical safety of the product is the presence of a screen on the heating cable of the mat. In accordance with the requirements of the Electrical Installation Rules, an electric heated floor, which includes a mounted heating mat, must act as an “electric potential equalization device” (EPED). The grounded shield of the cable installed on the mat mesh acts as a UVEP, which is confirmed by GOST R 50571.25-2001, part 7, clause 5.8. Some heating mat manufacturers offer products on the market that do not have a screen. This is very inconvenient, since in accordance with the PUE, in order to ensure the safe operation of such an electric heated floor, it is necessary to install a grounded welded metal mesh above the mounted mat, which acts as a UVEP.

By design features

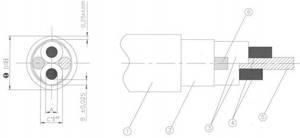

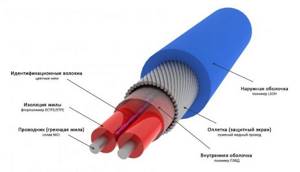

By design, thin heating mats are divided into single-core and double-core . These names come from differences in the design of the cables installed on them. The presented drawings show transverse and longitudinal sections of single-core (Fig. 2.1) and two-core (Fig. 2.2) cables mounted on a grid of mats.

Rice. 2.1. Typical structure of a single-core heating mat.

1 — Cable sheath, fluoroplastic PVDF

2 - Screen, copper wire

3 — Internal insulation of the heating core, fluoroplastic FEP

4 - Heating core, metal alloy with high electrical resistance

Rice. 2.2. Typical structure of a two-core heating mat.

1 — Cable sheath, fluoroplastic PVDF

2 — Screen, aluminum foil

3 — Internal insulation of heating cores, fluoroplastic FEP

4 - Heating cores, metal alloy with high electrical resistance

5 - Plastic filler cord

6 - Drainage copper screen conductor, 1×0.5 mm²

A single-core cable has a diameter of no more than 3.0 mm, a two-core cable has an oval cross-section with a maximum thickness of no more than 3.5 mm.

A two-wire mat is more convenient for laying and connecting to a thermostat, since it has only one three-wire power cable (phase + neutral + screen). A single-core mat has two two-core power cables (phase + screen and neutral + screen), see Fig. 3.

Rice. 3. General view of a single-core heating mat.

According to materials and heat resistance of heating mats

The last parameter from the technical characteristics of the mats is the maximum permissible temperature of the heating cable sheath in ON/OFF. condition. It depends on the heat resistance of the electrical insulating shells of the product. However, for a matte heated floor installed in a regular living room, the actual steady-state temperature of the cable sheath (approximately 35...45 ° C) is always less than the maximum permissible. It is advisable to install the most heat-resistant mats in rooms with high temperatures (baths, saunas, hammams).

As an example, we present the values of the maximum permissible temperature for three popular heating mats:

| Type and brand of heating mat | Shell material | Mat state | |

| OFF | ON | ||

| Single core DEVIheat™ 150S | Fluoroplastic | 120 °C | 110 °C |

| Twin-core DEVIcomfort™ 150T | Polyvinyl chloride | 90 °C | 85°С |

| Twin-core DEVImat™ 150T/200T | Fluoroplastic | 120 °C | 115 °C |

The table shows that fluoropolymer shells can withstand ambient temperatures in the most thermally intense conditions. However, even one of the most popular mats with a cheaper PVC sheath of the heating cable, DEVIcomfort™ 150T, is characterized by a maximum permissible temperature that greatly exceeds the typical operating temperature (35...45 °C).

Exploitation

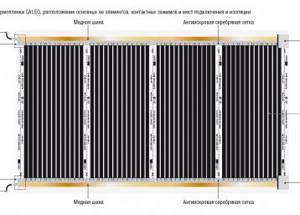

If infrared thermal film is used as the main source of heating, it should occupy at least 70% of the floor surface. It is not recommended to use it for heating in difficult climatic conditions.

In this case, the infrared film coating serves only as an additional source of heat. The thermal film is cut only in a specially indicated place - this is taken into account when calculating the amount of material.

Infrared heating is also applicable for commercial buildings that cannot be equipped with central heating. The use of thermal film at sub-zero temperatures prevents freezing and icing of the porch and pipeline.

Thermomats are used to heat floors for a short period of time. The use of mats is advisable if there are no plans to increase the current floor level (thick screed).

Thermal mats are mounted in a layer of tile adhesive, the thickness of which does not exceed 3-5 mm.

Cable underfloor heating is used as the main source of heat in rooms where central heating is difficult to install. In most cases, the system is equipped in rooms located on the first floors of buildings, bathrooms, corridors, and toilets.

