MesterulManole

5117 0 0

MesterulManole November 15, 2017Specialization: many years of experience in finishing works of residential and office premises, dachas, country cottages, etc. Hobby: cycling in all its forms

Insulated or non-insulated roof, what to choose?

There is a roof to be built, and you don’t know what to prefer: a warm or cold attic? I will tell you which method of arranging the under-roof space is preferable and why. In addition, you will learn how and with what materials you can equip an attic space in a private house.

The main advantages of attic insulation

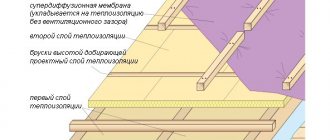

Layers of Insulation Before Laying the Floor

The benefits of properly insulating your loft are well known. First of all, it is about maintaining heat in the house. There are also other factors to consider, such as the health of you and your loved ones.

Proper attic insulation can bring many benefits to you, your family and your home.

1. Save money on electricity and gas bills

Better attic insulation saves you money. After all, a poorly insulated house can lose a quarter of its heat through the roof.

The simple solution is to install appropriate insulation

If this insulation is the recommended thickness of 270mm, you could save up to 25% on your electricity or gas bills.

Good insulation increases the value of your home

Improving the energy efficiency of your home makes it more valuable. According to statistics from completed home purchase and sale transactions, real estate with energy-saving technologies was sold at an average of 14% higher price.

Properly installed insulation can improve your health

Poorly insulated attics and those where flooring is installed incorrectly can cause damp and condensation. This can lead to mold which, along with dampness, means you are more likely to have respiratory problems, respiratory infections, allergies or asthma.

Problems often arise when insulation is compressed by improperly installed attic flooring. This will stop the air flow between the floor and the insulation.

It is important to lay a solid base on top of the insulation

This can lead to problems such as:

- The insulation loses its thermal efficiency.

- This causes cracks in the ceiling.

- Water vapor generated in the home rises until it hits the cool surface of the lower attic floor.

- This may cause condensation to form inside the insulation.

- The condensation then begins to seep down, creating dampness and affecting the ceilings.

If you want to use your attic space for storage, adequate air flow is essential. This should be considered an absolute necessity.

Helps the environment

A properly insulated private home can reduce CO2 emissions by up to 80kg per year. Reducing CO2 emissions means you are doing your part to reduce global carbon emissions. And therefore the consequences of climate change.

Reduced wear and tear on your boiler

- If your boiler has to produce more heat than it needs, consider it won't last as long as it could.

- Having proper attic insulation means that you will create a stable living environment inside your home.

- This will help extend the life of your boiler, which is another way to save money!

Features of the device and design of floors

Since attic floors perform two functions - load-bearing and insulating, they have a multi-layer structure. Each of the elements of the “pie” complements each other, which ensures the created structure has a long service life, strength and the ability to withstand heavy loads.

The construction of the floor in the attic requires the presence of the following layers:

- Finish floor . This name is given to the floor covering, which is laid on a rough base. If it is an attic, then when installing the finished floor, linoleum, laminate, parquet, etc. are laid. In non-residential premises there may be no finishing floor covering.

- Rough base . It is a boardwalk that is mounted on logs. The subfloor is lined with edged boards 4–5 centimeters thick or, to save money, with unedged boards.

- Lags . These are strong, level pieces of wood that are laid perpendicular to the floor joists to create a floor covering. When installing an attic floor on wooden beams, insulation is placed between the joists, which is protected from below with a layer of vapor barrier, and covered with waterproofing material on top. If you do not use insulating layers, then repairs will be required in a few years.

- Beams . The frame of the floors is built from thick and strong beams, which are either mounted on the projections of the walls or built into them. They must support the entire weight of the structure. A flat roof can also be made on wooden beams, which is quite practical.

- Ceiling trim . On the side of the rooms, the floors are decorated with finishing materials, for example, natural wood or plasterboard.

Before you start

Before you start insulating your attic, there are a few things to consider. These things will affect the work required to perform the job at a professional level.

