Types of heated floors

A person always strives to furnish his home with the maximum level of comfort, and so that the finishing will last for as long as possible.

Therefore, you need to use only the highest quality materials. Film heated floors under carpet will last a very long time if they are laid using the correct technology. There is nothing complicated about this, the main thing is to follow the recommendations of professionals and everything will work out. The material goes well with any type of heating elements. An infrared heated floor will serve perfectly and will not cause the slightest harm to the coating itself. This has been proven by many years of experience in using this combination. Infrared heating, in general, is considered one of the most effective methods, so the possibility of its use gives carpet good advantages over other finishing materials.

Can be installed under carpet and electric heated floors. They will also work effectively and are not dangerous to the material. According to statistics, this type is the most common. Users are attracted by the ease of installation, the relative cheapness of components and the possibility of flexible settings thanks to advanced thermostats with programmable functions.

Water heated floors are used less often. Installation of this type of heating is the most labor-intensive, as it requires preliminary installation and adjustment of the boiler. Unnecessary manipulations scare off many users who prefer simpler methods of floor heating. But it’s not for nothing that water heating is used as the main heating system in any room, so it would be a big mistake to write off water-heated floors. They do their job very well.

Is water heated flooring and carpet compatible?

For many of us, furnishing our own home is one of the most important tasks. We always try to achieve the highest possible comfort and create an atmosphere of warmth and coziness in our home. To achieve this goal, we use new technologies, acquire new technological equipment, and rely on new materials. Warm floors, for example, make it possible to provide effective heating of living spaces, and the floor covering already complements the surroundings.

Not only the interior of our home, but also the technological parameters of the habitability of the home and the corresponding level of comfort depend on what heating equipment we use and what materials we focus on. However, most often we do not rely on common sense and technical calculations, but follow our whims and desires.

In some cases, we have to combine things that are absolutely opposite in their parameters and characteristics. So, for example, is the water-heated floor in our house and carpet compatible? We will try to find answers to this and many other questions.

Warm floors and carpet, fundamental differences

Our natural desire to create a comfortable environment in an apartment or house sometimes encounters contradictions. The technical capabilities of modern equipment and new technologies allow us to provide a qualitatively new, efficient heating system in your home. Having given preference to heated floors, we bet that such heating will be the best, most convenient, and most effective. However, in some cases, our subsequent actions negate all the advantages of even the most advanced equipment. We are talking about an incorrectly chosen floor covering for a warm water floor.

Why is this possible? The reasons lie in the fundamentally different technological parameters of the heating system and the material used to finish the floor.

Warm water floors are a low-temperature system. The coolant circulating through the loops of the heating circuit can have a temperature of no more than 500C. By adding to this the substrate, concrete screed and floor covering, at the exit, on the floor surface, we obtain an optimal temperature of 270C. Thus, floor heating, due to its operation, provides a comfortable temperature regime inside the room.

When is it possible

Small decorative rugs near upholstered furniture are always allowed. Cloths occupying a large area on a heated floor are permissible only if they have high thermal conductivity. And even then, it is better to choose durable mats or openwork fabrics made from natural materials - synthetics will not last long.

As for mobile heated floors, they need a carpet - this is the very protection from mechanical impact. True, you should still not use options that are too dense and fluffy - with such a coating, the efficiency of the heaters is reduced, and their circuitry requires the connection of automatic thermostats. The best option is heat-resistant synthetics or natural fabrics of medium density. Let's say short pile. But it is better to avoid bright colors and patterns - it is unknown whether the dye will withstand the temperature test.

Methods of fixing carpet

Before you start laying carpet, you need to choose one of the methods of attaching it to the base, which for this type of covering can be the following:

- fixing the whole canvas with glue and without glue;

- gluing fragments;

- stretching the canvas onto slats with nails using a special tool (stretching), in which the coating is not attached to the base at all, but is held most securely.

Depending on the chosen fastening method, the carpet is also installed. The cloth purchased in the store needs to be spread on the floor of the room so that it is smoothed and leveled for a couple of days at room temperature.

Fixing carpet to wood using double-sided tape

Fixing with double-sided tape is a very popular way of laying carpet on a wooden floor. Double-sided tape comes in several types, with different widths. Depending on the type of floor covering, the width of the tape is selected. First, adhesive tape is glued to the floor.

It must be glued in the form of a grid. The size of the cells is 50 x 50 cm. The carpet is laid out on the floor, and it should extend 5 cm onto the walls. The protective film is removed from the adhesive tape and the product is glued.

Upon completion of gluing, all excess carpet around its perimeter is cut off. When installing skirting boards, you must leave a gap of 5 cm from the wall.

- it is possible to change the floor covering;

- no need to use a substrate;

- does not require the involvement of specialists;

Latex-based carpet is an inexpensive floor covering suitable for various rooms with not too much load. Read about carpet cleaning here.

- it is necessary to level the floor and carefully prepare it;

- there is a risk of deformation of the tape;

- Bubbles and wrinkles may form on the coating.

Scotch tape consumption is one roll per 8 square meters. The estimated length of the coil is 10 meters. This method is especially suitable for those who often change the design of the room.

Security measures

The IR device can be safely placed under the carpet, since such systems have long been recognized as completely safe. Any installation work must be carried out step by step, following the attached instructions. To avoid possible fire and electric shock, take the following precautions:

- Give preference to automation. For such equipment, a separate electrical branch should be used. It will be necessary to install machines that will be located near the meter. An RCD is also required.

