An autonomous heating system is a much more complex mechanism, consisting of a large number of interconnected components and assemblies that perform the corresponding functions. The three-way valve for the boiler in this mechanism plays the role of a mixer in which the temperature of the coolant is adjusted.

This is done so that the pipes are heated evenly and the heating level in each room is approximately the same. If you do not use the part, it will turn out that the water passing through the heat exchanger will not heat up equally, and as a result, some rooms will receive less thermal energy than all other rooms.

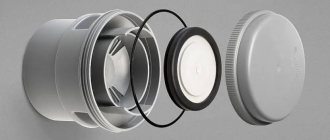

Valve device

A similar unit is installed on all models of heaters. Its design is standardized, so only the overall dimensions can differ. So a three-way valve for an Ariston, Arderia, Navien, boiler and any other model will look the same in appearance.

As for the technical characteristics, this parameter must be clarified in the data sheet. You should not try to attach a spare part to the boiler that does not fit in size, since it will still not function normally, but trouble in the form of a serious breakdown may well occur due to such actions. And in the end, the desire to save will lead to additional costs.

The three-way valve for solid fuel and gas boilers is also no different in design. The type of fuel used to obtain thermal energy does not in any way affect the circulation characteristics of the coolant. The fact is that the valve does not contact the combustion chamber in any way, so it does not need to be adjusted to the type of heating system.

As for the coolant, in 100% of cases Russian citizens use ordinary water at home. This is due to its availability and the absence of any problems with operation. There is no point in inventing anything if the heating already works well and has many years of successful experience in use.

These parts are made of bronze or stainless steel. Polymer analogues are still not widespread, although in the future one can predict an increase in their number if they perform well in operation.

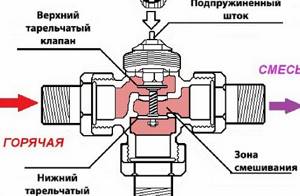

The design of a three-way valve for a gas boiler is very simple. It is T-shaped with two inlets and one outlet. Inside there is a special membrane that regulates the flows coming from different sources so that the optimal temperature is achieved.

There are automatic and mechanical options.

- In automatic modes, the membrane moves automatically, depending on the temperature of the coolant.

- In mechanical units, the position of the separator is set manually by a person, so it is necessary to additionally install thermometers on each incoming pipe in order to be able to monitor the temperature value.

So the operating principle of a three-way boiler valve is based on the well-known laws of physics.

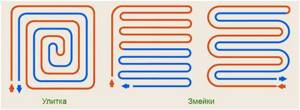

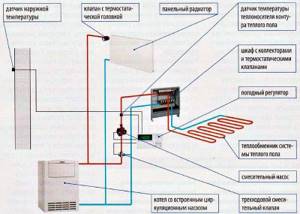

Water circuit installation diagrams

If the installation of warm water floors is carried out using a well-established, traditional technology in a clear sequence, then the installation of a heating pipe can be carried out in various variations. The main goal pursued when installing heated floors is to uniformly heat the entire area of the heated room. Laying a pipeline just the way you want means deliberately creating problem areas throughout the entire structure. The coolant tends to quickly lose temperature as it flows, so the pipes must be laid starting from the walls, then moving towards the entrance to the room or to its center. For this purpose, specially developed optimal schemes for laying the water circuit, each of which has its own characteristics.

The mixing unit and manifold are the beginning of the entire heating system. Water circuits are connected in a clear sequence. The beginning of the pipeline is to the inlet pipe, the end of the pipe is connected to the check valve.

You can install a warm water floor with your own hands, the contour of which will be laid as follows:

- pipe installation according to the snake pattern"

- laying the pipeline according to the snail pattern;

- combined scheme.

When installing heating in corner rooms, a pipe laying scheme is used for enhanced heating.

In each individual case, we can talk about the advantages of one or another scheme. For example: a snail is the simplest circuit. The bend of the pipe here reaches 900, while in a snake the heating pipe will be bent by 1800.

