Is it necessary to lay underlay under the IR floor?

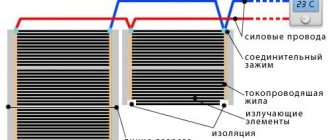

The installation of heated floors is as follows. The heating elements are sealed in durable plastic. When heated, infrared radiation is scattered in all directions. To prevent heating towards neighbors living on the floor below, it is necessary to lay heat-reflecting material for the infrared heated floor. The substrate simultaneously performs several important functions:

- Creates a flat plane. Basically, a substrate made of extruded polystyrene foam is used for this purpose. Thanks to a special locking system, it is possible to create a completely level base.

- Does not allow heat loss. Infrared radiation is strictly directed in one direction, which avoids increased energy costs.

- Helps with installation of finishing floor coverings. The base for an infrared heated floor may vary depending on what kind of material will be laid on top.

What does a layered “pie” look like under a film floor?

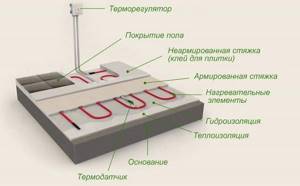

Installation of thermal insulation for a warm film floor requires compliance with certain recommendations and step-by-step installation. What should the resulting “pie” look like?

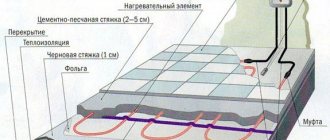

- Base. The plane is checked; if serious defects are found: drops, cracks, holes, the plane will need to be leveled. A layer of waterproofing is pre-laid. The beacons are placed and the screed is poured. Small unevenness can be smoothed out using leveling mixtures. In this case, a layer of waterproofing is not needed.

- Aluminium foil. Placed directly on the screed. Covering the base with foil is important to create a shielded surface that reflects radiation.

- Fiberboard sheets, magnesite plate. Placed on a concrete surface. Insulation is placed directly under the warm film floor. The joints of rolled materials are glued with bitumen film or special tape.

- IR floor film.

- An additional layer of underlay is laid on top of the mats, depending on the selected floor covering. So, cork material is suitable for laminate. The backing in this case will eliminate the likelihood of extraneous noise when walking on the board. The minimum thickness of the substrate is selected depending on how well the floors are leveled. For tiles, you will need to lay a reinforcing mesh.

A layer for a heated film floor must perform several important tasks: provide shielding of infrared rays and reduce possible heat loss.

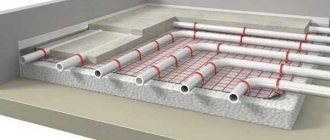

What type of substrate should be used for a water system?

The main condition for a heated floor system is to ensure an increased degree of heat transfer. In this case, heat will not be wasted. Provided that the floor is based on pipes, the underlay in the event of an accident will perform an additional waterproofing function.

Typically, a typical base for the substrate is foil, which helps to reflect heat, which should not go to heating the ceilings of the neighbors below. If the foil is sufficiently thick, it can be in its pure form or on a polymer base (glued in a thin layer). In principle, the heat insulator has a low degree of waterproofing. This protection must be ensured by laying a separate layer of insulating material.

The main difference when comparing identical underlayment models is the cost and different service life. And the modern market offer does not yet offer a wide range.

What kind of substrate is laid under a heated floor?

Magnesite or fiberboard sheets are traditionally used for this purpose. Another material that has proven itself well is Penofol. Thanks to the use of Penofol, the thickness of the reflective thermal insulation film for IR floors can be minimized. The advantage of Penofol is that it is both an insulating and reflective material and prevents the spread of:

- Warmth.

- Convection of air flows.

- Radiation.

When choosing a substrate, it is necessary to focus not only on economic considerations, but also on the actual technical features of the room.

What additional thermal insulation is needed under the IR floor?

The thermal insulation used when laying film heated floors is designed to achieve two goals:

- Prevent the entry of cold air from outside the room (basement, basement, etc.).

- Prevent free movement of heated air from the building.

When choosing an insulating material, you should follow the recommendations of the manufacturers of heated floors. Manufacturers believe that better thermal insulation is made of polyethylene foam with a reflective coating of metallized Mylar film. It is strictly not recommended to lay material using aluminum foil under heated floors. As recent studies have shown, the use of foil insulation leads to overheating of the infrared heating system and failure of individual elements. The effectiveness of IR floors is not affected by the type of insulation you plan to use. Therefore, the material can be almost any, based on the wishes and capabilities of the customer. The only limitation is the installation of thermal insulation with aluminum foil. For thermal insulation, you need to use a material that can stop possible heat loss, protect the floors from overheating and prevent cold from entering the heated room. The heating system using IR elements effectively heats the room. The choice of substrate and thermal insulation plays a significant role in ensuring performance and effectiveness. When selecting the necessary material, you need to focus on the opinion of the manufacturer, who provides comprehensive recommendations in the operating instructions.

Which substrate is better to choose and why?

There are a large number of products on the modern market that are used as reflective underfloor heating.

When choosing a substrate for a film floor, you should not be guided only by savings; you need to build on the technical features, characteristics of the room and the material. Let's look at the most effective and safe types.

Extruded polystyrene foam

The structure of extruded polystyrene foam is evenly spaced closed cells. The material has a low density and a high degree of moisture resistance.

It does not bend, so it is often used as a backing for laminate flooring. In addition, it has great strength and good thermal insulation properties.

The product is produced in rolls and sheets. The IR film spreads directly onto this substrate.

Lavsan

The substrate is made of foamed polyethylene with a lavsan metallized layer - the product is resistant to aggressive chemicals and microorganisms.

Lavsan flooring is laid under the film, thereby minimizing energy loss, increasing the efficiency of the floor, and ultimately leading to cost savings.

