The most economical electric boiler is a myth

Electricity is much easier to convert into heat than other energy sources - natural gas, solid fuel, diesel fuel. Here are 3 simple examples of heat by-products when using electricity:

- the windings of any operating electric motor always heat up;

- a light bulb (even an LED one) produces heat along with the light;

- Even the wires through which current flows become heated.

Please note that the equipment listed is designed to perform its functions, and not to heat the house. The motor rotates something, the lamp shines, the wiring supplies them with energy. The formation of excess heat is a side effect that occurs due to the resistance of these elements.

Spiral and induction heater converting electricity into heat with 99% efficiency

To convert all electrical energy into thermal energy, it is enough to create a high resistance section in the circuit, which itself will not collapse from heating. This element is called an electric heater. The second (more complex) way to obtain heat is to create Foucault induction eddy currents that heat a metal object in the area of action of the inductor coil.

Important point. Regardless of the conversion method, 98–99% of electricity will turn into heat. That is, any electric heating device operates with an efficiency of 98–99%, no less. This means that the most economical electric boiler does not exist; all units are equally efficient. No matter what home appliance sellers claim.

Connection to the house electrical network

The power of the vast majority of water heaters does not exceed 3.5 kW. If the consumption of your household appliance is within the specified limits, feel free to connect the boiler through a standard socket equipped with a grounding contact (required!). The work is simple: run a three-core cable from the distribution box using a corrugated cable or plastic box, and place a socket next to the heater.

Exposed wiring and outlet knobs are not popular with all homeowners. To make the electrical connection to the water heater more efficient, follow our instructions:

- Lay the cable in a hidden way - in the grooves of the walls or under plasterboard sheathing, connecting it to the nearest electrical outlet box or directly to the electrical panel.

- Install a two-pole 20 A circuit breaker in a convenient place, placing it in a decorative plastic box.

- Using the clamps, connect the cable to the machine.

- After unscrewing the fastening screws, remove the cover from the bottom of the boiler. There is a connector hidden under it where you need to connect the wires. Do not forget about the grounding contact - it must be connected to the appropriate bus.

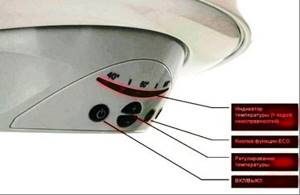

Plug in the boiler filled with water and check its functionality. Since on budget versions of the devices the heating temperature is regulated directly on the heating element, do not rush to put on the lid. Wait until the water reaches a comfortable temperature (look at the indicator) and turn the adjusting lever at the end of the heating element so that the heating element turns off.

Features of the electric boiler

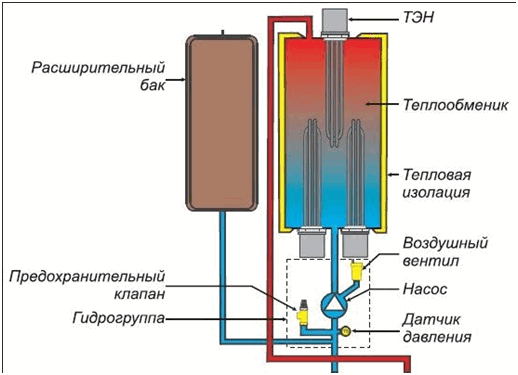

The main design elements of an electric heating boiler are a tank and a heating element. The devices are equipped with monitoring and automatic control systems.

Various models may also include expansion tanks and circulation pumps.

When purchasing a boiler, you should pay attention to the type of electric heating element. Over time, lime particles settle on the heating elements, which affects the power of the device

Electric boilers have several advantages:

- Fire safety . Thanks to automatic control systems and the absence of open flames, the devices are safe. They do not emit toxic substances or combustion products and are not capable of exploding.

- Ease of installation. Electrical equipment requires no flue or ventilation, making installation easy.

- High efficiency . Regardless of the type of heating device, all electric boilers are highly efficient.

- Compactness . Electrical appliances, especially wall-mounted ones, take up little space.

- Nice design . Most modern models are stylistically versatile and look good in the interior.

Electric boilers are almost ideal - easy to use and safe. Their only serious drawback is the high cost of electricity. One more nuance: for residents of regions where there are frequent interruptions in the power grid, it is better to choose boilers that operate from other energy sources, or take care of purchasing additional heating devices.

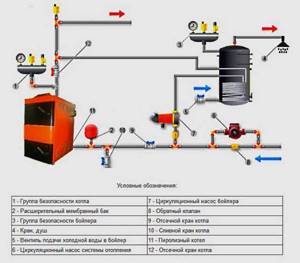

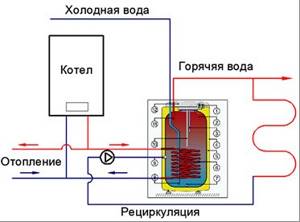

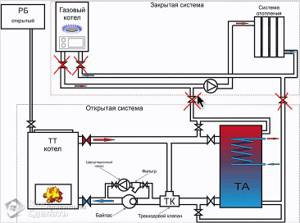

Connecting an indirect heating boiler

The unit is a tank with a built-in coil that heats the main volume of water. Accordingly, the heat exchanger is connected to the boiler, and the tank is connected to the hot water supply system. The same safety valve is used to drain excess water that expands when heated.

The easiest way is to connect an indirect heating boiler to a single-circuit boiler equipped with special pipes. Inside the heat generator there is a three-way switching valve that distributes the coolant flow for heating or loading the hot water boiler - as the electronic control unit orders. In this case, the heater coil is simply connected to the corresponding pipes.

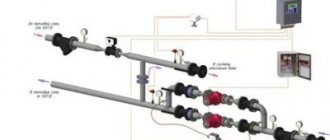

A typical diagram for connecting a water heater to a heat source includes the following elements:

- a separate circulation pump driving the coolant through the boiler coil;

- immersion thermostat that turns off the pump when the water is heated to the set temperature;

- 2 check valves that prevent the formation of parasitic flows through the heating and hot water circuits;

- hot water tank safety group;

- shut-off valves.