Where heated rooms have a linear slope, it is better to install the pipe according to the “snake” pattern. The pipeline is laid in the direction from the mixing unit towards the slope. Air pockets in this version can be easily removed, which cannot be said about a pipe laid in a snail pattern. In sloping rooms, removing air pockets can be problematic.

For large premises where it is necessary to use several water circuits of the same length for heating, the “snake” pipeline laying scheme is very convenient. Thanks to this installation method, it is possible to achieve balanced operation of the entire heating system.

Heating pipes laid on a prepared base are connected to a manifold that distributes the supply of coolant to the system. The distribution cabinet together with the mixing unit is installed either in the heated room or next to it, which significantly reduces the number of pipes and the consumption of other materials. The bends of the water pipe at the point of connection to the collector are sewn into a special protective box.

In each individual case, a certain order of laying the water pipe should be followed. When working with a snail circuit, the pipe is first laid along the perimeter of the walls, after which a turn follows from the farthest wall. In the opposite direction, the pipe is laid in a spiral, reaching the center of the heated room. For the snake circuit, the water circuit is laid out as follows. The pipe is laid along the perimeter of the walls, after which uniform bends are made in the opposite direction.

The combined installation schemes of heating pipes for heated floors, used in some cases, involve the simultaneous use of both options. One half of the room can be heated by a water circuit laid in a snake pattern, while the other part of the room will be heated by a pipe mounted in a snail pattern.

Types of valves

So, you can read more about the two existing types of valves below:

- 1. The three way thermostatic boiler valve is an automatic model. It will maintain the set temperature level without additional human intervention. At the same time, the most functional models are equipped with an additional safety system that blocks the movement of coolant if there is no circulation through one of the incoming pipes. This way, the batteries will not boil over.

- 2. The three-way thermal mixing valve for the boiler can be equipped with both automatic and manual control. The fundamental difference will be the need to regularly check the condition of the system so that it does not overheat. Today, mechanical devices have almost been abandoned, as they have been replaced by more advanced units.

Types of valve actuators and operating principle

All product modifications differ from each other in certain respects:

- Shutter mechanism: tension or stuffing box;

- plug configuration: L/T/S-shaped;

- type of shutter: cylinder, ball, cone;

- type of connection to the system: coupling, flange or welding.

The coolant is distributed by a drive, which are grouped into the following types:

- Hydraulic action;

- manual control;

- electromechanical movement;

- pneumatic actuation.

Electromechanical drives are manufactured thermostatic and capitate. In them, the signal for the process of mixing different temperature media comes from the control unit.

In servo-drive versions, control is carried out directly by controllers. Manual control of the TC operates by rotating the adjusting cap.

Connection and operation

Installing the part on the heater does not require any special knowledge. All you need is a set of wrenches to be able to tighten the valve, and a sealant paste with which you can “seal” the joints.

The connection of the three-way valve to the boiler is carried out according to the only possible scheme, so nothing can be confused even if you really want to. It makes sense to hire a technician only if the replacement is made under warranty and you don’t have to pay anything for it. Otherwise, you can do everything yourself within half an hour and save several hundred rubles.

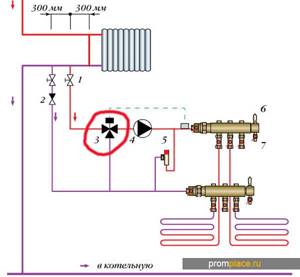

Installation diagram

Water heated floors today are a common system for heating a home; different schemes are used for its arrangement.

Three-way valve. We install it correctly.

Heated floor equipment with three-way valve

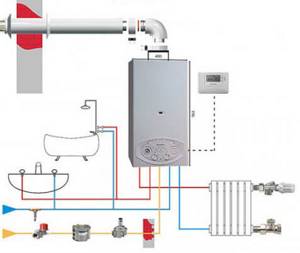

Installation of underfloor heating with the installation of a three-way thermostatic valve is suitable for mixed heating systems. Radiator (water temperature 80 degrees) and underfloor heating (the liquid should not heat above 50 degrees).