This type of reflective substrate is most suitable for infrared floors. It has a certain power density. Therefore, when choosing a lavsan bedding, the floor covering that is planned to be laid on a heated floor is taken into account.

Cork

Cork is a natural material made from crushed and compressed tree bark. The product is environmentally friendly and safe for health. It's not cheap, but it will last a long time. Available in rolls or sheets.

In addition, cork is resistant to deformation (it can take its original shape), has good heat and sound insulation, and is easy to install. The main disadvantage of cork bedding is its sensitivity to moisture. But this drawback is important to take into account when arranging water floors, and for infrared systems, cork is quite a suitable material.

Self-adhesive backing

The self-adhesive backing is equipped with a heat-reflecting foil layer on one side, and an adhesive layer on the other, with which the product is attached to the concrete base. The material is ideal for use on uneven and non-standard surfaces.

The advantages of these linings are high sound and waterproofing, and ease of installation, due to the ability of the product to be self-adhesive (no additional fixation is required).

Properties

Basic requirements for materials used for laying heated floors:

- strength;

- low level of thermal conductivity - they must insulate well and prevent the heat emanating from the pipes from escaping into the basement or foundation;

- ability to withstand high temperatures up to 90°;

- resistance to temperature changes;

- waterproofing properties;

- environmental friendliness.

Why do you need a thermal insulation substrate?

The substrate is a heat-insulating material that works like a “thermos”, and a waterproofing layer that protects against moisture. It is located between the base and the coolant, thereby softening the pressure that is exerted on the base. The main task of the substrate is to retain and transfer thermal energy upward, and not allow heat to escape into the floor.

The quality of heating is influenced by a well-equipped lining. The operation of the most powerful and expensive heating system will be ineffective if the insulation is incorrectly chosen, because the heat will be wasted.

Please note : according to technology, a heated floor system must transfer heat to at least 80% of the floor surface.

To achieve this result, it is necessary to use a heat-insulating material with low thermal conductivity in this layer of the cake. This quality allows you to reflect heat and direct it upward. That is, the underfloor heating, which is hidden under a concrete screed or located in the middle of the structure, is a key factor in effective heating.

Choosing a good substrate is not easy; you should pay attention to its practicality and manufacturability, it must be easy to use and have the necessary rigidity. Such a product will not be cheap, but it will last a long time and significantly increase the efficiency of the floor.

You can determine the best substrate by the presence of:

- good hydro- and thermal insulation properties;

- increased reflective properties;

- resistance to temperature changes, if it can withstand heating up to 90 degrees;

- resistance to deformation;

- fire resistance.

In addition, it must be environmentally friendly.

Types of heat-insulating materials

The following is used as a substrate:

- foamed polyethylene;

- foamed polypropylene;

- more durable extruded polystyrene foam;

- combined materials for laminate, consisting of two layers of polyethylene, between which a layer of foam is laid;

- isoplats (based on wood fiber boards);

- traffic jam

The metallized film gives the material additional heat-protective functions and prevents the substrate from heating up, as a result of which it is less deformed.

If the substrate does not have a metallized layer, you can lay foil on top of the substrate. If metallization with foil is not recommended for electric heated floors, since it conducts electric current, then in the case of water-heated floors this is not significant.

Installation of warm water floors can be greatly facilitated if you use a substrate on the surface of which there are “bobs” (embedded devices for installing fittings and pipes).

Inexpensive foamed polypropylene is more durable than polyethylene, is a good shock absorber, has a greater degree of sound insulation and retains heat excellently.

It is not afraid of moisture, while its wavy surface allows air to move freely under the coating and ventilate it.

The disadvantage of the material is its porous structure, so it becomes slightly deformed over time. A positive point is that for such a coating, floor differences of 3-4 mm are not critical. Extruded polystyrene foam is a little more expensive, but it is denser and stronger than foamed polypropylene, more resistant to stress, and at the same time quite effectively absorbs any vibrations and is able to smooth out minor unevenness in the floor. The closed cells of the material make it more moisture resistant.

Isoplat underlay is used mainly under “floating” coverings - parquet boards or laminate. It is produced without the use of glue and chemicals from coniferous wood and has high mechanical strength.

However, Izoplat must be installed using glue or fasteners.

Cork coating in rolls or slabs, made from cork oak chips, is not subject to deformation and almost does not shrink after getting wet, so it is an ideal coating for laminate or parquet.

Bitumen-cork substrates are more durable and moisture-resistant, but have a considerable price. It should be noted that cork should never be laid on an uneven screed; for every 2 meters, about 2 mm errors are allowed, otherwise the laminate will begin to sag, the locks will separate and cracks will appear in the coating.

Rules for installing substrates

It is recommended to install the elements on the most even surfaces; you should not rely too much on manufacturers’ advertising statements about high strength that allows installation on uneven surfaces. If the substrates are made of materials containing wood, then waterproofing must be done. Except in cases where water-heated floors are installed on wooden floors.

Installation of a polystyrene system using mounting mats

The presence of aluminum foil is an important advantage. It not only significantly improves heat saving performance, but also serves as another waterproof barrier. Special substrates not only improve the quality and efficiency of heating systems, but also significantly reduce the installation time. You should not save on their purchase; taking into account all factors, the money invested will not only pay off, but will also bring considerable direct profit.

Warm floor: installation stages

Features of installation of the substrate

The underlay for a warm water floor is laid on a concrete base, cleared of dust and construction debris.

There is no need to secure the heat-insulating material - later it will be pressed down with a reinforced metal mesh.

Tips and recommendations when installing the substrate:

- Before starting work, it must lie in the room to adapt to the temperature and humidity conditions.

- The thicker the substrate, the greater its thermal insulation properties; in the presence of an unheated basement or foundation, the thickest material is laid.