Existing insulation

Does your attic look like this?

Most attics already have some kind of insulation. Although in most cases it is either poorly installed, or compressed, or has a thickness significantly lower than the recommended 270 mm. If any of this describes your isolation, you probably need to work to fix it.

This is interesting: How to insulate a cold attic yourself

Can't see the insulation because it's hidden under the sheathing? Here are some options:

- If you can tell that the height of this floor is greater than 270mm or more above the ceiling, you may already have the insulation installed correctly.

- You can lift one of the boards farthest from the hatch and inspect what is under it. Just be careful, there may be electrical cables or pipes under the boards.

- Once you have access to the insulation, you can check its thickness. You can also check to see if it has been crushed by any plantings.

- There must be a gap to allow air flow over the insulation. Without this clearance, you may experience condensation buildup and related problems.

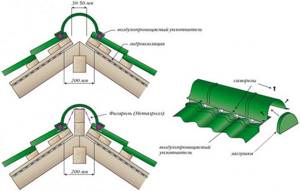

Roof installation with a cold attic

Most pitched roofs in our country have a cold attic in their design. This name is due to the air temperature in the attic, which should not differ much from the air temperature outside the house. With this arrangement of the attic space, a sufficiently large buffer air zone is formed, which allows you to effectively regulate the temperature in the attic if it is properly arranged.

Warm or cold attic

What you plan to store in your attic will determine whether you will find it warm or cold. You will need a warm attic if you plan to use it as a hobby room.

Or if you need to store climate sensitive materials. Otherwise, a cold attic will suffice, but let's look at the benefits and work involved with both.

Cold attics

The advantage of cold attics is that they are cheap and relatively easy to install. This is because the only insulation needed is between and on top of the floor joists, preventing heat from entering the attic.

In a cold attic, only the floor is insulated

This type of insulation is subject to temperature fluctuations and condensation. The term “cold” attic can be misleading as it can get very hot in the summer!

Warm attics

To create a warm attic, it is necessary to insulate the floor and the lower part of the roof. This will allow heat to penetrate inside and regulate its temperature. But this heat cannot escape through the roof.

In warm attics there is no problem when it gets too hot in the summer or very cold in the winter. Consequently, a much wider range of uses is possible.

The underside of the roof can also be boarded and decorated, which can greatly transform your attic. The downside is that creating a warm attic is more difficult without professional help. Therefore, it is more expensive.

However, there is one important advantage to creating a warm attic. This will easily increase the value of your property more than the cost of the work. It also gives you many more possibilities and options for using the extra space created.

This is of course not on the same level as a full loft conversion due to the weight limitations of conventional loft flooring.

Approximate instructions for installing a cold attic on a roof made of soft tiles

Due to the absence of a pie, it is easier to make a cold roof than a warm one:

1. Lay a continuous sheathing of plywood or OSB on the rafters. The slabs must be laid with joints spaced apart. The joints should be on the rafter legs. There is a technological gap of 3 mm between adjacent slabs/sheets. Fastening with self-tapping screws or nails.

2. Underlayment: On low-slope roofs, the entire roof area should be covered.

note

Installation of the carpet begins from the bottom: the lining is rolled out along the eaves overhang and fixed with roofing nails every 20 centimeters.

The top strip is laid with an overlap of 10 cm on the bottom strip. The overlap of the transverse joint is 15 cm. All joints of the strips are sealed. 3. Install cornice drip strips over the edge of the carpet. Fix with nails in a zigzag pattern every 10 cm.

4. Install the end strips in the same way.

5. In valleys, a valley carpet is laid over the lining. Fix the edges with nails every 20 cm.

6. The tiles are laid in rows from the eaves to the ridge. Installation of tiles on gable roofs begins from the end, on hip roofs - from the middle of the overhang.

7. The cornice row is laid on top of the plank with a distance of 3-5 cm from the edge. Place it on glue (or on a self-adhesive layer) and fix it with nails. The joints of the cornice strips must be covered with petals.