The coating is mounted directly on the reinforcing mesh or heat-insulating layer. It is possible to use cable flooring for outdoor heating:

- warming up the lawn, heating the soil in greenhouses;

- in order to eliminate icing of gutters, drains, roofs, pipelines;

- for heating stairs, driveways, sidewalks.

Installation:

- The direct action system heats the surface over a short period of time. Installation is carried out for the purpose of full heating or heating of individual rooms.

- The storage cable device is economical due to heat accumulation.

- When installing a cable system under a wooden floor covering, the free space is filled with a heat-insulating layer, and the cable is placed on a metal mesh.

Precautionary measures:

- To ensure the required level of heating, the power and type of power cable are carefully selected, and thermal insulation is organized according to the instructions.

- Do not lay the cable under furniture without legs or large household appliances to avoid overheating.

- Shortening the cable negatively affects the strength, so select the parameters of the heating elements in accordance with the size of the room.

- During the installation process, do not wear heavy shoes or step on the cable.

- Draw up an installation diagram - it will be needed if the heating elements are damaged.

- A corrugated tube is used to connect the temperature sensor.

- Upon completion of installation of the electric heated floor, check all connections, measuring the resistance level.

- The system is connected only after the screed has completely dried.

What is the function of thermal insulation?

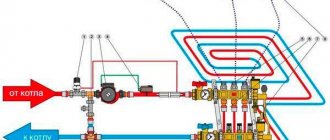

When installing a water heating system, the most important task is to minimize heat losses and direct all the heat directly to the room where the structure is installed.

If you simply lay pipes on the main floor, then there will be very little use from this system, since most of the thermal energy will go down to the basement or to the neighbors on the lower floor.

Thermal insulation is precisely designed to solve this problem, which, on the one hand, is a barrier to the entry of cold air from the basement (if the system is installed in a private household), and on the other, serves to preserve and distribute heat evenly throughout the room.

Properly selected and installed thermal insulation allows you to eliminate the loss of thermal energy and redirect the warm flows coming from the heating pipes upward, towards the room. In addition, the insulation prevents condensation from accumulating and prevents the formation of mold on the walls

When choosing a particular material, you need to focus on its initial characteristics and the features of the room

The classic types of insulation that were widely used in the past are ecowool and polystyrene foam. Actually, even now the inexpensive cost of these materials still attracts very thrifty buyers.

However, progress does not stand still, and manufacturers offer more practical and convenient thermal insulation materials - special mats for water floors.

Types of thermomats

Twin-core heating plate

There are several varieties of counterfeit materials, and when purchasing, you need to know exactly which one is suitable for a particular room. If you are faced with a choice of which heating equipment to purchase - single-core or double-core, you first need to study the characteristics of each:

- single-core heating plates. In this category of substrate materials, the wires consist of a single core. The base can be metals: brass, galvanized, nichrome and others. It is due to them that resistance occurs with subsequent heating. During operation, an electromagnetic field appears, which is partially neutralized by the protective aluminum film. Used outdoors or in industrial buildings;

- twin-core heating plates. Thanks to two conductors, the heating power is higher than conventional ones. Increased power consumption due to two cables, but easier installation. The electromagnetic field is dampened by wires, radiation is minimized. Suitable for bathrooms and living rooms.

Thermomats are an excellent analogue of classic floor insulation and are ideal for water-based coatings. Installing this type of heating is a good solution that combines quality and durability. And even a person with no experience can figure out the installation.

- Related Posts

- How does radiant floor heating work?

- How to choose a boiler for underfloor heating?

- What are the characteristics of Aura underfloor heating?

- How to choose tile adhesive for underfloor heating?

- How to check a heated floor?

- How to lay a water-heated floor under tiles?

Calculation of heating mats and infrared film

When choosing the required set of heating mat, infrared film (KEEPLY, CALEO, VIOLET FLOOR), the following formula is used:

Stotal – Szan. = S;

where: Stotal. – area of the room; Szan. – area occupied (locked) by furniture; S – area of the required set.

Calculation example:

The area of the children's room is 12 m2, of which 5 m2 are occupied by furniture. According to the formula:

12 m2 – 5 m2 = 7 m2

To heat this room, you should choose a heated floor with an area of 7 m2.

In the case of a thermomat, it is prohibited to shorten or extend it, so the area of the installed heated floor is rounded down. Thermal films KEEPLY, CALEO and VIOLET FLOOR can be cut, which makes it possible to connect individual strips of underfloor heating and combine different sets of this brand. For example, on 9 m2 an infrared film of 5 and 4 m2, or 4, 3 and 2 m2 can be installed. And also one large set can be used in several rooms. It all depends on the configuration of the room and the desired layout of the heated floor.