Thermal head for a heating radiator - operating principle, different types of devices, how to choose and install.

The question arises - how to cool the water from 80 to 50 degrees. This is what the three-way thermostatic valve is designed for. It is attached to the supply pipe, and a circulation pump is connected behind it.

The working process is as follows:

- waste cooled coolant is supplied from the return pipe;

- in the mixing chamber it is mixed with the hot liquid to a predetermined level;

- then the water flows into the branches of the floor.

The disadvantage of this method is the inability to dose the waste water mixture, and this leads to the entry of overheated or underheated coolant into the main line. Plus - easy installation and low price of equipment.

There are two installation schemes for a water heating floor with a three-way thermostatic valve; they differ in the direction of flow:

- T-shaped (symmetrical) - heated and cold coolant is supplied from the sides, water is mixed in the center of the valve body, and comes out in the middle.

- L-shaped or asymmetrical - the heated liquid enters from the side, and the cooled liquid from below. Mixed water comes out from the side, opposite the hot one.

Both valves are compact and widely used in warm hydrofloors.

Two way thermostatic return flow valve. Installation on heated floor!!!

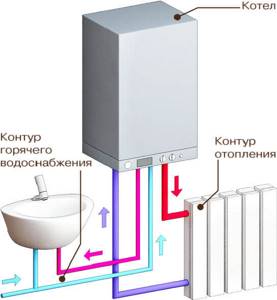

Features of a double-circuit gas boiler

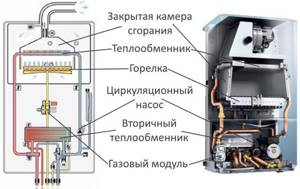

Knowledge of the features of its design will help you understand the principle of operation of a double-circuit gas boiler. It includes a number of components that promote heating of the coolant and are responsible for switching to the DHW circuit.

Uninterrupted operation of the unit is only possible if all component modules work harmoniously. General information about the main components will be enough to understand the operating principle of a double-circuit gas heating boiler.

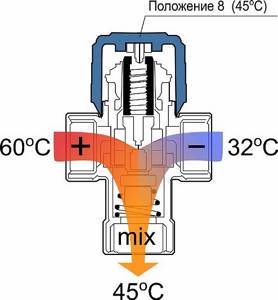

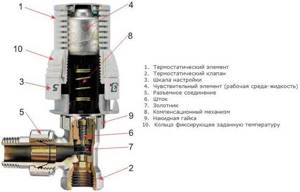

How to build a thermostatic valve

Thermostatic valves come in two types:

- mixing

- flow A entering the valve is distributed into flow B and flow AB - distribution

- flow A entering the valve is distributed into 2 flows

The mixing valve is installed on the return line, and the distribution valve is installed on the supply line. The operation of the valve is controlled by a thermal head with a thermal flask.

The thermoflask is attached using a special sleeve to the surface of the return pipeline in close proximity to the heating boiler. Inside the flask there is a working fluid, the temperature of which is equal to the temperature of the coolant before entering the boiler. If the temperature of the coolant increases, the working fluid increases in volume, and, conversely, when the temperature of the coolant decreases, the volume of the working fluid decreases. Expanding or contracting, the working fluid presses on the rod, closing or opening the thermostatic valve.

Using a thermal head, you can set a certain temperature, above (below) which the coolant will not be heated. How to set the temperature by choosing the operating modes of the thermal head is described in detail in the instructions for it.

Another feature of the thermostatic valve is that it reduces the flow of coolant to the boiler, but never closes it or opens it completely, protecting the boiler from overheating and boiling. The valve is completely closed only when the boiler is started.