8. The next rows are placed so that the petals overlap the attachment points of the previous ones.

9. In the valleys and at the ends, the tiles are cut and placed on glue. Fixation with nails.

10. At the junctions with pipes, walls, etc., triangular cross-section bars are installed. The carpet and tiles are placed on bars and the edges are glued.

11. The immediate junction with the pipe is treated with a valley carpet, covered with a metal apron, and the joints are sealed.

12. An aerator is installed on the ridge. Ridge aerators are included in the shingle material kit. They differ in design from different manufacturers; the installation procedure for each is described in the instructions.

13. Ridge tiles are placed on top of the aerator. It is recommended to overlap adjacent tiles in the dominant direction of the wind.

Installing flexible tiles is an energy-intensive task that requires care. Our company STM-Stroy has more than fifteen years of experience in installing any kind of roofing; we have qualified craftsmen.

We will provide you with a cold roof made of soft tiles in a short time, with high quality and for a reasonable price.

+7(495) 241-00-59

Installation and repair of roofing and facade coverings from economy to VIP class

Calculate online

my experience is your saved money and nerves.

I advise everyone who contacts me, even if you later leave to join another brigade. Ask questions, don’t be shy, I answer everyone - it’s free

+7(495) 241-00-59 I am available for calls 7/24 - I will be happy to help you, please contact me!

How attic insulation works

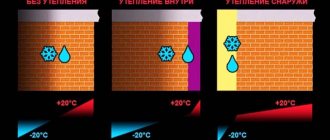

Simply put, attic insulation traps warm air inside your home and prevents it from rising through the roof. If installed correctly, it will still allow moisture to pass through and therefore prevent condensation.

In an uninsulated home, most of the heat you generate to keep you warm will escape through the walls, floors, doors and windows. And especially through the roof, through your attic. This causes you to generate more heat than you need, increasing both your energy bills and CO2 emissions.

Law of Diminishing Returns

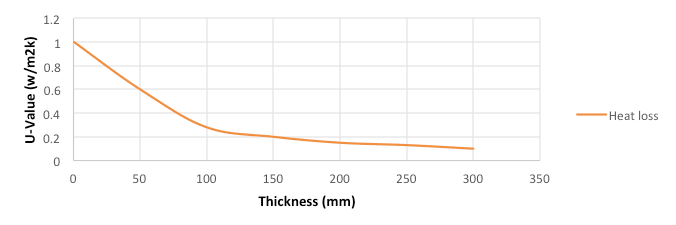

Everyone knows that insulation will help keep your home warm in the winter, but it can also keep your home cool in the summer. How much insulation you need will depend on a number of factors. But the level of thermal efficiency is simply a factor of the depth of insulation installed.

The current recommendation is 270 mm, which provides a U-value (watt/meter2/degree Celsius) of 0.15. 200mm insulation provides a U-value of 0.18 and 100mm provides 0.28.

This means that installing 100mm of insulation in a house without insulation will increase efficiency by 72%. The next 100 mm increases efficiency by another 10%. The difference between 200mm and 270mm is only about 15%.

Graph shows diminishing returns on additional attic insulation

How much attic insulation do I need?

To make the most of the benefits of attic insulation, you need to at least cover the entire floor with clearance around the edges for air flow.

To measure insulation, you can simply measure all the rooms directly underneath and add them together, taking into account the width of the walls. You don't have to be precise, and you should always underestimate so that you have extra insulation if necessary.

This is interesting: Insulating an attic in a private house - subtleties and nuances of the process

If you are building a warm loft you will need a lot more insulation to cover the underside of the roof along with the gable and walls.