Another plus

I can’t help but mention that one of the advantages of heating mats is the ability to install them yourself. The readiness of the kit and the ease of laying the mat on the floor allows you to lay it yourself with minimal skills.

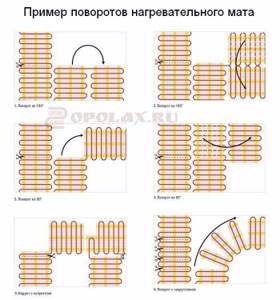

You can rotate the mat 90˚, 180˚ and almost any other angle. To do this, the mat mesh is simply cut with simple scissors, and the cable is turned to the desired angle. Let's look at the photos of such turns.

Functions of construction mats

Expanded polystyrene for underfloor heating ensures the proper functioning of the heating structure. To do this, it is important to provide a good base for the warm water floor. Mats help distribute heat over the entire surface and retain it even after the energy supply for the functioning of the heated floor is stopped.

Also, such mats provide complete insulation from cold air. Thus, during cold weather, cold will not penetrate into a room with a warm water floor. Condensation does not form if such a substrate is present. Accordingly, there is no mold on the walls either.

Material structure Source allelectrics.ru

Features of the material for the production of mats

Modern mats are made from extruded polystyrene foam - a material that not only has excellent thermal insulation properties, but also has a whole list of other advantages.

Main advantages:

- Low vapor permeability rate (0.05 mg (m*h*Pa). For comparison, for mineral wool this figure is 0.30. This means that polystyrene foam does not allow water vapor to pass through well and does not accumulate moisture, is constantly in a dry state, and as a result does not contribute to the formation of condensation .

- Low thermal conductivity , which means maximum heat retention in the room.

- Soundproofing characteristics.

- Does not attract rodents and is not a breeding ground for the formation and development of microorganisms.

- Durability . According to the results of tests (alternating high and low temperatures from plus 40 to minus 40 degrees and exposure to water), the service life of products made from this material is up to 60 years.

The mats use expanded polystyrene with a density of up to 40 kg/m3, so they can withstand heavy loads perfectly.

This property is especially valuable when installing a water floor, since a fairly heavy structure consisting of water pipes, a layer of concrete and a finishing floor covering is laid on top of the mats.

Weight of the water heated floor system per 1 sq.m. is about 200 kg, the thickness of the layers is approximately 150 mm. The main load falls on the bottom layer. The high density of polystyrene foam ensures the strength of the mats and allows them to support a heavy structure (+)

Benefits of using mats

If the mat is installed correctly, it can serve as an excellent soundproofing material. But there is a significant nuance - a water heated floor must be absolutely safe for those who live below. Therefore, along with reliability and durability, such a criterion as waterproofing is valued. And this same layer is designed to protect the substrate itself from the destructive effects of the cement floor mortar.

There is a non-professional opinion whose supporters talk about the possibility of abandoning mats when laying floors. But this position is erroneous, since heat losses will be so great that they will inevitably lead to significant financial losses.

If we consider the cost of all water floor systems as a whole, then the price of insulation is not so high. And a design made once and wisely will pay for itself one hundred percent during operation.

Types and types of electric floors

From the point of view of technical equipment, all modern electric floors can be divided into 3 main types:

- classic cable, which has several varieties;

- innovative infrared-carbon, rod and film;

- and thermomats, that is, thin cables on a mesh.

All these types of electric floors have a number of general characteristics:

- they require a dry mounting base;

- they need thermal insulation with grounding;

- they are equipped with a special thermostat.

In addition, they are all reliable and durable systems for additional heating of premises.

There are also several types of electric floors, which may belong to the same type (or may not), but differ from each other in:

- features of installation technologies;

- combination with various types of floor coverings;

- quality of generated heat.

Installation Features

Rod infrared floors are a multi-layer structure, which can be installed in two ways.

Laying on screed

On a screed - this means pouring a subfloor from a concrete solution that expands during the heating process. A layer of heat and waterproofing, mats, and reinforcing mesh are placed on it, on top of which a thin screed is poured and the floor covering is installed.

On a wooden floor

The essence of installation on a wooden floor, the method is also called laying, is to construct a “pie” consisting of an insulating substrate with a foil layer, a wooden log, a reinforcing mesh to which the heating elements will be fixed, and a finishing coating.

Laying tiles

Laying tiles on a warm floor is not particularly different from laying tiles on any other surface. However, in order not to damage the heating elements, it is recommended to fill the heated floor mats with a screed made of tile adhesive.