Construction device

The design of the device includes the following elements:

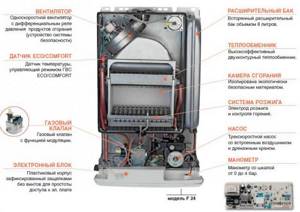

- Burner . It is the main module of the heating boiler. Its location is the combustion chamber. The burner's task is to heat the coolant and release thermal energy for the DHW circuit. To accurately maintain the required temperature, this element is equipped with an automatic combustion control system.

- The combustion chamber . Burner installation location. It can be open or closed. Closed structures are equipped with a fan that supplies air and removes smoke. Thanks to it, the effect of quiet noise is achieved when the equipment is operating.

- Circulation pump . Responsible for creating forced movement of coolant inside heating pipes and for the efficiency of hot water supply. Unlike a fan, there is almost no noise when the pump operates.

- Three-way valve . Thanks to this device, the boiler has the ability to switch to the water heating function for hot water supply.

- Main heat exchanger . The design of a wall-mounted double-circuit gas boiler involves its placement on top of the burner, inside the combustion chamber. This ensures the heating of water, which subsequently enters the heating pipes or the hot water system.

- Secondary heat exchanger . Responsible for heating water for domestic hot water supply.

- Automatic devices . Provide control over equipment operating parameters, monitoring the heating level of the coolant and water. This makes it possible to adjust the operation of the burner, control various components, maintain the flame, record problems that arise, etc.

The space at the bottom of the housing is intended for installation of switching taps for the heating circuit, hot and cold pipelines and gas supply. Some modifications of gas double-circuit boilers are equipped with twin heat exchangers: the operating principle of the double-circuit boiler does not change.

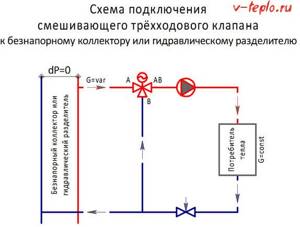

How to install a mixing valve yourself

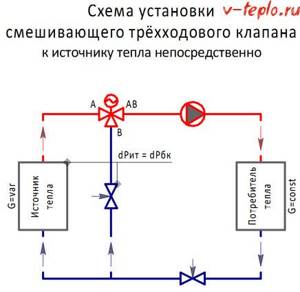

This installation scheme is used mainly in boiler rooms of those heating systems that are connected to a hydraulic separator or to a free-flow collector. And the pump located in circuit No. 2 ensures the required circulation of the working fluid.

Note! If the three-way valve will be connected directly to a bypass heat source connected to port B, then it will be necessary to install a valve with a hydraulic resistance equal to the same resistance of this source.

If this is not done, then the flow rate of the working fluid in the segment A-B will fluctuate in accordance with the movement of the rod. We also note that this installation scheme provides for the possible cessation of liquid circulation through the source if the installation was carried out without a circulation pump or a hydraulic separator in the main circuit.

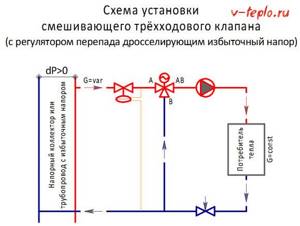

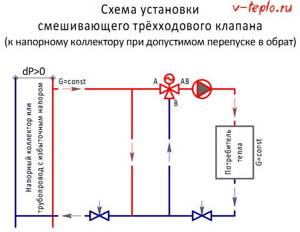

It is not advisable to connect the valve to heating networks or a pressure manifold in the absence of devices that throttle excessive pressure. Otherwise, the fluid flow in section A-B will fluctuate, and significantly.

If overheating of the return is allowed, excessive pressure is eliminated by means of a jumper installed parallel to the valve connection in the circuit.

Similarities with other designs

Although the design of a double-circuit wall-mounted gas boiler is far from simple, upon closer examination of the operation of its components, everything turns out to be not so scary. Equipment of this type resembles a gas instantaneous water heater (especially the presence of a burner and heat exchanger). All other parts are borrowed from a single-circuit wall-mounted boiler. A significant positive role is played by the built-in piping, consisting of an expansion tank, a circulation pump and a safety group.