- Installation should begin after the concrete screed has completely dried.

- The substrate is laid only with the reflective layer facing up.

- To avoid unevenness, the edges of the material should not overlap.

- You cannot use different thicknesses of underlayment.

- When using materials with a relief surface, they are laid with uneven surfaces down.

- For waterproofing purposes, all sheets are connected with metallized construction tape.

- In order not to displace the insulating layer while walking and not to damage it when laying the covering, you should not lay it at once; 2-3 rows are enough, which are then covered with the floor covering.

The substrate must “go” onto the wall to a height slightly higher than the screed. The second row is necessarily offset from the joints of the first row.

It is more convenient to use a substrate with markings on the metallized side.

Features of choosing a substrate

You need to choose the substrate carefully, since not only the operation of the heated floor, but also the atmosphere in your home depends on it. Therefore, when purchasing insulation, professionals advise paying attention to the following points and making a choice based on the parameters listed below.

Video

By type of heated floor

It is necessary that the substrate meets the requirements laid down by the heating system manufacturers:

- Water floor - for this design, a foil backing with a reflective coating is used. This mat is inexpensive and is great if you want to save living space, but the type is not recommended for basement floors. For water floors, it is better to take film models; although they are more expensive, they are equipped with increased thermal properties. An excellent solution for a water structure is an extruded foam substrate with bosses; it has improved quality and ease of installation, since the pipes are laid in grooves. Choosing rolled cork or expanded polystyrene would also be a good option.

- Electric floor - foil roll or tile insulation is suitable. The presence of an aluminum reflective layer is not recommended; it is better if it is vacuum deposition. If the height allows for a thicker cake, then it is worth putting polystyrene foam with a foil layer 2 - 3 cm thick. If height is limited, polyethylene foam 2 - 3 mm can be used as thermal insulation.

Prices

The cost of thermal insulation materials can vary significantly and depends on their composition, thickness and manufacturer.

A thin substrate is cheaper, so if pipes are laid on screed or self-leveling floors, with a solid, insulated foundation, it is enough to choose a 3 mm substrate. The width of the roll or tile may also vary from manufacturer to manufacturer.

An overview of the properties of the substrate is presented in this video:

Average prices for underlays for warm water floors, February 2015

| Name | price, rub. per sq. m |

| Foamed polyethylene 3 mm | 8,50 |

| Foamed polyethylene 5 mm | 14,30 |

| Foamed polyethylene 10 mm | 28,00 |

| Foiled polypropylene foam 3 mm | 75,00 |

| Foiled polypropylene foam 5 mm | 79,00 |

| Foiled polypropylene foam 10 mm | 100,00 |

| Cork 4 mm | 270,00 |

| Cork 6 mm | 400,00 |

| Cork 10 mm | 450,00 |

Popular parquet boards: DIY installation in various ways.

You can find out prices for permanent polystyrene foam formwork.

Read about such a simple method of fastening linoleum joints as cold welding in our article.

The best film heated floors

The cost of 1 m2 of product is approximately 25 USD. It depends on the manufacturer, the quality of the film, and its characteristics. Therefore, to install heating in a small room with an area of 10 m2, you will have to spend $250. And this does not even take into account installation work. The price is much higher than traditional heating. This suggests that the choice of a warm film floor should be weighed.

The most popular systems today are Caleo and Daewoo. So, Kaleo, to visually depict the work of their product, placed it in an aquarium with fish. It has been equipped with a heater for several years, confirming the environmental safety of the line. Choosing a manufacturer of film heated floors is a serious matter. In this case, it is necessary to clarify whether there are the necessary certificates that can document the fire safety of the product.

So, which film is better for underfloor heating? Of course, it is impossible to give a definite answer. Everything is quite individual. Some consumers are looking for a product with a higher heat output, others are looking for a cheaper product, and others are just looking for a product to follow the trend.

It is important to note that reviews will tell you which film heated floor is better. By reading them, you can learn from the experience of other consumers the nuances of the functioning of certain types and the quality of products from a particular manufacturer

Reviews

“Is it possible to lay polystyrene foam under heated floors?” Alksey, Tula

"Do not risk. Expanded polystyrene, of course, is a type of foam, but the production technology is completely different, so it is more elastic. The foam is fragile, you won’t even notice the damage, and the heat will escape through the cracks. Nobody forces you to buy a cork (it is only used under expensive laminate or parquet). Take polypropylene, you can’t go wrong, or thicker polyethylene.” Sergey Ivanovich, Zhukovsky

“The floor of the house is icy. The entire foundation fell out. Is it very troublesome to install heated floors?” Gennady, Voronezh

“You can’t make the foundation yet - even with heated floors, it’s troublesome to transport coal by car or pay for gas. Warm floors are still a good thing. The legs are comfortable. Just don’t try to mess with it without a backing – you’ll be heating the street. I watched a smart guy on YouTube and decided to save money on a cheap substrate. I wonder why he needs heated floors at all? We already have global warming, but this smart guy is heating up the street intensely.” Sergey Ivanovich, Zhukovsky

“Don’t you need plastic film for the backing?” Oleg, Vladivostok

"For what? Metallization behind the eyes." Slava, Penza

“People, does anyone know how much a warm water floor will cost?” Alexey, Vologda

“Learn to use Google. Calculate your square meters, the cost of pipes (it’s better to take metal-plastic), substrate, mesh, concrete screed, flooring, and the cost of the work, of course, if you don’t dare to do it yourself.” Sergey Ivanovich, Zhukovsky

- Previous entryInstalling warm water floors under laminate: installation features

Thermal insulation for heated electric floors, which one to choose?

3 288

Currently, many people install engineering systems in the form of heated floors in their homes. They replace the classic (radiator) heating method, as well as the use of convectors, heating panels, fan heaters, etc. as heat sources for heating rooms.