The operation of the pumping unit is controlled by a thermostat built into the boiler (it has a special socket). When water withdrawal begins, the container cools down and the thermoelement starts the pump; when it is heated sufficiently, it stops.

Advantages and disadvantages of heating with an electric boiler

The main advantage of the scheme is simplicity. Almost any craftsman can assemble such a structure, since for this purpose neither special qualifications nor complex tools are required. Another advantage is the low price. Most often, electric water heaters for heating are sold at lower prices than electric boilers. Thanks to this, when creating a heat supply system for small objects, you can save significantly. In this case, you can get a very reliable, highly functional system that can be controlled via modern communication lines, for example, Wi-Fi. That is why it integrates well into the Smart Home program.

The disadvantages of using water heaters include:

- Low power.

- The heating element is constantly in working condition, which leads to rapid wear. To guarantee, you need to choose devices with 2 or more heating elements.

Determining the efficiency of a new water heater

How to start using your new boiler economically and correctly? Experts focus on determining its energy efficiency when purchasing.

General rules

Before purchasing equipment, the user needs:

- compare the energy efficiency of expensive and budget models in the store to establish the return on investment of the equipment;

- clarify that the energy efficiency class includes efficiency, losses per hour during heating and maintaining temperature, circulation. Information is indicated in the manufacturer's booklet;

- take into account the displacement of the container, the operating speed of the heating element, the type of installation to clarify the total costs.

Interesting to know! On European boiler models, energy efficiency has been indicated since 2013, on American ones - since 2009.

Calculation of annual operating costs

For calculations, you will need information about the energy efficiency class, type and cost of the coolant. Further calculations are performed using the formula:

- for gas models, the number of days per year is multiplied by energy efficiency and the cost of a cubic meter of gas;

- for electric boilers, the number of days per year is multiplied by energy efficiency and the cost of kW/hour.

Interesting to know! The DOE test for water heaters takes into account cold (15 degrees) and hot (60 degrees) temperatures and determines the unit's performance for a family of 3 as 240 liters per day.

Heating element power as a saving factor

The greater the power of the heating element, the faster the water will heat up. Keep in mind that in houses with a single-phase wiring diagram, from 7 to 10 kW of power are allocated. A high-performance water heater will lead to increased load on the network, huge energy costs and tripping of circuit breakers.

How does an electric water heater for heating work?

As a rule, such devices are used exclusively for hot water supply. But modern technologies make it possible to use it as an additional thermal circuit for heating water in a heating system. Before using the water heater to prepare the coolant for heating devices, it is necessary to modernize its recharge circuit:

Create a forced coolant circulation circuit.

It is necessary to connect the heating circuit with the installation of protection and control devices: an expansion tank, a circulation pump and shut-off and control valves, a control and protection unit with primary sensors for temperature and pressure of the medium.

The originality of the idea, and its practical implementation, lies in the synchronous operation of the same source: for hot water supply and heating. For this reason, it is recommended to first select an electric pump of the required electrical power. It must be able to cover all hydraulic losses in the system and evenly distribute heat throughout the heating devices. Experts recommend installing water purification filters at the inlet in front of the boiler in simultaneous hot water and heating systems.

Method of heating water with a water heater

Modern electric water heaters for heating operate on the same principle as boilers. A large sealed container is filled with water, which is heated using electric heating elements. In this case, heat loss occurs through the housing.

In boilers, the coolant increases the temperature when passing through a heat exchanger with a built-in heating element. Since the volume of this chamber is relatively small, heating occurs quickly. At the same time, heat losses are minimal. It should also be noted that in most cases the design already includes a circulation pump, an expansion tank and a convenient control system. Apart from the latter, electric water heaters for heating of the VEO type do not have these elements.

Storage tank and heating boiler

The storage tank is ultimately completely identical to a classic water heater. The difference lies in the internal coil, which is connected to the heating system.

We recommend: Calculation of heating radiators, number of sections and battery power

A professionally organized heat supply system through a heat exchanger implies that this component will act as a thermal accumulator. The liquid medium in the tank receives heat through a coil heat exchanger connected to the in-house heating pipe system.

Indirect heating boiler

The optimal alternative for heating small rooms is to include an indirect heating boiler in the heat supply scheme. They can be universal, capable of operating on different types of energy carriers: gas, flue gases from the combustion of solid fuels and electricity.

Typically, such devices are installed in heat supply circuits to increase overall efficiency in the form of an additional heating source. The main one is the traditional heating boiler. For efficient operation of an indirect heating water heater, it must be installed before entering return network water into the boiler unit. In this way it is possible to create an optimal heating system.

Distinctive features of the boiler for the heating system

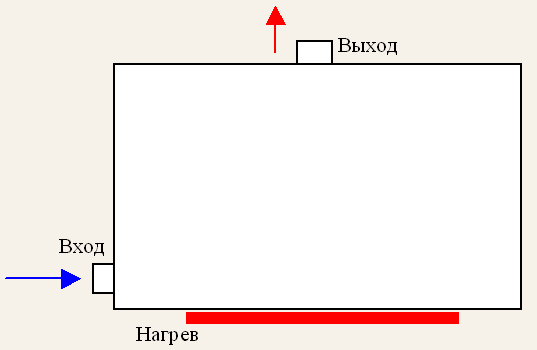

As you know, a boiler is a closed vessel that has two holes.

The first hole serves as an inlet for cold water, the second as an outlet for hot water. The boiler is powered from the electrical network. All boilers are divided into two groups - flow-through and storage. In a storage boiler, a certain amount of water is heated (the amount of water depends on the displacement of the boiler); in a flow-through boiler, any amount of water can be heated, but this requires more electricity. It must be said that using a boiler for heating is quite possible; moreover, today manufacturers produce boilers specifically designed for heating water in the system. These boilers have two significant differences from those intended exclusively for heating water for domestic purposes - for example, for bathing or washing dishes.

Firstly, in such boilers the inlet for cold water is located at the bottom, and the outlet for hot water is at the top. This arrangement of the holes is explained by the fact that when the water heats up, it rises, and therefore the hottest water is located at the top of the boiler, and it is the use of such water that will make the heating system as efficient as possible.

