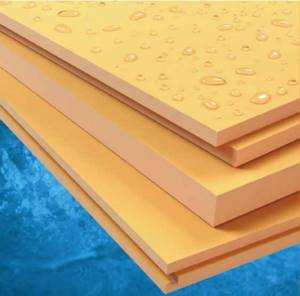

Penoplex - insulation from the company of the same name

started its activities in 1998 . The company specializes in the production of decorative, finishing and building materials. Extruded polystyrene foam is what Penoplex insulation is. It differs from its cheap analogue - polystyrene foam - in greater strength and very low vapor barrier. The highlight of this insulation is its thermal insulation properties. A material with a thickness of 20 cm can be compared with mineral wool with a thickness of 40 cm and the same brickwork. Despite all its advantages, this material has a significant disadvantage - it practically does not remove steam, due to which additional work is required when using it.

- Floor insulation.

- Blind area device.

- Insulation of wells and septic tanks.

- Construction of paths and platforms under gazebos.

- Base equipment.

- Equipment for flat roofs.

- Thermal insulation of facades and internal walls.

It is worth noting that when insulating facades, it is necessary to organize a ventilation system in advance in order to normalize the humidity in the house and minimize the possibility of dampness.

Neglecting these measures may contribute to the development of mold and mildew. Constant humidity will negatively affect human health and the durability of building materials.

Penofol - universal insulation

Thin material made of foamed polyethylene has not only thermal insulation properties, but also steam, hydro and sound insulation . Therefore, it does an excellent job of protecting a building from drafts, moisture, noise and wind, which makes it a universal building material. The layer thickness can reach 40 mm. One or two sides are covered with aluminum foil, which makes the insulation reflective. The principle of operation is the reflection of heat, its accumulation and release. Therefore, in such a building it will be warm in winter, and not hot in summer. Let's list the advantages of insulation:

- Ease of installation.

- Good sound insulation.

- Low vapor permeability does not require additional work to install additional vapor barrier.

- Versatility of use.

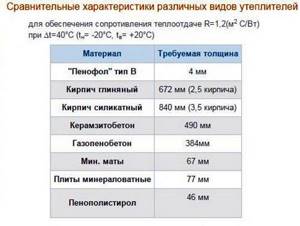

- Compactness. A 4 mm insulation layer corresponds to the characteristics of 3 cm thick penoplex.

- Fire safety.

Despite its advantages, penofol has a number of disadvantages, for example, it cannot be used under plaster or wallpaper . It is not recommended as a stand-alone insulation for external walls. Most often used as an additional layer.

- Living spaces.

- Saunas and baths.

- Hangars, warehouses.

- Industrial and administrative buildings.

- Trade pavilions.

- Refrigeration chambers.

- Cars, vans and railway carriages.

- Heating, water supply and ventilation systems.

Also used for floors, ceilings, interior walls, shielding of heating radiators.

Based on the above, you can see that penofol and penoplex are new, high-tech, high-quality building materials on the market.

Their qualities meet the necessary requirements for construction, and thanks to advanced technologies, they simplify both installation and transportation to the site. Simple installation allows you to quickly carry out the necessary work and significantly save both money and time.

Advantages and disadvantages

The use of penofol has its advantages:

- The small thickness of the material allows you to create reliable thermal insulation of the room.

- Installation of building materials does not require special skills or special tools. Working with this material is much easier than with other types of insulation.

- The material is environmentally friendly, which makes it possible to use it for storing food.

- Fire safety. This building material belongs to the class of fire-resistant materials.

- Ease of transportation. The thickness of the product allows the insulation to be rolled up, which allows it to be transported in the luggage compartment of a car.

- Excellent sound insulation. Mounting penofol on top of the frame of building structures provides good insulation of extraneous sounds.

Penofol has not only positive qualities. There are also disadvantages to using this building material:

- The insulation is soft. Because of this, this product is not used for finishing plastered walls. When lightly pressed, the material bends.

- To fix the insulation you will need special adhesives. It is not recommended to nail it to the surface, because in this way penofol loses its thermal insulation qualities.

It is better to insulate walls with penofol; it is too soft for a substrate and quickly loses its heat-insulating properties

Being one of the latest technological solutions to the issue of thermal insulation, foil-foamed polyethylene foam has both strong and weak qualities.

Advantages of the material:

- insignificant thickness with high thermal insulation rates;

- ease of use - does not require special equipment, can be easily cut with ordinary scissors;

- the material is soft and does not crumble or break when used;

- environmentally friendly;

- good hydro- and sound insulator;

- fireproof;

- rolls are easy to transport;

- affordable.

For comparison: the popular insulation mineral wool is almost 2 times inferior in thermal insulation properties to Penofol, and with low moisture resistance it is limited in use in wet rooms. Therefore, when choosing between foamed polyethylene and mineral wool, preference is given to the first.