One of the varieties of such a system is an electric-type heated floor. It is installed instead of the main heating system during the construction of private mansions and when performing renovation work in existing residential premises. Electric floors can also serve as an additional source of heat throughout the entire room or heat the necessary spaces (kitchen, bathrooms, children's room, etc.).

The use of warm electric floors in apartments and houses is currently not a tribute to a fashion trend, but a necessity, which is caused by the following factors:

- creating comfortable conditions;

- health care;

- savings.

Structure of electric heated floor

The essence of creating a floor for an electrical structure is to lay a special cable, electric heating mats or sections under the main floor covering. A huge advantage of such heating is that it can be carried out at will, and can also be programmed to turn on and off at certain times.

A warm electric floor is a complex structure; its performance depends on the correctly selected materials, components and devices, as well as the installation of all components in their place. Insulation is an important component of such a system. Properly selected for specific needs, it will direct and retain heat in the room, helping to save electricity consumption and household money.

Film infrared heated floor under laminate - advantages

- uniform thermal radiation - makes it possible to heat the laminate over the entire surface;

- economical energy consumption. Allows you to save up to 30% of costs compared to other floor heating systems;

- there is no risk of damage to the integrity of the laminated coating, because there is no need to heat the system to high temperatures. Thanks to the use of infrared radiation, first of all, objects in the room are heated, and not the air;

- no need to perform “wet” work. Laying laminate flooring does not require pouring screed;

- the ability to use any type of substrate;

- availability. In large trade pavilions there are demonstration models where you can clearly (visually and tactilely) evaluate the operation of the system (available in the large cities of Moscow, St. Petersburg, etc.) or order it in an online store, based on the technical characteristics and reviews of the owners.

We recommend

detailed description - device ннфракрасного пленочного теплого пола do it yourself (types, calculation, installation)

Features of electric floor heating

It is a well-known fact from basic physics: warm air in a room tends to rise to the top, while at the same time it remains cold below. Such changes negatively affect a person’s well-being. You can get a cold and feel uncomfortable. The body will be healthy only when the feet are warm.

Installation of an electric heated floor promotes uniform heat distribution, proper heat exchange and the creation of the necessary microclimate in the room. The creation technology is simple, well developed by companies specializing in underfloor heating installation services. It is used for all types of premises. This type of floor is safe to use and does not require maintenance during system operation.

When creating an electric heated floor, you must adhere to 5 prerequisites:

- it must occupy at least 70% of the area of the room in which it is installed;

- when installing, you need to use a resistive one, preferably a two-core heating cable, always shielded, infrared film or special electrical mats;

- high-quality insulation must be selected and laid correctly;

- the screed must be made of sand-cement in compliance with the required proportions; it must be no more than 50 mm thick;

- As a final floor covering after installing the electrical system, you can use ceramic tiles, natural and artificial stones, laminate, carpet, parquet and other materials that will match the installed electrical system.

If you are laying laminate flooring on a heated floor

Laminate is a natural floor covering, which means it has all the advantages and disadvantages of natural wood. It is for this reason that when laying laminate boards on a heated floor, the use of an underlay is a prerequisite. If it is not installed, the floor will be very noisy. In the case when a heated floor is mounted on a self-leveling floor or a thin screed, the “substrate - heated floor” system involves the use of the thinnest material, about 3 mm thick. During operation, it will be flattened to 2.5-2.0 mm under the weight of other layers. As a result, the substrate will simultaneously be a good heat insulator and retain high sound insulating properties.

Electric floor systems

Currently, there are cable, rod, liquid and film electric floor heating systems. Cable floors appeared in the 90s. A special shielded cable warms the floor surface to the set temperature. It is set on a thermostat, which responds to signals from a temperature sensor or a special external device that records the air temperature in the room. The heating cable can be installed in special mats with a certain pitch, which speeds up the installation process of heated floors.

Warm electric floors of the rod type are made of coal heating elements. They are connected by conductors and form a grid. Each carbon element is a separately functioning device. This is very important - if one of them fails, the rest will work.

The electrical liquid system consists of polyethylene pipes of a certain diameter filled with a heat-conducting liquid, inside of which there is a heating core. The pipes at their ends have a connecting coupling on one side and a damping device on the other. The latter compensates for the expansion of the non-freezing liquid. Such a system is connected to the power supply using a special regulator.

A polymer film is a product with heating elements applied to it, emitting heat in the long-wave range. Film thickness – no more than 3 mm, width – 0.5÷1 m; it has, depending on the production technology, different heat transfer.

Polymer film is not used for laying under tiles.

Thermal insulation requirements

Why is thermal insulation (also called insulation) needed when installing heated electric floors? During the operation of such a floor, heat losses occur, which are associated with heating of the cable/mat/film and the floor. Laying a special material called thermal insulation will help to avoid heat loss. It will be the basis on which the components of the heated floor are mounted.

In the retail chain, materials with thermal insulation properties are presented in a large assortment; buying them is not difficult. They are made from different components in the form of rolls, panels, films and membranes. Not all materials are suitable for creating electric heated floors. The requirements for thermal insulation material for electric heated floors are as follows:

- must have a low thermal conductivity coefficient;

- have resistance to elevated temperatures;

- easy to install and not deform during operation;

- should level out minor unevenness in the base;

- must withstand heavy loads;

- have soundproofing properties;

- withstand aggressive environments;

- have a high degree of strength;

- do not absorb moisture;

- be electrically safe;

- be made from environmentally friendly materials (should not release toxic substances into the environment);

- have a long service life.

Types of thermal insulation

Material selection

Usually the material for lining under the heating elements is polyethylene foam or

Foam backing.

polypropylene, which, moreover, are covered with a lavsan film with a layer of metal coating. The metalized coating helps heat to be evenly distributed under the floor covering, and the insulation itself prevents heat from being absorbed by the screed.