Secondly, the boiler, designed for heating water in the heating system, has a large hole diameter. If you look at factory-made boilers, you will see that both the cold water inlet and the hot water outlet are never smaller than 2 inches in diameter (about 4.8 cm).

If the boiler has both of these distinctive features, then it can safely be used as the basis for a heating system - that is exactly what it is intended for. And the movement of water through the heating system itself is carried out due to the fact that cold and hot water have different densities, and cold water, entering the boiler, displaces the hot water first to the top, and then through the hole into the pipes of the system.

Heating inertia

The rate of increase in water temperature in pipes for electric boilers is quite high. The average heating time from 25 degrees to 60 degrees is 15-20 minutes, depending on the volume of the system. In this regard, heating using a water heater is significantly inferior to traditional heating. In order for the volume of water in a boiler with a capacity of 150 liters to reach the desired temperature, you need to wait about an hour. The main criteria influencing this indicator are the power of heating elements, the volume of the tank and the entire system as a whole.

However, when the electric boiler stops working, the water in the pipes quickly cools down. At the same time, in a water heater system, a large volume of hot liquid is in the tank and will require several circulation cycles for it to cool. Those. In the event of an unexpected power outage, the coolant in the boiler system will remain hot for some time.

Summarizing these factors, we can determine the main conditions for using an electric water heater for heating:

- The area of the heated room should be relatively small. This is due to the ratio of 1 kW of thermal energy per 10 sq.m.;

- Good quality running water to preserve all heating elements;

- To fill the tank, it is necessary to create the same pressure as in the water supply - 4 atm. This applies only to those cases when a regular boiler is installed that is not intended for heating from a water heater. In specialized models, the minimum pressure value is much lower - from 1.5 atm.

You can use an electric water heater to heat a house with a small area of up to 80 square meters. First of all, this applies to country houses.

The second way to use an instantaneous water heater for heating is to install a heated floor system. But even in this case, you must carefully read the diagram for connecting the device to the pipeline.

Review of water heaters for electric heating

Manufacturers of heating devices already produce conventional boilers, adapted for installation in heat supply networks. Their thermal power has been increased to 12 kW, in addition, they have increased input diameters for connection to the in-house heating system.

Heating from a boiler is not difficult to implement. Since such equipment is widely represented on the market, both domestic and foreign manufacturers. Their choice will depend on the required type of energy carrier and the type of heating: capacitive or indirect heating. The latter are more used in autonomous heat supply schemes, so the principle applies here - the more, the better. They are well used during the heating season, and

In summer, for hot water supply, it is wiser to use combined water heaters.

The most popular models of water heaters that are used in heating systems:

- Heating boiler Thermex Champion Titaniumheat 150 V, made in Russia, heating element, volume 150 l, price - 12,190 rubles.

- Water heater for heating Gorenje TGU150NGB6, made in Serbia, heating element, volume 150 l, price - 14,320 rubles.

- Ariston ABS PRO R 150 V, made in Russia, heating element, volume 150 l, price – 14970 rub.

- Bosch WSTB 200, made in Germany, indirect heating, volume 197 l, price - 40,833 rubles.

- Baxi Premier plus 150 (30 kW), made in Italy, indirect heating, volume 150 l, stainless steel tank price - 68,600 rubles.

- Buderus Logalux SU160/5 made in Germany, indirect heating “coil in coil”, stainless steel DUPLEX, volume 160 l, price - 68869 rub.

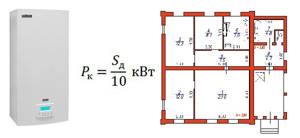

Selection of heat generator by power

To select the power of an electric boiler, first of all, calculate the heat losses of your home. You probably know the approximate method of calculation: to heat 100 square meters of building area, a heating unit with a capacity of 10 kW is taken, for 200 m² - 20 kW, and so on. If you want to get a more reasonable result, use our calculation methods.

A very approximate calculation method - we divide the area of all rooms by 10, we get heat loss in kilowatts

Now let’s define the tasks that an electric boiler must solve (select the desired list item):

- round-the-clock heating of an apartment, cottage, country house;

- the same, with water heating for domestic needs;

- work at night at a cheap rate;

- standby heating – maintaining the air temperature +5…10 °C.

Note. Night heating of the house with an electric boiler can be combined with heating of the heat accumulator. At 7.00 the unit turns off, then the water system receives the heat accumulated in the buffer tank. 2 conditions: the allocated limit for electricity consumption must be 15...20 kW + powerful electric boiler.

Full heating with electricity is not cheap and is used as needed. A more profitable option is night heating from 23.00 pm to 7.00 am, when the cost of energy is half as much. The standby mode is used on objects under construction or dachas, where the owners spend 2-3 days weekly.

We select the power of the electric heating boiler depending on the tasks:

- For round-the-clock operation, the unit is selected with a margin of 10...20%. That is, the heat loss figure is multiplied by a factor of 1.1–1.2. For example, a house with an area of 60 square meters loses 4 kW, the productivity of the electric boiler will be 4 x 1.2 = 4.8 kW.

- For hot water supply (DHW), the power of the unit should be increased by 50%. That is, multiply the figure 4 kW from the example by a factor of 1.5 (we get 6 kW).

To obtain hot water, it is customary to connect a single-circuit electric boiler to an indirect heating boiler through a three-way valve. The latter switches the coolant between the tank and the heating system - An electric heating device for night heating can be taken without a power reserve if it is replaced in the morning by a gas or solid fuel boiler. Reducing the temperature to 18–19 °C during sleep will not cause much discomfort, but will save money.

- The power of the electric boiler that maintains positive temperatures in the building is taken with a reduction factor of 0.6–0.7 (minus 30–40%) of the amount of heat loss.

Advice. To organize DHW, you do not need to look for a double-circuit boiler. Usually there are 2 options: installing a separate electric water heater or a powerful heat generator plus an indirect heating boiler.