When studying the principle of operation of a gas double-circuit boiler, it is important to keep in mind that mixing water from the hot water system with the coolant should not be allowed under any circumstances. To pour liquid into the heating system there is a separate pipe, which is part of the circuit. To prepare hot water, a certain volume of coolant is used, which moves inside the secondary heat exchanger.

Purpose of the thermal valve

The valve solves two problems: maintains the room temperature at a comfortable level and saves energy.

But in order for it to really cope with such functions, you need to understand in what cases the device is appropriate and how to install it correctly.

If in the middle of winter there is a need to open the windows so that the temperature in the room drops to an acceptable level, a thermostat is definitely needed. But it won’t help when the radiators are barely warm—it will probably make it even colder.

In the second case, it is better to try to regulate the temperature in the room differently: change the volume of coolant in each radiator, adjust the operation of the boiler (for a large area), select the optimal circulation pump or adjust the operation of the existing one.

The price of a thermostat ranges from several hundred rubles (200-600), so re-equipment of the heating system will not be expensive. But there are also expensive models

As a temporary measure, control valves can be used. But it is not recommended to use ball valves for these purposes.

Principle of operation

Now you can take a closer look at the operating principle of a double-circuit boiler. Armed with knowledge of why individual elements and modules are needed and having understood the principle of operation of a gas boiler, it’s time to move on to studying the question of how a wall-mounted gas boiler works in general.

As you know, equipment of this type is designed for two modes:

- Heating.

- Heating water for the home.

It should immediately be noted that this type of equipment cannot operate simultaneously in two modes. This explains the presence in its design of a three-way valve that directs a certain part of the coolant to the hot water system.

Rules for installing a three-way valve in a heating system

It is not difficult to install a three-way valve with or without a servo drive with your own hands. This is just a shut-off valve, but it should be noted that it can have different methods of fastening. There are usually two of them: threaded or flanged. In the first position, the thread can be internal or external. In any case, the connection to the pipes is made using sealing materials such as fum tape or tow. As for the flange connection, to ensure its tightness it is necessary to make a gasket from heat-resistant rubber or paranite.

Correct connection of the valve to the pipes

There are two nuances that relate to proper installation:

- The device is usually installed on the return circuit before the circulation pump, because the outlet pipe is always open.

- The valve must be installed in the pipeline system exactly in the arrow of the coolant movement. The latter is indicated on the device body.

Types of connection between valve and pipes

Heating mode

The operation of a double-circuit boiler in heating mode is no different from the operation of a simple flow-through heater. The initial switching on of the burner is accompanied by a sufficiently long period of operation, which allows the temperature in the heating circuit to be raised to the required values. When the optimal mode is reached, the gas supply stops. If there is an air temperature sensor in the home, the automation itself will monitor its readings. The gas burner modes of a double-circuit boiler can be switched by special weather-dependent automation that monitors the temperature outside the house.

Nominal diameter and adjustment

The flow area of the safety valve must be equal to or greater than the cross-section of the pipe on which it is installed. Otherwise, the hydraulic resistance of the device will be too large, as a result of which the operation of the system will be disrupted.

The adjustment of the heating system safety valve depends on the type of clamping mechanism. Spring devices have a cap, the rotation of which sets the pre-compression of the spring. These products are characterized by high adjustment accuracy of +/- 0.2 atm.

Lever-weight valves are adjusted with less precision. To do this, you need to move the load along the lever or increase its mass.

Hot water supply

The hot water supply system turns on only when you directly turn the water tap valve. The occurrence of a flow provokes the operation of a three-way valve: this way the heating system is started. At the same time, a flame appears in the gas burner if it was still turned off. As a rule, it takes a few seconds for hot water to appear from the tap.