The foam underfloor heating has a low degree of thermal conductivity, which prevents heat from escaping into the ceiling and screed. The temperature limit of the material (up to 90 degrees) allows you to lay pipes or heating cables directly on the film. Along with excellent thermal and waterproofing properties, a layer of such material also has excellent sound insulation. It is also worth considering that the markings applied to the substrate will allow you to lay the cable according to the calculated step, this will increase the accuracy of the work and a reliable result.

Main types of thermal insulation

Thermal insulating materials for installing electric heated floors are made from natural and synthetic raw materials. From a large assortment, we can highlight the thermal insulation materials presented below.

Natural thermal insulation is made using a special technology from cork oak bark and is therefore called cork. Such insulation is supplied to the retail chain in the form of rolls 10 m long and 1 m wide. Thickness ranges from 1 to 10 mm. During installation there is no need to glue it, it is easy to install, has excellent sound and heat insulation properties, and can have a rubberized base, which eliminates the need for additional waterproofing.

Installation must be carried out using heat-reflecting material, because The design does not have the required component of an electric floor, which allows heat to be reflected to the floor surface.

Cork thermal insulation

Modern thermal insulation materials of artificial origin for electric floors include the following products:

- "Penotherm". It is made of porous polypropylene, has a cellular structure, without and with markings. The latter makes the installation process easier. Aluminum foil serves as a heat-reflecting layer. Depending on the quality of installation, it can increase thermal efficiency by up to 70%. The insulation is supplied to the retail chain with a width of 1200 mm and a length of 10 and 30 m, of various thicknesses.

Insulation "Penotherm"

- "Penofol". Made from foamed polyethylene. It has a foil layer with a thickness of 100 microns. Available in four types, differing in surfaces. "Penofol" type A has a foil surface on one side, type B has a foil surface on both sides, type C has one side with foil and the other has an adhesive layer, type ALP also has a foil side and is located on the other polyethylene film. Rolls have a thickness of 3÷10 mm and a length of 10÷30.

Thermal insulation material "Penofol"

- "Folgoizolon". It is made of foamed polyethylene and has air bubbles in its design, as well as a foil layer. Available in two modifications: cross-linked (PPE) and non-cross-linked (NPE) polyethylene foam, differing in service life. For products made from cross-linked polyethylene it is much higher. Thanks to the material with high technical characteristics, it retains heat well. Supplied with or without underfloor heating markings in sheets rolled into rolls of various thicknesses and lengths. It is an ideal heat-insulating material for installing heated floors on balconies, loggias and other cold rooms.

Material "Folgoizolon"

The foil layer must be laminated.

Additional insulation can be a polyethylene laminated film with markings for underfloor heating. Products with a thickness of 3 or 5 mm, a width of 1 m and a length of 10 to 30 m are used.

Insulation film

Main characteristics

- In order to understand what type of underlay you need, you must know what the underlay is for in heated floor systems.

- So, the underlayment must first of all have excellent thermal insulation and waterproofing properties. It should increase the efficiency of the heating system.

- An important property of the substrate is its ability to reflect thermal rays.

- The substrate must withstand temperature changes, working in close contact with the heating elements.

- Also, the substrate should not allow water vapor formed during heating to pass through.

- An excellent additional property of the substrate will be sound insulation.

A high-quality substrate is easy to install, has increased resistance to deformation and is environmentally friendly.

Rolled underfloor heating

This photo shows a rolled underfloor heating substrate, which is equipped with an additional reflective layer with a characteristic metallic sheen.

Features of installing a substrate under a laminate board on a warm floor

One of the most sensitive finishing flooring materials is laminated board. It is made of wood, and, as a result, it has all the characteristics of a wooden board, which has both its advantages and disadvantages. When laying laminate flooring on a heated floor, the use of an underlay is a prerequisite.

In addition to preventing heat damage to the laminate flooring, the laminate underlay also serves as a sound insulator, preventing the finished flooring from being too loud. The minimum thickness of the laminate floor board substrate on a heated floor must be at least 3 millimeters. During operation, such a substrate becomes somewhat compacted without losing its insulating properties.

Step-by-step algorithm for laying a substrate under a laminate board on a heated floor

Let's consider the procedure for laying a foam polyethylene backing under a laminate board on a heated floor.

First of all, you need to clear out your workspace. To do this, you can use a regular broom or vacuum cleaner.

Cleaning up the workspace

Then we lay the rolled backing on the cleaned surface.

Place the roll backing on the cleaned surface

The spread substrate can be secured with double-sided tape, after which you can proceed directly to laying the laminate boards.

We fix the substrate and proceed to laying the laminate

Underlay for heated floors with liquid coolant

For any design of heated floors, the substrate must serve to increase the heat transfer of the heating elements. If you use a liquid coolant - that is, you are constructing warm water floors - your substrate can additionally perform the functions of waterproofing the surface.

When installing heated water floors, you can use a substrate that will additionally serve as the basis for installing the coolant piping system. Such a substrate has special protrusions, in the spaces between which the pipeline system is mounted.

Underlay for pipes for heated floors

As a rule, such a substrate is made of polystyrene foam. One type of substrate for a warm water floor is shown in the photograph.

It must be remembered that a good substrate will be based on foil. If your substrate does not have a foil layer, then it makes sense to place a separate thin foil material on the floor, and then a heat-insulating substrate.

Installation features

Properly selected material for thermal insulation not only makes staying in the room comfortable, but also reduces electrical energy consumption. The technology for making electric heated floors depends on it.

All work on arranging an electric heated floor comes down to the following operations:

- preparation of the base;

- installation of thermal insulation;

- installation of heating cable/mats/film;

- performing a screed;

- installation of finishing floor covering.