The performance of the heater for nightly “charging” of the heat accumulator depends on the volume of the tank and is calculated individually. The selection of an electric boiler under standard conditions is described in the video:

Photos in the text to illustrate what was said

Storage tank and electric boiler

Installation of an electric boiler in a heating circuit

Boiler Ariston ABS PRO R 150 V

Water heater model Thermex Champion Titaniumheat 150 V

Types of electric boilers for heating systems

Indirect heating boiler

Types of devices

When choosing a boiler for heating, many are interested in its two parameters. The first is the volume of the tank, the second is the electrical energy consumed.

Instantaneous water heater

A flow-through water heating boiler does not have a container designed for a large volume. It is designed so that the water consumed is heated instantly. There are two types used in everyday life:

- Electric - production takes place in a compact case, wall mounting. Water is heated as it passes through an electric heater.

- Gas - water flows inside the heat exchanger. A gas burner burns under it, which heats the liquid.

We recommend: Gas heaters for tents - how to choose, review of the best models, prices and reviews, where to buy

An instantaneous electric water heater intended for heating has the following device:

- Body - the material is metal or plastic, the outside is covered with a special coating for protection and decoration.

- Heat transfer tube - located inside the housing, most often has a spiral shape.

- The heating part is located in the heat exchange tube or in a separate metal glass.

- Flow meter - there is a reaction to the closing/opening of the faucet mixer.

- Electromagnetic starter - controls a magnetic starter and is a powerful electric heater.

- Thermostat - turns the unit on/off, regulates the supply of hot water based on the pressure power.

- Thermal fuse - necessary for emergency shutdown of the device.

| pros | Minuses |

| Light weight, compact parameters | Due to their complex manufacturing, their price is quite high. |

| It is possible to operate immediately as soon as it is turned on, since the water heats up quickly | High electricity consumption |

| Connection and installation can be done independently in an hour and a half | To connect, it becomes necessary to lay another network cable separately |

| All parts inside are made of metal that is not subject to corrosion |

Electric storage boiler

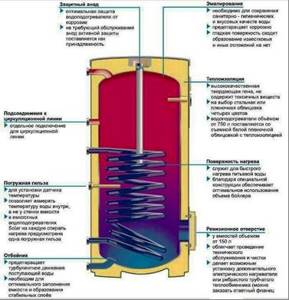

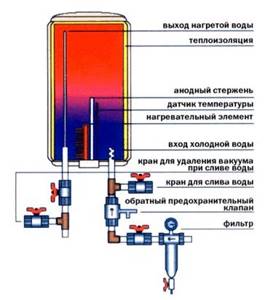

Electric storage boilers are most often used in everyday life. Externally they have differences, but the device itself is the same:

- The case is made of steel with a thickness of 0.8 millimeters. A polyester enamel coating is applied on top, serving not only as decoration, but also as protection.

- The tank is located inside the body, made of steel 1.2 millimeters thick, the outside is coated with corrosion protection. It has three types. The first is a heat-strengthened coating, used in inexpensive models. It is considered not particularly durable: the enamel can crack and crumble due to a sharp change in temperature. The second is glass ceramics, applied at high temperatures, very durable. The third is titanium coating, the most durable and strong, used on expensive models.

- Thermal insulation - minimum thickness is 20 millimeters, maximum - 40. It looks like a layer between the tank and the outer casing.

- Magnesium anode - designed to protect against rust. Installation takes place near the heating element and protects the tank and heating part from electromechanical corrosion.

- Heating element - located at the bottom of the tank.

- Thermometer - digital or mechanical. Located outside the housing, designed to control water.

- Thermostat - automatically turns on/off the heating element. Adjustment is manual or electronic.

- Indicator LED - connected to the thermostat, lets you know when the heating element is on or off.

- Water pipes are made of metal, end with a thread on the outside, and are connected to the water supply.

- Mounting Bracket - Used to mount the unit to the wall.

| pros | Minuses |

| A large assortment | Installation should only be carried out on a solid wall due to the heavy weight of the devices |

| Installation is simple, easy, completed in a couple of hours | Maximum service life is nine years, as corrosion resistance is reduced |

| Part replacement takes a maximum of one and a half hours | Due to the insulation, the parameters are quite dimensional |

| Low electricity consumption | Takes a long time to heat up (from half an hour to nine hours) |

| A thick layer of scale appears |

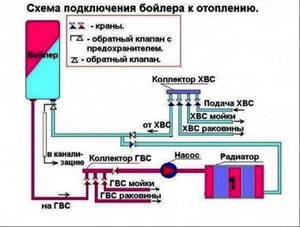

How to connect the device to the water supply network

The design of an electric or gas boiler provides for the selection of water for DHW needs from the upper zone of the tank, where it reaches its maximum temperature. Makeup from the cold water supply is carried out to the lower zone. This leads to the following problems with emptying the tank:

- draining is impossible from the “hot” side - the end of the tube is located too high, so literally 2 liters will flow out of the container;

- if you connect the pipe directly from the “cold” side, then to empty it you will have to unscrew the American pipe;

- draining water through the standard valve is inconvenient and time-consuming - the cross-section of the fitting is too small.

The presented boiler connection diagram solves the listed problems and allows you to empty the tank at any time, spending literally 15 minutes. Each element of the harness clearly performs its function:

- Ball valves on the main lines serve to isolate the water heater from the water supply and domestic hot water networks.

- A tee with a third ball valve on the “cold” side is designed to completely empty the tank.

- The safety (also known as non-return) valve discharges excess water, whose volume increases when heated. The second function is to prevent the tank from emptying back into the supply line.

- American ones allow you to disconnect the device without disassembling the system.

To correctly assemble the electrical boiler piping, it is enough to connect the pipes according to the diagram and attach them to the wall with clamps. Lastly, the American ones are screwed on, and a flexible hose is put on the “spout” of the safety valve and directed into the sewer. The installation process of a storage water heater is clearly demonstrated in the video:

After assembly, check the tightness of the joints by opening the cold water supply. Filling the tank is done with the “hot” mixer tap open to release air. After making sure the connections are secure, proceed to electrical installation.