- Control block. You will need a thermostat if you plan to use carpet. It will help avoid overheating and reduce energy consumption.

- High-quality grounding. All conductive elements require separate insulation. Conductive tape will be needed to cover the entire perimeter of the film.

Distinctive features of infrared heating

Infrared radiation is recognized as the most effective heating method, surpassing its electrical counterpart in many respects.

Features of an infrared heater

- The carpet does not deform due to its slow and uniform heating.

- When exposed to infrared rays, overheating of the floor covering practically does not occur.

- Less energy consumption.

- Quick, easy to do-it-yourself installation.

Since infrared film does not require a screed, the floor level rises slightly, practically without reducing the overall height of the room. This circumstance makes it possible to put the heated floor into operation immediately after all work is completed, since there is no need to wait until the screed gets stronger.

Infrared heater

Principle of operation

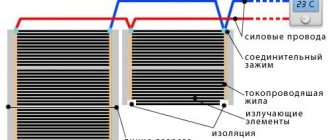

IR floor is a thin film, between the layers of which carbon plates are placed. They serve as a heating element that generates heat. The device operates from the mains, heating is carried out using infrared rays measuring 10 - 20 microns.

The film quickly heats the floor, and the presence of a thermostat allows it to turn off when the desired heating level is reached, and turn on again when cooling. As a result, the device operates approximately 20 minutes per hour.

Film flooring has the highest efficiency when compared with other systems. With rapid heating, electricity consumption is not significant, thereby infrared flooring is considered more profitable and economical.

In addition, it does not heat the air masses in the room, but the objects in it, and they already heat the air. This allows you to create a wonderful atmosphere in the apartment, since the air does not dry out, while it is saturated with negatively charged particles.

Infrared flooring is perfect for different rooms; the ideal option is to install it under the tiles in the toilet or bathroom (we suggest you read the step-by-step instructions for installing the TP in the bathroom).

Features of laying roll coverings

After the heated floors have been laid, it’s time to think about installing the floor covering (how to install a water circuit with your own hands is described in the corresponding article).

To lay roll material, you will need to follow the following recommendations step by step:

Prepare the base - you need to level the floor to cover it with a leveling mixture. If the differences or chips are not so large, the unevenness is eliminated with putty. After drying, the surface is primed twice. When using a polystyrene system, the mats are covered with plywood or gypsum fiber board. The joints are puttied. The coating is brought into the room and left for 5-6 hours so that the material warms up to the air temperature in the room. It is strictly forbidden to lay linoleum on water-heated floors that have been brought in from the street immediately before installation. After heating to room temperature, the material is rolled out over the entire area and trimmed. The laid flooring should be approximately 0.3-0.5 cm away from the wall. The joints will subsequently be covered with skirting boards. Carpet or linoleum laid on a water-heated floor will “settle down” after about a day, and the waves will disappear. When laying over a concrete floor, it is best to glue the flooring to the surface

When choosing an adhesive composition, you should pay attention to its purpose. There are special adhesives and mastics with high elasticity that allow the material to “walk” as the surface heats and cools. If the floors are covered with linoleum, without an adhesive base, simply pressed against the base with skirting boards, waves will certainly appear over time

A special feature of carpet is that fine dust, which is attracted by the cement screed, easily passes through the pores of the material. Therefore, it is better to place it on plywood or gypsum board.

If the floors are covered with linoleum, without an adhesive base, and are simply pressed against the base with baseboards, waves will certainly appear over time. A special feature of carpet is that fine dust, which is attracted by the cement screed, easily passes through the pores of the material. Therefore, it is better to place it on plywood or gypsum board.

Which linoleum is better for a water floor?

Choosing linoleum for a water-heated floor can be difficult, since there is a wide variety of products that differ in both purpose and performance characteristics.

You should pay attention to the following criteria:

- Class - the optimal choice would be commercial or semi-commercial material. These classes have a high level of wear resistance, can easily withstand high temperatures and retain color and pattern during use.

- Type of material - multilayer polyvinyl chloride linoleum should be laid. It is believed that polyvinyl chloride type coating is completely safe for laying on top of heated floors. An alternative could be vinyl material. You can cover warm water floors with vinyl linoleum only if there are no allergy sufferers in the house.

- Cost – linoleum for heated floors cannot be cheap. Budget options usually quickly turn yellow, lose their pattern and shape, and are toxic.

When choosing a finishing material, you should seek help from a consultant and purchase one that is of high quality and wear resistance.

Which carpet is suitable for a water floor?

When choosing carpet for a water-heated floor, you should follow the same instructions as when purchasing suitable linoleum:

- Base – material with a thermal insulation or sound insulation backing is not recommended. The layer retains heat, leading to overheating and increased energy consumption.

- Purpose – for an apartment you should choose a carpet for a semi-commercial type of water-heated floor. Commercial flooring with high wear resistance and fine pile is installed in the office. The use of natural carpets in this case is impractical.

Under certain conditions, roll materials can be used as a finishing coating for warm water floors. In this case, you will need to comply with the rules associated with installation and safe subsequent operation.

