How to drain water from the expansion tank of a double-circuit gas boiler?

Hi all! The author of the site Blogvp.ru, Vitaly, is in touch! I think you will agree that it is not a very fun experience to be left without heating and hot water on winter days. And this prospect came up several times in my house. I want to tell you how I struggled with this and what knowledge I acquired in this matter.

In my house, for about six years, a gas double-circuit wall-mounted boiler ARISTON CLAS 24 FF has been working to create comfort. Undoubtedly, the thing is extremely convenient; anyone who used, for example, geysers from the early nineties will understand.

But, as they say, nothing lasts forever, and therefore sooner or later, you have to deal with the refusal of technology to perform the intended work.

And although I practiced on my Ariston, so to speak, some faults will be common to any boiler. So, let's get down to business.

The pressure in the boiler slowly drops, you have to periodically add water to the boiler

First, let's look at cases where the pressure drops all the time. This is a fairly common problem - it manifests itself in the fact that the pressure in the heating system slowly decreases and when it drops below normal, some boiler models turn off.

There are two reasons why this can happen.

Leak in the heating system

An elementary coolant leak from pipes or leaky radiators, but most often what is used as a coolant? That's right water!

Believe me! It’s not easy to detect such a leak during the heating season, but the fact is that you won’t see a puddle on the floor, unless of course it’s a serious leak. Most often, these will be just droplets and you will not see these droplets, since they quickly evaporate from heated pipes.

As a result, slowly but surely the pressure will drop. You add water over and over again and this continues to kill the radiators. Because the oxygen released from the incoming fresh water does not benefit them.

How and where to look for a leak

You need to pay attention to radiator plugs, joints or soldering of pipes and fittings. You can often see traces of water leaks in the form of rusty or salt stains. But this depends on the composition of the water in your area.

It is not uncommon for modern radiators, aluminum or bimetallic, to also become unusable, sometimes in extremely inconspicuous places, between the ribs or from below, they begin to dig in due to metal corrosion. Not rust, of course, but various chemical processes also damage them. Radiators must be carefully inspected while searching for leaks.

It will be easier to detect various types of leaks if you turn off the heating for a while, let the radiators cool and add pressure to about 2.5 Bar. After this, you will be able to see drops or puddles on the floor. Carefully inspect the floors under the radiators, pipe connections, and soldering areas.

The boiler can also be the cause of the leak. For example, the primary heat exchanger itself or its connections are leaking. But as long as these are small droplets, you will not notice anything; they evaporate during operation of the boiler. As soon as it starts to leak more actively, you will notice “drops” from the boiler.

Regardless of whether the burner is on or not, the leaking feed taps or emergency relief valve will be clearly visible.

So, the first reason for the pressure drop in the system is a coolant leak.

Expansion tank

Another reason is the expansion tank. This is a sealed container divided in half by a membrane, one half of the tank is filled with inert gas or just air, the other is filled with coolant (read water).

Expansion tank

It is designed to compensate for the pressure created during the expansion of the heated coolant.

When heated, the water in the system expands and fills its half of the tank, compressing the gas; when cooled, the coolant is again pushed into the heating system.

This is how temperature expansion in the heating system is compensated.

But sometimes the tank itself may malfunction.

Expansion tank malfunctions

For example, the tank body has lost its tightness and air is escaping from it. This does not happen often, and usually results in a fairly rapid decrease in pressure in the tank, from almost instantaneously to several days.

Also pay attention to the spool so that it does not poison the air either.

The spool (as in a car or bicycle) is located in the upper part of the tank; air is pumped through it, thereby creating the necessary pressure in the expander tank.

Another bad problem with the expander is the rupture of the membrane inside the tank, although it is not so delicate, and you need to “try” hard to break it. But if this happens, then identifying such a problem is not difficult.

In this case, the coolant enters from the heating system into that part of the tank that should be filled with air, and if pressing the spool needle throws water out of the tank, then water has penetrated where it should not be - the tank needs to be replaced.

But most often the pressure in the tank decreases very slowly, due to minor natural leaks. This decline occurs over many months or several years.