Distinctive features

Despite the fact that both insulation materials have good thermal performance, they differ from each other in many ways:

- The scope of application is the first distinguishing feature. As you can see above, penofol is a universal material that can be used almost everywhere, even for insulating or soundproofing cars. Penoplex, on the contrary, is used only for thermal insulation of rooms, roofs, floors and walls. However, penofol is not recommended for use as an independent insulation for external walls.

- Technical characteristics are the next distinguishing feature. Unlike penofol, penoplex does not have good vapor barrier properties, therefore it is used only with additional vapor barrier work (if necessary).

- Price . Foil insulation is not only universal, but also costs much less. If used correctly, especially if installed in a bathhouse, gazebo, or cottage, you can save significantly not only on the product, but also on installation, which is easy to do with your own hands.

Criterias of choice

The main technical characteristics that you need to pay attention to when choosing thermal insulation materials for balconies and loggias:

- heat transfer coefficient - the higher the indicator, the smaller the layer of insulation you need to use, which saves precious space and reduces the load on the slab;

- resistance to mechanical stress - it is easier to apply a layer of finishing material to durable materials;

- vapor and hydraulic permeability - the microclimate in the room and the need to use additional materials depend on these indicators.

It is also worth considering the installation features - the simplicity of the process is especially important if the work is planned to be carried out independently without the involvement of specialists.

Recommendations

Referring to the above, we can note clear boundaries for the use of building materials. So, if you need to insulate a summer house, a bathhouse, a gazebo, or create a screen for heating devices that will trap heat in the room, feel free to choose penofol. Do not forget that installation is carried out with the foil side facing the energy source, and the ventilation joints ( 2-2.5 mm ) must be sealed with foil tape. The material is also perfect for sound insulation, waterproofing and vapor barrier of roofs, ceilings and floors. For work on external walls, it is better to use penofol as additional protection.

Penoplex will be a good solution for installation where vapor barrier properties are not needed. Otherwise, you should not forget to do additional work. Thermal insulation of external walls, plinths and basements is the most optimal option for using the material. Installation, unlike penofol, is best done with the help of specialists . This will help avoid unpleasant consequences and save money.

When it comes to choosing insulation for civil or industrial construction, a dilemma often arises. This happens because the modern market is overflowing with offers and choosing truly high-quality and safe material becomes difficult. Each manufacturer insists that its insulation is the best. Below we will look at two modern insulation options.

Thermal insulation Izover

Izover is the only domestic brand that produces thermal insulation based on mineral wool, made from both fiberglass and stone fiber. The company's products have been represented on the world market for more than 75 years. Thermal insulation is available in slabs and rolls.

Scope of application

Thermal insulation of floors above a cold basement/foundation

Insulation scheme:

- base;

- thermal insulation Izover;

- logs;

- vapor barrier Izover;

- finishing floor

Installation recommendations

The manufacturer recommends a lag pitch of 600 mm. This ensures easy installation of the thermal insulation of the floor between the joists. Here it is necessary to install a vapor barrier, which is always installed on the side of the warmer room before the finishing coating (overlapping using a vapor-permeable mounting tape).

Before installing thermal insulation, install a waterproof membrane . In this case, it is recommended to use rolled material, which is convenient to roll out between the joists. The rolls have a fixed width of 1220 mm, which makes it convenient to cut across into two equal parts of 610 mm each. The best solution is Izover Classic, Izover Pro

For quick cutting, you should use a knife with a blade length of 120 mm or more . It is recommended to lay the material in several layers with the seams staggered, which will protect the floor from the formation of cold bridges.

Insulation of attic floors and attic floors

Insulation scheme:

- base;

- thermal insulation Izover;

- logs;

- vapor barrier;

- finishing floor

When installing, follow the recommendations given above.

Thermal insulation of floors along joists: warm interfloor ceilings

Insulation scheme:

- base;

- thermal insulation Izover;

- logs;

- vapor barrier;

- finishing floor

The installation recommendations are the same. Recommended materials: Izover Classic, Izover Optimal, Izover Pro.

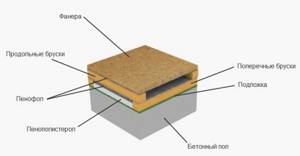

Thermal insulation of floors on floor slabs

Insulation scheme:

- floor slab;

- leveling layer of sand;

- thermal insulation Izover Floating floor;

- waterproofing;

- screed – cement-sand or dry;

- finishing floor

In this case, thermal insulation can be arranged in two ways: installing a floor using joists or a floating floor.

The manufacturer's recommendations are as follows:

- if the screed is cement-sand, then a layer of waterproofing is laid on top of the thermal insulation. This will prevent moisture from the screed from getting into the insulation. The material is installed with an overlap of 200 mm;

- Before the screed device, cut strips of Izover slabs are installed around the perimeter, not exceeding the height of the screed. The screed should not be closely adjacent to the walls, as this will lead to poor heat conservation.

If insulation is carried out using joists, installation is carried out in the standard manner described above.