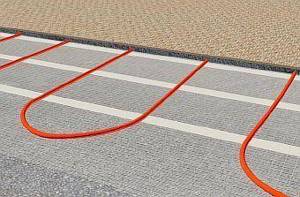

Cable electric flooring under carpet

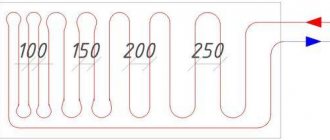

This type of heated floor is popular today because, unlike water, it does not require connection to heating. Heat is generated by heating a special cable. It is installed according to the type of pipe laying or using special rolls on which the cable is already attached.

Rolled cable floor

Cable types:

- single-core - the system must be closed;

- two-wire - the system may not be closed.

However, it is recommended to take into account the following aspects:

- increased load on the power grid;

- increase in the amount payable for electricity;

- the same loss of height as when installing a heated floor.

The floor is not laid in places where large furniture such as cabinets and sofas are installed. If a cable passes through this area, the area is at risk of overheating, which will damage both the flooring and furniture.

Methods of fixing carpet

Before you start laying carpet, you need to choose one of the methods of attaching it to the base, which for this type of covering can be the following:

- fixing the whole canvas with glue and without glue;

- gluing fragments;

- stretching the canvas onto slats with nails using a special tool (stretching), in which the coating is not attached to the base at all, but is held most securely.

Depending on the chosen fastening method, the carpet is also installed. The cloth purchased in the store needs to be spread on the floor of the room so that it is smoothed and leveled for a couple of days at room temperature.

Free way.

This method of flooring is considered the most economical, as it is carried out using improvised means. It has two varieties, distinguished by the method of fixation:

- Along the perimeter. This mounting option is the simplest, because the carpet is attached using a plinth. To begin with, the material is spread around the entire perimeter of the room. A prerequisite is an allowance on each side, which should be about 15 cm. The carpet is leveled from the center to the edges. This process can be carried out either with a special roller or by hand. Only after careful smoothing is the excess material cut off, and the remaining carpet is secured with skirting boards around the perimeter. In the doorway it is most often secured with a metal strip or threshold.

The advantages of this installation:

- The material can be easily dismantled if necessary and re-attached.

- The entire flooring process does not require the help of professionals, which saves a lot of money.

- No additional equipment or materials are required for fastening.

- It is not necessary to prepare the floor before starting work.

- After a long period of use, wrinkles or bubbles may form on the surface.

- This fixation method is not suitable if the room has mobile furniture equipped with roller wheels.

- Rearranging furniture may be more problematic as the covering may move.

- Careful care of the carpet will be required, since the use of washing vacuum cleaners is not recommended.

- The material should be monolithic, and the room should not be too large.

Laying tiles

You can lay tiles on top of an infrared warm structure in the following ways:

- Using reinforcing mesh:

- the mesh is laid on top of the polyethylene;

then concrete or self-leveling mortar is poured;

- Only after the composition has completely dried is the tile laid.

- Using plasterboard sheets, which are placed on polyethylene, and tiles are laid on the plasterboard.

To fix the tiles to the floor, you will need glue or a special mixture.

Step-by-step process for laying tiles:

- The adhesive composition is applied to the back side of the facing material with a notched spatula, after which the product is fixed to the base. To make even seams between tiles, it is recommended to use plastic crosses.

To ensure good adhesion of the product to the surface and to level out protruding areas, the tiles are tapped with a rubber hammer.

When the glue dries a little, the crosses are pulled out and the joints are grouted.

Device

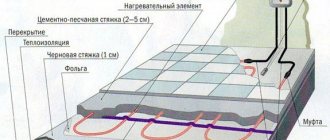

A heated floor system is a multi-layer cake that performs several tasks simultaneously:

- cutting off the subfloor from the heater to eliminate wasteful consumption of thermal energy;

- floor heating;

- protection of the heater from mechanical damage (especially important for water pipelines);

- floor covering that directly transfers heat into the atmosphere of the home.

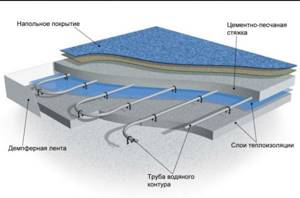

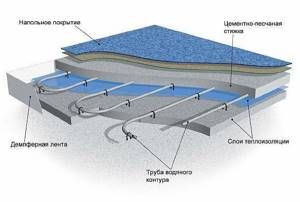

For water floors

For water heated floors, the usual composition of the cake is as follows.

On a concrete subfloor:

- Concrete floor.

- Waterproofing layer.

- Insulation layer (EPS).

- MAK mesh (or a similar mesh to equalize the load on the pipes).

- Water heated floor pipes.

- Concrete screed.

- Carpet.

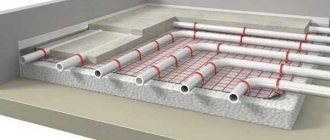

On a wooden subfloor:

- Heated floor pipes (or, as an option, modules or polystyrene foam with laid heated floor pipes).

- A protective layer of plywood, chipboard or similar rigid sheet materials.

- Carpet.

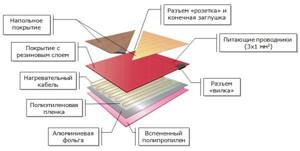

For electric

Pie composition for electrical systems.

For concrete floors:

- Concrete subfloor.

- Waterproofing, insulation layer.

- Heating cable (mats).

- Screed layer.

- Carpet.