Steam and thermal insulation of a cold attic

For a roof with a cold attic, it is most important to minimize heat loss through the attic floor

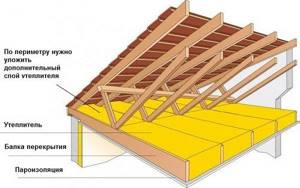

. For both wooden and reinforced concrete floors, a vapor barrier is mandatory. It is laid on the ceiling itself and protects the insulation from vapors that can condense in the heat insulator after passing through the ceiling of the living room. Slab and bulk materials can be used as insulation. The ceiling pie consists of a vapor barrier, floor beams and insulation.

The following types of heat insulators are often used in ceiling coverings:

:

- expanded polystyrene and foam boards;

- mineral wool slabs or mats;

- expanded clay granules;

- fuel or granulated slag;

- sawdust with lime or clay;

- pumice.

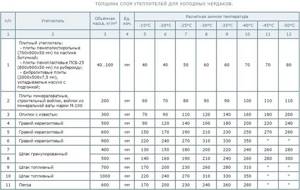

The thickness of the required insulation layer is selected depending on the estimated winter temperature using the table below.

Winter temperatures are calculated according to SNiP 2.01.01-82 (building climatology and geophysics) or selected by regions of the Russian Federation from the corresponding climate maps.

The insulation is laid between the joists or ceiling beams, and a boardwalk is made on top for the attic passages. Joists are usually 50 mm thick, and decking boards are 25-35 mm thick.

For ventilated attic spaces, soft or semi-solid heat-insulating materials are considered the most optimal.

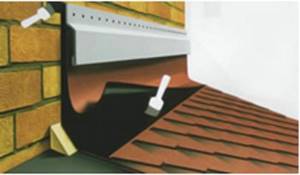

Attic waterproofing device

Waterproofing roofs with a cold attic, according to many experts, is a controversial issue. Some say that waterproofing must be present under the roofing material, while others categorically recommend that it be abandoned. Here, a lot depends on the type of roofing material and the angle of inclination of the roof slopes.

Metal roofs are most susceptible to corrosion, which occurs due to possible small leaks or condensation

.

Therefore, we once again draw your attention to the fact that ventilation plays one of the main roles in the fight against condensation.

.

For flat metal roofs, experts recommend installing superdiffusion membranes. It will prevent moisture from entering the outside of the roof when snow or rain blows in. No matter how well the roof is laid, there is always the possibility of minimal leaks. That is why, by paying a little extra, you will receive additional protection from moisture getting on the insulation in the ceiling of a cold attic.

Possible leaks or condensation entering hydrophobic insulation materials significantly reduce their thermal insulation properties.

If, for example, slate is used as a roofing material, then waterproofing can be abandoned. There is also corrugated sheeting with an anti-condensation coating on the market, which can hold up to 1 liter of water per 1 m2. For our part, we recommend always using waterproofing membranes, because this is the cheapest and easiest additional way to protect your roof from possible leaks

.

When installing waterproofing membranes, a counter-lattice is used. It serves as a fixing strip and, due to its height, provides the necessary clearance for ventilation of the under-roof space. The installation of lathing in a cold attic is no different from insulated roofs. The dimensions of the sheathing and its pitch determine the type of roofing being installed.

Cold attic temperature

To prevent ice and icicles from forming on the roof, it is necessary to maintain the correct temperature and humidity conditions in the attic. If the thickness of the thermal insulation material is insufficient, significant heat losses occur through the ceiling. Warm air, heating the roof covering, causes snow to melt and ice dams to form. By choosing the right insulation layer, this can be avoided.

The effectiveness of a heat insulator can be assessed by measuring the temperature of the top layer of insulation. The electronic thermometer is immersed in insulation by 10-20 mm. The temperature readings taken should correspond to the values in the table below.

As you can see, the design of a cold attic pie is not particularly complex in design. The main task is to ensure the necessary intensity of ventilation and the thickness of the thermal insulation layer in the ceiling.

Various types of attic insulation

There are many types of insulation materials available on the market. Let's consider below how to insulate an attic in a private house.

Roll insulation

An attic that hasn't been touched in decades may have some insulation between the joists, albeit very little. This is the most common type of attic insulation, and not just because it's cheap.