At the same time, the pressure in the expander chamber gradually decreases; naturally, it will also decrease in the readings of the boiler pressure gauge.

The behavior of the boiler very much depends on the level of this same pressure in the expander and can manifest itself in different ways. Under the next heading you will find a description of these problems.

The pressure rises and falls - the boiler does not operate stably

From all of the above, it is clear that air comes out from the part of the expansion tank in which it should be or does not have sufficient pressure. And here the pandemonium begins with changes in the operation of the boiler. All this can manifest itself in different ways and depends on the pressure in the air chamber of the Republic of Belarus.

For convenience, we will divide these manifestations into different stages.

FIRST STAGE - The pressure in the boiler drops slowly, about once a week you have to top up the boiler, while there are no obvious leaks in the expander, and there are no obvious leaks in the heating system itself.

SECOND STAGE - On the boiler pressure gauge, the pressure is constantly “walking” In heating mode it rises above 3 Bar, until the relief valve is activated; in hot water mode, on the contrary, it drops to values less than 1 bar and then the boiler may begin to shut down, the protection is activated. (If it has a pressure sensor)

THIRD STAGE - If there is absolutely no air left in the tank, then the pressure on the pressure gauge drops to zero in a very short time, sometimes in a minute.

There is only one way out for all options! It is necessary to again create the necessary pressure in the expansion tank of your boiler, in its air part.

How to pump up a boiler expansion tank

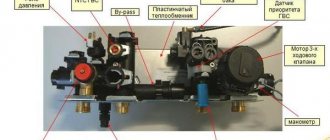

Diagram of boiler taps Ariston Class 24

A Connection for draining water into the central heating circuit (CH)

B Connection for draining water into the hot water supply circuit (DHW)

C Connection for gas supply

D Connection for cold water supply

E Connection for supplying water from the central heating circuit

S Safety valve outlet

T Drain tap

F Filling tap

How to properly pump air into the expansion tank

We follow the specified order

- Turn off the boiler from the network.

- We turn off all the taps to the boiler, supply, return, and cold water input.

- Open the drain fitting in the boiler. (T) and drain the water completely. (Here is an article about how to drain water from the boiler) The pressure in the boiler should be zero.

- We connect the pump with a pressure gauge to the RB through the spool - the drain fitting is open.

- The pump needs to pump air into the tank until water stops flowing from the drain fitting. At this stage, the main goal is to empty the tank of water.

- We release the pumped air.

- We inflate again, monitoring the pressure with a pressure gauge. The pressure in the expander should be within 1.1-1.3 bar. (See the passport for the boiler - often indicated)

- Close the drain plug.

- We open all the taps to the boiler - everything that was closed.

- We feed the boiler through the make-up tap (F) to a pressure of approximately 1.2-1.5 bar

- Let's start the boiler.

For these purposes, you can use any pump and pressure gauge. There is a car nipple there. I used an auto compressor. True, for this I had to drag the battery home. With an electric compressor, be careful to turn it off in time and not overpump.

Before starting, it will not be superfluous to expel any air that has entered the system.

In Ariston class 24, to do this, press and hold for about 5 seconds. ESK button. The boiler will go into purge mode for 6 minutes, exit this mode on its own, or you can force it by pressing ESK again.

Why is it important to pay attention to pressure in the boiler?

If people do not live permanently in the house where the double-circuit boiler is located, only on short visits, then it is important to pay special attention to the required pressure. Imagine this picture. No one is home for a long time, the lights go out, and accordingly the boiler also turns off, the water cools down - the pressure in the system, due to weak pressure in the expansion tank, drops below the boiler switch-on threshold.

Then the following happens... The electricity turns on, but the boiler does not start, the pressure has dropped too much. You arrive a week later and find your house frozen, the water frozen in the pipes and radiators is mercilessly tearing them apart. An ice age is coming for you. Therefore, it is better to be safe than sorry.