Classification

Electric boilers are divided into three main types:

- heating elements;

- electrode;

- induction

In addition, there are a number of other differences between them. For example, there are floor or wall models. They can be connected to 380V or 220V - depending on the size of the room (used for a private house or small apartment). Also the main indicator is the number of circuits in which hot water is located - one or two.

heating elements new

An electric boiler operates based on the process of converting current into thermal energy through the use of tubular heaters installed directly in the tank. The heating element raises the temperature of the liquid inside the pipe. When it enters the heating system, it warms up the room.

To ensure that the device always works as required, a control unit is provided. The heating is controlled by a room temperature controller. It is he who perceives a decrease in this indicator and reports the need to increase heating. The required pressure appears as a result of connecting the pump. Thanks to the use of modern technologies, after the room temperature rises to the set point, the mode is turned off. After some time, the pump that moves the coolant also stops working.

The main advantage of this type of boiler is the absence of contact between the liquid and the heat exchanger. This allows the use of protective devices for automatic shutdown.

The equipment makes it possible to simply implement smooth or step control.

Like any other devices, these have their drawbacks. Heating element boilers have a limited service life compared to other boilers. Premature burnout due to improper use cannot be ruled out. Before purchasing, be sure to pay attention to the possibility of repair or replacement.

Also, scale quickly forms on the tubular heater itself. This significantly reduces the service life of the device. It is imperative to artificially reduce the hardness of the liquid.

Such water heating boilers are single- and double-circuit units. The latter provide hot water supply and heating.

In most cases, installations are hung on the wall, although there are also those that are located on a flat, hard surface.

This type is considered the most popular among electric boilers.

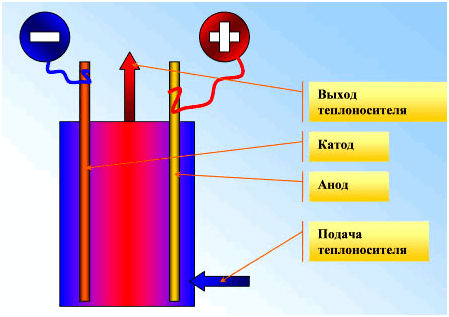

Electrode

Heating of the coolant is carried out by direct passage of current through it. In this case, there are no “intermediaries” in the form of heating elements. Electrolysis does not occur since the anode and cathode are constantly changing places.

It is important to note that if operated without liquid, the electric heating or hot water boiler will not fail. In addition, scale does not destroy the electrodes - sometimes a slight decrease in power is observed.

The coolant temperature increases quickly. This increases the pressure with which water moves through the network - there is no need to install a pump. Perfect for the bathroom as it doesn't take up much space.

We recommend: Insulating walls from the inside (inside) of a house or apartment with your own hands

Such a water unit has an efficiency of about 96%. At the same time, it is durable and reliable in use.

Such a device cannot be connected through a protection element. Only special antifreeze is used as a coolant.

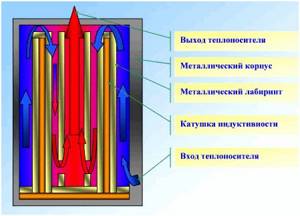

Induction

Such installations have a design similar to a transformer consisting of two circuits. The primary is the magnetic system, and the secondary is the heat exchange device. By means of an alternating field, electricity allows the coolant to be heated.

The main advantages include safety, as well as interaction with various heating fluids. Like the previous option, it is well suited for the bathroom.

But there are also disadvantages. The main ones are the initial price, as well as the cost of subsequent operation.

Boilers

It is worth mentioning electrical storage installations. In fact, they are heating elements equipment installed in parallel. In this case, they can be intended either separately for hot water supply or heating, or for both directions. For the latter, indirect heating systems are used. Such storage electrical installations make it possible to raise the temperature of water for household needs with coolant intended for heating.

This boiler is ideal for use in country houses. It is mainly installed together with boilers that use any energy source. At the same time, it is barely warm on the outside, since usually such installations have high-quality protection that allows energy to be stored inside for a long time.

Which boiler to choose: single-circuit or combined?

This is one of the most asked questions boiler sales people hear. What is the correct answer? Let's figure it out together.

First, let's look at the design of a combination boiler, such as the Vitopend 100-W type A1JB.

Several elements are responsible for preparing hot water in the boiler:

- Firstly, a three-way switching valve, which, using boiler automation, determines where the heat will be spent: for heating or DHW.

- Secondly, a plate heat exchanger made of stainless steel, in which cold water is heated without mixing with the coolant.

- Thirdly, flow and temperature sensors, with the help of which the boiler automation can control the burner power and supply hot water with a given temperature to the consumer with an accuracy of 1°C.

Where can I buy?

The operation of the boiler for preparing DHW is carried out as follows - by opening the DHW tap, the user creates a flow of drinking water through a plate heat exchanger, in front of which a flow sensor is installed, and it, in turn, transmits a signal to the controller that water consumption has begun and it needs to be heated.

The three-way valve is switched, and the burner is started and adjusted using a temperature sensor. The water is heated in flow mode.

It should be noted that due to flow-through heating of water without storage tanks, it is impossible to organize a hot water circulation line on combination boilers, therefore, on sanitary fixtures that are sufficiently distant from the boiler, during prolonged downtime, the hot water in the hot water pipe simply cools down. This increases the waiting time for water to reach the required temperature.

It is also necessary to understand that reaching a given mode also takes some time. For Vitopend 100-W boilers, from the moment of requesting hot water to the supply of water at a temperature of 40°C, this time is about 40 seconds.

Viessmann also produces boilers equipped with a CombiComfort system (for example, Vitodens 100-W type B1KC), which keeps the DHW heat exchanger always in “hot” operating condition. In these boilers, the time to reach the set temperature is significantly reduced.

Depending on the power, Vitopend 100-W boilers can produce the following water flow rates at a comfortable temperature of about 40°C:

- 11.3 l/min (12, 24 kW at ΔT=30°C)

- 14 l/min (29.9 kW at ΔT=30°C)

- 16 l/min (34 kW at ΔT=30°C)

Is it a lot or a little?