Watch a short video about the production of roll insulation at Knauf factories:

Sheet insulation is usually made from stone, glass or mineral fiber and comes in rolls. It's very easy to install, especially between joists, which is all you'll need if the temperature of the attic itself doesn't need to be controlled.

This type of insulation is used for floor insulation, but is not suitable for roofing.

So if you plan to spend time in the attic or store temperature-sensitive items, you'll also need to insulate the underside of the roof.

Loose insulation

If you already have insulation between the joists but it needs to be filled in, you can use additional layers of insulation or use a loose-fill insulation. It consists of a loose and lightweight material that can be laid on top to achieve the desired depth.

- The big advantage of loose-fill insulation is that it is very cheap, especially if you use recycled materials - it could even be shredded newspaper.

- It is also made from other materials such as cork granules, cellulose fiber or mineral wool.

- In the past, loose-fill insulation was made from a dangerous material you've probably heard of called asbestos.

Bulk insulation can really only be used for replenishment. And not very effective if used as primary insulation.

Blown Fiber Insulation

If you need to insulate hard-to-reach nooks and crannies, blown fiber insulation is the ideal solution. These can be various types of bulk materials that are blown into the gaps by machine.

The cost of processing services is significant

However, this is only a partial solution and is not enough to insulate the entire attic, especially if it is drafty. It is also expensive because the equipment used is owned by construction companies, which means it will increase the cost of your renovation.

Sheet insulation

If you want a temperature-controlled attic, you'll also need to insulate the underside of the roof. You can buy insulation sheets for this purpose.

Sheets can be made of various materials, natural or synthetic. The quality of insulation is usually excellent, and the boards can be decorated. This is the most expensive type of attic insulation and must be installed by a qualified professional.

This type of insulation requires professional installation.

Roofing pie composition

A modern roof is a multi-layer structure made from materials for various purposes.

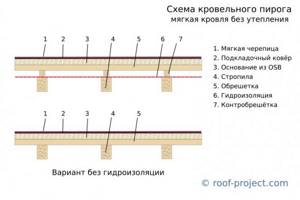

A cold roof has the following structure:

- soft tiles;

- lining carpet made of polymer materials;

- base for laying tiles;

- lathing from edged boards;

- rafters

Soft tiles are the top layer of the roofing pie. Available in the form of separate strips (shingles) with figured cutting. The material is based on: fiberglass, fiberglass or cardboard impregnated with bitumen with various polymer additives. This gives the material elasticity in the cold and reduces fluidity in the heat.

The lower part is self-adhesive and covered with a protective film. The top one is colored granular topping.

Properly laid soft tiles form an airtight coating that is resistant to precipitation, has low thermal conductivity and protects against noise.

Underlay carpet - compensates for unevenness of the base and serves as an additional waterproofing layer to protect the base from moisture if the top covering is damaged.

It consists of fiberglass or other polymer fibers, which are impregnated with a bitumen-polymer mixture and sprinkled with fine sand on both sides so that the material does not stick together during transportation and storage.

The base for laying soft tiles must be level and durable. For this, OSB-3 boards or moisture-resistant plywood are used. The thickness is chosen depending on the pitch of the rafters and the snow load in the region in which construction is taking place.

Lathing - made from edged boards, 25 - 30 mm thick. Attached directly to the rafters or counter-lattice, it serves as the basis for laying OSB-3 boards or plywood.

Rafters are the main load-bearing part of the roof.

They are made from timber or softwood boards. The size depends on the design loads and the type of roof.

How much does it cost

The price of insulation varies. In Leroy Merlin, the cost of insulation varies depending on the region. Below are prices for insulation materials for Moscow and the region:

| Name of material | Price |

| Ursa insulation heat standard 100 mm 8 m² | 528 RUR/pack (66 RUR/m2) |

| Thermal insulating PIR board PirroUniversal 50x600x1200 mm | 485 RUR/pcs. (618 r/m2) |

| Insulation TechnoNIKOL GreenGuard Universal 50 mm 8 plates 600x1200 mm 5.76 m² | 598 RUR/piece (103 RUR/m2) |

Do-it-yourself attic insulation

Creating a warm attic is definitely not a DIY job. This is because there is work to be done on the roof itself, and damage to it can have dire consequences on the stability of your entire home.