Source: https://otoplenie-help.ru/kak-slit-vodu-iz-rasshiritel-nogo-baka-dvuhkonturnogo-gazovogo-kotla.html

Removing sediment

Although there is nothing complicated in this process, we do not recommend doing it yourself. Many experts carry out sediment removal at the place where the water heater is installed, and some recommend removing it and performing all work on the floor:

- The first step is to remove the device casing.

- All electrical wires are disconnected.

- The union nut that holds the heating element is removed. To do this you will need a gas wrench. Please note that as soon as you begin to loosen the tubular electric heating element, water will immediately flow out from under its edge. And along with it comes mud sediment.

It is recommended to place a container under the drain so as not to stain the floors. Completely remove the heating element and clean it through the hole formed in the water heater. You can open the water shut-off valve slightly so that water gets inside the boiler. This will make washing faster and more efficient.

If you are completely satisfied with the process, we begin assembling Ariston according to the opposite scheme of assembly. A very important point is to install the heating element correctly and hermetically.

How to drain water from a gas boiler: what are the requirements

Hello, dear readers of the site ballony.com.ua, for full service you need to know how to drain water from a gas boiler. The process as a whole is not particularly difficult and may have some differences depending on the model of the device.

Gas boilers equipped with a heating function transfer energy thanks to the coolant. And high-quality maintenance of this device involves dismantling some of its components, as well as draining the liquid. And while it is in its internal cavity, its repair is impossible.

articles:

- Preparation

- House and apartment

- Boilers

- Prerequisites for draining water

- Operations by brand

Preparation

In order for the process of draining water to take place correctly in an apartment or house, you need to comply with some criteria. Also, the work takes place strictly in a certain sequence.

In any case, preparatory operations are carried out first. To do this, you must have a special hose in your working arsenal. Its inner diameter must match the outer size of the drain valve. This part is located below the boiler line, on the “return” section of the heating network, at the very bottom.

Two more conditions must be met:

- The presence of a container of suitable volume for draining liquid or toilet.

- All cut-off valves of the mounted apparatus are carefully checked. The shut-off valves should be examined only after the boiler is turned off.

Then the hose is connected to the drain fitting, directed into the container, and the device turns on.

House and apartment

The procedure for draining liquid from the boiler has similar principles for both home and apartment. The main thing is not to violate the correct algorithms.

What are the requirements in a private home? As a rule, the heating system here is autonomous. And drainage does not need to be coordinated with neighbors.

All actions are performed in the following sequence:

- Disconnecting the device from the network.

- Cooling water in pipes and radiators.

- Cold water valve blocked.

- Opening the air valve.

- Opening the taps on the boiler and radiator itself.

- Connecting the hose to the drain valve.

- The other end of the hose is placed in the toilet or large container.

- The drain valve opens.

- Pumping out water. It continues until the pressure gauge displays a zero parameter.

- Opening the Mayevsky tap. Starting air flow into the heating network. This will release any remaining liquid.

- The hose is moved to the supply valve, which opens. Water from the top pipe drains into it.

If you doubt the success of independent work, you can involve specialists. The average price for work in a private house is in the range of 3,000 – 4,000 rubles. If you need to drain all the water to replace the coolant and pump it in, the cost reaches 6,000 rubles.

Actions in the apartment are often associated with emptying batteries of liquid. But if the system has boiler shut-off valves connecting it with supply and return pipes, it is not necessary to drain water from all its circuits.

Draining water from the heating network in an apartment is greatly simplified if:

- There are new radiators and they have the required fittings.

- There are shut-off valves on the way from the radiator to the riser.

Then the algorithm of actions is as follows:

- The water supply to the battery is blocked - the adjustment taps are turned.

- The exhaust valve on the bottom side of the battery opens. Instead, there may be a plug - it can be unscrewed using an adjustable wrench.

- Place a bucket for liquid or attach a hose.

The process becomes more complicated if there is an old battery, missing or painted shut-off valves. Then the entire system is freed from water. To do this, an application is submitted to the management organization. The technician turns off the valve in the basement and empties the specific riser of water.