Below are the water consumption for some sanitary fixtures according to current standards:

- 7.2 l/min - washbasin with mixer tap

- 9 l/min – sink, sink

- 7.2 - 12 l/min - shower

So what can we conclude? If you are the owner of a small house or apartment with one bathroom, or if your family has 1-2 people, then a combination boiler is perfect for your hot water supply needs. But if you have a large house with several bathrooms and your family has more than 2 people, then the second option is for you.

The second option is a single-circuit boiler that uses a Vitocell indirect heating boiler to prepare hot water.

Most boilers manufactured by Viessmann, already in the basic configuration, allow you to carry out and control the preparation of hot water using a boiler.

A single-circuit boiler, such as the Vitodens 100-W type B1HC or the Vitopend 100-W type A1HB, includes a three-way valve, which, when it is necessary to prepare hot water, switches and directs the coolant into the boiler coil, thereby heating the cold water to the set temperature. Once the desired temperature has been reached, the three-way valve switches back to heating.

In other boilers, such as Vitogas 100-F, Vitocrossal 100, etc., switching to DHW preparation is arranged in a different way. They do not have a three-way valve, but the automation of these boilers controls the boiler loading pump, which turns on when it is necessary to heat the water.

What are the advantages of a system with a boiler?

Firstly, you can always choose a boiler of the required volume based on your needs. You will not be limited by the number of bathrooms or plumbing fixtures, or the number of residents. You always have a supply of drinking hot water. The only condition is that the boiler power must be consistent with the boiler power.

Secondly, you can always organize a hot water circulation line and make the use of hot water as comfortable as in an ordinary city apartment with a central hot water supply. To configure the system according to the needs of the buyer, there are stand-alone boilers located directly under the wall-mounted heat generator, and free-standing ones (vertical and horizontal).

Data on the performance of combined boilers was at the beginning of the article. Now, as an example, let's look at the numbers for a boiler with a power of 24 kW with the minimum possible boiler with a volume of 100 liters:

540 l/h - long-term capacity (ΔT=35°C)

143 l/10 min - short-term performance at a given temperature (for example 60°C).

In systems with a boiler, it is advisable to set a higher DHW temperature, and obtain a comfortable temperature for the user using a mixer. This way you can comfortably use several plumbing fixtures at the same time. Depending on your needs, you can choose a larger and more powerful boiler.

Also, you cannot do without a system with an indirect heating boiler when using a Vitosol solar collector. For these purposes, a special series of bivalent water heaters Vitocell 100-W type CVBB is produced, which have two heating coils: for the boiler and for the solar collector.

Is there an alternative? Surprisingly, there is a third solution.

The Viessmann company produces boilers with a DHW buffer tank. In the line of household equipment, these boilers are represented by the models Vitodens 111-W type B1LD and Vitodens 222-F type B2TB.

These boilers are equipped with a stainless steel buffer tank with layer-by-layer loading of 46 and 100 liters, respectively. When using hot water, this reserve is consumed. At the same time, the boiler switches to an operating mode similar to that of a combi boiler, resulting in a continuous process of preparing DHW. For example, consider the volumes of hot water produced by this 26 kW boiler in 10 minutes:

- Vitodens 111-W - 180 l/10min (ΔT=35°C)

- Vitodens 222-F — 230 l/10 min (ΔT=30°C)

The undeniable advantage of the system is its compactness, because all the elements are housed in a single wall-mounted housing.

Boilers with a buffer tank do not have the disadvantages of combined boilers and at the same time remain compact.

General positive aspects

Generally speaking, all electric boilers, regardless of type, have a number of advantages:

- ease of execution;

- there is no need to separately create a place for installing equipment;

- no need to think about purchasing, delivering and storing energy;

- there is no need to remove the chimney;

- safety, because there is no possibility of leakage of toxic substances;

- environmental friendliness - no harmful emissions.

If you install electric double-circuit water heating units, connecting all its functions, the consumer will not experience any problems with heating the room or supplying water at the required temperature for household needs.

Mistakes made during installation

When carrying out installation work, it is important to avoid any mistakes. This can lead to unpleasant consequences. For example, it is important not only to ensure that the water heater is located close to the boiler, but also to set the correct direction of the pipes to the pipeline for easier installation. Another common mistake is incorrect connection of the pressure pipe and coolant inlet. Cold water is always supplied to the lower pipe, and hot water to the upper part of the water heater. There is also a risk of the pump being connected incorrectly. It is important to comply with the parameters set out by the manufacturer.

So, we have discussed with you possible methods of connecting a water heater to the heating system. We hope this information will be useful to you and will help you complete this task yourself. We also provide diagrams and video material to help.

The nuances of choosing the right model

Electricity is an expensive energy resource. If the boiler is selected incorrectly, you will have to pay huge electricity bills.

Therefore, it makes sense to pay attention to some nuances:

- functions . It is necessary to decide what functions the boiler should perform - only heat the house or additionally supply it with hot water.

- Technical parameters of the boiler. Be sure to take into account not only the heated area, but also the degree of its thermal insulation.

- Price . In many ways, the cost of heating devices depends on power, but that’s not all. Additional features can lead to a significant increase in the price of the model. Therefore, you need to clearly understand whether your budget allows you to overpay for convenience.

Even before you start looking for a boiler, you should find out how powerful it should be.

You can calculate the power based on average indicators: 1 kW of electricity is enough to heat a room of 10 square meters. with a ceiling height of up to 3 m. It turns out that a device with a power of 6 kW or more is suitable for heating a small house with an area of 60 m2.

When purchasing an electric boiler, energy consumption is of fundamental importance. It’s better to overpay for a more expensive model, but save on its operation

It is advisable to take into account the degree of thermal insulation and buy a boiler with a small power reserve (20%). If the house is poorly insulated, it is better to choose a gas or solid fuel model, since heating with electricity will be too expensive.