Advantages

The positive characteristics of the product are revealed as follows:

- Isover is characterized by a low thermal conductivity coefficient, which is ideal for floor insulation;

- fast, easy installation and transportation;

- fire safety - all products have been tested in special centers. Isover is a non-flammable material;

- noise protection – insulation blocks the spread of acoustic noise;

- stability in the floor structure. The service life is 50 years;

- safety. Izover has an eco-label, which confirms its safety for the environment and human health. The material can be used in children's rooms and institutions;

- the material is elastic, which allows it to be placed in the frame, eliminating the formation of cracks.

Flaws

Practical experience has shown that the material emits a pungent odor, disintegrates from moisture, loses its shape and settles. It is recommended to install a high-quality hydro and vapor barrier.

Peculiarities

The brand’s specialists provide support to their clients, which allows them to choose the most effective flooring solution.

To install the material by surprise when cutting, special allowances of 5 mm must be provided on each side. This will help securely fix the thermal insulation without the use of fasteners.

Penoplex - insulation from the company of the same name

started its activities in 1998 . The company specializes in the production of decorative, finishing and building materials. Extruded polystyrene foam is what Penoplex insulation is. It differs from its cheap analogue - polystyrene foam - in greater strength and very low vapor barrier. The highlight of this insulation is its thermal insulation properties. A material with a thickness of 20 cm can be compared with mineral wool with a thickness of 40 cm and the same brickwork. Despite all its advantages, this material has a significant disadvantage - it practically does not remove steam, due to which additional work is required when using it.

Main types of thermal insulation

Thermal insulation materials are most often classified according to the type of raw material.

Organic

The main characteristics are as follows:

- materials are obtained through the use of organic substances. This group includes polymers (foamed polyethylene, expanded polystyrene, products based on them). This group includes insulation materials Penoplex, Penofol;

- The disadvantage of such insulation is low fire resistance, so the scope of application is limited to t +90°C or special protection is installed from non-combustible materials.

Penofol - universal insulation

Thin material made of foamed polyethylene has not only thermal insulation properties, but also steam, hydro and sound insulation . Therefore, it does an excellent job of protecting a building from drafts, moisture, noise and wind, which makes it a universal building material. The layer thickness can reach 40 mm. One or two sides are covered with aluminum foil, which makes the insulation reflective. The principle of operation is the reflection of heat, its accumulation and release. Therefore, in such a building it will be warm in winter, and not hot in summer. Let's list the advantages of insulation:

- Ease of installation.

- Good sound insulation.

- Low vapor permeability does not require additional work to install additional vapor barrier.

- Versatility of use.

- Compactness. A 4 mm insulation layer corresponds to the characteristics of 3 cm thick penoplex.

- Fire safety.

Despite its advantages, penofol has a number of disadvantages, for example, it cannot be used under plaster or wallpaper . It is not recommended as a stand-alone insulation for external walls. Most often used as an additional layer.

- Living spaces.

- Saunas and baths.

- Hangars, warehouses.

- Industrial and administrative buildings.

- Trade pavilions.

- Refrigeration chambers.

- Cars, vans and railway carriages.

- Heating, water supply and ventilation systems.

Also used for floors, ceilings, interior walls, shielding of heating radiators.

Based on the above, you can see that penofol and penoplex are new, high-tech, high-quality building materials on the market. Their qualities meet the necessary requirements for construction, and thanks to advanced technologies, they simplify both installation and transportation to the site. Simple installation allows you to quickly carry out the necessary work and significantly save both money and time.

Polyurethane foam

Polyurethane foam, which is more often called sprayed foam rubber, refers to insulation materials that are gradually leaving the construction market, moving to other industries. Supplied in rolls, layer thickness from 3 cm.

Pros of polyurethane foam

- Low price.

- High thermal conductivity coefficient.

- Ecological cleanliness.

- Easy installation.

Cons of polyurethane foam

- Flammability.

- Destruction when exposed to ultraviolet light.

- The polymer structure is destroyed by exposure to water and steam.

- Over time, thermal insulation becomes less effective due to depolymerization.

Distinctive features

Despite the fact that both insulation materials have good thermal performance, they differ from each other in many ways:

- The scope of application is the first distinguishing feature. As you can see above, penofol is a universal material that can be used almost everywhere, even for insulating or soundproofing cars. Penoplex, on the contrary, is used only for thermal insulation of rooms, roofs, floors and walls. However, penofol is not recommended for use as an independent insulation for external walls.

- Technical characteristics are the next distinguishing feature. Unlike penofol, penoplex does not have good vapor barrier properties, therefore it is used only with additional vapor barrier work (if necessary).

- Price . Foil insulation is not only universal, but also costs much less. If used correctly, especially if installed in a bathhouse, gazebo, or cottage, you can save significantly not only on the product, but also on installation, which is easy to do with your own hands.