If the upper and lower radiator pipes are separated by a vertical jumper (bypass), and the system has one pipe, the procedure is different:

- The bypass valve opens.

- The shut-off valves are closed - the entry of coolant is blocked.

- The exhaust valve or plug opens. The water is drained.

If heat in an apartment building is generated due to isolated autonomous heating technology, independent drainage of water is strictly prohibited.

Boilers

Residential premises are heated by a boiler with one or two circuits. In the second case, the owners also provide themselves with hot water.

Many heating devices also have internal cavities where the coolant reaches a given temperature. And after draining the liquid from the unit, its interior becomes free of water, and convenient conditions are created for working with all components and contacts.

The nuances of emptying boilers in the house were reflected above. But there are some more subtleties:

How to drain water from a double-circuit gas boiler correctly? This means emptying the heat exchanger. To do this, turn off the boiler and open the hot water tap until it cools down. After this, the flow of cold water is blocked. If necessary, all its contents are removed from the heat exchanger. Then the hot water supply fitting is unscrewed.

How to drain water from a modern wall-mounted gas boiler? Such devices have a drain fitting and an air vent. These elements work automatically. And to free such a boiler from liquid, simply open the drain valve after the preparatory stages.

Prerequisites for draining water

This procedure is carried out in the following cases:

- Replacement of heating equipment.

- Correction of boiler malfunctions and repair of individual mechanisms.

- Elimination of leaks at valve contacts, fittings and other pipes.

- Turning off the heating for a long time in winter.

- Replacing the coolant.

Anyone with even modest technical skills can carry out the work.

It is also important to know when not to perform such a bowel movement. There are three situations here:

- The boiler is not threatened by cold. You need to leave a little water in it to protect the interior from rust.

- There was stagnant water in the device because it had been turned off for some time. Stale water is renewed. To do this, fill the tank full several times.

- The boiler is still under warranty.

Operations by brand

Boilers of different brands have their own characteristics, which are reflected in their documents. Below are examples of some models from well-known companies and measures for the necessary emptying of water.

First: Bosch boiler, Gaz 6000 W modification.

The system pumping valve is unscrewed. Cold water enters the heating circuit. The pressure gauge should show no more than 2 atm. The plug on the radiator is unscrewed, a fitting and a rubber hose leading to the sewer are placed there. Then the air is bled off from the radiators. In this model, this will be done by an automatic device (air vent).

Second: Vaillant device, atmoTEC pro model.

When installing it, you should install a special drain valve. It can be located near the boiler or in the lower piping area. In the first case, only the boiler is drained, in the second, the heating system is drained as well.

If there is no such valve, you will have to install a valve on the return line.

Third: Beretta unit, CIAO 24 CSI device. To drain liquid from it, you should focus on this diagram:

Process:

- The device turns off.

- The liquid drain valve (letter C) becomes loose.

- Water is drained from the very bottom of the heating system.

If there is a threat of freezing of equipment, the DHW circuit is emptied in the following algorithm:

- The main tap on the water supply is closed.

- All valves with water (both hot and cold) open.

- Analogous to step 3 from the previous process.

Fourth: Navien, model – Deluxe. Look at the diagram of the device.

And then proceed like this:

- Turn off the power to the boiler and turn off the gas valve.

- Block two heating network valves and one cold water valve.

- Open the tap that you usually use at home and drain the hot water.

- Close the DHW valve.

- Open the cap on the bottom side of the case and drain the water into a container.

Fifth: Ferroli boiler modification Divatech D F24.

All actions come down to opening the drain tap and turning the place from which the water comes. There is no special pen here. The drain in the model is white, the filler is black.

Sixth: Buderus, Logamax U072 device.

There is a check valve on the cold water inlet section. The liquid is eliminated through a drain line leading from the valve to the sewer. At the same time, a water seal is installed, and the stream breaks into a receiving funnel. This way the pump of the device is protected from the penetration of debris.

Seventh: Neva Lux model 8618.

Actions:

- The device is disconnected from electricity.

- The gas valve is blocked.

- The air vent opens slightly.

- The drain valve opens. Water is directed into the container.