Advice! How to insulate the concrete floor of a cold attic yourself

However, it is possible. If you are planning to carry out roof insulation work in your attic, there are a few safety issues to consider before you begin.

- If you are working in an attic without a floor, crawl/tip boards must be installed to ensure safe movement. They can be temporarily fixed in place to eliminate the risk of creating traps or movement.

- Make sure your attic is well ventilated and free of condensation.

- Make sure the attic is well lit so you can see exactly what you are doing. Ideally, try using several LED lights in different locations - LEDs don't get hot and produce a powerful, bright white light.

- Wear a protective face mask to prevent inhaling dust particles.

- Crawling on your knees for any length of time can be quite debilitating, so you may also benefit from using knee pads.

- Finally, if your home was built before 2000, there may be asbestos-containing materials in your attic. If you suspect there is, read the next section very carefully.

This is interesting: Insulating the attic in a house with a flat and pitched roof

Dangers of asbestos

As mentioned above, it is possible that there are asbestos-containing materials in your attic. Asbestos has been used for thousands of years due to its fantastic properties (durable, fire-resistant, acid-resistant, alkali-resistant, heat-resistant and non-conductive).

Its harmful qualities were discovered only relatively recently. Exposure can lead to a serious long-term lung disease called asbestosis or mesothelioma, which is a type of cancer that develops in the lining that lines the body's organs.

So how do I know if I have asbestos in my attic? If your house was built before 2000, then the likelihood of it being in the attic is high. After this date, it began to be used much less frequently.

You won't know you have asbestos in your attic (or anywhere else in your home) until a professional comes and checks. Asbestos fibers are invisible to the naked eye and have no taste or odor, so it is difficult to tell for sure just by looking at part of the house. For this reason, asbestos is known as the "hidden killer."

The only reliable way to know whether a product or material contains asbestos or not is to have a sample tested by an ISO 17025 accredited laboratory.

Features of a cold roof

Cold roofing scheme.

A cold roof differs from a warm roof in its structure, although its design itself is extremely simple. The only thing that needs to be taken into account is the roofing option. When using metal tiles, a ventilation gap must be provided for proper removal of condensate from the under-roof space. This is done so that the steel sheet is not subject to corrosion.

The installation of a cold roof involves the installation of a rafter system on which a membrane or polyethylene film is laid for waterproofing. After this, the counter-lattice, sheathing and covering in the form of metal tiles are nailed.

The features of such a roof are the complete absence of a heat insulation layer, the presence of ventilation outlets under the ridge and on the slopes to remove moisture. Design and installation are not difficult, the main thing is to correctly carry out all the preliminary calculations.

The installation itself includes the following features:

- If you plan to install a warm roof in the future, you need to be very careful when choosing a membrane to protect against excess moisture. For a future attic, only specialized waterproofing in the form of membranes made from PVC is suitable.

- If further insulation is not planned, then micro-perforated waterproofing is used, designed specifically for cold roofs. Such a film does not allow thermal insulation materials to be laid next to it, that is, with further insulation, you will have to spend money on a new membrane. If this condition is not met, then the roof will be virtually unprotected from moisture in the future, the insulation will be constantly wet, and the roof covering will be susceptible to corrosion.

What tools are needed for the job?

Here are some tips on what tools you will need to insulate your attic:

- Garbage bags.

- Medical mask or respirator.

- Protective clothing.

- Roulette.

- Hand saw.

- Utility knife or scissors.

- Mobile desktop.

How to install attic insulation

If you are working with an area without a floor covering, you will need the boards we mentioned above. This will ensure you don't stick your leg (or your whole body) through the ceiling below and accidentally become a TikTok sensation when your kids post a video! Not to mention, falling off the floor can seriously damage your health!