It is also important to understand how a double-circuit boiler heats water. As stated above, when it is turned on, the heating system is turned off. The regulation of this entire procedure is carried out thanks to a three-way valve, which redirects a certain volume of heated water inside the secondary heat exchanger (there is no flame on the secondary at all). The incoming coolant begins to heat the water circulating in the heat exchanger. Despite some complexity of the circuit due to the small circulation circle of the coolant, double-circuit gas boilers with separate heat exchangers are easy to maintain and repair. OGV boilers are also popular, allowing efficient supply of hot water.

Scope of application and installation nuances

Installation of a mixing valve for heated floors is intended to achieve the following goals:

- protection of a solid fuel boiler from condensation and overheating due to sudden power outages;

- reducing and maintaining the required temperature in heated floors;

- separation of coolant supply to different elements of the system.

The temperature of the coolant in the heated floor system cannot exceed 45-50 degrees, in order to avoid various damage to both the system and the finishing coating.

To protect the solid fuel heating element during warming up, do not allow cold coolant to enter the boiler from the return line. They use the following scheme: until the coolant warms up to 55-60 degrees, it circulates in a small circle. When the temperature rises to operating mode, the valve opens and directs the entire flow to the radiators.

In warm water floors, the valve performs essentially the same role. The circulation pump pumps hot coolant through the pipelines until it begins to cool or overheat. When one thing or another happens, the sensor is triggered, and the thermostatic head or drive begins to move the valve stem and regulate the mixing of the coolant to the desired temperature.

One more example. To quickly warm up a heat accumulator, a temperature of about 80-90 degrees is needed, but such a temperature is absolutely unacceptable for heated floors and radiators. A three-way valve with a separate pump installed after the accumulator helps lower the supply temperature to the rest of the system through admixture.

When installing a thermostatic mixing valve, you should pay attention to the location of the circulation pump, which is always located on the side of the open pipe

In the heating system, the highest temperature is in the boiler; it is connected to the boiler directly, and the remaining elements are connected through a three-way valve, since they need temperatures lower than the original one.

There are inexpensive valves of a simplified design; the control element is located in the body and autonomously maintains a fixed temperature, which is usually indicated on the body. Its advantage is its low price, but its disadvantage is the lack of customization. A three-way valve with a thermal head or drive is a useful and sometimes irreplaceable element in a heated floor system, and indeed in the entire heating system. It makes it possible to use heating fluid efficiently and economically. In some systems it serves as an element that protects against damage and breakage.

Characteristics of combined type heat exchangers

Combined heat exchangers provide boiler equipment with the following advantages:

- High efficiency in the DHW system.

- Simplicity of the internal structure.

At the same time, the likelihood of scale formation increases. However, separate heat exchangers still have more advantages, which explains their high popularity. Due to the complexity of the design, almost complete disappearance of scale is achieved. While the hot water supply is running, the circulation of coolant inside the heating pipes stops. If this process drags on for a long time, it can lead to an imbalance in the heat balance in the house. In this case, a double-circuit gas boiler operates, as in the summer, when there is no need for heating.

After tightening the valve, the three-way valve is activated, after which the double-circuit boiler goes into standby mode. In some models, the cooled coolant begins to heat up immediately. The operation of a double-circuit boiler for heating only will continue until the next time the tap is opened. The productivity level of individual modifications can reach 15-17 l/min: this is directly affected by the power of the boiler equipment.

Having an idea of the operation of gas double-circuit boilers, it is easy to understand the purpose of its individual components. In some cases, this makes it possible to independently carry out repair and maintenance activities. Due to the high saturation of the internal layout, the developers were able to create very efficient heating equipment. The compactness of boilers of this type eliminates the need to equip a separate boiler room.

Increasingly, boilers are used for heating and hot water supply in homes. They are compact, powerful, and easy to use. Gas today is cheaper than other types of fuel. If you are thinking about installing such equipment in your home, it is important to understand how a gas boiler works. This will help you quickly understand how to operate the equipment and operate it successfully.