At the base preparation stage, it is necessary to dismantle the old screed, level the surface as much as possible (differences should not exceed 10 mm) and clean it from dirt and dust. If necessary, the base surface must be waterproofed.

Before you begin laying thermal insulation for an electric heated floor, you need to decide on its thickness. It has been experimentally established that above unheated rooms it should be 50÷100 mm, and for interfloor ceilings - 20÷30 mm. Seams and joints of thermal insulation must be taped with special tape (foil), between the wall and the screed - with damper tape. When laying several thermal circuits with different temperatures, a T-shaped damper profile is used to separate them.

Thermal insulation material is not only laid on the base of the floor, it must be laid along the perimeter of the wall to a height of up to 20 mm.

Installation of electric heating elements must be carried out taking into account the characteristics of the installed system (single- or two-core cables, mats, UV films).

It is better to screed the floor using a sand-cement mortar with the addition of special plasticizers that will prevent cracking. Its thickness should be at least 3 cm. After drying, begin laying the finishing floor covering. It can be tiles, parquet, linoleum or another type. They are installed taking into account the manufacturer's recommendations.

Video

A thermal insulation layer under a warm electric floor is not a luxury, but a necessity. It will help to evenly distribute the heat from the heating elements, retain it and direct it in the required direction. Poorly performed installation at any stage of creating electric heated floors will entail negative consequences. This will affect comfort, increased energy consumption and, as a result, unnecessary waste of money.

Home Installation, laying, calculation Substrate for film heated floors: choose the right one

Even with heated floors, the house can be cold and damp. The fault lies with poorly selected material. To avoid problems, choose a substrate for infrared heated floors from professionals. This way you are guaranteed to get a warming result.

The substrate under the film heated floor is the main component of the heating design. Properly selected polystyrene foam or lavsan, technically precisely executed thermal insulation will invariably help avoid loss of precious heat. Choose a high-quality underlay for IR film heated floors. Be sure to consider its functions:

- thermal insulation;

- hydro and sound insulation;

- final alignment.

We carry out installation

As an example, let’s look at the installation of film heated floors.

There are following instructions:

- We lay the thermal insulation substrate on the cement base.

The underlay under the laminate for heated floors is laid end-to-end. In this case, the sheets are connected to each other using tape.

- We place a heating film on top of the substrate. The strips should not intersect or overlap.

Advice! You can cut the film electric heated floor only in those places indicated by the manufacturer (dashed line). Otherwise, you risk compromising the integrity of the wiring.

Heated floor elements must be laid at a distance of at least 100 mm from the walls. In this case, the area covered by the film must be at least 70% of the area of the room.

Laying film under furniture is prohibited! Marks along which the film can be cut are present on the canvas every 20-30 cm.

- Electric heated floors made from films use a parallel connection circuit. For this purpose, special clamp-contacts are made. By crimping they are connected to copper busbars. In this case, the contact point on both sides is insulated using bitumen insulation (supplied in the kit).

In order to install the strips, a stranded copper wire with a cross-section of at least 2 square meters is used. (assuming the current is 16-20 A).

- The temperature sensor is being installed. We do it this way: we cut off a strip of bitumen insulation and glue the temperature sensor under the heating film near the thermostat.

- Check the functionality of the heating elements. To do this, the system is turned on for 15 minutes.

- A layer of vapor barrier must be laid on top of the heating surface. It is represented by ordinary polyethylene film.

shkolapola.club

What kind of underfloor heating should there be: installation features

Depending on the type of flooring, different materials are selected. The main nuances are presented in the table:

| Type of floor | Types of materials | How is the work carried out? | Meaning |

| Electric | Technical pressed cork | Performed in 2 levels | Uniform heat distribution from the cable, preventing its overheating, removing excess heat energy |

| Foam materials | The first is at the stage of rough work | ||

| Magnesite slabs | The second - during final installation | ||

| Infrared film | Foamed polystyrene | The substrate for infrared heated floors under the laminate is laid only on the screed, which is first covered with foil | Redirection of heat in the room, reflection of IR radiation, prevention of 30% heat loss |

| Polymer | Installation of metallized lavsan is carried out on a film with resistors. The reflective side is directed upward | ||

| Metallized lavsan | The insulation is applied completely, the joints are connected and glued | ||

| Magnesite slabs | Heating elements are placed on top of the reflective coating layer | ||

| HDL sheets | Then comes the heat-reflecting substrate for the infrared floor, IR film | ||

| Water | Roll stopper | Lay a layer of foil on a polymer base | Reduction of heat loss, auxiliary waterproofing |

| Isoplat | |||

| Extruded polystyrene foam | Fix the coating material | ||

| Expanded polystyrene foam | Perform a reinforcing screed on a water floor | ||

| Molded foam | |||

| Laminate flooring | Underlay for film heated floors under laminate | Installation is carried out on a cement screed between the insulated system and the laminate | Preventing deformation of laminate panels, eliminating creaking due to play |

| Rolled polyethylene | They use the thinnest material up to 3mm, thickness varies from 2 to 5mm | ||

| PPE laminated |

When choosing polystyrene, pay attention to self-centering locks. With their help, you can lay foam boards easily and conveniently. You will not need additional fasteners; the pipe system is guaranteed to fit into special valves.

The underlay for laminate under infrared heated floors serves simultaneously:

- insulation;

- shock absorber;

- protection for laminate panels.

Therefore, choose specialized material with enhanced thermal conductivity.