It is better to take glue with epoxy resin. It should be diluted to the consistency of thick sour cream and applied to the fiberglass mesh in a thick layer. After the glue has completely dried, you can proceed to tiling.

The adhesive is applied to the floor and tiles using a notched trowel. Then, the tile is applied to the floor and pressed down lightly. After the glue has dried, the seams should be treated with grout.

How to choose?

When choosing mats, it is necessary to verify the authenticity of the material presented, since the market is saturated with various fakes, and with strict requirements for the properties and functions of thermal insulators, a mistake in this matter will be very expensive. To avoid such problems, you need to check the availability of documents for the goods, certificates of conformity and warranty cards.

Some rooms already have thermal insulation, then you need to take thinner material. In warm rooms, it is possible to use mats without thermal insulation properties, but equipped with bosses to clearly fix the heating circuit.

Specifications

Before you buy a heating mat, you should familiarize yourself with its technical characteristics.

Standard parameters for heating mats for most manufacturers are indicated in the table data:

| Parameters of underfloor heating, heating mats | Meaning |

| Cable type | Single-core, double-core shielded |

| Rated voltage | 220-230 V |

| Power density | 90-150 W/m |

| Thickness of underfloor heating mats | 3.0 mm |

| "Cold Ends" | 2*1 m, 1 mm², screen |

| Screen | Made of copper, 10*0.15 mm |

| Internal insulation material | Fluoroplastic |

| External insulation material | Fluoroplastic |

| Allowable resistance | 5-10% |

| Width of mesh (width for warm floor mats) | 450 mm |

| Heating zone width | 500 mm |

| Max t on the surface of a working cable | 90 degrees |

| Coloring of power wire cores | Phase – black, zero – blue, ground – screen |

| Coverage area | 1-13.5 m |

Option one - use copper pipes

In this case, there is no need to dwell on this option for a long time. It has already been written above that copper for heated floors is an expensive pleasure.

Here, not only the cost of consumables is taken into account, but also the complexity of installing the entire heating system. Laying copper pipes is carried out using special equipment and in compliance with a certain technology, so it will not be possible to make this heating option yourself

Despite the high cost of copper pipes and installation costs, such products have high technological characteristics. Copper conducts heat well and is highly resistant to corrosion.

Comments:

Carlson

Great review! Self-regulating cables are still really blatant “G”, which is not suitable for heated floors, especially in the form of mats. I have never come across any worthy offers in this segment - it’s all just China.

Paul

I do not recommend such mats to my clients. Maybe such designs help beginners; I find it much more convenient to attach the cable directly to the floor, and you can bend it in any direction.

Larion

Pavel, I agree. In any case, reinforced mesh + cable + fastenings will cost less than the assembled mat.

Andrey

Maybe it's time to indicate prices in rubles! We live in Russia after all!

Leave a comment Cancel reply

Related Posts

Advantages and disadvantages of infrared heated floors. Installation diagram

The underfloor heating regulator is an important part of the entire system.

Warm floor Unimat - a well-advertised middling product

Caleo warm floors are a very high-quality heating device.

Costs for installing heated floors, mats, prices

Heating mats are in leading demand among all underfloor heating systems, due to their high installation readiness. For heating mats, the price depends on the cable cross-section - 2.5-4.5 mm - the larger it is, the higher the heat transfer, the higher the costs . For polystyrene foam mats for heated floors, the price depends on the total length and thickness of the product. Average costs, for example, for Devi heated floors (mats and minimats) the price will be 45 USD/m².

Leading manufacturers of mats for laying water-heated floors

In order not to doubt the quality of the purchased mats for laying water-heated floors, you should choose products from leading manufacturers. We advise you to pay attention to the products:

- Oventrop , demonstrating high performance characteristics. The German company offers mats with “bobs” for dry installation, roll and folding thermal insulation. The first type can be with or without thermal and sound insulation;

- Knauf. The manufacturer offers high-quality slabs with high performance characteristics;

- Rehau. Despite the price, mats for warm water floors made in Germany are in steady consumer demand. The most popular are foam styrene mats with “bobs”. Supplied with clamps for fastening pipes;

- Energyflex. The domestic manufacturer offers a wide range of models, in which there is sure to be a suitable option for water heated floors;

- Ecopol. The Russian company offers smooth mats and those with bosses. The locking connection and the presence of a waterproofing layer ensures the formation of a strong and reliable foundation. The level of thermal insulation characteristics depends on the thickness of the thermal insulation layer. The latter can be 20, 30 mm or absent in principle.

Knauf - proven quality