Characteristics of thermal valves

For your information, here are a number of basic technical characteristics of thermostatic valves:

- The maximum operating pressure level is 1.0 MPa.

- Pressure testing before commissioning is 1.5 MPa.

- The maximum operating temperature is +110 ºС.

- The maximum permissible ambient temperature is +50 ºС.

- The valve capacity is from 1.6 to 2.5 m³/h.

- Temperature control range - +20…+60 ºС.

- Response time: 25 min.

- MTBF with manual control - 8000 cycles.

What materials are they made from?

Corrosion-resistant metals are used to make the thermostatic valve body:

- Brass.

- Bronze.

- Stainless steel.

Additionally, the surfaces of brass products are nickel-plated, and the bronze body is either also nickel-plated or coated with a layer of chrome.

How does a gas boiler work?

What does the equipment consist of? It is important for every user to know the answer to this question, because different situations may arise during work. In addition, knowledge about the structure of a gas boiler and its components will help you choose the model that is suitable specifically for your premises.

Main nodes

Burner . The rectangular design is equipped with nozzles. Through them, gas enters the burner and is distributed. This way the surface of the radiator is heated evenly over the entire surface.

There are two types of burner:

- Atmospheric. Installed near the chimney. The principle of operation is simple: air is taken from the room to maintain the flame. In this case, it is necessary to have a window and normal ventilation. The advantage of the atmospheric type is independence from electricity. More often found in floor-standing models.

Water is dripping from the safety valve. What to do

Storage water heaters today are in increasing demand among our compatriots. These units simply allow them to effectively solve many business problems, but sometimes it happens that the device itself becomes the source of the problem.

One of the most common problems you encounter is water leakage. If water drips from the safety valve, then it is necessary to establish the cause as soon as possible, because in some cases this process should not be considered a malfunction. That is why there is no need to rush into the decision to call a water heater repair specialist.

Possible causes of malfunction

The reasons for water leakage from the valve may be:

- Valve malfunction;

- Incorrectly set pressure difference in the system;

- Other reasons, in particular, water may leak from the valve, but this will not be considered a failure.

The first two reasons involve repairing the unit.

Troubleshooting Methods

Gas water heaters should be tested first. It is necessary to determine in what situation the water leaks out.

If you notice that water flows out during the heating process, then most likely your unit is fully operational. The fact is that when heated, water expands, and accordingly the pressure of the liquid on the walls of the tank increases

When the pressure exceeds the norm, the valve gets rid of excess water. A solution to this problem can be to connect a rubber hose and lead it into a sewer or container of the required size.

If the safety valve of the water heater allows cold water to pass through, then most likely the reason is that the pressure in the water supply is too high. The solution to this problem is to install a reducer to normalize the pressure in the water supply network. To do this, you must contact a qualified specialist. You also cannot do without the help of a professional if you are inclined to conclude that the cause of the water leak is a malfunction of the valve itself.

Therefore, the first step to solving water heater leakage problems is to determine the cause of the leakage and determine the nature of the problem. Remember that it is always safer to seek help from a professional than to repair complex equipment yourself, because inept repairs can lead to a more complex malfunction.

Simplified budget elements

Three-way valves of the autonomous type are considered simplified. Their internal structure is truly simplified, since neither a thermal head with a controller nor a rod are provided in them. The thermostatic element is installed internally and is designed to operate at a specific temperature (often 50°C or 60°C). It is no longer possible to change the settings; the flow temperature at the valve outlet will always correspond to the specified ±2°C. This option is for those who install a valve in simple heating systems and want to save money. The cost of simplified elements is approximately 30% lower than the average cost of the bulk of regulators.

A thermostatic three-way valve is necessary in complex systems that include several circuits: hot water, heating, underfloor heating. It allows you to save fuel by more efficiently using the thermal energy generated by the boiler. Despite many advantages, installing a valve is not always justified, so you should consult with a specialist regarding the advisability of installing it.