Attention! For electrical cable systems, the layer of screed may be thinner - sometimes only to level the surface, since there is no danger of rupture of pipes under pressure. For wooden floors:

For wooden floors:

- The cable (mats) or film emitter is laid directly on the subfloor.

- A protective layer of sheet materials is laid on top - chipboard, plywood, etc. (this is not necessary for film systems).

- Carpet.

To eliminate wasteful heat consumption, it is recommended to place a layer of foil film between the heater and the subfloor, which reflects infrared rays upward and prevents unnecessary heating of the subfloor.

What type of device to choose

All manipulations are carried out in stages. Types of electric heated floors can be divided into three groups:

- Thermal mats. It is a mounting grid on the surface of which heating elements are fixed. The cable is used both single-core and two-core. For installation you will need a layer of tile adhesive or screed.

- Resistive. The package includes a heating cable (self-regulating), which is laid on the surface of the rough coating. Placed in a layer of screed.

- Carbon (infrared) floor. It is a thin film on the surface of which heating elements made of carbon are placed (they emit infrared rays). To achieve greater strength, the material is laminated. In this case, there is no need for a screed.

Laying scheme for carpet

Most craftsmen agree and recommend installing infrared film devices. The use is due to a number of advantages:

- high level of fire safety;

- space saving. The height of the room will remain the same, since the height of the mats used does not even reach a centimeter;

- installation work is carried out with your own hands, without involving third parties. If necessary, the material is divided into several fragments, and no screed is needed;

- the device allows you to partially heat the room;

- mats can be used in combination with any type of flooring;

- if necessary, the device is dismantled and placed in another place;

- environmental friendliness. Heat accumulates under the floor. Heat is distributed evenly, but not above human height.

Warm floor under carpet: features of choice

The question of whether it is possible to lay a carpet on a warm floor and whether it is worth doing this arises quite often. In addition, many who want to install such a heating system are stopped by the need to remove the main floor covering before installing it: such repairs are always associated with a fairly large investment. Modern manufacturers have offered a simple and effective option - electric heated floors under the carpet.

It is a mobile system that can be easily installed anywhere in the room. To put it into operation, simply connect it to the power supply. Such solutions are especially in demand in the office, nursery, living room, and by the bed in the bedroom. Sometimes heated flooring under the carpet is laid on the balcony for additional heating in cool weather. As a covering, you can use a wicker, pile or lint-free carpet of medium thickness (as it increases, the heat transfer will significantly decrease).

Electric heated floor under carpet: pros and cons

Benefits of portable systems

- Simple and quick installation, mobility of the equipment: before connecting, just spread a mat or film under the floor covering. Dismantling involves disconnecting the device from the power supply. As a result, the warm floor under the carpet can be easily and quickly moved around the house.

- It is possible to regulate the heating temperature using a thermostat. A special rotary lever is provided for control.

- You can lay heated flooring under a carpet on a wooden floor: the temperature does not exceed +30 ⁰С, which makes it absolutely safe for use in such conditions.

- The energy consumption of portable models is similar to stationary versions and is 250 W/m2.

- The mobile heated floor under the carpet is resistant to mechanical damage, corrosion, and temperature changes. If the integrity of the film is damaged, it will continue to work fully.

- Warm floors under carpets operate with an efficiency of 90%.

- A high level of safety is ensured by automatically turning off the mat in the event of a break in the power supply circuits.

- Mobile heated floors under the carpet do not dry out the air, so they are not dangerous for allergy sufferers.

Disadvantages of using film heated floors under carpet

Those who doubt whether it is possible to lay a carpet on an infrared heated floor, as a rule, have only a few arguments.

- Malfunctions of the temperature sensor, which can occur if it is covered with a floor covering;

- The inability to install heavy furniture on a film heated floor under a carpet or carpet (this is due to overheating that occurs in such cases and a decrease in the service life of the heating mat itself);

- Possibility of laying only on a flat surface without significant defects (in places where depressions, bumps, cracks form, the warm floor under the carpet will wrinkle under external pressure, which will lead to additional damage).

Although it is worth recognizing that all of the listed “disadvantages” are rather features of such heating systems.

Warm floor under carpet: features of choice

A portable heated floor under a carpet is a system of standard design, but produced in a completely ready-to-use form. Depending on the design features, it is possible to use a cable or infrared system. In the first case, the mat uses a resistive cable, in the second - a film in a protective sheath, which prevents damage during storage, transportation or during operation. It is worth noting that the infrared floor under the carpet has a thickness of 0.6 mm, and the cable one – 1.8 mm.

An important selection parameter is the overall dimensions of the canvas. Depending on the features of use and the parameters of the carpet for a warm floor, you can choose a portable mat of any shape and size

It is worth paying attention to the power of the model, on which the intensity of heating the room will ultimately depend. But at the same time, installing too powerful a heated floor under a rug in a private house or apartment also does not make sense, since the coverage area is small

Mobile mat - palace

Its surface is made of artificial felt, which is durable and easy to clean. The canvas has certain dimensions and is available in two modifications: 2 by 1.5 m and 2.8 by 1.8 m. The basis of its heating filling is a thin cable in a protective hermetic sheath. The mat is connected to the power supply via a 2.5 meter installation wire. Such a mobile heated covering can be placed under woven, lint-free or pile carpets of medium thickness, the surface of which will be evenly heated to 35 degrees. The infrared heated floor under the carpet is connected to the electrical network using a universal plug suitable for any type of socket. The wire is fixed through the power box. The optimal temperature regime is maintained by a functional and convenient power regulator.