10 common mistakes in installing film heated floors

1. Recess for terminals in the floor

Almost everyone forgets to make a recess in the subfloor. It is in the floor, and not in the soft substrate. The 100% thickness of the substrate is not enough to hide the terminal. And if the terminal is not recessed below the finishing coating, gradual pressure will first expose it from the insulating mastic, and then, most likely, it will cut through the copper busbar. In the best case, the strip of infrared film will simply stop working, in the worst case, if there is poor contact between the terminal and the bus, the resistance will increase greatly and this place will heat up very strongly and quickly, which can lead to damage to the final coating. Be sure to make recesses in the subfloor for the terminals and temperature sensor. It also needs to be hidden so as not to be crushed.

2. It's always better to solder

Despite the fact that the most common method of installing a heated film floor is copper terminals and eyelets, soldering copper wire directly to a copper busbar is considered the most reliable. In fact, copper clamps can be used to reliably crimp a heated film floor, but for some reason many people forget to correctly mount the entire system. Soldering has a larger contact area and a smaller thickness, so even if you install a film heated floor incorrectly somewhere, the chance that the film will fail is much less.

3. Installation of wires in the substrate

Almost all of our clients are confident that cutting through a 3mm heat-reflecting woven substrate and placing wires in the slot is enough. Absolutely not true and very dangerous. Installation wires, and this is usually PuGV (Installation flexible vinyl chloride wire) has 1 layer of not very thick insulation. And the floor covering that presses on it, and believe me, it presses, over time can wear out the already rather thin insulation. It is also absolutely forbidden to install overlapping wires.

4. Incorrect installation of temperature sensor

People often come to us and say that their underfloor heating gets very hot. We begin to find out - it turns out that the temperature sensor was placed at some distance from the heated floor. Or under the substrate. With this installation, the thermostat does not read the temperature correctly, because A film heated floor heats the surface directly where it is located. And the heat does not dissipate even 1 cm through the laminate.

5. Use of additional substrates

It is rare, but it still happens that when people install a heated floor, they first lay a heat-reflecting substrate, an infrared heated floor on it, and then lay a foam substrate on top for laying the laminate. This is not worth doing. The foam substrate on top of the heated floor will interfere with heat transfer, but it does not provide any useful function at all. The heat-reflecting layer also serves as a soft substrate for the laminate. There is no need to put anything else on top.

6. Use of industrial film

On many sites and videos on the Internet, diagrams of layer-by-layer installation of infrared heated floors indicate that it is necessary to lay additional industrial dense polyethylene film, arguing that it provides additional waterproofing. It is not clear what kind of waterproofing we are talking about. The heated floor canvas itself is laminated with a thick layer of heat-resistant polyethylene and does not allow moisture to pass through, and all connections are sealed with special butyl rubber tape, which also does not allow moisture to pass through. Therefore, you should not waste your money again.

7. Setting up a programmable thermostat

One of the most common mistakes when installing a programmable thermostat for a heated film floor is that the builders who connected the thermostat, or the owner himself, do not perform the initial setup of the programmable thermostat after the 1st turn on. And this is very important! After all, as a rule, programmable thermostats have two temperature sensors (air to regulate the air temperature in the room and remote for heated floors) and which sensor to use to regulate the temperature is set in the thermostat settings. The air sensor is most likely turned on from the factory, which is not suitable for regulating the temperature of a heated floor. You should definitely switch the settings to use a remote sensor for heated floors. Otherwise, your floor will not work adequately; when it gets very hot, it will try to warm up all the air in the room to the set temperature.

8. Less heating is better than more.

Some buyers, with a controversial installation option: put a little less heated floor, then in some place the floor will not warm up, or put a little more, but then a small part of the heated floor will be located, for example, under a cabinet, they often choose the second one. You shouldn’t do this, because a small piece of heated floor under the cabinet can really fray your nerves, damaging the final coating due to overheating. But the missing unheated area (this is usually no more than 20 cm) in domestic use, you most likely simply will not notice.

9. Self-regulating film cannot be placed EVERYWHERE

Almost all clients who come to us for a self-regulating film heated floor are sure that this film can be laid out over 100% of the room area. So to speak, from corner to corner. This is not worth doing, because... Although the film is self-regulating and can change its resistance and heat release depending on the heating temperature, when completely locked, it will still heat up to +60 - +70. Yes, in no case will it melt itself, but it can damage the final coating. Over time, with such heating, any material will lose its original properties - the laminate will dry out, linoleum will change color, etc.

Samreg film gives you greater fire safety, but you still have to install it, bypassing solid furniture.

10. The heat-reflecting substrate is not foil, but lavsan

Often our clients refuse to buy the heat-reflecting substrate that we offer to purchase for installing a heated floor, arguing that exactly the same aluminum substrate was left over after insulating the house, or they already bought it at a hardware store. Of course, we don’t mind, why would a client overpay for material he doesn’t need? However, it is worth paying attention to whether you have the right substrate. It is strictly prohibited to use the aluminum substrate with film heated floors, because it conducts electric current. And after installing such a substrate, at least the entire system will hum. A process called electromagnetic induction will occur. In simple words: a substrate with an aluminum conductive layer will vibrate, creating a low-frequency hum. In addition, over time, if installed incorrectly, the waterproofing of current-carrying connections with a film heated floor can simply wear out and begin to come into contact with the conductive layer, creating short circuits. Therefore, always use only a heat-reflecting substrate based on a Mylar reflector. It looks like foil, but it doesn't conduct current. Contains polymer reflective material.

How to choose a substrate for a heated floor?

Choose a substrate for an infrared floor with good characteristics; only in this case will you properly arrange the heating system. Signs of a high-quality and safe substrate for infrared heated floors:

- high level of reflection;

- service life more than 100 years;

- efficiency;

- excellent thermal and waterproofing properties;

- resistance to temperature fluctuations;

- ease of execution;

- sound and vapor barrier;

- fire safety;

- resistance to deformation.