The second method is to use a relief valve located at the bottom of the boiler.

Eighth: Baxi, modification of Main Four 24. This diagram helps in the procedure:

Shut off the system, open the drain valve (letter B). The water will flow out through a special nozzle on it.

Ninth: Ariston, model Class 24.

For work you need: an adjustable wrench, a hose, a screwdriver, a 4 mm hexagon. Stages of the procedure:

- The device is de-energized.

- The cold water tap closes.

- The hot water valve is unscrewed. This equalizes the pressure inside the boiler.

- Air is introduced into the boiler: the valve on the pipe supplying hot water opens.

- A hose of the required diameter is connected to the device, the drain valve is opened, and the entire tank is emptied.

An example of the procedure is shown in this video:

Source: https://ballony.com.ua/kak-slit-vodu-s-gazovogo-kotla.html

Methods for draining liquid

The easiest option is to use a drain valve specially designed for such purposes, located on the back wall of the boiler. But in some cases it can be difficult to reach, for example, if the device is placed in a closet or narrow pantry. In such a situation, use a hose. Afterwards, carefully turn the fitting tap, directing water into the container.

If you do not have access to the drain fitting, you can use a safety valve. It is usually used to relieve excess pressure. Unlike the drain valve, it is located on the front of the boiler, so it is much easier to reach. You can even do without a hose by simply placing a container of the desired size under it and turning the handle to release the water. Or you can still connect the hose to the nozzle located on the valve and easily rotate in the desired direction.

However, this method also has its drawbacks. As a rule, the safety valve is rarely used, so its rubber gasket, which is under pressure, usually becomes deformed. After refilling with water, it may leak and the rubber gasket will have to be replaced.

After draining the liquid from the heating boiler using one of the proposed methods, you can proceed directly to diagnosing and replacing equipment parts. Once the work is completed, before refilling the circuit with water, it is important to ensure that the drain valve is carefully closed.

How to pump up the boiler expansion tank?

The expansion tank in a heating boiler performs an important function - it compensates for pressure surges when the temperature values of the coolant change, be it ordinary water or antifreeze. The tank itself consists of two parts, between which there is a membrane.

One part contains the coolant, the other contains air, through which the required pressure is created. And for normal operation you need to periodically pump up the tank. Next, you will learn how to pump up the boiler expansion tank and how to detect when you need to do so.

A common situation: you turn on the water and run a bath. At this time, the boiler switches from heating mode to hot water supply mode. While the water is being collected, the coolant gradually cools down, and the expansion tank does not function at this time.

And when you turn on the tap, the boiler should start heating again, but this does not happen. The reason is a sharp drop in pressure, as a result of which the automation simply blocked everything.

This means it's time to pump up the air and increase the pressure in the tank.

How to pump air into the boiler expansion tank?

Please note that you will not be forcing air into the system itself, but only into the expansion tank. Accordingly, it is not advisable to look at the boiler pressure gauge. Your main reference point is the pressure gauge on the pump itself.

You can use a regular pump that is used to inflate car tires. You can, of course, use a compressor. Although not necessary. Your task is to pump up the pressure to just 1 atmosphere.

An ordinary pump will handle this quite well.

The upload process consists of four steps:

- First, unplug the system and remove the plug from the outlet. This will primarily keep you safe.

- Next, drain the water from the boiler. If the equipment is new and installed correctly, then there is no need to drain all the water. It is enough to turn off the cold water supply, open the hot water supply tap, and also open the hot water supply valve on the closest mixer. This way the water contained in the boiler will be completely drained. Most modern boilers have special fittings for draining water. You can use them, but it is inconvenient - you will have to drain the water into buckets, basins, large bowls, then pour it out and repeat the procedure. The first method is faster and easier. Draining water from a gas boiler is necessary to make sure that you will pump air into the expansion tank. If there is any water left in it, it will be ineffective.