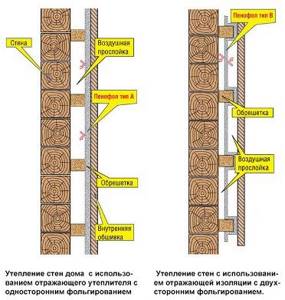

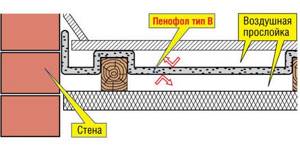

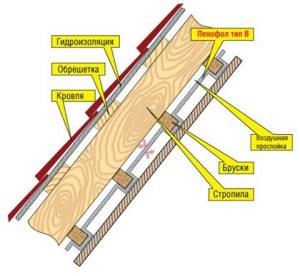

How to insulate with penofol

It should be noted that insulating anything (a wall, ceiling or roof) with penofol is really quite simple. If you follow the manufacturer's instructions, then to achieve maximum efficiency it is necessary to provide an air gap of 1.5 to 2 cm wide on both sides. To create such a gap, rolled penofol will have to be attached to wooden sheathing strips attached to the base.

That is, first you need to take 20 mm thick planks and attach them to the wall vertically or horizontally at intervals equal to the width of the penofol roll. If the house is wooden, then the planks are fastened with self-tapping screws; for brick or concrete bases, dowels will be required. Then strips of the required length are cut from the roll and attached to the planks with staples from a construction stapler.

Important. Unlike various thin films, the installation of penofol sheets is carried out not overlapping, but end-to-end. In this case, the foil side should be facing inside the room, and the joints should be carefully taped with aluminum tape.

When the layer of thermal insulation made of penofol is fixed and taped, the same strips are installed on top of it with your own hands to provide an external air gap. They are attached with self-tapping screws to the previous sheathing, and the outside is lined with plasterboard sheets or other finishing methods are used. Please note that a vapor barrier film is not laid, since there is no need for it; penofol itself is a vapor barrier.

It must be said that in practice, few people follow the instructions; usually penofol is attached directly to the wall or ceiling, and the air gap is made only on one side. This reduces the thermal insulation properties of the material, and further we will tell you why. When thermally insulating roofs or inclined walls of attics, installation of penofol is carried out by attaching it to the lower planes of the rafter boards. This means that the space between the rafters is filled with other insulation, since thin polyethylene alone will not be enough.

Important. If penofol can replace a vapor barrier, then under no circumstances can it replace waterproofing. You cannot lay it in the under-roof space in front of mineral wool; a diffusion membrane is needed there. It does not allow water to pass through, but also does not prevent the passage of vapors escaping from the cotton wool.

Floors in wooden houses are also insulated with foamed polyethylene, laid between the joists. Again, waterproofing is laid first, then slab insulation, and penofol on top. Putting it at the very bottom or in the screed is pointless; compression causes the material to cease to be heat-insulating. Although in practice such errors can be encountered often.

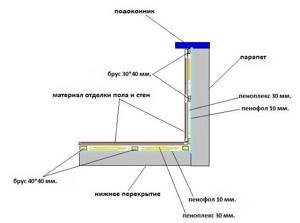

Another area of application of penofol is the insulation of balconies and loggias, where the material is laid as a second layer after more serious insulation materials - extruded polystyrene foam or polystyrene foam. The installation method is still the same: first, the sheathing bars are placed, polystyrene slabs are laid between them, and polyethylene foam is attached on top. After this, interior finishing is carried out.

Recommendations

Referring to the above, we can note clear boundaries for the use of building materials. So, if you need to insulate a summer house, a bathhouse, a gazebo, or create a screen for heating devices that will trap heat in the room, feel free to choose penofol. Do not forget that installation is carried out with the foil side facing the energy source, and the ventilation joints ( 2-2.5 mm ) must be sealed with foil tape. The material is also perfect for sound insulation, waterproofing and vapor barrier of roofs, ceilings and floors. For work on external walls, it is better to use penofol as additional protection.

Penoplex will be a good solution for installation where vapor barrier properties are not needed. Otherwise, you should not forget to do additional work. Thermal insulation of external walls, plinths and basements is the most optimal option for using the material. Installation, unlike penofol, is best done with the help of specialists . This will help avoid unpleasant consequences and save money.

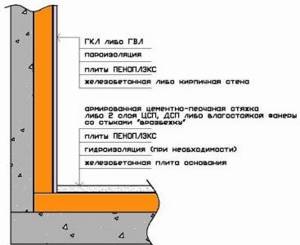

Balcony insulation with penoplex and penofol

To insulate the balcony, a sufficient amount of thermal insulation materials is used. Some of these materials are penofol and penoplex. A special technology for insulating a balcony with penoplex and penofol with your own hands helps to significantly reduce heating costs. Thanks to these insulation materials, even in winter the temperature on the balcony will be comfortable.

1. Penoplex is an extruded polystyrene foam with cells measuring 0.1-0.2 millimeters.

2. This thermal insulation material is produced in the form of slabs. The thickness of the slabs ranges from 20 to 100 millimeters.