Types of heated floors covered with carpet

Currently, there are a wide variety of heating systems for carpeted floors, which are combined with carpet in different ways. Let's look at each type in detail.

Water heated floor

A water floor is a structure made of pipes through which warm water moves. Heating is provided by power supply or heating system. Pipes can be made of: metal, polypropylene, copper, cross-linked polyethylene. You should not skimp on the choice of material; any problems will inevitably lead to the dismantling of the entire cake, including the finishing coating.

In addition, this is an excellent solution for rooms whose walls face the street; increasing the number of turns around them will help avoid drafts. In multi-storey buildings with central heating, this model is not recommended.

Pros of a water floor Cons The heating process is slow, this is important for carpets; with a sharp change in temperature, deformation is possible. Installing a water system is labor-intensive work. The carpet does not fade, since water moves through the pipes, so there are no overheating spots on the coating. The height of the floor rises by 10 - 15 cm due to the concrete screed.

The design of a water heated floor under a carpet is: a concrete sub-base, a layer of waterproofing and insulation, a MAK mesh, a pipeline, a concrete screed and carpet.

Electric heated floor

In an electric heated floor, instead of pipes, there is a heating cable through which electricity passes. Fiberglass mesh or mounting tape is used for fixation. Installation of this system is possible in any room, and installation is easy to do yourself.

The cable system is ideal for houses with ceilings, where heavy loads are contraindicated.

Pros Cons Provides uniform heating, which will not lead to deformation of the coating. A rapid heating process can lead to overheating of the carpet structure, causing it to quickly fail. It is possible to adjust the temperature, which is very important, since the carpet cannot be heated by more than 30 degrees. The presence of an option that allows you to set a limit temperature that will be maintained automatically. The formation of overheating zones in places of contact with furniture, which will cause fading of the coating and damage to the cable. Simplicity and low cost of installation. Significant electricity costs. Installation without a concrete screed is allowed; instead, an adhesive composition for slabs can be used

Despite all its positive aspects, this type of heated floor cannot be called ideal for carpeting. Because if one section of the cable is damaged, the entire system stops working.

The cake of an electric floor under a carpet looks like this:

- concrete base;

- waterproofing gasket;

- insulation;

- coolant;

- concrete screed;

- carpet

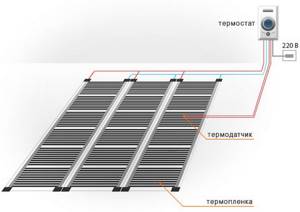

Infrared heated floor

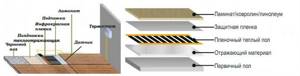

Infrared design is a type of electric flooring. This is a double-sided roll film with built-in heating elements (graphite strips). The tape model is effective in operation, but only dry installation is possible.

| pros | Minuses |

| Heating is uniform, which eliminates deformation. | The main and main disadvantage of this model is its high cost. |

| Infrared rays act sparingly, which does not lead to carpet fading. | |

| The presence of a thermostat allows you to control the temperature. | |

| Very easy to install and operate. | |

| Minimum energy costs. | |

| If one of the IR strips fails, the entire system will continue to function. | |

| Fireproof | |

| No need for screed |

Infrared film heated floor

Film heated floors are an excellent alternative if it is not possible to install a permanent (stationary) heating system. This is a mobile device; it can be moved from room to room, or placed in a separate area that needs to be heated.

More often, such warm floors are located under carpets, and are laid directly on laminate floors, linoleum, or tiles. Connect to power using the cord included in the kit.

Carpet, as a covering for a heated film floor, is an excellent choice, since its main characteristics are:

- mobility;

- the presence of an option that allows you to control the temperature;

- no damage to the coating;

- power consumption costs are not high;

- ability to choose the device of the desired size.

The ease of installation of this system under the carpet is also of no small importance, since there is no need to level the surface and carry out work on installing the device. Moreover, it will be inexpensive

Pros and cons of mobile heated floors

Stationary systems differ in the varying complexity of installation. But it is not always necessary to heat large areas. Also, when housing is rented, installing a long-term “Warm Floor” is irrational.

In this case, the ideal option is a mobile heated floor. The design is an infrared film that is laid under the carpet. It is connected to the household network using a cord with a plug.

It should be noted that mobile systems are intended only for carpeting. They will not fit under tiles or laminate!

Among the advantages of mobile heated floors, the following should be highlighted:

- For carpet coverings, this is the best option, since such a system is designed specifically for them.

- Ability to set the desired temperature.

- Availability to control heating, achieve the desired size.

- If necessary, it is easy to move to another location.

- In order to start using, you do not need to carry out installation work.

- The system consumes a small amount of electricity.

Thermal insulation properties of carpet: does it make sense to heat the floor?

Warm floors and carpet are incompatible things in the minds of many people. This opinion was formed because the thickness of the coating itself allows it to act as a heat-insulating material. In other words, some of the heat will be reflected from the carpet and go virtually nowhere. This is absolutely justified for thick, dense carpet flooring, but it is fundamentally incorrect for standard tufted flooring options - in terms of their thermal insulation properties, they are very similar to laminate or linoleum, and therefore the answer to the question of whether it is possible to lay carpet on a warm floor depends entirely on the what type of it is planned to be used.