Additional water system improvements

To create an additional level of comfort and improve the performance of the water supply system, additional improvements can be made, such as:

- additionally take care of disconnecting the water heater from the system by installing ball valves in case of need for its maintenance, breakdown or simply shutdown to reduce energy costs;

- installation of additional heated towel rails that will be warm all year round;

- carrying out additional thermal insulation of pipes from the water heater to the water supply systems to reduce heat loss;

- installing the water heater as close to the water supply points as possible, otherwise you will have to drain cold water from the taps in order to wait for hot water. In this case, it is necessary to install a recirculation pump for more efficient and economical use of cold water drained from the tap into the hot water supply system to the water heater - to reduce its consumption and economical use, so as not to drain it into the sewer. Calculations indicate water savings per year for a family of 4 people at the level of 15,000 - 000 liters.

The results of these improvements:

- savings (on water, on gas - since the boiler will rarely turn on, on electricity);

- always warm water on taps;

- the service life of the main boiler increases, since the boiler will turn on less often and operate less often, so all components will last much longer.

What will help you save on heating?

There are several devices that help reduce energy consumption and reduce the cost of heating a home:

- Thermostats . Heating boilers equipped with thermostats do not overheat the rooms, but at the same time maintain the set temperature.

- Programmers . “Smart” boilers regulate the room temperature according to a specific schedule. Although the boiler itself is constantly running, the heating element consumes electricity only 34% of the time. Read more about installing a heating system in a smart home here.

- Multi-stage power regulators . Thanks to automatic regulators, energy resources can be used extremely rationally.

- Microprocessors . The devices smoothly regulate the power of boilers, and some devices can even be controlled remotely - from smartphones or other gadgets. Such models are expensive, but worth the money spent.

The energy consumption of an electric boiler is significantly affected by the presence or absence of a circulation pump.

If it is not included in the model, it is advisable to purchase it separately and connect it to the heating system.

If there is a possibility that the house will be left for some time during the cold season, it is better to choose a model with a coolant freeze protection system

When purchasing a boiler for a country house or cottage, you should pay attention to antifreeze protection systems for the coolant.

Correct use and maintenance

In order for the boiler to serve for many years and not cause problems during operation, you need to use it correctly and take care of the device itself. The integrity of the mechanism should also be checked regularly. It is necessary to do everything that is done to check the performance of any heating boiler. The water needs to be filtered before it is redirected to the water heating tank. This will protect the pipes from further scale and corrosion.

By following simple rules, you can maintain normal operation of the device for a very long time. The following procedures must be followed:

- checking the functionality and integrity of the structure every 30 days;

- control the tightness of connections. Sometimes after each autumn-winter season, when the water heater works non-stop, some parts of the device begin to wear out and become unusable. Therefore, it is recommended to change the gaskets between the connections in the pipes at the end of the heating season; this will ensure more reliable heating throughout the entire room;

- Constantly monitor the maintenance of the same temperature level while heating the water with the boiler. Actual indicators should not differ from the calculated ones by more than 20%, otherwise this will indicate a malfunction of the device;

- regularly clean the water heater and its components from scale and other external reactions that cause wear and tear on the system;

- connect the stabilizer to the boiler so that heating is supplied without interruption.

In addition, the water heater must be cleaned every time. To do this, it is worth disassembling the device and cleaning each element separately. Particular attention should be paid to the coil, as it accumulates the most dirt and scale. If used correctly, the device will last a very long time and provide constant heat supply throughout the house.

Connecting an indirect heating boiler to a single-circuit boiler - diagram

According to the diagram, you need to find the terminals for the boiler sensor in the boiler and connect the ends of the wires to them.

Conventional indirect heating boilers work mainly with automated boilers.

Connecting the boiler to the boiler using a three-way valve This connection diagram is perfect for gas boilers equipped with a circulation pump and automation. Preference is given to wall-mounted models that can be hung at a height of 1 m above the floor.

The best position is when the bottom of the hot water tank is higher than the heating boiler and radiators. How to properly connect an indirect heating boiler to a heating system? They are less often connected to free-standing boilers of similar volume.

Indirect heating boiler design

Indirect heating These water heaters do not produce thermal energy themselves. If you need to create a connection diagram for a solid fuel boiler that runs on wood, we recommend choosing the option shown in the picture below. Some manufacturers deliberately produce equipment with standard dimensions of connectors and fittings.

In this scheme there is no three-way valve; the circuit is connected through ordinary tees. With this part, the unit lasts much longer. Operating at very high temperatures can cause premature damage to the inside of the tank. Types of double-circuit gas boilers with a built-in boiler, are they needed? Boilers are used in conjunction with single- and double-circuit gas boilers. The circulation pump is common here; it circulates the coolant through the heating circuit and through the water heater.

How to connect an indirect heating boiler (water heater)

Scheme for connecting an indirect heating water heater to a gravity system When implementing this scheme, the circuit that goes to the water heater is made into a pipe with a diameter 1 step larger than the heating one. They have a coil and a built-in heating element.

This piping method is useful for those who use the boiler in constant mode 2: Option with two circulation pumps If the boiler is used rarely, for example, seasonally or on weekends, or there is a need for water whose temperature is lower than in the heating system, use a scheme with two circulation pumps . The heating system of an apartment or house is working, and the water in the boiler is heating up as if in passing as a side effect. A boiler connected to heating equipment and electric heating elements. This method is only possible if you have separate boiler equipment that can operate from natural heating sources in the form of liquefied gas, coal or firewood all year round. The hot water supply circuit also has higher priority over the heating circuit, but this is achieved only by adjusting the switching algorithm. Performing piping requires preliminary competent thermal calculations. Ufa. Connection diagram for an indirect heating boiler.

How to make a harness without errors?

In order for both units - both the gas boiler and the BKN - to operate without failure and throughout their entire service life, it is important to properly perform the piping, that is, install the safety group and other elements. When installing coarse filters, be sure to check its location - there is an arrow on the body indicating the direction of water movement

When installing coarse filters, be sure to check its location - there is an arrow on the body indicating the direction of water movement.

Such a filter cannot be installed vertically, since as a result, coarse particles accumulate in the pipe and not in the filter itself. Cleaning can only be done by pressure washing - this way you can dirty the entire boiler room.

The expansion tank must not be installed separately, but between the boiler and the check valve, otherwise it will be useless and will not perform its functions.