3. Penoplex can differ in density, flammability class, and also in the size of the slabs.

4. This material is used not only for insulating balconies, but also for foundations, roofing, and walls. Penoplex is also actively used in transport construction.

5. Thanks to penoplex, you can save a large amount of building materials. Penoplex slabs, which are only 20 millimeters thick, can replace a thirty-centimeter-thick brick wall in terms of thermal insulation. Calculation of penoplex for the balcony should be made before the start of installation of thermal insulation work.

1. Penofol is available in rolls. This insulation is based on sewn polyethylene foam covered with aluminum foil.

2. The thickness of penofol is available from three to ten millimeters.

3. Thanks to the layer of aluminum foil, the heat flow is reflected and stored indoors.

How to insulate a balcony with both penofol and penoplex

Insulation of a balcony with two thermal insulation materials at once is carried out using the following technology:

1. First of all, it is necessary to make a frame on which the thermal insulating foam boards will be attached. The frame is made of wooden beams.

2. After the wooden frame is completely ready, you need to measure the walls and floor to be insulated, and carefully cut the foam boards according to these markings.

3. You can attach penoplex to a wooden frame using disc-shaped dowels, a special adhesive, polyurethane foam or mastic.

Izolon or penofol: which is better?

Penofol can be compared with only one group of thermal insulation materials of the Izolon brand, namely “heat-reflecting insulation IZOLON”.

The ISOLON company offers insulating materials based on polyethylene foam (ISOLON 100) or cross-linked polyethylene foam (ISOLON 500) with aluminum foil or lavsan applied on one side.

When comparing Isolon 100 and penofol, there is no significant difference in properties and method of application, so the final winner will have to be determined by availability and cost. The only advantage of Izolon is that the range has been expanded with sheet material with a thickness of 15 to 50 mm.

Thermal reflective insulation based on Isolon 500 is made from cross-linked polyethylene foam, which gives it much greater strength and a slightly lower thermal conductivity coefficient. Depending on the frequency of foaming (5-40 times), the compressive strength at 10% deformation ranges from 0.011 to 0.15 MPa.

In most cases, it is enough to use penofol, however, Izolon makes it possible to use heat-reflecting screens in cases where the performance characteristics go beyond the limits permitted for penofol.

Its composition is polyethylene foam with a foil layer. A lightweight universal material, most often produced in roll form and is an excellent choice for insulating a balcony:

- service life – more than 100 years;

- does not support combustion, upon contact with an open flame it breaks down into water and carbon dioxide;

- resistance to temperature changes without changing properties;

- high rates of heat and sound insulation;

- flexible roll material allows you to effectively and easily insulate the most inaccessible places;

- It is used not only as an insulating layer, but also as a protective layer against leaks when pouring floors.

Main disadvantages:

- high price;

- it is necessary to strictly follow the installation technology;

- thin material breaks easily, and damage to the structure leads to loss of characteristics.

Do-it-yourself thermal insulation of the loggia

- Characteristics of insulation

- Loggia insulation technology

- Laying penofol with an inner layer

- Insulation of floors and ceilings using penofol

- List of tools and materials

Currently, any apartment or private house needs insulation work. Insulation is one of the most important tasks. Insulation is necessary to maintain an optimal indoor microclimate. Loggias are in direct contact with the outside air, which can contribute to the appearance of drafts and condensation. All this can lead not only to a decrease in the temperature of the house, but also to the development of colds in residents. Very often, in the absence of thermal insulation materials, dust and dirt penetrate into the premises through the loggia, which worsens the sanitary and hygienic living conditions.

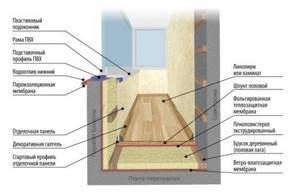

Scheme of proper thermal insulation of a balcony.

The insulation of the loggia can be carried out with a variety of materials. Today there is a wide range of insulation materials on the market. The most common of them include mineral wool, polystyrene foam, polystyrene foam, including extruded polystyrene foam, and others. They all have their own area of application. Polyurethane foam is more suitable for thermal insulation of walls, mineral wool - for roofs, and so on. Insulation of the loggia is best done using penofol and penoplex. These are modern building materials. Let us consider in more detail how the insulation of a loggia with penoplex and penofol is organized, how the insulation of a loggia with polystyrene foam differs, the main stages of work, the advantages and disadvantages of these insulation materials.

Benefits of penofol - debunking myths

Manufacturers and sellers of penofol attribute wonderful thermal insulation characteristics to this insulation, which is actually a myth.

Also, installation diagrams with air gaps, one of which we described at the beginning of the previous section, can be considered misleading the buyer. How the manufacturer proposes to insulate floors and roofs is shown in the figures:

In fact, the presented schemes are nothing more than another way to improve the thermal insulation of external fences using air gaps, since penofol’s own resistance to heat transfer is absolutely not enough.