- Pump up the tank. Each tank has a regular nipple to which the pump can be easily connected. In most cases, you do not have to remove the boiler lid to access the nipple. When you pump up the tank, constantly monitor the pressure gauge on the pump. Your task is to pump up to approximately 1.2 atmospheres. This is the optimal value. If it turns out more, you need to loosen it. Otherwise, the system may simply not work until the pressure returns to normal. If you see water still coming out of the faucet while pumping, this is normal.

- Connect the boiler. When the pressure in the expansion tank reaches normal, you can reconnect the boiler. First, close the water supply tap and open the cold water tap. At the same time, dirty water and air bubbles will begin to flow. When this stops, the tap can be closed. Next, the feed tap must be opened again to fill the boiler to its operating condition. Here you need to look at the pressure gauge located on the body.

After this, you can open the supply and return taps. If you see that the pressure is weakening, you can add water. Next you need to remove air from the pump. Unscrew the plug at its end and bleed the air in the same way as is done on Mayevsky taps.

An important question for owners of wall-mounted and floor-mounted heating boilers: “how often do you need to pump up the expansion tank?” We recommend doing this every two years in new boilers, and every year in boilers that have already been in service for several years. Optimally - before the start of the heating season.

How to identify a malfunction and why does the pressure in the expansion tank drop?

The most common signs of malfunction:

- “Jumping” pressure during boiler operation. For example, when the system operates for heating, it increases, and when switching to hot water supply it decreases. In the latter case, the indicator may even drop to zero.

- You have to constantly recharge the heating system, although leaks cannot be detected, and the heat exchanger works normally. Often the problem arises when there is a heated floor in the house.

In some cases, the reasons for the drop in pressure can be discovered independently. Very often they arise precisely because of coolant leaks. Moreover, more often when using antifreeze as a coolant.

Antifreeze, due to its consistency, can penetrate even the smallest cracks, and the pressure drops. To correct the situation, you need to find the leak and fix it, then pump up the tank to the required pressure.

During operation, the pressure in the boiler itself may drop and return to normal after startup. If it does not align, this is a sign of a malfunction. Further, the system will fail even more. In such a situation, it is best to immediately contact a specialist for diagnostics, service and repair.

If you need boiler repair or maintenance, call Profteplo

We work in Kaluga and the region, diagnosing, servicing and repairing systems of any complexity. We carry out both simple tasks of pumping air into an expansion tank, and complex complex repairs of modern systems. We provide a guarantee for all types of work.

If you need advice or want to use the service, just call the number or leave a request directly on the website. The master will arrive on the day of your call and will perform all the necessary types of work.

WANT MORE NEWS?

Source: https://teploknam.ru/stati/kak-nakachat-rasshiritelnyj-bak-kotla.html

Preservation of a well for the winter

The idea of conserving wells is the same. But wells are dug for closer water and are more susceptible to contamination. They are simply bigger. At the mouth of a well, especially if there is no cover or house, anything can fall. Then the well is susceptible to contamination due to the fact that there are toilets, landfills, and garbage dumps nearby.

Try this experiment. In rainy times, buy potassium permanganate, make a bucket of the solution thicker and pour it during rain into the ground 10–15 meters from your well. And watch. If the well pumps water every day, in a week and a half to two weeks pink water will appear in it.

This experiment clearly shows what your well is fed with, what water, what source. What if the bucket is not potassium permanganate, but gasoline? What if the car is washed nearby? Therefore, a well requires a triple rate of bleach - three matchboxes per bucket, and the bucket is filled with 100 liters of water.

The well needs to be filled with bleach twice a year - at the end of the season, after the rains, and at the beginning, after the flood. They took out the pump, added bleach, and closed the lid tightly. Ready.

The pressure in a double-circuit boiler either drops or rises, what to do?

Hi all! The author of the site Blogvp.ru, Vitaly, is in touch! I think you will agree that it is not a very fun experience to be left without heating and hot water on winter days. And this prospect came up several times in my house. I want to tell you how I struggled with this and what knowledge I acquired in this matter.

In my house, for about six years, a gas double-circuit wall-mounted boiler ARISTON CLAS 24 FF has been working to create comfort. Undoubtedly, the thing is extremely convenient; anyone who used, for example, geysers from the early nineties will understand.