Avoid falling through when working in the attic

- Then check to see if there are spotlights in the ceiling. If you do this, you will need to install caps to prevent your new insulation from coming into contact with the hot back of the fixtures.

- The first 100 mm layer of insulation must be laid between the beams. Check the average distance between the joists and cut the insulation while it is still packed using an old handsaw to the required width. (Usually the gap between the beams is 380 mm or 570 mm).

Laying the first layer of insulation between the beams

- Roll out the cut insulation between the joists over the entire required area, and then lightly press the insulation material to fit between the joists. Install insulation around attic hatches, if there are any.

- The second layer of insulation 170–200 mm must be laid perpendicularly (at a right angle) above the beams. If there are no staples or other obstructions, this layer can be laid full width.

- Start at the furthest point from the attic hatch and spread the insulation over the joists to ensure even coverage without gaps throughout the space.

Congratulations! You've just insulated your attic! You've just increased the value of your home and are about to save on your energy bills!

Cold roofing made of corrugated sheets: device and technology

A house with a cold attic is far from uncommon in modern construction. This solution is especially relevant for outbuildings, as well as summer cottages. Often a cold roof made of corrugated sheets is also made in residential buildings, when the main area of the house is enough for its owner and there is no need to make an attic.

The installation of a cold roof is advisable, first of all, for economic reasons. Firstly, you save on materials, and secondly, by isolating a large area of under-roof space from the rest of the house, you do not spend money on heating it. And thirdly, installing a cold roof is much easier than laying a full-fledged roofing pie.

This article is devoted to how to properly make a cold roof from corrugated sheets.

Contents of the article

(click to open)

In conclusion

The benefits of proper attic insulation should already be quite obvious. It's worth remembering that even if you already have insulation, it's a good idea to either check it yourself or have someone check it for you.

The insulation must be at least 270mm thick, must not be compressed in any way, and if there is sheathing above it, there must be a gap for air flow. Poorly installed insulation can cause a host of problems, so have yours checked today!

Installation of a cold roof made of corrugated sheets in a residential building

The design of a cold roof is very simple. The slopes do not require any insulation, vapor barrier, or, moreover, finishing. Naturally, the savings in this case are quite significant, given that the price of thermal insulation and finishing is 50-60% of the cost of the entire roof. In addition, due to the simplicity of the design, a cold roof made of corrugated sheets can be installed with your own hands without any problems.

The cold roof pie consists of the following elements:

- rafters;

- waterproofing film or membrane;

- counter-lattice;

- sheathing;

- corrugated sheeting

Cold roof waterproofing: is it necessary?

Waterproofing a cold roof will protect the room from possible leaks and condensation that forms on the inside of the metal roofing. Since condensation is released on metal surfaces when there is a temperature difference, there is a common misconception that it will not occur if an uninsulated roof made of corrugated sheets is installed.

Naturally, such an opinion is not true, since, despite the fact that the under-roof room is not insulated or heated, the temperature inside will still differ from the temperature outside, and often quite significantly. Therefore, the answer to the question: “Will there be condensation on the corrugated sheeting if the roof is cold?” - unequivocal: “Yes, it will be.”

In this regard, it becomes obvious whether waterproofing is needed under the corrugated roof of a cold roof. The consequence of its absence will be that condensation will fall on the ceiling, increasing the humidity in the attic. This will lead, at best, to accelerated deterioration of wooden structures, and at worst, to a catastrophic decrease in the thermal insulation properties of the insulation if it is unprotected.

The waterproofing membrane of the cold roof is laid on the rafters and secured with a counter-lattice, after which the lathing for installing the corrugated sheeting is installed.

If you do not intend to insulate a cold roof in the future, then you can use microperforated film as waterproofing, which costs much less than special membranes. However, it must be installed with a mandatory sag of 20-30 mm so that moisture flows into the space between the rafters, and does not moisten them, seeping through due to the capillary effect.