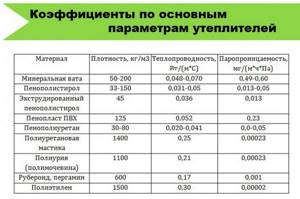

This can be easily checked by taking as a basis the best thermal conductivity indicator from the technical characteristics table - 0.037 W/m2 °C. Next, we take the canonical formula and determine the thermal resistance of a material 4 mm thick:

- δ – penofol thickness in meters, taken 0.004 m;

- λ is its thermal conductivity coefficient, equal to 0.037 W/m2 °C.

We get R = 0.004 / 0.037 = 0.11 m2 °C/W. Now look at the comparison table, which is presented on the same resource as the technical data. It says that 4 mm of penofol can easily replace 77 mm thick mineral wool or 46 mm thick polystyrene foam.

This means that, for comparison, it is necessary to determine the thermal resistance of a 77 mm mineral wool layer (its thermal conductivity is 0.05 W/m2 °C):

Rminwool = 0.077 / 0.05 = 1.54 m2 °C/W, which is 10 times more than that of foamed polyethylene.

Hence the conclusion: the presented comparative table is a pure fake. The data given in it is unreliable, and although the material is a good insulator, it is not better than others. The reason is that it is too thin, although its thermal conductivity is equal to extruded polystyrene foam.

Against this background, all other advantages of penofol fade. However, there is another myth - about the reflection of infrared heat back into the room thanks to the foil surface. But none of the manufacturers explains what the foil will reflect behind the interior trim. After all, infrared radiation spreads across open space; it will not pass through drywall or other obstacles.

What is really good about penofol is its low cost and ability to act as a vapor barrier together with other insulation, as evidenced by reviews on the forums. In addition, it is easy to install and the process does not take much time. You can also note the durability of the insulation, reaching 50 years, provided that it is located inside the building and not outside. By the way, it is better not to use penofol for external insulation of walls; it will be of little use there. You should not use it for thermal insulation of a bathhouse, like any polymer; when heated to 100 ° C, the material will begin to release harmful substances.

Characteristics of insulation

Scheme of insulating a balcony with penoplex and penofol.

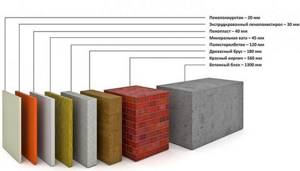

Before you directly insulate the loggia. you need to remember that this must be done comprehensively, that is, finishing the floor, walls, and ceiling at once. Any thermal insulation must meet some basic requirements: be safe for humans, have a low thermal conductivity coefficient, not change its physical and chemical properties, and be accessible to buyers. Penofol and penoplex insulation technology will reduce the cost of heating an apartment or house. So, penoplex is extruded polystyrene foam. It contains many small cells filled with air, which provides good thermal insulation properties. It is available in the form of slabs of various thicknesses (from 20 to 100 mm). It belongs to materials with average flammability. Can be used to insulate walls and floors.

Penoplex does not absorb moisture, so it does not require additional waterproofing. In addition, penoplex is a lightweight, environmentally friendly and easy to install material. It has low vapor permeability, which is important for interior work. As for penofol, it is available in rolls. It contains a foam filler, covered with aluminum foil on top.

Return to contents

Mineral wool

This is an accessible and inexpensive material. There are several types of mineral wool: slag, stone and glass wool. The latter can pose a health hazard, so you must work in special clothing. The starting material (slag, rock or glass) is melted and formed into fibers. Tile wool is easy to install, but for rolled wool it is necessary to construct a sheathing.

- The material retains heat well.

- Mineral wool is fireproof.

- It is affordable and is on sale everywhere.

- Has high sound insulation properties.

Mineral wool has a number of disadvantages, due to which it is undesirable to use it for insulating a balcony or to use it only to a limited extent.

- The insulation is quite bulky and, together with the sheathing, takes up a lot of space.

- Mineral wool gets wet easily and quickly, including absorbing moisture from the air. Once wet, it becomes heavy and loses its heat-protective properties.

- If the cotton wool is not covered well enough, its fibers can become airborne, which is harmful to health.

There are many varieties of mineral wool

Loggia insulation technology

Scheme of insulating a balcony from the inside.

The insulation of the loggia, as mentioned above, should cover the walls, floor and ceiling.

Insulation of loggia walls with penofol is carried out as follows. First you need to clear the walls of debris, remove nails and screws, and level the surface.

It should be as level as the floor. If there are cracks or defects, they must be filled with foam.

If necessary, you can use plaster or putty for leveling.

Thermal insulation includes a layer of penoplex, penofol and facing material.

It is recommended to start insulation from the far corner of the loggia. To do this, you need to take a foam board and attach it to the wall. Next, secure it with dowels or glue it. In the first case, you will need to drill at least 5 holes for fastenings in the slab and wall.

Penoplex slabs must be fastened in such a way that the vertical seams do not coincide. The plates have grooves on the sides for tighter adhesion to each other. It is important not to leave any gaps. In most cases, when installing the final slabs, you will have to adjust them. To do this, first measure a section of the wall, and then cut out a slab of the same size. The material can be cut easily with a simple knife.