It is also important to take into account that heat loss can be compensated for by taking care of thermal insulation under the floor heating system

The need to use underlay for carpeting

Most of us like to save money, especially when it comes to some additional costs when laying flooring. Carpet is considered the most budget-friendly, soft and beautiful floor finish from the “set it and forget it” series. But it's not that simple.

An underlay for carpeting is a must because it:

- Extends the service life of flooring;

- Makes the floor softer and warmer;

- Creates the feeling of a thick carpet, even if short-pile material is laid;

- Improves sound insulation;

- Creates an additional waterproofing layer.

Thus, the answer to the question of whether a carpet underlay is needed is clear - you can’t do without it!

Temperature limits for a wooden base under heated floors

Any coating or base for electric heating has its own thermal limitations in operation. So, the optimal temperature for a wooden floor is 25–26 degrees. The maximum permissible temperature is 27 °C. This indicator is valid for the floor surface. But you should understand that the sensor is not mounted on the floor, but directly in its structure. Therefore, on the thermostat you should expect the parameters listed in the following table:

From the above data it is clear that for soft species (pine) higher temperatures are allowed, while when using hard types of wood (oak, hornbeam) one should strive for a slightly lower regime.

When using infrared heating in a room with poorly organized insulation, the issue of achieving optimal temperature conditions is not extremely pressing. In this case, it is possible to operate heating devices with a specific power of at least 80 W/m2.

↑ Film heated floor under carpet

Infrared heated floors will help create comfortable living conditions indoors. Compared to its main competitor – the electric cable thermomat, it has a number of advantages:

It is an excellent solution when installing heating in rooms with low ceilings. The effective height loss due to the use of thermal film with thermal insulation is in most cases no more than 0.5 cm. This is the only option in cases where it is necessary to install a heated floor system under an already completed floor covering. Infrared film flooring allows you to avoid interfering with the structure of the previously created floor cake. To install a film heated floor under the carpet, you only need to carry out a small cosmetic repair, during which the thermal film will need to be laid on the old screed. Installation of heated floors takes place in a very short time. In fact, this work can be done in 1-2 hours in one room

And what is very important, the floor can be fully used immediately after installation. Particularly valuable is the possibility of using heating film under the carpet in cases where only certain areas of the room need to be insulated. Since this heating method is environmentally friendly, it is especially recommended for use in a children's room.

Which thermal film is better to choose for carpet? It is recommended to use PET film, which is made from a material acceptable for use in electronics and electrical engineering.

Externally, this film is translucent, with a milky white tint. It costs more than the usual transparent one, but has a number of important advantages:

- high insulation characteristics;

- protection from exposure to electromagnetic radiation;

- fire resistance;

- breakdown voltage is more than 100 kV.

System advantages

Heated floors have the following advantages compared to conventional methods of heating rooms:

- Lack of air convection, which in turn eliminates the appearance of drafts.

- Safety . The installation of water, electric, or any other type of heated floor does not involve the installation of radiators above its surface. Therefore, children can in no way be burned by hot equipment.

- It is possible to create local heating zones (children's room, area near the bed, etc.).

- Harmony of design. Heat sources are disguised and do not spoil the appearance of the room.

Installation of infrared heated floors

Such structures can be installed independently. To do this, just study the step-by-step instructions supplied by the manufacturer. But first you need to purchase the necessary components, such as:

- thermostat sensor;

- additional set of wires;

- a set of infrared film, which is sold in rolls;

- To avoid possible heat loss, you will need material for a thermal insulation gasket.

Step-by-step installation scheme (including on a wooden floor):

- First, the surface to be used is prepared. Old material (if necessary), construction and other debris is removed. Severe irregularities are eliminated. It is necessary to level the surface if the level of difference exceeds several millimeters per meter of surface.

- It is recommended to use a thermal insulation layer to minimize heat losses. A non-conductive material should be used (this will improve overall safety). Construction tape is used to fasten sheets of material.

- Warm flooring is installed under the carpet. The entire surface of the room is covered with mats, with the exception of areas where furniture will be located.

- Connecting the device. To do this, connect a thermostat, which is recommended to be mounted on the wall, half a meter from the floor. Wiring is laid, the connection to which is made in parallel. This entire layer is well insulated using sealants.

- The thermostat can be installed in several ways (external and internal). You can groove the area from the floor surface to the place where it is to be installed. If the renovation of the room has already been completed, you can use a plastic box in which all the wires are conveniently placed. The sensor is mounted under the film in a small recess. After connection, the device undergoes a performance check. A working system should heat the surface in five minutes. Grounding plays an important role, so all ends of the film should be taped with special tape, which is then attached to the wire.

- Installation of the insulating layer. When using carpet, a top layer of insulation is mandatory. For this, plywood is used, which can protect infrared mats from any mechanical damage, and the carpet from overheating.

- Carpet installation. Before this, the material is rolled out throughout the room and left completely undisturbed for the day. During this time, the material will straighten on its own. Adhesive tape is used for fixation. You can only walk around the room the next day.

Carpet installation | Warm floor

Carpet - a soft pile covering on a jute or rubber base with pile in the form of full or cut loops - is widely used in the decoration of residential and office premises, and hotels. The service life of the coating can be increased by following the technology of its installation. Carpet can be laid on any flat surface, including parquet, wood floors, and linoleum.