How to choose a boiler

Regardless of how the boiler and boiler work, before installing it you should carefully select a storage tank. All tanks are made of stainless steel or coated ferrous metal. The first option is cheaper, the second is quite expensive, but has a longer service life. It would be good if the inside of the tank was equipped with a porcelain glass or enamel coating. In this case, it will reliably protect the metal from corrosion, and with moderate heating (not higher than 60 °C) it will last longer than the heating unit itself.

The key criterion when selecting a water heater is the correct ratio of its capacity and the power of the heating equipment. Not everyone knows that 140 and 200 liter tanks can produce approximately the same volume of hot water per hour. Therefore, if the boiler has high power, the consumer does not necessarily need to install a large tank.

If the house uses low-power heating equipment, a water heater of significant volume will not produce the displacement stated in its passport. For example, when using a 23 kW heating device and a 200-liter water heater, the consumer will receive the same amount of hot water per hour as a 140-liter tank provides. In other words, if you buy a 200-liter tank, you will overpay.

Pros and cons of boiler-based heating

Heating obtained from a water heating tank has its advantages and disadvantages.

| pros | Minuses |

| No special tools, skills or engineering education required for installation | The installation process, in terms of labor resources, is quite expensive |

| Boilers are much cheaper than heating boilers | The unit is constantly in operating mode |

| Thanks to the thermal insulation layer, water heaters spend less derived heat than space heaters | The water supply must be constant, which can cause corrosion to occur prematurely. |

| It is possible to use wall or ceiling mounting type, so they take up little space | There is no required power to heat a large area |

| The amount of resources consumed is scanty, electrical energy consumption is minimal | |

| Allows you to independently regulate the temperature |

Installation of boilers for heating a private house: differences between water heaters and boilers

Equipment tends to break down or become obsolete, which is why it ends up among other garbage. However, it can serve faithfully for a long time. Many DIY homeowners have successfully used electric boilers to heat their homes.

Boiler

This practical attitude towards old things did not go unnoticed by other owners - many are interested in the question: “Is it possible to use such devices not as an addition, but as the main supplier of heat in the house?” Let's try to sort this issue out.

Recommendations for use

Ensuring long-term and uninterrupted operation of the heater is possible with systematic maintenance, which includes

- Cleaning the storage tank. If this is an electrical device, then so is the heating element. It is necessary to remove scale, which quickly corrodes metal walls.

- Timely replacement of the magnesium anode. This point also applies to electric boilers.

- Check the integrity of the thermal insulation layer, as damage to it will cause serious heat loss.

- Checking pipe connections and fittings for leaks. A leak that is not detected in time can cause a decrease in the efficiency of the entire system.

Electric heating boiler

Author: Dmitry Belkin

Since it turned out that a lot of people really (in all seriousness) want to make heating from improvised means, I am writing this warning.

I don’t like the idea of using various heating devices for purposes other than their intended purpose, and I strongly do not advise anyone to do this in reality. This answer is only a theoretical discussion (like blah blah).

Good question. The answer to this is “In most cases it’s impossible!” But let me hang on to this question and theorize a little.

What is a heating boiler in general and an electric heating boiler in particular? This is a closed vessel, most often made of metal, which has an inlet for cold water and an outlet for hot water. Here is its schematic image:

Why did I depict the cold water inlet at the bottom and the hot water outlet at the top? Because water, when heated, rises and at the top point it is hottest.

If you plan to use gravity heating, then another condition is imposed. entrances and exits should be of fairly large diameter. On factory heating boilers, including electric ones, with a capacity of 20-50 kW, these diameters are at least 2″.

If your storage water heater has this configuration, it means that it is made specifically for heating water in the heating system. However, there are water heaters designed to heat water in water supply systems. They have a slightly different design. An approximate design of such a boiler is shown in the following diagram.

We see the following fundamental differences.

- The entrance and exit are at the bottom.

- The inlet and outlet have a small diameter. Usually only 1/2″.

These differences, quite obviously, will not allow us to use such a heater, even theoretically, in a gravity heating system, where the movement of water occurs due to the difference in the densities of hot and cold water. However, there are no problems if we do heating with a circulation pump and the heating circuit itself is not too large and branched. For the heating system of a large house, more than 150 sq.m of heated area, it is necessary to increase the diameter of the inlet and outlet pipes.

Thus, to build a small heating circuit with a circulation pump, you can use a storage water heater for water supply systems. You just need to increase its power. The power of such a heater can be calculated by referring to special reference books, but I do not think that it will be less than 1 kW for every 10 square meters of your heated room.

Here's a question. Is it possible to use a flow-through heater for such a heating system? I believe that an instantaneous water heater would be even better, since it already has the required power. Do not forget that we are considering the option of a not very large heating system with a circulation pump.

As a conclusion, please take into account that these reflections are of a theoretical nature. If the question is to save on a heating tank, then I would make it myself, namely, I would order it at the factory according to the first diagram given. The heating tank does not require any special steel and does not require anti-corrosion treatment. This circumstance makes such a homemade tank definitely cheaper than a factory storage tank, and, moreover, a flow-through counterpart for water supply systems.

Similar materials - selected by keywords

Copyright Information ©

If you liked this answer and want to thank me for it, then you can always safely send money to my mobile phone +7 916 418 5270

Comments (24)

Hello, can you tell me if it is possible to create heated floors using a water heater? And what is better, storage or flow?

Through cumulative - more likely no than yes. There won't be enough power. Yes, and it has a different function (cumulative). But through a flow one it’s more likely than not. But you also need to look at the power. Yes, and automation is needed. You don't want boiling water on the floor.

Please tell me. There is a 6 kW instantaneous water heater. The heated room is 50 sq.m. Is it possible to use it for heating without installing a tank? What should the connection diagram be: open or closed? Thank you.

Actually, you can try it. But there are nuances.

In fact, a flow-through heater is designed to not last that long. We washed our hands and turned it off. It is completely unclear how it will work in heating boiler mode. Well, let’s assume that washing your hands, bathing, and so on for the whole family is 1 hour a day. And you want to turn it on around the clock, and probably for a whole season.

What temperature will it maintain and will this temperature be controlled somehow? Control is a must!