Return to contents

Laying penofol with an inner layer

Scheme for insulating a loggia with penofol.

As with floor insulation, in this case you will need penofol. This is the next stage of work. The rolls are laid on foam boards. Before this, you need to carefully seal all the joints. It must be remembered that penofol is placed with foil inside. It is fastened with self-tapping screws. In addition to retaining heat, it serves as a vapor barrier film. The seams are taped with special tape. It is advisable to lay it evenly and not overlapping. After this, installation of the sheathing begins. It is necessary to ensure ventilation of the insulation and to secure the facing layer.

For lathing, it is optimal to use wooden slats with a cross-section of 40 x 20 mm. They are nailed to the surface parallel to the floor, that is, horizontally, at a distance of 40-45 cm from each other. Lastly, they are nailed at the window. Levelness is checked using a building level. If necessary, you can use polystyrene foam when you need to level the surface. By the way, you can also insulate a loggia with polystyrene foam, but this method is more effective. Once the sheathing is ready, you can begin the exterior finishing. For these purposes, lining or plastic panels are suitable.

Return to contents

Insulation of floors and ceilings using penofol

Scheme for insulating a loggia with penoplex.

Thermal insulation of the floor is an important component of the renovation. The technology is similar to the previous one. First, you need to level the floor surface, remove old baseboards, and so on. Then the sheathing is made from beams. Their height depends on how many layers of insulation are required. The frame is attached, retreating 10 cm from the edge of the wall. The step between the beams is 50-60 cm. The sheathing is fastened with a puncher or hammer. First, drill a hole, insert a dowel and nail a self-tapping screw. At the next stage, the insulation is installed. It is important that the rolls fit tightly together. It is recommended to cut penofol sheets slightly larger than the distance between the beams. This will ensure they fit snugly.

After this, plywood sheets are laid. When attaching them around the entire perimeter, it is necessary to leave a small gap of 1 cm. The sheets are fastened with self-tapping screws every 45 cm. Thermal insulation with penoplex involves a concrete screed with a layer of about 4 cm. Insulation of the ceiling is similar to insulation of the floor. But there are also differences. Here, after laying the first layer of insulation, it needs to be fixed with a wooden strip using self-tapping screws. The slats are taken in length equal to the width of the loggia. The joints are filled with polyurethane foam. The second layer of penofol will be attached with horizontal slats.

Glazing and preparatory work

It is clear that it only makes sense to insulate a glazed balcony. The type of glazing should be “warm”: PVC profile with double glazing and hinged doors. The basis for the structure is often brick or foam block masonry. In terms of weight and thermal conductivity, foam blocks are better than bricks, so you should opt for them. Before starting insulation work, it is necessary to seal all cracks and joints with foam. Also note that the insulation layer may cover the window frame. To prevent this from happening, use an expansion or additional profile.

List of tools and materials

Scheme of insulating a balcony from the inside without installing a vapor barrier.

To organize the insulation of the floor, ceiling and walls of the loggia, you need to purchase the necessary tools and raw materials. To insulate the floor, walls and ceiling you will need: a building level, polystyrene foam boards, foam foam rolls, dowels, nails, hammer, screwdriver, drill, tape, polyurethane foam, primer (putty), glue. In addition, facing material (panels) will be required. When insulating a floor with penoplex, sand, crushed stone, water and cement are needed to prepare concrete. To insulate the floor, walls and ceiling of the loggia, you will also need wooden slats with a cross-section of 20 x 40 mm.

Complex insulation of the floor, walls and ceiling of the loggia with penofol and penoplex is the best option.

Do-it-yourself insulation of a loggia with penoplex and penofol: installation and installation features

Today there is a wide selection of insulation materials that can be used to insulate not only residential premises, but also balconies.

After all, this is also an additional and useful room, which is often used by apartment owners. Insulating a loggia with penoplex and penofol with your own hands is quite feasible.

However, it is not necessary to have construction skills. By thermally insulating the loggia, heat will be reliably maintained throughout the entire apartment. This article will advise you on how to install it correctly.

Why insulate the loggia

Firstly, such a procedure will restore order in this room, which is required to store many household items.

If you create a neat look, it will become an additional place for relaxing or working at the computer. Many apartment owners in a high-rise building convert the loggia into their own office.

A beautiful view from the window only makes the workforce more energetic. If the living space has little space, a loggia will create additional space.

But for comfort and warmth it is necessary to properly insulate it.

Secondly, by insulating this space, the interior appearance of the room will significantly improve and acquire a cozy and tidy surface. Which will significantly highlight the interior.

Thirdly, when insulating the loggia. the whole room will become warmer and more comfortable. This work can be easily done on your own. You just need to choose the right thermal insulation materials.

In general, insulating a loggia with penoplex and penofol with your own hands has many advantages, namely:

- Saving material resources;

- Strengthening the structure;

- Additional living space;

- Beautiful, neat appearance;

- Preservation of heat throughout the apartment.