There is a huge variety of insulation on the market for heating electric and water structures. The most effective and safe ones include:

| Groups | Materials | Examples |

| Natural | Jute | "Jute inter-crown insulation" |

| Suberic | "Izospan" D, DM, FB | |

| "Sedacor" thickness 10/4/2 mm | ||

| Artificial | Lavsan underlay for heated floors | PPE laminated “Termoizol” foil, thickness 2-10 mm |

| "Merilon" foamed polyethylene | ||

| "Euro-insulation" foil insulation | ||

| Polystyrene | "Izolon" foil foam, 2/4/5/8/10 mm | |

| "Stenofon" foam insulation | ||

| "Folgoplast" | ||

| Expanded polystyrene | "Polifom" | |

| "Izobond" | ||

| Polyethylene foam | "Multifoil" from Valtec | |

| "Energoflex" polyethylene foam, thickness 3-5 mm | ||

| Polyvinyl chloride foam | "Arbiton Izo-Floor" extruded polystyrene foam |

The cost of a heat-reflecting substrate for a heated floor varies between 300-900 rubles, it all depends on the thickness and manufacturer.

Underlay for heated floors. What it is? What is the meaning of this element

The main condition for the successful operation of a home heating system underfloor heating is not only correctly connected and configured equipment.

In many ways, the efficiency of heating depends on how well the underfloor heating substrate is made, how the water heating circuits are laid and, finally, what kind of finishing floor covering is chosen. Even if you have the most powerful heating boiler, a pumping and mixing station with a lot of auxiliary instruments and devices, a pipeline made of the most expensive pipes, just one detail can neutralize such advantages. Incorrectly laid pipes and incorrectly selected insulation for a water floor will make even the most modern equipment ineffective. Precious heat will be wasted, giving only a small part of the floor surface.

Such indicators are achieved by laying the layer cake in the correct sequence, which contains a waterproofing layer and a backing. This layer cake element is made from heat-insulating materials with low thermal conductivity. Due to this quality of heat-insulating materials, the necessary heat-reflecting effect is achieved. The heat, reflected from the substrate, rushes upward in bulk, transferring the optimal amount of calories to the floor surface. The underlay placed under a heated floor, in which the water circuit is hidden in a concrete screed or located in the middle of the flooring system, becomes a key factor in the efficiency of underfloor heating.

With this we actually answered the question of why a substrate is needed. Thermal insulation is laid on a rough prepared surface, increasing the heat transfer of the water circuit towards the floor surface.

It is appropriate to recall here that water floors are usually installed on concrete and wooden floors. A leak resulting from damage to the integrity of the heating pipe, the formation and accumulation of condensation can cause flooding of the basement and lower floor rooms.

For heated floors, the thickness of the substrate is important. The quality of a layer cake depends on the materials used in the construction. It would be optimal to use an insulating material for the substrate of the required rigidity and with the highest thermal conductivity coefficient

It is important that the material is technologically advanced, i.e. convenient and practical to work with it

A good underlay will not be cheap, but it will last a long time and will significantly improve the functionality of water floors.

The main qualitative characteristics in this case include the following aspects:

- optimal parameters of hydro and thermal insulation;

- presence of high reflectivity;

- environmental safety of the materials used;

- high resistance to sudden temperature changes;

- simplicity and practicality of installation;

- high resistance to deformation;

- fire resistance.

The listed parameters correspond to the ideal version of the substrate equipment, however, in some cases, it is necessary to use materials with similar characteristics. The most common material used as insulation for warm water floors is polystyrene foam. This synthetic material is best suited in its parameters for installing warm water floors in a country house, in a house or in a city apartment.

Laying technology: secrets of specialists

Follow the following list of work stages when laying the infrared film underfloor heating:

- Prepare a hole for the thermostat.

- Provide power to your system by choosing a convenient outlet.

- Carry out thermal insulation work. Use reflective insulation. Correctly calculate the thickness of the lavsan substrate layer under the infrared heated floor, it should be within 3-5 mm.

- When laying insulation, fasten it with mounting tape and direct the film towards the wall with a thermostat, this way you will significantly reduce the size of the wire.

- Maintain a distance of 10-20 cm near the walls. If there are installed heaters, such as a fireplace, stand back at least 1 meter.

- Lay the substrate evenly under the infrared heated floor under the laminate, watch the density of the material. If you do everything correctly, the approximate value will be 150g/m2.

- Lay the film carefully along the joints.

- Use IR film systems to heat floors with underlays.

- Cut the coating only in bright areas.

- Tape the joint edges and outer sides with tape.

- Insulate the ends of the film, stick on bitumen insulation.

- Place the wires in the thermal insulation of the covering.

Carry out professional work taking into account the type of heating system and the selected material of the heat-reflecting substrate.

Order a consultation with a specialist for the correct selection and installation of the substrate for film heated floors: infrared, electric, water. Call or leave a request on the website.

Popular posts

- Chair for dressing table Chairs for dressing tables in Moscow - 189 Products Company from Moscow, delivery 29643 a In…

- Silicone sanitary sealant Silicone sanitary sealant white in Moscow - 1491 products Company from Moscow, delivery (tomorrow) 140...

- Shelf in the hallway Currently, there are a huge number of different options for shelves in the hallway, and this is directly ...

- Underlayment for linoleum What kind of underlayment is used under linoleum? Discussions about the need to use a substrate for linoleum are conducted by professionals...

Cork backing

A material of universal use, one of the most successful options for insulating floors with water heating systems.

Cork insulation for heated floors

Environmentally friendly material, made from cork tree bark. The raw materials are pre-crushed, and special binding components are added to the mass. The mass is pressed and dried on production lines. Finished products are sold in sheets or rolls. The cork substrate has high thermal protection and can withstand significant loads. To improve performance, the front surface is covered with foil.

Cork backing

Cork backing