Tip: To remove static electrical charges, use special conductive glue and copper tape connected to ground. A conductive primer is applied to the base of the floor. One copper strip is required per 40 m2 of floor. It goes out to the wall and connects to the house's grounding system.

Carpeting in rooms can be found quite often

The carpet, cut at the factory, is glued end to end. Canvases with raw edges are laid overlapping. There are several options for laying carpet: loose, with fastening around the perimeter, stretching (tension method), sticker.

Basic installation rules

Carpet laying

- Carpet with a pattern that needs to be adjusted must be purchased with a reserve; the covering must be laid, taking into account the structure and direction of the pile.

- Artificial carpet must be secured to prevent movement. This will extend the life of the coating.

- Work on laying carpet begins from the center of the room.

- The strips are cut with a margin of 15–20 cm for uneven walls and corners.

- Carpets with long pile are laid in bedrooms, material with short pile is suitable for a children's room and living room.

- Furniture can be installed on the coating no earlier than one day after gluing.

Tools

To install carpet you will need a special knife, a metal ruler and a roller with a hard surface. A knife for cutting carpet is more like a manual sewing machine; it has a handle and an angle. Pressing the corner to the coating, pull the handle, leaving a cut strip on the side. It is not recommended for inexperienced layers to use ordinary construction or light roller knives.

Before laying carpet, prepare your tools

A roller for rolling out a pile coating resembles a paint roller, but it is wider and has a hard surface. If you level the carpet with a soft paint roller, noticeable marks will remain on the carpet.

These tools are special ones, used only for working with pile coverings, so it is not advisable to buy from them; it is better to rent them.

Joints of canvases

When working with carpet, it is recommended to avoid joints or seams. The problem is not that they can be noticeable, but that parts of the coating can move apart or creep onto each other due to temperature fluctuations in the size of the canvas. It is best to purchase one piece of carpet with a margin of 30–40 cm in length and width in each direction from the size of the room.

Carpet joints

If you still have to make joints, do it like this:

- one piece of fabric is placed on top of another with an overlap of 5–10 cm so that the direction of the pile is the same;

- cut both sheets at once along the ruler with a knife to the floor;

- bend the ends a little and take out the lower cut strip;

- if the joint is visible due to a slight tear, the edge of the canvas is folded back, pressed again to the floor and rolled with a roller.

To design the joints of carpet with other coverings, metal threshold strips are used. This usually happens in doorways.

Free styling

This is the simplest and most economical way. The material is laid loosely on the floor, such as a rug or carpet, but so that it extends 5–10 cm onto the walls. Then, with a special roller, they roll it from the center to the walls to level it out. In the corners, make V-shaped cuts at 90° with scissors or a knife, and cut off the excess along the entire perimeter using a light roller knife. Using a cutting roller, the knife is pressed into the corner and evenly moved along the walls along the corner. This method is convenient when laying carpet in one sheet in a large or narrow room.

Free laying of carpet

The disadvantage of this method is the possible bubbling of the coating when rearranging heavy furniture or moving it on wheels.

Edge fixation

This method resembles free laying, but the carpet fabric is pressed along the edges with baseboards. Before laying carpet, remove the baseboards. The canvas is placed on the floor in the same way as with the free installation method (with a trough with a slight overlap on the walls) and smoothed with a roller from the center to the edges. The edges are cut, leaving a bend of 3-4 cm on the wall. Then these strips are folded so that the bend passes exactly in the corner, and the baseboards are secured with mounting nails or self-tapping screws.

The carpet must be secured at the edges

The method is simple to implement and economical, but is suitable for rooms with a constant temperature, humidity level and stationary furniture. Can be used as a temporary option.

Installation with double-sided tape

This method is applicable if the pile cloth is laid on a smooth and flat surface: tiles, porcelain tiles, laminate, linoleum, parquet. The adhesive tape is selected according to the type of carpet, the width of the tapes is 63–180 mm. The method is suitable for those who like to frequently change the decor in their home, as well as for finishing floors in office premises. Narrow tapes 63 mm will last 2-3 years, and wide ones (180 mm) - up to 7 years.

Double-sided tape is glued to the floor with a 50x50 cm grid of strips 8–10 cm wide. The protective film on top is not yet removed. For 8 m2 of carpet you will need approximately 10 m of tape. Cut out the carpet fabric with a margin of 5 cm for each wall. The carpet is placed on this mesh, leveled and the edges are cut as described above. Having finished cutting, one half of the carpet is carefully rolled over the other with the wrong side up. On the opened half of the floor, the protective film is removed from the strips of adhesive tape, and the canvas is gradually rolled onto such a “sheathing”. Do the same with the second half of the canvas. The work should be done by two people.

The carpet can be fixed by laying it on double-sided tape

The advantage of the method is the ease of replacing the coating if necessary, high installation speed, and the absence of a substrate. You should work very accurately and carefully, because if there is any mistake, the whole work will have to be done again. If the carpet is stuck to the tape, it will be very difficult to correct mistakes. Disadvantages include the possibility of bubbling and deformation of the tape due to changes in temperature and humidity levels.

Glue method

Carpet is glued to concrete or wooden bases in rooms where there is intense human traffic. The advantage of the adhesive installation method is that the pile covering can be washed using a washing vacuum cleaner, furniture on wheels can be moved over it, and no wrinkles or bubbles remain during installation.