Features of insulation

As you know, walls can be insulated in two ways: externally, internally. For internal installation, the floor and walls are covered with insulation.

The external appearance is based on the fastening of heat insulating sheets to the façade of the building. Of course, most consumers choose the first option.

After all, external insulation does not take up space, the room remains without changes in area. But high floors do not always make it easy to carry out this work.

The video will help you understand the topic:

Therefore, you have to choose internal insulation. It is more practical and easy to implement.

If you plan to save heat on the loggia, it is worth considering some nuances:

- Walls and floors will require more thorough insulation. They must be treated as responsibly as possible;

- Installation of building “warm” material requires a ceiling. floor, walls. If you choose one surface, the work will not be beneficial;

- When choosing a material, you should pay attention to its size. Minimum thickness will save space;

- The insulation must be environmentally friendly. The health of apartment residents depends on this.

Modern thermal insulation materials come in a huge variety, but not all of them are effective. Therefore, it is necessary to study the thermal insulation properties of each of them.

Thermal insulation Parok

PAROC Group is an international manufacturer of stone wool. Manufacturing know-how has been developed by the brand since 1930. Today, the brand is the leading supplier of thermal insulation in Finland, Sweden, and the Baltic countries.

Scope of application

The material is presented in the form of structural boards for thermal insulation in energy-saving structures, eco-houses, private mansions, cottages, and apartments in apartment buildings.

The installation of different types of floors requires the implementation of different solutions. Interfloor ceilings , along with protection against heat loss, receive sound insulation between floors. The principle of operation of ventilated floors is similar to the principle of operation of ventilated facades in the lower part of the building, but with the difference that the foundation slabs must be protected from moisture.

Thermal insulation Parok is successfully used in two main areas: new construction and reconstruction.

Thermal insulation for new house construction

Interfloor ceilings

Basalt wool Parok is an elastic material that works like a shock absorber between the slabs. Insulation not only retains heat, but also blocks sound vibrations that occur when walking or as a result of other movements.

Interfloor ceilings: wooden floors

Basalt wool slabs are placed between two layers of floor slabs. The building material used is fiberboard or gypsum boards with a thickness of 13-25 mm. Instead of one of the layers, a finishing coating, for example, a layer of parquet, can be used.

Installation diagram:

- finishing layer of floor covering;

- flooring board (fibreboard, gypsum);

- slab Parok SSB1/SSB4;

- flooring slab;

- load-bearing wooden beams with installed heat insulator Parok Extra, or Parok Extra Smart, Extra Plus, Parok UNS 37z;

- ceiling.

Interfloor ceilings: concrete floating floors

The optimal solution for thermal insulation can be the installation of a floating concrete floor with laying basalt wool slabs under a concrete layer with a thickness of at least 50 mm. The slab placed on top of the basalt insulation must be well insulated from the surrounding walls. The manufacturer recommends using part of the insulation to form a gap between the walls and the floor slab (during the concrete pouring process).

Installation diagram:

- finishing soy;

- floating concrete slab;

- basalt wool slab Parok SSB1/SSB4;

- load-bearing structure: concrete;

- ceiling.

Insulation of floors of the first floors (foundation slabs)

When constructing the first floors, thick concrete slabs are used (reinforced concrete floor slabs supported on the foundation, monolithic reinforced concrete pad acting as a load-bearing base). Installation of thermal insulation can be carried out above the slabs, below the level of the slabs, taking into account the heating system of the house. If the house is intended for permanent residence, the insulation is installed under the slabs, which will allow for maximum heat retention.

Installation of penoplex and penofol

Penoplex is an ideal, modern option for insulating loggias. It does not absorb moisture, is lightweight and easy to style.

It is the most common material in construction. It is easy to work with, easy to cut and install.

Penoplex will serve reliably for many years. It is laid without additional waterproofing. It does not clutter or burden the structure. Has an affordable price.

Penofol consists of layers of foam and cotton wool. It retains heat perfectly, preventing moisture and cold from entering the apartment. Will prevent the appearance of corrosion and mold on the walls.

The rolls in which the material is produced are easily glued to the surface, and the small thickness will save space.

Heat conduction and moisture absorption

The thermal conductivity coefficient is one of the main parameters for insulation. The thermal conductivity parameter of the first is on average in the range from 0.028 to 0.031 W/mK, it all depends on the operating conditions. The second has an identical thermal conductivity parameter of 0.031 W/mK. It turns out that the effectiveness of materials in this area is the same.

The same applies to water absorption of materials. The first has an indicator of up to 0.2% of the volume per day, just like the second. This is truly surprising and shows that each of the materials copes well with moisture and resists it. Therefore, if anyone asks whether Penoplex or mineral wool is better, then we can confidently say that the first option. When wet, mineral wool loses its properties.

Note! The same applies to the frost resistance of the material. Its properties are not lost during frequent freezing and defrosting.