But, as they say, nothing lasts forever, and therefore sooner or later, you have to deal with the refusal of technology to perform the intended work.

And although I practiced on my Ariston, so to speak, some faults will be common to any boiler. So, let's get down to business.

In what cases should you drain the water?

Water acts as a coolant in the system - it transfers energy from the boiler heat exchanger to the radiators. It is necessary to drain it from the heating system when:

- a breakdown of one or more system elements was detected;

- it is necessary to eliminate leaks at the connections of taps, fittings or other pipes of the device;

- it is necessary to replace the coolant - for example, if rust or scale has accumulated in the old one.

It is also necessary to drain water from the heating system in winter if you plan to leave the room without heating for a long time. Otherwise, the water may freeze, expand, and pipes may burst.

How to regulate the pressure in the expansion tank of a gas boiler

The expansion tank is an integral element of the heating system. It plays an important role in compensating for the thermal expansion of the coolant and normalizing the pressure in the system. Therefore, it is necessary to control the pressure in the expansion tank of the gas boiler.

Operating principle of the expansion tank

To organize efficient heating, the system must be filled with coolant. When the liquid is heated to a high temperature, its volume increases and its excess is discharged into the expansion tank.

The requirements for it differ in different heating systems. For example, with the natural movement of the coolant, it is enough to install a metal container of the required size as an expansion tank.

The forced circulation system includes a factory-made sealed tank. It is a container divided into two parts by an elastic membrane. It is made of special rubber, which must be quite durable. One part of the tank is filled with air or water, the other is designed to allow excess liquid to enter.

Note!

If an expansion tank is not included in the heating system, then when heated, the water will increase and may simply rupture the pipeline or boiler.

Expansion tanks differ in volume. When choosing this element, you should be guided by the fact that the tank must accept at least 10% of the mass of the coolant. It is advisable to buy a container with a small margin.

What tasks does the expansion tank perform?

The expansion tank in a closed heating system performs two important functions:

- Compensates for thermal expansion of the coolant. For every 100°C increase in temperature, the volume of water increases by 4.5%. The fluid pressure in the system increases and puts pressure on the walls of pipes and radiators. If the gas boiler is not equipped with an expansion tank or one container is not enough, then this element is installed on the “return” of the device.

- Softens water hammer in the heating system, which may occur due to accumulated air masses or blocked fittings.

From this it can be seen that without an expansion tank, the heating system simply cannot work correctly.

Expansion tank pressure

At production, a certain air pressure is established in the expansion tank of the gas boiler. However, it may not be suitable for optimal operation of the unit. Then the pressure parameter can be easily reconfigured. Manufacturers provide a spool in the housing of the air-filled part of the tank. By twisting it, you can adjust the pressure.

Please note that the pressure gauge only shows excess pressure. That is, if we use the concept of absolute pressure, then 1 atmosphere (bar) should be added to the reading.

The initial value in the expansion tank is set at 0.2 bar below the pressure in the heating pipes, equal to the static pressure. It is calculated as the difference between the top heating point and the middle of the expansion tank.

If the heating height is 7 m, then the static pressure will be 0.7 atm from the ratio 10 m = 1 atm.

If the pressure in the tank exceeds the optimal value

, for example, it is 2.8 bar, then when the pump starts, the pressure will change, but only slightly. High pressure in the tank worsens the compensating properties of the tank - oxygen will push the incoming liquid back.

If the tank pressure is too low

, then the excess coolant, once in the tank, will push through the membrane and fill the entire space. When the water temperature and, accordingly, the pressure increases, the safety valve will operate.

Preparatory stage

To free the heating equipment from liquid, first of all you need to select a hose that matches the diameter of the drain fitting. To work, you will also need a container that can hold the entire volume of drained water.

Afterwards, turn off or cool the boiler and turn off the taps at its inlet. If the device remains in operating mode, further actions may result in equipment failure. Only after making sure that the power is turned off and the taps are securely closed can you proceed directly to draining the water from the system.