The disadvantage is that the process is labor-intensive, and the coating cannot be reused. When changing the coating, the base should be prepared again.

There are two gluing methods: single and double gluing. If the base is flat, single sizing will be optimal. Substrates with extreme slopes or lumpy surfaces are usually covered with carpet using the double-gluing method.

Carpet gluing

Instead of tape, strips of special glue are applied to the base with a notched trowel. The size of the spatula and teeth is indicated on the glue package. Some manufacturers supply glue complete with a spatula. Glue is used according to the recommendation of the coating manufacturer. The pile covering is laid on a dry and clean floor, trimmed as in the free-laying method without bending the edges. After this, half of the canvas is wrapped and glue is applied around the perimeter and in strips from the center of the room to the walls; glue can be applied in cells. After this, lay the first half and do the same with the second. The coating is rolled with a roller from the center to the walls. The work is done quickly until the glue sets.

Double sizing is used to lay carpet on a backing. First, a felt or synthetic polymer backing is glued onto the base, then glue is applied to it and the carpet is glued.

It is usually not possible to remove and reuse a glued carpet intact.

Stretch styling (with tension)

This method is applicable on uneven substrates made of wood or linoleum. Carpeting is laid using special elements called grippers. The gripper is a thin bar from which points protrude at an angle of 45°. On different sides, the blades of the tips are directed in different directions.

Special grades of carpet are attached to the jagged strips, and the selected type of gripper strips must be suitable for the type of covering. For the flooring, first select a gripper carpet, and then, according to the instructions, attach it to it.

Stretch styling

Gripper strips are placed along the walls in accordance with the instructions supplied with them. The upper points of the planks should be directed towards the walls, and the lower points away from the walls. The covering fabric is cut flush with the outer edge of the gripper strips, and then these strips are moved to the walls along with the carpet using a special device. The gripper sticks into the base and holds the carpet. This is how the covering is stretched. The stretching of the canvas is completed by the installation of wide plinths with a recess inside, covering the protruding bumps of the covering around the perimeter.

When installing with gripper strips, sometimes a felt backing is placed under the carpet, but the best way is to carefully study the instructions and strictly follow the manufacturers' recommendations.

Laying gripper carpet is more expensive and is available to professionals. For those who plan to lay carpet on the floor themselves, it is better not to experiment with grippers.

What is carpet underlay for?

When laying carpet, it is recommended to use underlay. It serves as a shock absorber, taking on all the loads and extending the service life of the coating. Carpet on a backing seems softer and fluffier. The substrate serves as an additional heat and sound insulator, does not allow moisture to pass through, and evens out minor irregularities and recesses. Polyurethane foam, polyurethane, felt, smooth rubber, polyurethane foam are offered as substrates on the market.

To make the carpet last longer, lay a backing

Expert advice: when choosing a substrate, you should take into account its density, springiness, and elasticity. The substrate should “breathe” and not have an unpleasant odor. The recommended thickness of the substrate is from 0.65 to 1 cm, depending on the load on the floor.

Types of materials for floor waterproofing

Paint insulation

Such compositions can be used for waterproofing when insulating wooden and concrete floors. Silicone, acrylic, rubber, polymer based mastics are applied to the surface using a brush or roller. The layer of such insulation is 3-6 millimeters.

Coating insulation

It is very common and is used to protect internal and external surfaces from moisture. When applied, it forms a monolithic layer of high density. It is a bitumen-polymer base with the addition of solvents and additives that increase plasticity. Very reliably protects the treated subfloor. Coating insulation used for floor insulation will significantly increase the efficiency of insulation.

Pasted waterproofing

It is produced in the form of rolls and is a durable fiberglass base coated with a bitumen-binding composition with the addition of polymers. Very easy to install. On one side there is a self-adhesive base. The installation of such waterproofing for insulation can be done with your own hands without the use of professional equipment and tools. Affordability complements the advantages of adhesive insulation.

Safety precautions

When installing heated floors under linoleum on a wooden floor, you must follow the safety rules:

- The thermostat can only be connected after a power outage.

- You should check the presence of insulation on all contacts and only then test the system.

- If there is no thermostat, it is prohibited to connect the heating.

- The heating temperature should not exceed 30°C. Otherwise, harmful substances will begin to be released, and the coating may completely deteriorate.

- Damage to the heating film must not be allowed, so if linoleum is used, then hard material (plywood) should be laid under it as a protective layer.

Based on the above material, we can conclude that it is not difficult to install and connect a heated floor under linoleum to a concrete floor. If you have experience in electrical work, you can make the connection yourself, but you should remember the safety rules.

How to assemble an IR mat

The warm floor under the carpet is assembled with your own hands on the free surface of the room. First, steam and thermal insulation materials are laid out. Using ordinary scissors, the infrared film is cut according to the selected dimensions and laid out on top of the insulation. The conductive film strips are connected in parallel, secured together with clips. All contacts must be carefully insulated with mastic glue for rigidity. The film, thermostats and electrical wire are combined into one system and connected to an outlet to test functionality. The final stage is to lay a vapor barrier on top again, then a finishing layer of carpet or just a regular rug. Warm floor under the carpet is ready for use! The top covering over the film material should not be too thick, otherwise all the heat will remain under the carpet.